Filtre F7

Diunggah oleh

Anonymous 4MLEo9TVQDeskripsi Asli:

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Filtre F7

Diunggah oleh

Anonymous 4MLEo9TVQHak Cipta:

Format Tersedia

air filtration excellence for buildings

Understanding the new Air Filtration Standard: EN 779: 2012 & Eurovent 4/11 A guide to Energy Classification of Air Filters for General Ventilation Purposes

EN 779: 2012

A New Test Standard for Filter Efficiency

particulate

Air filters generally rely on two main principles for capturing contamination: one being mechanical and the other electrostatic.

Mechanical filtration basically relies on a barrier of fibres interwoven to form a matrix through which the air has to pass, the closer or tighter the matrix, the higher the filter efficiency. The electrostatic principle is employed to charge material fibres (often with a more open matrix) during production in order to enhance filter efficiency. It has been established beyond doubt that certain types of challenge such as combustion particles in normal atmospheric air may neutralise such charges resulting in serious loss of filter efficiency. This has led to three fundamental changes within the 2012 standard (differing from the 2002 version):

1. Compulsory discharge of all media: High efficiency filters of F7 - F9 are subject to a discharge process to remove any electrostatic charge inorder to establish an initial untreated efficiency. 2. Minimum Efficiency value introduced: Filter grades F7 - F9 were previously determined by an average efficiency. The new standard requires that in addition to this, minimum efficiency values must also be met. The minimum efficiency value is defined as: the lowest efficiency among the discharged efficiency, initial (clean filter) efficiency and that established throughout the full dust loading test. The minimum efficiency values required to be met are detailed in the table below. 3. Medium Grade classification introduced: Filter grades previously defined as fine grade filters F5 & F6 are now classified purely as medium grade filters, M5 & M6 (no minimum efficiency requirement is applied to the M grades.

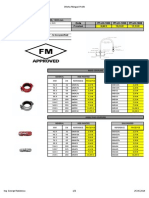

Classification of Air Filters according to EN 779: 2012 Class

G1 G2 G3 G4 M5 M6 F7 F8 F9

Final Pressure drop (Pascals 250 250 250 250 450 450 450 450 450 Average Arestance of Synthetic dust 50 Am < 65 65 Am < 80 80 Am < 90 90 Am 40 Am < 60 60 Am < 80 80 Am < 90 90 Am < 95 95 Am Average Efficiency of 0.4 m particles Min. Efficiency of 0.4 m particles 35% 55% 70%

EUROVENT 4/11

Guideline on Energy Efficiency

Eurovent 4/11 is a guideline that defines a method of air filter classification with regard to energy-efficient operation. The method allows for an energy rating classification of filter grades G4, M5 & M6 and F7 to F9, and is based on the testing of air filters against EN 779: 2012, with a calculation that encompasses three set and one variable criterion. Set criteria: A rated air volume (0.944 M3/s), a filter operation time based on 12 months (6000 hours) and a fan efficiency of 50%. Variable value: an average operating pressure loss, determined by establishing a nominated final filter pressure loss at a given test dust holding capacity (this varies for different grades and is detailed as MG, MM and MF in the table below). The average pressure loss is the mean between the initial (clean filter) pressure loss and the nominated final pressure loss. The calculation used is:

W=

q p t V

1000

Where qV = 0.944 M3/s; t = 6000 h and = 0.5.

Where: W = qV (air volume: 0.944) x p (average pressure loss) x t (time/hours: 6000) x 1000 (fan efficiency: 500) The resultant W being the comparative value for energy use as kWh/year. This value is then applied to kWh values in table 2 to determine an Energy Class (A to G). Energy efficiency class limits for each filter class to EN 779 measured at 0.944 M3/s are below:

Filter class

MTE ASHRAE

G4

MG = 350 g

M5

MM = 250 g

M6

-

F7

35%

F8

55% MF = 100 g

F9

70%

kWh

kWh

0 650 >650 780 >780 910 >910 1040 >1040 1170 >1170 1300 > 1300

kWh

0 800 >800 950 >950 1100 >1100 1250 >1250 1400 >1400 1550 > 1550

kWh

0 1200 >1200 1450 >1450 1700 >1700 1950 >1950 2200 >2200 2450 > 2450

kWh

0 1600 >1600 1950 >1950 2300 >2300 2650 >2650 3000 >3000 - 3350 > 3350

kWh

0 - 2000 >2000 - 2500 >2500 - 3000 >3000 - 3500 >3500 - 4000 >4000 - 4500 > 4500

A B C D E F G

0 600 >600 700 >700 800 >800 900 >900 1000 >1000 1100 > 1100

The Unique Bacticell Air Filter Cartridge

TESTIMONIALS

The Bacticell Filters we have fitted in our plant have not only increased the air quality in our food processing facility, it has helped us reduce our carbon footprint in 3 ways : 1. Reduced our running costs by between 9% to 12 % whilst helping us realise cost savings of >7k due to the increased surface area. 2. The requirement for filter changes has reduced, which means less waste to dispose of. 3. Less changes mean less service visits, so less fuel used in running vehicles. We are very satisfied with the continued support and innovation provided by the team at Nationwide and hope to continue our partnership with them.

Energy performance detail in conjunction with Eurovent 4/11 for a Grade F8 Bacticell tested in accordance with EN 779: 2012

the benefits of the Bacticell Air Filter Cartridge extend beyond its primary function as an alternative to the conventional bag filter ... (H&V News Judges, 2012)

Nominal Air flow: Initial efficiency 0.4 m: Minimum efficiency 0.4 m: Annual energy consumption:

0.944 m3/s EN779 68 % 68 % 1345 kWh/annum

� 3 filter grades, 3 standard face sizes, 3

header depths

� Initial

pressure loss: 86 Pascals 100 Pascals (F8) 105 Pascals (F9)

(F7),

� Standard

filter depth of only 300mm valuable space-saving opportunities at design stage. for standard size bag filters

� Completely interchangeable as replacements

NFC is the only UK manufacturer to produce a cartridge with a re-usable housing, reducing waste at disposal and cost in supplying and fitting replacement cells. Bacti-G treated, water-repellent glass paper is uniformly pleated and sealed into individual cells, then fitted in a vee-formation within the housing. The totally rigid structure ensures that the filter will not sag or collapse under reduced or nil airflow, eliminating the possibility of particulate sieving caused by air turbulence.

We installed the first 'batch' 2 years ago and following their performance we have now changed all our bag filter plants in favour of the Bacticell Cartridge. The installed life of the Bacticells is working out to be virtually 3 times greater than that of the bag filters (as you indicated it would). My 'filter change' labour costs have been reduced considerably as has our waste filter disposal.

Environmental Features

Re-usable housing Replacable filter cells

Unique Benefits from the Bacticell Air Filter Cartridge

Lower waste disposal costs. Less down-time at filter change. Lighter and less bulky to transport. Eradicates bacterial/fungal growth on contact to reduce contamination of ductwork and occupied areas, and reduces health risk for engineers at filter change. Uses up to 30% less fan energy compared to an equivalent grade bag filter. Entire filter conforms to stringent independent test standards in respect of flammability and toxic smoke emission. Full test certificate available.

Our site has been upgrading all their Air Handling Units as parts of their energy reduction programme. The upgrade includes replacing bag filters with Bacticell filters which have significantly lower pressure drop and reduce the energy required to run the units. The additional benefit is that they need replacing less often and the modular design reduces the manual handling of the filters. This AHU upgrade programme has currently contributed to a 7% energy reduction across the site.

Bacti-G anti-microbial protection Energy consumption Flammability & toxic smoke emission

This list represents some of the micro-organisms that can be eradicated upon contact with the Bacticell Cartridge

BACTERIA Salmonella E-coli Listeria Sp Pseudomonas Sp Proteus Sp Klebsiella Sp Flavobacterium Sp Bacillus Sp Alcaligenes Sp Strep. faecalis Staph. aureus Aeromonas Sp Achrombacteria Sp Prot. vulgaris Clost. welchii Strep. mutans M.R.S.A. E.coli 0157 Legionella FUNGI Streptomyces Sp Aspergillus Sp Cephalosporium Sp Fusarium Sp Paecilomyces Sp Cladosporium Sp Penicillum Sp ALGAE Chlorella Sp Oscillatoria Navicula Scenedesmus Melsira YEAST Coniophgoraputeana Monilia albicans Candida Sp Rhodotorula Sp Cryptococcus Sacchromyces

VIRAL CHALLENGE MS2 coliphage (synthetic test virus)

F6-F9 Rigid Pack Cartridge

Performance Detail

Initial pressure loss ranging from 80 to 105 Pascals dependent on grade selection. The NFC Rigid Pack cartridge is available in energy class A or B, dependent on grade. This cartridge provides a low-cost option for clients wishing to receive the benefits of a rigid structure to avoid the risk of bags deflating or sagging, and the potential to make some energy savings as a result of a lower initial pressure loss. However, the unit requires complete disposal. The filter is constructed from high efficiency glass paper, close pleated and separated by hotmelt beeds. The pleat packs are then sealed within a heat resistant plastic case with an integral header frame. Environmental Features

Standard depth 300mm Life-span Energy consumption

Rigid Pack Benefits

Standard depth for all grades provides opportunities for spacesaving at AHU design stage. Can last up to 3 times longer than a conventional bag filter. Lower energy consumption compared with a conventional bag filter due to increased media filtration area.

M6-F8 ESB Micro-safe Glass Bags

Performance Detail

Whilst installed life and environmental benefits may not be as great as with the Bacticell Cartridge, NFCs standard class ESB (Energy Saving Bags ) Micro-safe glass bag filters can also provide an alternative energy saving option. The range is also available as an NFC Class A option catering for additional levels of protection against flammability and toxic smoke emission. All NFC ESB (Energy Saving Bags) are manufactured from micro-safe glass fibre to meet energy class A, B or C dependent on number and length of pockets (greater material area reducing operational pressure loss). In some circumstances the ability to switch to a cartridge filter is not feasible. Nationwides ESB Micro-safe Glass Bags provide greater consistency in performance compared with synthetic bags, and in the case of Nationwide they conform to stringent independent test standards in respect of flammability and toxic smoke emission. Full test certificate available.

Applying EN 779: 2012 in conjunction with Eurovent 4/11 (Energy classification)

Due to the requirement for F7 to F9 filter grades to meet minimum efficiency requirements, certain filter types previously available will undoubtedly undergo re-classification. Bag filters manufactured from synthetic materials are most likely, as the majority rely on electrostatic properties to enhance performance/efficiency. Independent tests conducted on many of these products indicate minimum efficiency levels (after discharge) to be well under 30% for previously graded F7 and F8 classes. (Minimum efficiencies now required to be met are: 35% for F7, 55% for F8 and 70% for F9). Products relying mainly on mechanical properties to achieve filter efficiency requirements (such as glass bag filters and cartridges manufactured from filter paper materials) are less likely to require re-classification as these typically achieve minimum efficiency levels (after discharge) in the order of: >50% for F7 and >70% for F8. In addition to meeting the above requirements, air filter manufacturers and suppliers must now support product claims with independent testing by a laboratory authorised to test products against EN 779: 2012. Without such tests being conducted, an energy rating classification to Eurovent 4/11 cannot be applied.

FOR FURTHER INFORMATION

NORTHERN OFFICE Sales & Technical Enquiries, Manufacture Tel: 01524 389713 Fax: 01524 555769 NFC House, Vickers Industrial Estate Mellishaw Lane, Morecambe Lancashire LA3 3EN SCOTLAND OFFICE Tel/Fax: 01355 226811 info@nationwidefilters.com www.nationwidefilters.com SOUTHERN OFFICE Contract Management Tel: 01372 728548 Fax: 01372 742831 Unit 16, First Quarter Business Park Blenheim Road, Epsom Surrey KT19 9QN

NFC/EN779-4/11/Issue 1

Anda mungkin juga menyukai

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- Belaria+SRM+ +technical+ INM-en+ 2017 PDFDokumen30 halamanBelaria+SRM+ +technical+ INM-en+ 2017 PDFAnonymous 4MLEo9TVQBelum ada peringkat

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (400)

- Dpu PDFDokumen4 halamanDpu PDFTEIUSANUBelum ada peringkat

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- Tuyau Sme PDFDokumen2 halamanTuyau Sme PDFteiusanuBelum ada peringkat

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (895)

- Catalogue NST PDFDokumen12 halamanCatalogue NST PDFTEIUSANUBelum ada peringkat

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- Katalog Fire Protection Systems G 105Dokumen108 halamanKatalog Fire Protection Systems G 105lucasBelum ada peringkat

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- Guide Technique - FLUXO PDFDokumen24 halamanGuide Technique - FLUXO PDFteiusanuBelum ada peringkat

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- Correspondance Pouce MMDokumen4 halamanCorrespondance Pouce MMhichamBelum ada peringkat

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- PowerBloc EG20 - COGENERARE PDFDokumen12 halamanPowerBloc EG20 - COGENERARE PDFAnonymous 4MLEo9TVQBelum ada peringkat

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (588)

- Belaria+SRM+ +technical+ INM-en+ 2017 PDFDokumen30 halamanBelaria+SRM+ +technical+ INM-en+ 2017 PDFAnonymous 4MLEo9TVQBelum ada peringkat

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (73)

- Belaria+twin+ Technical+ INM-en+ 2017 PDFDokumen38 halamanBelaria+twin+ Technical+ INM-en+ 2017 PDFAnonymous 4MLEo9TVQBelum ada peringkat

- Bio Lyt (50 - 160) - Carte Tehnica PDFDokumen14 halamanBio Lyt (50 - 160) - Carte Tehnica PDFAnonymous 4MLEo9TVQBelum ada peringkat

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- Bio Lyt (50 - 160) - Carte Tehnica PDFDokumen14 halamanBio Lyt (50 - 160) - Carte Tehnica PDFAnonymous 4MLEo9TVQBelum ada peringkat

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (266)

- Bio Lyt (50 - 160) - Carte Tehnica PDFDokumen14 halamanBio Lyt (50 - 160) - Carte Tehnica PDFAnonymous 4MLEo9TVQBelum ada peringkat

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- Catalogue Escospeed PDFDokumen8 halamanCatalogue Escospeed PDFAnonymous 4MLEo9TVQBelum ada peringkat

- Max-3 - Carte Tehnica PDFDokumen17 halamanMax-3 - Carte Tehnica PDFAnonymous 4MLEo9TVQBelum ada peringkat

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- Catalogue CST PDFDokumen29 halamanCatalogue CST PDFTEIUSANUBelum ada peringkat

- Belaria+twin+ Technical+ INM-en+ 2017 PDFDokumen38 halamanBelaria+twin+ Technical+ INM-en+ 2017 PDFAnonymous 4MLEo9TVQBelum ada peringkat

- Belaria+SRM+ +technical+ INM-en+ 2017 PDFDokumen30 halamanBelaria+SRM+ +technical+ INM-en+ 2017 PDFAnonymous 4MLEo9TVQBelum ada peringkat

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2259)

- Gear Box CouplingDokumen30 halamanGear Box Couplingdeepthik27100% (2)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- Ofeta Fitinguri Cu DiscountDokumen6 halamanOfeta Fitinguri Cu DiscountAnonymous 4MLEo9TVQBelum ada peringkat

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- PowerBloc EG20 - COGENERARE PDFDokumen12 halamanPowerBloc EG20 - COGENERARE PDFAnonymous 4MLEo9TVQBelum ada peringkat

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (344)

- Katalog Fire Protection Systems G 105Dokumen108 halamanKatalog Fire Protection Systems G 105lucasBelum ada peringkat

- Sisteme Fixare - Sustinere - INKA PDFDokumen36 halamanSisteme Fixare - Sustinere - INKA PDFMatthew SuttonBelum ada peringkat

- Therapetic Apparatus CatalogueDokumen14 halamanTherapetic Apparatus CatalogueAnonymous 4MLEo9TVQBelum ada peringkat

- Catalogue Escorail PDFDokumen4 halamanCatalogue Escorail PDFTEIUSANUBelum ada peringkat

- Wind Turbine and Car Inverter CatalogueDokumen10 halamanWind Turbine and Car Inverter CatalogueAnonymous 4MLEo9TVQBelum ada peringkat

- Solar Controller and Inverter CatalogueDokumen10 halamanSolar Controller and Inverter CatalogueAnonymous 4MLEo9TVQBelum ada peringkat

- Instala II de Aer Condi Ionat Þ Þ Tip Casetã: DC InverterDokumen1 halamanInstala II de Aer Condi Ionat Þ Þ Tip Casetã: DC InverterAnonymous 4MLEo9TVQBelum ada peringkat

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (121)

- Prospect DuctDokumen1 halamanProspect DuctAnonymous 4MLEo9TVQBelum ada peringkat

- Bauma 2016 ExhibitorsDokumen3 halamanBauma 2016 Exhibitorsfredaster21Belum ada peringkat

- MMF 1.0.0Dokumen2 halamanMMF 1.0.0unconformistBelum ada peringkat

- New Drilling Fluid Technology-Mineral Oil Mud: SPE, Chromalloy Drilling FluidsDokumen7 halamanNew Drilling Fluid Technology-Mineral Oil Mud: SPE, Chromalloy Drilling FluidsElias Glz VegaBelum ada peringkat

- IX PracticalDokumen30 halamanIX Practicalprateekixa2Belum ada peringkat

- Basket FilterDokumen1 halamanBasket FilterShreya TrikhaBelum ada peringkat

- Water 09 00498Dokumen12 halamanWater 09 00498H.M. KabilBelum ada peringkat

- Whatman Price List Booklet 2018Dokumen96 halamanWhatman Price List Booklet 2018N PhBelum ada peringkat

- Test Bank For Sociology in Our Times 11th Edition Diana KendallDokumen36 halamanTest Bank For Sociology in Our Times 11th Edition Diana Kendallzebrula.violatorzw1hf100% (39)

- Draft Guidelines For Manufacturing Homeopathic MedicinesDokumen40 halamanDraft Guidelines For Manufacturing Homeopathic MedicinesAMEEN ARTSBelum ada peringkat

- Landry and HassetDokumen6 halamanLandry and HassetCharan KumarBelum ada peringkat

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- GB 5009.229-2016 食品安全国家标准 食品中酸价的测定 (1) .zh-CN.enDokumen15 halamanGB 5009.229-2016 食品安全国家标准 食品中酸价的测定 (1) .zh-CN.enSandraBelum ada peringkat

- 4 KSU - FiltrationDokumen15 halaman4 KSU - FiltrationmeitaBelum ada peringkat

- KMML 2013Dokumen13 halamanKMML 2013KuttikuttanBelum ada peringkat

- Vakuumbandfilter enDokumen14 halamanVakuumbandfilter enFrank Vega OrtegaBelum ada peringkat

- Inorganic Chemistry Lab ManualDokumen25 halamanInorganic Chemistry Lab ManualAbhik SarkarBelum ada peringkat

- Perormance Task 1 - Water PurificationDokumen3 halamanPerormance Task 1 - Water PurificationG12 Cuba Francesca MarieBelum ada peringkat

- Foreign Particle GuidelineDokumen19 halamanForeign Particle Guidelinem_ihab777629Belum ada peringkat

- Collecting and Filtering Used Cooking Oil: Email: Mike@biotuning - Co.ukDokumen3 halamanCollecting and Filtering Used Cooking Oil: Email: Mike@biotuning - Co.ukKhandurasBelum ada peringkat

- Interview Questions With AnswersDokumen4 halamanInterview Questions With AnswersMohamed HashemBelum ada peringkat

- 32 05 01 PDFDokumen4 halaman32 05 01 PDFacetonaflores0% (1)

- Chemistry Reviewer 1Dokumen13 halamanChemistry Reviewer 1John Van Dave TaturoBelum ada peringkat

- Producing Organic Concoctions and ExtractsDokumen26 halamanProducing Organic Concoctions and ExtractsRowena SarsuaBelum ada peringkat

- Laporan Praktikum Kimia Organik II Iodoform: Kelompok C-12 Moh. As'ad 110118375Dokumen23 halamanLaporan Praktikum Kimia Organik II Iodoform: Kelompok C-12 Moh. As'ad 110118375MUHAMMAD DIAN WARDANA PUTRABelum ada peringkat

- Static and Dynamic SpargersDokumen4 halamanStatic and Dynamic Spargerstinhtt2001Belum ada peringkat

- Experiment No. 2 Lab Report Group 6 ChemDokumen13 halamanExperiment No. 2 Lab Report Group 6 ChemJanray CastilloBelum ada peringkat

- Analysis of HoneyDokumen7 halamanAnalysis of Honeymazahir razaBelum ada peringkat

- OPRP PLAN Updated & FinalDokumen2 halamanOPRP PLAN Updated & Finalsajid waqas100% (1)

- A. Power Plant Overview (By Mr. Tomy Suryatama)Dokumen34 halamanA. Power Plant Overview (By Mr. Tomy Suryatama)Dimas Febrian SaputraBelum ada peringkat

- Bha Glossary Dust Collection Terms Smart Brief PDFDokumen2 halamanBha Glossary Dust Collection Terms Smart Brief PDFarchana2512Belum ada peringkat

- Dust CollectorsDokumen50 halamanDust Collectorsprakash bhadoria100% (1)