Air Calculation Theroretical

Diunggah oleh

uksrajHak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Air Calculation Theroretical

Diunggah oleh

uksrajHak Cipta:

Format Tersedia

1.

Fuels and Combustion

Calculation for Requirement of Theoretical Amount of Air

Considering a sample of 100 kg of furnace oil. The chemical reactions are:

Element Molecular

Weight

kg / kg mole

C 12

O

2

32

H

2

2

S 32

N

2

28

CO

2

44

SO

2

64

H

2

O 18

C + O

2

CO

2

H

2

+ 1/2O

2

H

2

O

S + O

2

SO

2

Constituents of fuel

C + O

2

CO

2

12 + 32 44

12 kg of carbon requires 32 kg of oxygen to form 44 kg of carbon dioxide therefore 1 kg of

carbon requires 32/12 kg i.e 2.67 kg of oxygen

(85.9) C + (85.9 x 2.67) O

2

315.25 CO

2

2H

2

+ O

2

2H

2

O

4 + 32 36

4 kg of hydrogen requires 32 kg of oxygen to form 36 kg of water, therefore 1 kg of

hydrogen requires 32/4 kg i.e 8 kg of oxygen

(12) H

2

+ (12 x 8) O

2

(12 x 9 ) H

2

O

S + O

2

SO

2

32 + 32 64

32 kg of sulphur requires 32 kg of oxygen to form 64 kg of sulphur dioxide, therefore 1 kg of

sulphur requires 32/32 kg i.e 1 kg of oxygen

Bureau of Energy Efficiency

18

1. Fuels and Combustion

(0.5) S + (0.5 x 1) O

2

1.0 SO

2

Total Oxygen required = 325.57 kg

(229.07+96+0.5)

Oxygen already present in

100 kg fuel (given) = 0.7 kg

Additional Oxygen Required = 325.57 0.7

= 324.87 kg

Therefore quantity of dry air reqd. = (324.87) / 0.23

(air contains 23% oxygen by wt.)

= 1412.45 kg of air

Theoretical Air required = (1412.45) / 100

= 14.12 kg of air / kg of fuel

Calculation of theoretical CO

2

content in flue gases

Nitrogen in flue gas = 1412.45 324.87

= 1087.58 kg

Theoretical CO

2

% in dry flue gas by volume is calculated as below :

Moles of CO

2

in flue gas = (314.97) / 44 = 7.16

Moles of N

2

in flue gas = (1087.58) / 28 = 38.84

Moles of SO

2

in flue gas = 1/64 = 0.016

100

) (

%

2

2

x

dry moles Total

CO of Moles

volume by CO l Theoritica =

100

016 . 0 84 . 38 16 . 7

16 . 7

x

+ +

=

= 15.5 %

Bureau of Energy Efficiency

19

1. Fuels and Combustion

Calculation of constituents of flue gas with excess air

% CO

2

measured in flue gas = 10% (measured)

100 1

%

%

%

2

2

x

CO Actual

CO l Theoritica

air Excess

|

|

.

|

\

|

=

100 1

10

5 . 15

% x air Excess |

.

|

\

|

= = 55%

Theoretical air required for 100 kg

of fuel burnt

= 1412.45 kg

Total quantity. of air supply required

with 55% excess air

= 1412.45 X 1.55

= 2189.30 kg

Excess air quantity = 2189.30 1412.45

= 776.85 kg.

O

2

= 776.85 X 0.23

= 178.68

N

2

= 776.85 - 178.68

= 598.17 kg

The final constitution of flue gas with 55% excess air for every 100 kg fuel.

CO

2

= 314.97 kg

H

2

O = 108.00 kg

SO

2

= 1 kg

O

2

= 178.68 kg

N

2

= 1087.58 + 598.17

= 1685.75 kg

Calculation of Theoretical CO

2

% in Dry Flue Gas By Volume

Moles of CO

2

in flue gas = 314.97/44 = 7.16

Moles of SO

2

in flue gas = 1/64 = 0.016

Bureau of Energy Efficiency

20

1. Fuels and Combustion

Moles of O

2

in flue gas = 178.68 / 32 = 5.58

Moles of N

2

in flue gas = 1685.75 / 28 = 60.20

100

) (

%

2

2

x

dry moles Total

CO of Moles

volume by CO l Theoritica =

100

20 . 60 58 . 5 016 . 0 16 . 7

16 . 7

x

+ + +

=

100

956 . 72

16 . 7

x = = 10%

Theoretical O

2

% by volume % 5 . 7 100

956 . 72

100 58 . 5

= = x

x

Optimizing Excess Air and Combustion

For complete combustion of every one kg of fuel oil 14.1 kg of air is needed. In practice,

mixing is never perfect, a certain amount of excess air is needed to complete combustion and

ensure that release of the entire heat contained in fuel oil. If too much air than what is

required for completing combustion were allowed to enter, additional heat would be lost in

heating the surplus air to the chimney temperature. This would result in increased stack

losses. Less air would lead to the incomplete combustion and smoke. Hence, there is an

optimum excess air level for each type of fuel.

Control of Air and Analysis of Flue Gas

Thus in actual practice, the amount of combustion air required will be much higher than

optimally needed. Therefore some of the air gets heated in the furnace boiler and leaves

through the stack without participating in the combustion

Chemical analysis of the gases is an objective method that helps in achieving finer air

control. By measuring carbon dioxide (CO

2

) or oxygen (O

2

) in flue gases by continuous

recording instruments or Orsat apparatus or portable fyrite, the excess air level as well as

stack losses can be estimated with the graph as shown in Figure 1.2 and Figure 1.3. The

excess air to be supplied depends on the type of fuel and the firing system. For optimum

combustion of fuel oil, the CO

2

or O

2

in flue gases should be maintained at 14 -15% in case

of CO

2

and 2-3% in case of O

2

.

.

Bureau of Energy Efficiency

21

1. Fuels and Combustion

0

10

20

30

40

50

60

70

80

90

100

8.4

9 10 11 12 13 14

Carbon dioxide %

E

x

c

e

s

s

a

i

r

%

15

Figure 1.2 Relation Between CO

2

and Excess Air for Fuel Oil

Figure 1.3: Relation between Residual Oxygen and Excess Air

0

50

100

150

200

250

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15

Residual Oxygen(%)

E

x

c

e

s

s

a

i

r

(

%

)

Oil Firing Burners

The burner is the principal device for the firing of fuel. The primary function of burner is to

atomise fuel to millions of small droplets so that the surface area of the fuel is increased

enabling intimate contact with oxygen in air. The finer the fuel droplets are atomised, more

readily will the particles come in contact with the oxygen in the air and burn.

Normally, atomisation is carried out by primary air and completion of combustion is

ensured by secondary air. Burners for fuel oil can be classified on the basis of the technique

to prepare the fuel for burning i.e. atomisation.

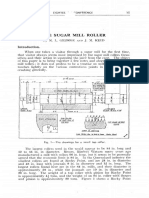

Figure 1.4 shows a simplified burner head. The air is brought into the head by means of

a forced draft blower or fan. The fuel is metered into the head through a series of valves. In

order to get proper combustion, the air molecules must be thoroughly mixed with the fuel

molecules before they actually burn. The air in the center is the primary air used for

atomization and the one surrounding is the secondary air which ensures complete

combustion.

Bureau of Energy Efficiency

22

1. Fuels and Combustion

Figure 1.4 Burner Head

The mixing is achieved by burner parts designed to create high turbulence. If insufficient

turbulence is produced by the burner, the combustion will be incomplete and samples taken

at the stack will reveal carbon monoxide as evidence.

Since the velocity of air affects the turbulence, it becomes harder and harder to get good

fuel and air mixing at higher turndown ratios since the air amount is reduced. Towards the

highest turndown ratios of any burner, it becomes necessary to increase the excess air

amounts to obtain enough turbulence to get proper mixing. The better burner design will be

one that is able to properly mix the air and fuel at the lowest possible air flow or excess air.

An important aspect to be considered in selection of burner is turndown ratio.

Turndown ratio is the relationship between the maximum and minimum fuel input without

affecting the excess air level. For example, a burner whose maximum input is 250,000 Kcals

and minimum rate is 50,000 Kcals, has a Turn-Down Ratio of 5 to 1.

1.8 Combustion of Coal

Features of coal combustion

1 kg of coal will typically require 7-8 kg of

air depending upon the carbon, hydrogen,

nitrogen, oxygen and sulphur content for

complete combustion. This air is also known

as theoretical or stoichiometric air.

If for any reason the air supplied is

inadequate, the combustion will be

incomplete. The result is poor generation of

heat with some portions of carbon remaining

unburnt (black smoke) and forming carbon

monoxide instead of carbon dioxides.

Figure 1.5 Coal Combustion

As in the case of oil, coal cannot be burnt with stoichiometric quantity of air. Complete

combustion is not achieved unless an excess of air is supplied.

The excess air required for coal combustion depends on the type of coal firing equipment.

Hand fired boilers use large lumps of coal and hence need very high excess air. Stoker fired

boilers as shown in the Figure 1.5 use sized coal and hence require less excess air. Also in

Bureau of Energy Efficiency

23

Anda mungkin juga menyukai

- Detailed SoP - Birsa Sinchai Koop SanvardhanDokumen62 halamanDetailed SoP - Birsa Sinchai Koop Sanvardhanuksraj0% (1)

- ASCI - Agriculture Skill Council of India QPDokumen6 halamanASCI - Agriculture Skill Council of India QPuksrajBelum ada peringkat

- Solved 2017 SSC CGL 17 Aug Shift-1 Paper With SolutionsDokumen40 halamanSolved 2017 SSC CGL 17 Aug Shift-1 Paper With SolutionsuksrajBelum ada peringkat

- 3Dokumen1 halaman3uksrajBelum ada peringkat

- MUDRA - Loan ApplicationDokumen5 halamanMUDRA - Loan ApplicationuksrajBelum ada peringkat

- 5201 Designer SketcherDokumen20 halaman5201 Designer SketcheruksrajBelum ada peringkat

- Drip Irrigation Pipe: Profile No.: 33 NIC Code: 24311Dokumen8 halamanDrip Irrigation Pipe: Profile No.: 33 NIC Code: 24311uksrajBelum ada peringkat

- The Sugar Mill Roller: BV R. I,. Geokge MDokumen9 halamanThe Sugar Mill Roller: BV R. I,. Geokge MuksrajBelum ada peringkat

- 5001 Yarn OpenerDokumen19 halaman5001 Yarn OpeneruksrajBelum ada peringkat

- Forging Members DirectoryDokumen11 halamanForging Members Directoryuksraj33% (3)

- Busan To Kolkata: Vessel Name VOY Doc C/Time Cgo C/TimeDokumen1 halamanBusan To Kolkata: Vessel Name VOY Doc C/Time Cgo C/TimeuksrajBelum ada peringkat

- 1.2311 40crmnnimo8-6-4 MCM: Chemical CompositionDokumen3 halaman1.2311 40crmnnimo8-6-4 MCM: Chemical CompositionuksrajBelum ada peringkat

- Item Mat GRP Quantity Unit Last PO / Rate Vendor Consumption (Last 6 Months) Current StockDokumen6 halamanItem Mat GRP Quantity Unit Last PO / Rate Vendor Consumption (Last 6 Months) Current StockuksrajBelum ada peringkat

- Sugar CaneMill V5.1Dokumen7 halamanSugar CaneMill V5.1uksraj100% (1)

- AtoZ Alloys Pvt. LTDDokumen1 halamanAtoZ Alloys Pvt. LTDuksrajBelum ada peringkat

- Welcome To India in BusinessDokumen6 halamanWelcome To India in BusinessuksrajBelum ada peringkat

- 2010 Paper 2Dokumen22 halaman2010 Paper 2uksrajBelum ada peringkat

- Answer: CDokumen24 halamanAnswer: CuksrajBelum ada peringkat

- 614 Furnace Oil Burner DesignDokumen4 halaman614 Furnace Oil Burner DesignuksrajBelum ada peringkat

- JEE 2009 Paper I: (A) (B) (C) (D)Dokumen19 halamanJEE 2009 Paper I: (A) (B) (C) (D)uksrajBelum ada peringkat

- Energy Efficiency in ForgingDokumen42 halamanEnergy Efficiency in ForginguksrajBelum ada peringkat

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (588)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (400)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (74)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (121)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- RT Finalpresenatation08 161118104713Dokumen56 halamanRT Finalpresenatation08 161118104713sajay2010Belum ada peringkat

- Simrit - Broșura Merkel PTFE U-RingsDokumen20 halamanSimrit - Broșura Merkel PTFE U-Ringsjo_rz_57Belum ada peringkat

- MechatronicsDokumen61 halamanMechatronicsSajitha ManuBelum ada peringkat

- Review On Fabrication of 3 Axis Spray Painting Machine Ijariie1981Dokumen4 halamanReview On Fabrication of 3 Axis Spray Painting Machine Ijariie1981Anonymous Clyy9NBelum ada peringkat

- Shaft Locking DeviceDokumen24 halamanShaft Locking DevicechienhamthepBelum ada peringkat

- Vlsi DesignDokumen58 halamanVlsi Designy satishkumarBelum ada peringkat

- EEE141 Course OutlineDokumen5 halamanEEE141 Course OutlineLittle WizardBelum ada peringkat

- Thermo 2, Lecture1 PDFDokumen99 halamanThermo 2, Lecture1 PDFMaricar HababagBelum ada peringkat

- (NagpurStudents - Org) Advanced PhysicsDokumen4 halaman(NagpurStudents - Org) Advanced PhysicsVaibhav NardangeBelum ada peringkat

- Welding of 4140 & 316Dokumen5 halamanWelding of 4140 & 316Engineer AnasBelum ada peringkat

- Cohesive Energy 1Dokumen5 halamanCohesive Energy 1kalloliBelum ada peringkat

- Unit-I: Fundamentals of Gas DynamicsDokumen45 halamanUnit-I: Fundamentals of Gas DynamicsMuthuvel MBelum ada peringkat

- Leica ICD Brochure enDokumen4 halamanLeica ICD Brochure enCsaba GibártiBelum ada peringkat

- Quiz 3 For CHM 520: JK 92 S JK 67 SDokumen15 halamanQuiz 3 For CHM 520: JK 92 S JK 67 SnotmeBelum ada peringkat

- Yang Et Al. (2017)Dokumen11 halamanYang Et Al. (2017)Francisco OppsBelum ada peringkat

- Nonlinear Analysis Methods For Reinforced Concrete Buildings With Shear WallsDokumen8 halamanNonlinear Analysis Methods For Reinforced Concrete Buildings With Shear Wallsakif-benzer-6764Belum ada peringkat

- Reservoir Management Session 3 W Solutions PDFDokumen39 halamanReservoir Management Session 3 W Solutions PDFEmad ZakiBelum ada peringkat

- Projects List: Mechanical EngineeringDokumen4 halamanProjects List: Mechanical EngineeringNaga KiranBelum ada peringkat

- Estimating Hydropower Potential of An Ungauged Stream: January 2013Dokumen10 halamanEstimating Hydropower Potential of An Ungauged Stream: January 2013sisay dejenieBelum ada peringkat

- MIT16 842F15 Ses 8 Sys IntDokumen42 halamanMIT16 842F15 Ses 8 Sys IntssvivekanandhBelum ada peringkat

- Session - 5 FEA of Grids: Module Code: 19STC502A-2021Dokumen34 halamanSession - 5 FEA of Grids: Module Code: 19STC502A-2021rajaBelum ada peringkat

- International Conference: 26-27 (Saturday-Sunday)Dokumen5 halamanInternational Conference: 26-27 (Saturday-Sunday)suryamishraBelum ada peringkat

- SkyscrapersDokumen31 halamanSkyscrapersAnas Shaikh100% (1)

- Single Phase Matrix ConverterDokumen9 halamanSingle Phase Matrix Converteranahope93Belum ada peringkat

- Leica CME ManualDokumen24 halamanLeica CME ManualMaria DapkeviciusBelum ada peringkat

- CHM 2045 Lab ReportDokumen11 halamanCHM 2045 Lab ReportlexilocoBelum ada peringkat

- Gate FTDokumen51 halamanGate FTjayavardhanaBelum ada peringkat

- 2017 - OPUS Quant Advanced PDFDokumen205 halaman2017 - OPUS Quant Advanced PDFIngeniero Alfonzo Díaz Guzmán100% (1)

- 3.2 - 3.4 NotesDokumen4 halaman3.2 - 3.4 NotesSamih AliBelum ada peringkat

- 02 InstrumentsDokumen11 halaman02 Instrumentsmariamwassem123Belum ada peringkat