DS 164 02 ZincAnode304 MZS

Diunggah oleh

Power PowerHak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

DS 164 02 ZincAnode304 MZS

Diunggah oleh

Power PowerHak Cipta:

Format Tersedia

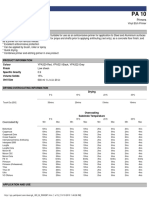

Zinc Anode 304 MZS Inorganic Zinc Silicate Coating

USES

Recommended for use on steel structurals, exterior of storage tanks, bulk handling equipment, pipelines, etc. The product is suitable for both coastal and industrial/inland environments.

SCOPE

A two pack solvent base inorganic zinc primer for protection of steel against severe corrosive environment . It provides outstanding cathodic protection and forms a tough abrasion resistant film. It is however, not recommended for contacts with strong acids or alkalis of pH below 5 or exceeding 10. The coating attains water resistance within 30 minutes of application and is unaffected by rain, condensation or dew.

PRODUCT DATA

Type : Two pack pack, self cured Composition : Ethyl Silicate/Metallic Zinc Mixing Ratio : Part A: Part B; 17.6 ltr: 2.4 ltr Pot Life : 6-8 hours Application : Conventional or Airless spray Recommended DFT : 60-75 microns per coat Corresponding WFT : 100-125 microns per coat Theoretical Spreading Rate : 8.0-10.0 Sq.Mtr/Ltr Drying Time : TOUCH HANDLE HARD Curing Time : 6-7 days Overcoating Interval : MIN MAX Flash Point : Above 220C Colour : Grey Finish : Matt Packing : 20 Ltrs (mixed paint) Thinner/Cleaner : Thinner 870 Storage Life : Upto six months as long as the sealed containers are kept under cover in a dry place : Overnight : Indefinite : within 30 minutes : 2-4 hours : Overnight

RESISTANCE GUIDE Chemical Resistance :

EXPOSURES SPLASH & SPILLAGE MILD FUMES / OUTDOOR RESISTANCE

Acids Alkalis Solvents Salt Water

Good Good Excellent Excellent Excellent

Good Good Excellent Excellent Excellent

Temperature Resistance : Continuous : upto 4000 C Intermittent : 4260C Weatherability : Excellent Flexibility : Fair Abrasion Resistance : Excellent - increases with age

DATA SHEET No. : 164 / rev02 Issue Date : Mar 2009

under normal temperature conditions.

Zinc Anode 304 MZS Inorganic Zinc Silicate Coating

SURFACE PREPARATION

Remove grease, oil and other contaminants and blast clean to a minimumm of Sa 2.5 Swedish Standard SIS 05 5900 with a surface profile not exceeding 35-40 microns. The surface should be clean and dry before application of Zinc Anode 304 MZS

APPLICATION

Stir Part A thoroughly to uniform consistency. Mix the components in the recommended proportion with constant stirring preferably with a mechanical stirrer. Continue stirring until the components are thoroughly mixed. Strain the mixture through a 80 mesh sieve. Allow the mixture to mature for 15-20 minutes before application. Stir again before use and continuously during application. Conventional Spray: Add upto 10% Thinner 870 depending on conditions. Use any standard pressure pot equipment at an atomising pressure of 3.5-4.4 kg/cm2 Airless Spray : Apply preferably without thinning. However, add upto 10% Thinner 870 depending on conditions. Use any 2 . standard equipment having pump ratio 30 : 1. Tip size 0.38 0.48 mm. Tip pressure 110 160 Kg/cm

TYPICAL PAINTING SPECIFICATIONS

Surface Steel

1st Coat Zinc Anode 304 MZS

2nd Coat Epilux 4 HB MIO

3rd Coat Epilux 4 CR Enl or Epilux 155 HB or Epilux 89 HB Epilux 5 CTE or Epilux 555 CTE HB Berger Epoxy PU HB or Bergerthane Enl

4th Coat Epilux 4 CR Enl. or Epilux 155 HB or Epilux 89 HB Epilux 5 CTE or Epilux 555 CTE HB

Steel

Zinc Anode 304 MZS

Epilux 610 Primer Berger Epoxy PU HB or Bergerthane Enl

Steel

Zinc Anode 304 MZS

Steel

Zinc Anode 304 MZS

Lumeros HR/47 or Lumeros HR/47 or Silicone Acrylic HB Silicone Acrylic HR Ctg Coating

Overcoating of Zinc Anode 304 MZS: The surface must be fully cured and free from residual solvent prior to overcoating. This normally takes 10-12 hours but under conditions here humidity is below 80%, the time taken may be longer. While overcoating a mist coat should first be applied to avoid bubbling due to air entrapment.

Notes :

1. Use off the mixed paint within the stipulated pot life period. 2. Both components are also available in liquid form for ease of application. 3. The product cures by reaction with moisture and may be applied at high humidity levels provided the blasted surface is free from condensation and meets the requirement of Sa 2.5 Swedish Standard 4. Brush and spray equipment should be cleaned with Thinner 870 otherwise equipment is liable to be damaged 5. At lower relative humidity, drying and curing are likely to be extended. 6. Damaged areas can be touched up with Epilux 4 Zinc Rich Primer Health & Safety : Please refer to the separate Safety Data Sheet available with detailed information.

DISCLAIMER

The information contained within this Data Sheet is based on information believed to be reliable at Data Sheet No: 164/ the time of its preparation. The Company will not be liable for loss or damage howsoever caused rev02 including liability for negligence, which may be suffered by the user of the data contained herein. It is the users responsibility to conduct all necessary tests to confirm the suitability of any product or Issue Date : system for their intended use. No guarantee of results is implied since conditions of use are beyond Mar 2009 our control.

BERGER PAINTS INDIA LIMITED

Berger House,129 Park Street, Kolkata 700017 Phone : (033) 2229 9724 (5 lines) / 2249 9754 (4 lines) Fax : 91-33-2249 9729 / 2249 9009 Email : NORTH : protectondelhi@sify.com SOUTH : bpil_ch2@sify.com

Anda mungkin juga menyukai

- Zinc Anode 304 MZ Ds 099 02Dokumen2 halamanZinc Anode 304 MZ Ds 099 02Power PowerBelum ada peringkat

- Zinc Anode 304 MZS Protects Steel Against CorrosionDokumen2 halamanZinc Anode 304 MZS Protects Steel Against CorrosionBhanu Pratap ChoudhuryBelum ada peringkat

- Zinc Anode 304 MZV Protects Steel Against Severe CorrosionDokumen2 halamanZinc Anode 304 MZV Protects Steel Against Severe CorrosionMANIMARAN QCBelum ada peringkat

- DS 099 Rev01 Zinc Anode 304 MZDokumen2 halamanDS 099 Rev01 Zinc Anode 304 MZvkvc soodBelum ada peringkat

- DS 099 Rev01 Zinc Anode 304 MZDokumen2 halamanDS 099 Rev01 Zinc Anode 304 MZsojeckBelum ada peringkat

- Berger MIO Coating Brown.253140503Dokumen2 halamanBerger MIO Coating Brown.253140503Gaurav TripathiBelum ada peringkat

- SYNTHETIC ROZP PRIMER 12744 SPECDokumen2 halamanSYNTHETIC ROZP PRIMER 12744 SPECmahotkatBelum ada peringkat

- Epigard Zinc Rich Primer PDFDokumen2 halamanEpigard Zinc Rich Primer PDFKarthimeena MeenaBelum ada peringkat

- Epigard Rich Primer - 2006-005 PDFDokumen2 halamanEpigard Rich Primer - 2006-005 PDFabdulyunus_amirBelum ada peringkat

- DATA SHEET NO. 2006-013 Epigard High Build Mio Brown / GreyDokumen2 halamanDATA SHEET NO. 2006-013 Epigard High Build Mio Brown / Greyvijayakumar_samyBelum ada peringkat

- DATA SHEET NO. 2006-013 Epigard High Build Mio Brown / GreyDokumen2 halamanDATA SHEET NO. 2006-013 Epigard High Build Mio Brown / Greyvijayakumar_samyBelum ada peringkat

- Zinc Anode 304 Protects Steel Against CorrosionDokumen2 halamanZinc Anode 304 Protects Steel Against CorrosionIsaac SamuelBelum ada peringkat

- Shalimar Aluminium PaintDokumen2 halamanShalimar Aluminium PaintDeepak Tantuway100% (1)

- Epiplus 556Dokumen2 halamanEpiplus 556hareesh13h100% (1)

- D9 SB ZINC SILICATE Inorganic Zinc Primer Data SheetDokumen2 halamanD9 SB ZINC SILICATE Inorganic Zinc Primer Data SheetPrashant MalveBelum ada peringkat

- Zinc Silicate 8641Dokumen2 halamanZinc Silicate 8641Ryan NortonBelum ada peringkat

- 2006-008 (NXPowerLite)Dokumen2 halaman2006-008 (NXPowerLite)vijayakumar_samyBelum ada peringkat

- DATA SHEET NO. 2006-008 Epigard HB Zinc Phosphate Primer Grey / RedDokumen2 halamanDATA SHEET NO. 2006-008 Epigard HB Zinc Phosphate Primer Grey / Redvijayakumar_samyBelum ada peringkat

- Shop primer data sheetDokumen2 halamanShop primer data sheetKarthimeena MeenaBelum ada peringkat

- Metrotect Acothane TU Brush GradeDokumen3 halamanMetrotect Acothane TU Brush GradeandyvaughanBelum ada peringkat

- Ul Ul Ul Ultracote Tracote Tracote TracoteDokumen3 halamanUl Ul Ul Ultracote Tracote Tracote TracoteJenniferValleBelum ada peringkat

- Amercoat 370Dokumen3 halamanAmercoat 370Victor Hugo Bustos Beltran100% (1)

- 004 - Zinc Chromate PrimerDokumen3 halaman004 - Zinc Chromate PrimeridiotfellowBelum ada peringkat

- Apcosil - PC 2568Dokumen3 halamanApcosil - PC 2568Naren SudarsanBelum ada peringkat

- Interprime 160Dokumen0 halamanInterprime 160Mehman NasibovBelum ada peringkat

- DS - 751-Rev01 - Epilux 65 ZR PrimerDokumen2 halamanDS - 751-Rev01 - Epilux 65 ZR PrimerPammy JainBelum ada peringkat

- Xylar Data SheetDokumen3 halamanXylar Data Sheetsarath6725Belum ada peringkat

- Hi-Temp 1027 PDFDokumen4 halamanHi-Temp 1027 PDFquiron2014Belum ada peringkat

- High-performance epoxy coating data sheetDokumen2 halamanHigh-performance epoxy coating data sheetamadan64Belum ada peringkat

- Protective Coatings for Steel StructuresDokumen3 halamanProtective Coatings for Steel StructuresPavul RajBelum ada peringkat

- 003 - Red Lead Primer PDFDokumen3 halaman003 - Red Lead Primer PDFMohamed RiyaazBelum ada peringkat

- DS BR ACRYLIC PU CoatingDokumen3 halamanDS BR ACRYLIC PU CoatingSomak DuariBelum ada peringkat

- Interprime 198 PDFDokumen4 halamanInterprime 198 PDFandreaju2013Belum ada peringkat

- Epirez 733Dokumen3 halamanEpirez 733Andy AcousticBelum ada peringkat

- DS 122 Rev 01 Epilux 4 High Build Epoxy FinishDokumen2 halamanDS 122 Rev 01 Epilux 4 High Build Epoxy FinishSuriya NaanBelum ada peringkat

- M4 Ep PDFDokumen2 halamanM4 Ep PDFjunaid112Belum ada peringkat

- DS 058-Rev-02 Epilux 155 High Build MIO CoatingDokumen2 halamanDS 058-Rev-02 Epilux 155 High Build MIO CoatingsojeckBelum ada peringkat

- Epilux 44 Enamel: Product Data Resistance GuideDokumen2 halamanEpilux 44 Enamel: Product Data Resistance GuideKishore Nayak kBelum ada peringkat

- Apcoguard SF 725Dokumen3 halamanApcoguard SF 725kiran vargheseBelum ada peringkat

- 4040 Energrease LC2-M 200811Dokumen2 halaman4040 Energrease LC2-M 200811Nikola RandjelovicBelum ada peringkat

- Transpoxy Masterbond 4.68 Epoxy Primer Data SheetDokumen2 halamanTranspoxy Masterbond 4.68 Epoxy Primer Data Sheetjoydeep24088563Belum ada peringkat

- Resicoat R4-ES Fusion Bonded Epoxy: Product Data SheetDokumen2 halamanResicoat R4-ES Fusion Bonded Epoxy: Product Data SheetmarciojunkBelum ada peringkat

- PDS - EP-10 Etch PrimerDokumen2 halamanPDS - EP-10 Etch Primercarlogeretto2Belum ada peringkat

- Bitumastic 300MDokumen2 halamanBitumastic 300Mtharman749781Belum ada peringkat

- Carboguard 635 Thinned 50% - Sealer PDSDokumen5 halamanCarboguard 635 Thinned 50% - Sealer PDSjakeBelum ada peringkat

- DS - 752-Rev01 - Epilux 485 HB IntermediateDokumen2 halamanDS - 752-Rev01 - Epilux 485 HB IntermediatePammy JainBelum ada peringkat

- Pa 10Dokumen3 halamanPa 10LymeParkBelum ada peringkat

- 97 145Dokumen2 halaman97 145anon_251242493Belum ada peringkat

- 8810Dokumen2 halaman8810Sikander Aleem100% (1)

- DS - Epilux - 4 - HB - Epoxy - Finish F-6BDokumen2 halamanDS - Epilux - 4 - HB - Epoxy - Finish F-6Bparvez_ameenBelum ada peringkat

- 1040 Stangard (ST) Epoxy MasticDokumen5 halaman1040 Stangard (ST) Epoxy MasticMayank Gupta0% (1)

- Korepox H.S. EH4158 (Two-Component) : Product DescriptionDokumen2 halamanKorepox H.S. EH4158 (Two-Component) : Product DescriptionTrịnh Minh KhoaBelum ada peringkat

- Insulect Specification PDFDokumen10 halamanInsulect Specification PDFThuan NguyenBelum ada peringkat

- Thermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesDari EverandThermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesPenilaian: 3.5 dari 5 bintang3.5/5 (3)

- The Art of Lead Burning: A practical treatise explaining the apparatus and processesDari EverandThe Art of Lead Burning: A practical treatise explaining the apparatus and processesBelum ada peringkat

- Soldering electronic circuits: Beginner's guideDari EverandSoldering electronic circuits: Beginner's guidePenilaian: 4.5 dari 5 bintang4.5/5 (9)

- The Art of Lead Burning: A practical treatisening the apparatus and processesDari EverandThe Art of Lead Burning: A practical treatisening the apparatus and processesBelum ada peringkat

- Corrosion: Corrosion ControlDari EverandCorrosion: Corrosion ControlL L ShreirPenilaian: 5 dari 5 bintang5/5 (1)

- Logistics Reading ListDokumen4 halamanLogistics Reading ListPower PowerBelum ada peringkat

- Safe - ErectioSafe Erection of Structural Steel For Buildingsns - Web PDFDokumen36 halamanSafe - ErectioSafe Erection of Structural Steel For Buildingsns - Web PDFFarid RezaeianBelum ada peringkat

- Erection Method StatementDokumen32 halamanErection Method StatementDilxan Fdo100% (4)

- ExecutionDokumen53 halamanExecutionPower PowerBelum ada peringkat

- Detroit Stoker CatalogDokumen40 halamanDetroit Stoker CatalogPower Power100% (2)

- BHEL Tender ClarificationDokumen133 halamanBHEL Tender Clarificationelangorenga0% (1)

- Cleansing of Entire Digestive TractDokumen9 halamanCleansing of Entire Digestive TractPower PowerBelum ada peringkat

- We Need To Support Ayurveda Just Like We Did With YogaDokumen3 halamanWe Need To Support Ayurveda Just Like We Did With YogaPower PowerBelum ada peringkat

- Rust o Cap LX Pc2761Dokumen1 halamanRust o Cap LX Pc2761Power PowerBelum ada peringkat

- Pictorial Surface Preparation Standards For Painting Steel Surfaces - MHG PaintsDokumen24 halamanPictorial Surface Preparation Standards For Painting Steel Surfaces - MHG PaintsBellana SirishBelum ada peringkat

- India Today How Modi Takes To Next LevelDokumen8 halamanIndia Today How Modi Takes To Next LevelPower PowerBelum ada peringkat

- Biomass Co-Firing. An Efficient Way To Reduce Greenhouse Gas Emissions (Altener (Veijonen, AlakangasDokumen28 halamanBiomass Co-Firing. An Efficient Way To Reduce Greenhouse Gas Emissions (Altener (Veijonen, AlakangasRicardo Escalada CuadradoBelum ada peringkat

- Catalog Chptech 4Dokumen21 halamanCatalog Chptech 4Hayat KhanBelum ada peringkat

- CD Instructor ManualDokumen48 halamanCD Instructor ManualJoey E. CrumbyBelum ada peringkat

- Steam Turbine DesignDokumen14 halamanSteam Turbine DesignFaiz de PorrasBelum ada peringkat

- Phoenix S-Wall Technical-Manual enDokumen44 halamanPhoenix S-Wall Technical-Manual enRavikanth Aluri100% (1)

- Statutory Clearances Required For Starting A Captive Coal MineDokumen25 halamanStatutory Clearances Required For Starting A Captive Coal MinePower PowerBelum ada peringkat

- Rock Dust Revised PoliciesDokumen12 halamanRock Dust Revised Policiespower groupBelum ada peringkat

- HAZOP Hazard Operability StudiesDokumen4 halamanHAZOP Hazard Operability StudiesSrinivas BobbyBelum ada peringkat

- Amonia Plant - RisksDokumen14 halamanAmonia Plant - Risksanburishi100% (1)

- ID Fan Designing QuestioneareDokumen2 halamanID Fan Designing QuestioneareMuhammadBelum ada peringkat

- Efficient Engineering R 0Dokumen6 halamanEfficient Engineering R 0Power PowerBelum ada peringkat

- Preventing Explosions in IndustryDokumen11 halamanPreventing Explosions in IndustryPower PowerBelum ada peringkat

- Excel To Revit ConverterDokumen1 halamanExcel To Revit ConverterPower PowerBelum ada peringkat

- SAGE: System For Algebra and Geometry ExperimentationDokumen4 halamanSAGE: System For Algebra and Geometry ExperimentationPower PowerBelum ada peringkat

- Hindi Text For LeaningDokumen1 halamanHindi Text For LeaningPower PowerBelum ada peringkat

- Autodesk Robot Structural Analysis Professional 2015 What Is NewDokumen15 halamanAutodesk Robot Structural Analysis Professional 2015 What Is NewRangel Sonaglio100% (1)

- Tower - Model - Generation NewDokumen1 halamanTower - Model - Generation NewPower PowerBelum ada peringkat

- Ap41s 81 2009Dokumen11 halamanAp41s 81 2009Anita VkBelum ada peringkat

- A Combinatorial Approach To Hybrid Enzymes Independent of DNA HomologyDokumen5 halamanA Combinatorial Approach To Hybrid Enzymes Independent of DNA HomologyArdiellaputriBelum ada peringkat

- Conservation of Energy Lab AlternativeDokumen3 halamanConservation of Energy Lab Alternativeapi-292550476Belum ada peringkat

- Mohamed Abdel-Hameed Ahmed: Curriculum VitaeDokumen3 halamanMohamed Abdel-Hameed Ahmed: Curriculum VitaeHatem HusseinBelum ada peringkat

- Field Effect Transistors in Theory and Practice: Application NoteDokumen11 halamanField Effect Transistors in Theory and Practice: Application Notesai dharmaBelum ada peringkat

- Buried Pipe - Neven DrobnjakDokumen9 halamanBuried Pipe - Neven DrobnjakAnjani PrabhakarBelum ada peringkat

- Sellos T-5610 T-5610QDokumen8 halamanSellos T-5610 T-5610QBenicio Joaquín Ferrero BrebesBelum ada peringkat

- BHEL FANS - Best Operation PracticesDokumen19 halamanBHEL FANS - Best Operation Practiceshonchoabhi100% (1)

- HMTDokumen3 halamanHMTRuby SmithBelum ada peringkat

- Fabshield Offshore 71ni-1Dokumen2 halamanFabshield Offshore 71ni-1Anonymous ejnktktkY7Belum ada peringkat

- Chapter 15 Acid Base Equilibrium and BuffersDokumen9 halamanChapter 15 Acid Base Equilibrium and Buffersmememe123123Belum ada peringkat

- Chris DeArmitt PHD ThesisDokumen160 halamanChris DeArmitt PHD Thesisalinbu2007Belum ada peringkat

- Tolerances of A Polystyrene Film: 2.2.25. ABSORPTION Spectrophotometry, Ultraviolet and VisibleDokumen3 halamanTolerances of A Polystyrene Film: 2.2.25. ABSORPTION Spectrophotometry, Ultraviolet and Visibleivan cuadradoBelum ada peringkat

- BEOL IntegrationDokumen39 halamanBEOL IntegrationGabriel DonovanBelum ada peringkat

- Salkowski Test ConclusionDokumen3 halamanSalkowski Test Conclusionclint xavier odangoBelum ada peringkat

- York Yvaa IomDokumen144 halamanYork Yvaa Iomtm_20100% (1)

- Thermoforming TroubleshootingDokumen10 halamanThermoforming TroubleshootingdynafloBelum ada peringkat

- FNL Flanged Housings Provide Simple, Reliable Bearing SupportDokumen22 halamanFNL Flanged Housings Provide Simple, Reliable Bearing Supportsaeed shirvaniBelum ada peringkat

- Chapter 8Dokumen58 halamanChapter 8haitham101297Belum ada peringkat

- Astm A 1084 2013 PDFDokumen17 halamanAstm A 1084 2013 PDFjoao carlos protzBelum ada peringkat

- Mil DTF 5541fDokumen12 halamanMil DTF 5541fMarcos PerezBelum ada peringkat

- Lee Et Al 2005Dokumen9 halamanLee Et Al 2005Hyejin Yeni PatmawatiBelum ada peringkat

- Evidence and Processes of EvolutionDokumen14 halamanEvidence and Processes of EvolutionMiralen EndozoBelum ada peringkat

- Disintegration TestDokumen19 halamanDisintegration TestUsman Najeeb Cheema100% (1)

- Book 1 System 2016Dokumen155 halamanBook 1 System 2016annis99Belum ada peringkat

- Engine Oil Volatility Noack Evaporation MethodDokumen5 halamanEngine Oil Volatility Noack Evaporation MethodAvinash Gamit100% (1)

- Aggregate Impact Value TestDokumen3 halamanAggregate Impact Value Testanatoink2Belum ada peringkat

- Paper 2 June 2007 PhysicsDokumen16 halamanPaper 2 June 2007 PhysicssolarixeBelum ada peringkat

- Fire Characteristics of Styropor FoamsDokumen4 halamanFire Characteristics of Styropor FoamsRosman Al-QadriBelum ada peringkat

- ASG Newformat FREDDokumen88 halamanASG Newformat FREDSigmaBelum ada peringkat