Reducing Runout On 3 Jaw Chuk

Diunggah oleh

kokiskoJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Reducing Runout On 3 Jaw Chuk

Diunggah oleh

kokiskoHak Cipta:

Format Tersedia

R. G.

Sparber October 10, 2011 Page 1 of 12

Reducing Total Indicated Runout on a 3

Jaw Chuck

By R. G. Sparber

Copyleft protects this document.

1

There are times when

I want to center a

piece of round stock

in my 3 jaw chuck.

These cases are rare

because I try to just

start with an oversized

piece and turn it

down. This

automatically places

the center of rotation

of the part at the

center of the part

within the limits of the

lathes run out.

This article along with a supplied Excel spreadsheet will enable you to take a few

measurements and calculate the needed pair of shims to center the round stock.

This article has two parts. The first part explains how to use the spreadsheet. The

second part presents the math underlying the spreadsheet.

1

You are free to copy and distribute this document but not change it.

R. G. Sparber October 10, 2011 Page 2 of 12

Centering Round Stock in a 3 Jaw Chuck

This procedure assumes that your round stock is smooth and perfectly round. If it

is not smooth, then the Dial Test Indicator cannot give reliable readings. If it is not

perfectly round, then the readings will define an erroneous center. It also assumes

that the jaws all move in and out by the same amount as the key is turned. It does

not assume that the jaws perfectly meet at the same distance from the center of

rotation. If they did, this procedure would not be needed.

1. Measure the diameter of the stock. The spreadsheet handles imperial and

metric.

2. Clean the outside of the stock as well as the jaws.

3. Chuck up the stock.

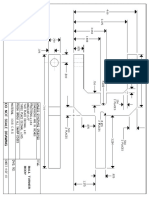

4. Mount your DTI so it is at the

same height as the center of rotation.

5. Find the point on the

circumference that is closest to the

center of rotation and note the DTI

reading. Call this value min.

6. Find the point on the

circumference that is the furthest from

the center of rotation and note the DTI

reading. It should be 180 from min.

Call this value max.

7. Turn the chuck so that the max

point is no more than 120 from a jaw

that is vertical. Call this vertical jaw J1.

Jaw J2 will be counterclockwise from

J1 and jaw J3 will be clockwise from

J1.

8. Measure the angle, A defined

between J1 and the max point.

9. Now plug in diameter, min, max,

and angle A into the spreadsheet. It

will tell you the thickness of two shims.

One of the jaws will not need a shim.

J2

J1

J3

A

R. G. Sparber October 10, 2011 Page 3 of 12

Shop Testing

This is a demonstration, not a proof. I took some round stock and verified it read

the same diameter at various points around its perimeter using my Harbor Freight

digital caliper. Then I used my digital caliper plus my spacer blocks to measure

this diameter. The caliper has a resolution of 0.0005 and past experience has

shown me that this is repeatable. A stack of spacer blocks 1.564 tall gave the

same reading as the diameter of the round stock.

I then cleaned all mating surfaces and chucked up the round stock. My DTI was set

to zero at the max point. The min point, 180 degrees from max, read -0.0032.

I then turned the chuck so the jaw counter clock wise from the max point was

vertical. This is my Jaw 1. A level was used to set Jaw 1 vertical and a protractor

level was used to measure the angle of 25.

I then plugged into my spreadsheet:

Diameter 1.464

Max 0.0

Min -0.0032

Angle 25

I read out:

Jaw 1: 0.003

Jaw 2: 0.

Jaw 3: 0.001

I then found a 0.00315 and a 0.00125 shim and installed them without rotating

the part with respect to the jaws.

My lathe bearings are not perfect and side pressure does move the chuck. So I

ended up turning the chuck under power at 26 RPM. It was easy to follow the DTI

needle which swung a total of 0.0005.

So I was able to reduce TIR from 0.0032 down to 0.0005 by using two shims.

R. G. Sparber October 10, 2011 Page 4 of 12

Behind the Spreadsheet

Looking into the face of the 3 jaw chuck we see jaws J1, J2, and J3. I will assume

that they are the same distance from the center of rotation (COR) in order to

simplify the math. But in fact, any error is absorbed in the shim calculations.

Held in the chuck is a piece of round stock of radius r. The center of this piece of

stock is at the point (x

1

,y

1

).

The distance along the axis followed by each jaw from the tip of the jaw to the

surface of the stock is the needed shim. One of these shims can be set to zero but at

this point we dont know which one. So I will carry all 3 variables through the

derivation.

R. G. Sparber October 10, 2011 Page 5 of 12

The distance from the COR to the circle defined by the jaws has a radius of S.

Each jaw has a shim of thickness n

i

. Measuring from the COR, we have a

distance S-n

i

, i=1,2,or 3. Measuring from the positive X axis, I have S-n

1

at 90, S-

n

2

at 120, and S-n

3

at 330.

These same 3 points can be defined by looking at the round stock. If (x

1

,y

1

) was

(0,0), it is easier to see. In this case, we know the radius, r. The angle would be the

same as the jaws. Not terribly useful since this is just the case of zero TIR. I will

show how to find coordinates for the general case of non-zero (x

1

,y

1

).

The strategy is therefore to define each of the 3 contact points with respect to a jaw

and the corresponding point on the surface of the stock. This gives me values for

the three (S-n

i

). I then center the part which means that the distance from the COR

out towards each jaw is simply r. The needed shim is then (S-ni) r. Recalling that

the assumption that the jaws move in and out together, I can add a constant to all

three shims such that they are equal to or greater than zero.

R. G. Sparber October 10, 2011 Page 6 of 12

Jaw 1

This set of equations is unique because I have defined the axis that Jaw 1 moves

along to be coincident with the Y axis.

My point of contact is (x

3

,y

3

) but x

3

= 0. From Jaw 1s viewpoint, it is at y

3

=S-n

1

.

From the viewpoint of the round stock I can find y3 because I have a right triangle

with known base and hypotenuse. The vertical distance from the contact point

down to y

1

is r

2

-

1

2

. I can then say that

3

=

1

+ r

2

-

1

2

. Matching up

the two equations I can say that S-n

1

=

1

+ r

2

-

1

2

(equation 1).

R. G. Sparber October 10, 2011 Page 7 of 12

Jaw 2

Things get messy now but at least the approach for Jaw 2 is the same for Jaw 3.

From Jaw 2s standpoint, I can say

4

= -( -n

2

) cos (equation a)

4

= -( -n

2

) sin (equation b)

R. G. Sparber October 10, 2011 Page 8 of 12

From the round stocks viewpoint, I can define a right triangle with a rise of

1

-

4

and a base of

1

-

4

. My hypotenuse is r so I can write

r

2

= (

1

-

4

)

2

+ (

1

-

4

)

2

(equation c)

Next I feed equations a and b into equation c

r

2

= (

1

+( -n

2

) cos )

2

+(

1

+( -n

2

) sin)

2

(equation d)

Multiplying this all out and grouping like terms I get a polynomial of the form

= ( -n

2

)

2

+ ( -n

2

) +

Where A = 1, =

1

cos +

1

sin, and =

1

2

+

1

2

-r

2

. I then

solved for the positive root using

B+VB

2

-4AC

2A

to get (equation 2).

R. G. Sparber October 10, 2011 Page 9 of 12

Jaw 3

Similar to Jaw 2, I can say

5

= ( -n

3

) cos (equation e)

5

= -( -n

3

) sin (equation f)

from the jaws standpoint. Recall that Jaw 3 is 120 from Jaw 1 so must be 30

from the X axis.

R. G. Sparber October 10, 2011 Page 10 of 12

As viewed from the round stock, I can again define a right triangle with a base of

5

-

1

and height of

1

-

5

. Since I know the hypotenuse is r, I can write

r

2

= (

1

-

5

)

2

+(

1

-

5

)

2

(equation g)

I again combine the two equations, e and f, from the jaw with the one from the

round stock, g, and get a polynomial. The terms are A = 1, = -

1

cos +

1

sin, and = -r

2

+

1

2

+

1

2

. The positive root is used. This is (equation

3).

R. G. Sparber October 10, 2011 Page 11 of 12

Total Indicated Run-Out

The last piece of the puzzle is to translate the TIR readings into (x

1

,y

1

).

By definition, I =

mux-mn

2

. The TIR is the hypotenuse of my right triangle.

The angle a was measured. I can then say

1

= I sin (equation h)

1

= I cos (equation i)

R. G. Sparber October 10, 2011 Page 12 of 12

I end up with a set of equations, 1,2, and 3 of the form -n

, for i=1,2,3.

These values represent the positions of the three jaws when the part has a non-zero

TIR. What I want is the correction to drive the TIR to zero.

The shim needed on

Jaw 1 is (S-n

1

) r.

Note that the angle

does not enter into the

equation because we

are only talking about

the motion along the

axis traversed by the

jaw.

Similarly, I can say

that the shim needed

for Jaw 2 is (S-n

2

) r

and for jaw 3 is (S-n

3

)

r. We end up with

shims that can have a

positive or negative

value. Since the jaws

all move in and out by the same amount, I will not change the parts position as

long as I add the same value to each shim. I therefore choose to select the smallest

shim (most negative) and subtract that from all three shims. This will cause one

shim to be zero while the other two are positive.

I welcome your comments and questions.

Rick Sparber

Rgsparber@aol.com

Anda mungkin juga menyukai

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (894)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (587)

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (344)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (119)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2219)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (73)

- To Sir With LoveDokumen2 halamanTo Sir With LoveRamita Udayashankar100% (2)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- Anti-Gravity PropulsionDokumen16 halamanAnti-Gravity PropulsionTony FreelandBelum ada peringkat

- Anti-Gravity PropulsionDokumen16 halamanAnti-Gravity PropulsionTony FreelandBelum ada peringkat

- 6th Central Pay Commission Salary CalculatorDokumen15 halaman6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- Software Security Engineering: A Guide for Project ManagersDokumen6 halamanSoftware Security Engineering: A Guide for Project ManagersVikram AwotarBelum ada peringkat

- Skellig - Chapters 16-20 QuestionsDokumen1 halamanSkellig - Chapters 16-20 Questionselishasantos0% (1)

- Pragmatic Marketing FrameworkDokumen2 halamanPragmatic Marketing FrameworkohgenryBelum ada peringkat

- Wjec Gcse English Literature Coursework Mark SchemeDokumen6 halamanWjec Gcse English Literature Coursework Mark Schemef6a5mww8100% (2)

- Andy Landers - Freeze Zone OffenseDokumen6 halamanAndy Landers - Freeze Zone OffenseWinston Brown100% (1)

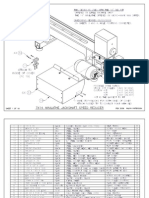

- Ball Turner Prints PDFDokumen10 halamanBall Turner Prints PDFkokiskoBelum ada peringkat

- Ball Turner PrintsDokumen10 halamanBall Turner PrintskokiskoBelum ada peringkat

- A Method of Dividing The Circumference of A CircleDokumen3 halamanA Method of Dividing The Circumference of A CirclekokiskoBelum ada peringkat

- SMD Electrolysis PDFDokumen1 halamanSMD Electrolysis PDFkokiskoBelum ada peringkat

- Quantum Wave of Life Evolution: Written by DR Kiril Chukanov, June 2009, Calgary, CanadaDokumen32 halamanQuantum Wave of Life Evolution: Written by DR Kiril Chukanov, June 2009, Calgary, CanadakokiskoBelum ada peringkat

- Quantum Wave of Life Evolution: Written by DR Kiril Chukanov, June 2009, Calgary, CanadaDokumen32 halamanQuantum Wave of Life Evolution: Written by DR Kiril Chukanov, June 2009, Calgary, CanadakokiskoBelum ada peringkat

- RB 7x12 Minilathe BedwaysDokumen2 halamanRB 7x12 Minilathe BedwayskokiskoBelum ada peringkat

- UFODokumen2 halamanUFOkokiskoBelum ada peringkat

- Assessing Potential Propulsion Breakthroughs: Marc G. MillisDokumen21 halamanAssessing Potential Propulsion Breakthroughs: Marc G. MillisnenucarqBelum ada peringkat

- Mysteries of The Unknown - The UFO PhenomenonDokumen162 halamanMysteries of The Unknown - The UFO Phenomenonanaximandre06100% (3)

- 1769 Compound Rest AssyDokumen1 halaman1769 Compound Rest AssykokiskoBelum ada peringkat

- Evading Thermal Imaging and Radar Detection-1Dokumen8 halamanEvading Thermal Imaging and Radar Detection-1kokiskoBelum ada peringkat

- WO9010337 Magnetic MotorDokumen23 halamanWO9010337 Magnetic MotorAndras KondratBelum ada peringkat

- GAA Bortone June02Dokumen2 halamanGAA Bortone June02kokiskoBelum ada peringkat

- r8 5c Collet DimensionsDokumen2 halamanr8 5c Collet DimensionskokiskoBelum ada peringkat

- Spindle, 7x10, 12 Mini LatheDokumen1 halamanSpindle, 7x10, 12 Mini LatheramaaramaaBelum ada peringkat

- Ralph Patterson Tailstock Camlock 2Dokumen13 halamanRalph Patterson Tailstock Camlock 2supremesportsBelum ada peringkat

- Drive TroubleshootingDokumen9 halamanDrive TroubleshootingkokiskoBelum ada peringkat

- Ralph Patterson Speed Reducer 2Dokumen27 halamanRalph Patterson Speed Reducer 2kokiskoBelum ada peringkat

- Change Gears Charts For Metric Threading On The 7x MiniDokumen2 halamanChange Gears Charts For Metric Threading On The 7x MinikokiskoBelum ada peringkat

- Cross slide nut modification for Grizzly 7x12/24 latheDokumen3 halamanCross slide nut modification for Grizzly 7x12/24 lathekokiskoBelum ada peringkat

- Rollies Dads MethodDokumen4 halamanRollies Dads Methodctin12Belum ada peringkat

- Metal Drilling Speed ChartDokumen3 halamanMetal Drilling Speed ChartkokiskoBelum ada peringkat

- Morse Taper Dimensions and Drill Chuck ArborsDokumen4 halamanMorse Taper Dimensions and Drill Chuck ArborskokiskoBelum ada peringkat

- How To Make Economical BateryDokumen85 halamanHow To Make Economical BaterykokiskoBelum ada peringkat

- Perreault, Bruce A. U.S. Patent Application Filed May 04, 2007Dokumen9 halamanPerreault, Bruce A. U.S. Patent Application Filed May 04, 2007kokiskoBelum ada peringkat

- Ball Turning Toolpost - Complete PDFDokumen5 halamanBall Turning Toolpost - Complete PDFRamanujam O SBelum ada peringkat

- Life Convict Laxman Naskar Vs State of West Bengal & Anr On 1 September, 2000Dokumen6 halamanLife Convict Laxman Naskar Vs State of West Bengal & Anr On 1 September, 2000Kimberly HardyBelum ada peringkat

- Are Moral Principles Determined by SocietyDokumen2 halamanAre Moral Principles Determined by SocietyKeye HiterozaBelum ada peringkat

- 17 Lagrange's TheoremDokumen6 halaman17 Lagrange's TheoremRomeo Jay PragachaBelum ada peringkat

- Perkin Elmer Singapore Distribution CaseDokumen3 halamanPerkin Elmer Singapore Distribution CaseJackie Canlas100% (1)

- Lived Experiences of Elementary Teachers in A Remote School in Samar, PhilippinesDokumen14 halamanLived Experiences of Elementary Teachers in A Remote School in Samar, Philippinesルイス ジャンBelum ada peringkat

- INTERNSHIP REPORT 3 PagesDokumen4 halamanINTERNSHIP REPORT 3 Pagesali333444Belum ada peringkat

- Evelyn Nakano Glenn, "From Servitude To Service Work: Historical Continuities in The Racial Division of Paid Reproductive Labor"Dokumen44 halamanEvelyn Nakano Glenn, "From Servitude To Service Work: Historical Continuities in The Racial Division of Paid Reproductive Labor"s0metim3sBelum ada peringkat

- Ash ContentDokumen2 halamanAsh Contentvikasbnsl1Belum ada peringkat

- Japanese Tea Cups LessonDokumen3 halamanJapanese Tea Cups Lessonapi-525048974Belum ada peringkat

- PallavaDokumen24 halamanPallavaAzeez FathulBelum ada peringkat

- Physical Education For Class - 11thDokumen19 halamanPhysical Education For Class - 11thdjjagu908Belum ada peringkat

- Accomplishment Report - 1st and 2nd SemDokumen41 halamanAccomplishment Report - 1st and 2nd Semshailean azulBelum ada peringkat

- Elementary Hebrew Gram 00 GreeDokumen216 halamanElementary Hebrew Gram 00 GreeRobert CampoBelum ada peringkat

- H-1 Nationalism in Europe NotesDokumen5 halamanH-1 Nationalism in Europe Noteskanishk kumarBelum ada peringkat

- Testing Your Understanding: The Dash, Slash, Ellipses & BracketsDokumen2 halamanTesting Your Understanding: The Dash, Slash, Ellipses & BracketsBatsaikhan DashdondogBelum ada peringkat

- PIC16 F 1619Dokumen594 halamanPIC16 F 1619Francisco Martinez AlemanBelum ada peringkat

- Levenbach Causal2017Dokumen15 halamanLevenbach Causal2017Jenna GrantBelum ada peringkat

- ASBMR 14 Onsite Program Book FINALDokumen362 halamanASBMR 14 Onsite Program Book FINALm419703Belum ada peringkat

- Book Review Reclaim Your HeartDokumen7 halamanBook Review Reclaim Your HeartShaheer KhanBelum ada peringkat

- Neoclassicism: Romanticism Realism ImpressionismDokumen16 halamanNeoclassicism: Romanticism Realism ImpressionismErika EludoBelum ada peringkat

- Viennas Cafe Louvre in The 1920s and 1930Dokumen18 halamanViennas Cafe Louvre in The 1920s and 1930Friso HoeneveldBelum ada peringkat

- Primer To Using Stampplot® Pro Standard User LicensedDokumen21 halamanPrimer To Using Stampplot® Pro Standard User LicensedSandy Rachman AdrianBelum ada peringkat

- Cambridge Assessment International Education: Biology 5090/61 October/November 2017Dokumen6 halamanCambridge Assessment International Education: Biology 5090/61 October/November 2017Zarish NoorBelum ada peringkat

- Universitas Alumni Psikotest LolosDokumen11 halamanUniversitas Alumni Psikotest LolosPsikotes BVKBelum ada peringkat