Baking Update: Bakers Yeast Production and Characteristics

Diunggah oleh

Cheu Hann JongDeskripsi Asli:

Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Baking Update: Bakers Yeast Production and Characteristics

Diunggah oleh

Cheu Hann JongHak Cipta:

Format Tersedia

LALLEMAND

VOLUME 1 / NUMBER 9

BAKING UPDA TE

Practical technology from Lallemand Inc., parent of American Yeast Sales, producers and distributors of Eagle yeast, fresh and instant.

AMERICAN YEAST SALES

Yeast Production

Bakers Yeast Production and Characteristics

cessed affects its composition, purity, and appearance. Information about yeast production can help bakers judge and use yeast better in their own processes.

PRODUCTION PROCESS

HE WAY YEAST is grown and pro-

YEAST PRODUCTION

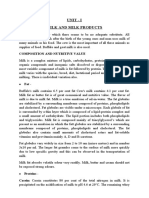

beet molasses pure culture fermentor flask clarifier seed yeast

water

cane molasses

Raw Materials. Cane or beet molasses is the primary raw material for bakers yeast production. It supplies all the sugar that yeast needs for growth and energy along with part of the needed nitrogen. Before it is fed to the yeast, concentrated molasses is diluted with water, claried, and heat sterilized. It is then supplemented with additional nitrogen, phosphate, vitamins, and minerals. Fermentation. Bakers yeast begins as a pure culture of the desired strain, which is inoculated from a small vial into a sterile ask of broth. From the ask it is transferred into a larger vessel, then through several fermentation stages of increasing volume. The larger-scale fermentations take place in 25,000- to 50,000-gallon fermentors that are equipped for aeration, cooling, incremental molasses feeding, pH control, and anti-foam addition. Each fermentation step requires about a day, so that at the end of a week more than 500,000 pounds can be produced from a single vial. Processing. Yeast broth from the fermentor at about 5 percent solids is concentrated in a centrifuge to about 18 percent solids and washed with water. Cream yeast is simply this liquid yeast that is cooled and delivered in bulk to the bakery. To make compressed (granular and cake) yeast, cream yeast is passed through a lter, which removes water and increases the solids concentration to about 30 percent. When a rotary vacuum lter is used, the cream is rst treated with salt, then sucked onto a thin layer of starch, rinsed with cold water to remove the salt, and scraped off the

Continued

vial

sterile mash tank sterilizer

nutrients pH and foam control

production fermentor

semi-seed fermentor

seed fermen.

cooling water filtered air yeast broth water centrifuge cooler yeast cream storage tank cream yeast

emulsifier or oil salt, starch granulator water

extruder and cutter

cake yeast

granular yeast

rotary vacuum filter

cake yeast packaging

bag yeast packaging

palletizers

yeast cooler distribution

YEAST PROPAGATION STAGES

Yeast Production Biochemistry

0.00001 Pounds of Yeast

(at 30% solids)

Vial

Flask Pure Culture Seed

0.1 2,000 20,000

Semi-seed Production

80,000 500,000

Bakers Yeast Production and Characteristics

(Continued)

starch. After ltering, small amounts of emulsiers or oils are added to assist in the extrusion and cutting of the yeast and to improve its appearance. Granular yeast is then crumbled and packed in bags; cake yeast is extruded and formed into blocks.

FINISHED PRODUCT

Composition. Compressed yeast contains about 70 percent water and 30 percent yeast solids. Of the yeast solids, about 50 percent is protein, 40 percent is carbohydrate, and the rest is fat and ash. The solids content can vary from about 27 to 33 percent, depending on how it is ltered. The higher the yeast solids, the higher the activity. The protein level can vary from about 45 to 60 percent and the carbohydrate level from 30 to 45 percent, depending mostly on how fast the yeast is grown. Higher growth rates give higher protein, higher activity, lower carbohydrate, and lower stability. Lower growth rates give lower protein, lower activity, higher carbohydrate, and higher stability. Purity. Bakers yeast is grown under sanitary (not sterile) conditions to ensure that the strain remains true to type and that no harmful organisms are present. Better sanitation procedures, fewer fermentation stages, and lower fermentation pH give lower contamination levels. All products should be free of Salmonella, Listeria, and E. coli, with low levels of coliforms and other sanitation-indicator organisms. Lactic acid

bacteria and wild (non-Saccharomyces cerevisiae) yeast are always present because they are common in the environment and grow under the same conditions as bakers yeast. Normal levels of these other microorganisms are not a problem because they occur naturally in our, and the bakers yeast cells greatly outnumber them. Appearance. Compressed yeast can range in color from dark brown to nearly white, and in texture from friable (easy to crumble) to gummy. Appearance is affected by yeast strain, molasses source, fermentation conditions, processing aids, moisture level, and age. Low fermentation pH gives higher purity but darker yeast. Emulsiers give lighter color and frozen storage gives mushier texture, but neither affects performance. High moisture makes yeast darker but affects performance only to the extent that yeast solids are reduced. Storage time, temperature, and oxygen make yeast darker and gummier and reduce its performance. Old or damaged yeast frequently appears dark and gummy, but because there are so many other factors involved, appearance alone is not a reliable indicator of yeast quality.

on the ability of Saccharomyces cerevisiae to assimilate inorganic nitrogen and grow via respiration instead of fermentation. Assimilating inorganic nitrogen is important because it allows bakers yeast to be grown on molasses as an economical source of sugar and other nutrients. Molasses is relatively low in nitrogen and has to be supplemented so that yeast can synthesize the protein and the other cell constituents they need for growth. Because Saccharomyces cerevisiae can use inorganic nitrogen, a combination of ammonia and ammonium salts are added to provide economical sources of nitrogen and pH control. Growing via respiration is important because it is about eighteen times as efcient as fermentation at converting sugar into yeast. The tendency of yeast to grow via respiration when large amounts of oxygen are present is known as the Pasteur effect. The tendency of yeast to grow via fermentation when high levels of sugar are present is known as the Crabtree effect. The combination of Pasteur and Crabtree effects in Saccharomyces cerevisiae is the reason commercial bakers yeast fermentations use high aeration and incremental feeding to maintain high oxygen and low sugar levels throughout the process.

AKERS YEAST production depends

LALLEMAND

BAKING UPDATE

Lallemand Baking Update is produced by Lallemand Inc. to provide bakers with a source of practical technology for solving problems. If you would like to be on our mailing list to receive future copies, or if you have questions or comments, please contact us at: LALLEMAND Inc. 1620 Prfontaine Montral, QC H1W 2N8 CANADA tel: (800) 840-4047 (514) 522-2133 fax: (514) 255-6861

To the best of our knowledge, the information in Lallemand Baking Update is true and accurate. However, any recommendations or suggestions are made without warranty or guarantee. 1996 Lallemand Inc.

LALLEMAND products are distributed by its subsidiaries, AMERICAN YEAST SALES and LALLEMAND DISTRIBUTION.

AMERICAN YEAST SALES

LALLEMAND

Lallemand Baking Update Volume 1/Number 9

Anda mungkin juga menyukai

- Mastering Sourdough Starters And LeavensDari EverandMastering Sourdough Starters And LeavensPenilaian: 5 dari 5 bintang5/5 (2)

- Lactobacillus and Streptococcus That Are Intentionally Added To Pasteurized Milk and Grown at 30°C orDokumen7 halamanLactobacillus and Streptococcus That Are Intentionally Added To Pasteurized Milk and Grown at 30°C orAriane Rose SincoBelum ada peringkat

- Cheese Making A Step-By-Step Guide for Making Delicious Cheese At HomeDari EverandCheese Making A Step-By-Step Guide for Making Delicious Cheese At HomeBelum ada peringkat

- Milk and Milk ProductsDokumen35 halamanMilk and Milk ProductsAnamaeBelum ada peringkat

- Group 2 Worksheet 9Dokumen11 halamanGroup 2 Worksheet 9Matthew Dominic MinguezBelum ada peringkat

- Milk Quality DefectDokumen32 halamanMilk Quality DefectMuhammad Farrukh Hafeez50% (8)

- Food Biotechnology Sub Topic: Processing Fermentation TechnologyDokumen2 halamanFood Biotechnology Sub Topic: Processing Fermentation TechnologyNorsyekii Chea-QirRaBelum ada peringkat

- Ayib, AdugnaDokumen22 halamanAyib, AdugnaAmbi Bekele ZewdieBelum ada peringkat

- Mbio313 Assignment 01 181-025-031Dokumen7 halamanMbio313 Assignment 01 181-025-031Razia UrmiBelum ada peringkat

- Cheese AdditivesDokumen27 halamanCheese AdditivesNiraj SinghBelum ada peringkat

- Chemistry ProjectDokumen14 halamanChemistry ProjectSahil PuwarBelum ada peringkat

- Sour DoughDokumen59 halamanSour DoughcrodmarcanBelum ada peringkat

- Chemistry Project 3Dokumen11 halamanChemistry Project 3Ravi SharmaBelum ada peringkat

- Cheese MakingDokumen30 halamanCheese MakingCAPRINOS BAJA CALIFORNIA SUR, MEXICO100% (4)

- Yeast and Molds Lactic FermentationDokumen35 halamanYeast and Molds Lactic Fermentationskmishra84100% (2)

- Lab YogurtDokumen6 halamanLab YogurtSikin Sikin0% (1)

- Development of Parmesan Cheese Production From Local Cow MilkDokumen7 halamanDevelopment of Parmesan Cheese Production From Local Cow MilkDea FazriahBelum ada peringkat

- MilkDokumen23 halamanMilkFahima VABelum ada peringkat

- CheeseDokumen30 halamanCheeseAdams SadikBelum ada peringkat

- Milk ProcessingDokumen10 halamanMilk ProcessingSabiha TabassumBelum ada peringkat

- Cheese MakingDokumen4 halamanCheese Makingmingix420Belum ada peringkat

- Cheese Production: by Primrose Katsande and Chipo ParaffinDokumen17 halamanCheese Production: by Primrose Katsande and Chipo Paraffinmatthew matawoBelum ada peringkat

- Microbiology of Milk and It's ContaminantsDokumen26 halamanMicrobiology of Milk and It's ContaminantsKavin ABelum ada peringkat

- Yeast ProductionDokumen21 halamanYeast ProductionIslam ImadBelum ada peringkat

- Unit - I Milk and Milk ProductsDokumen15 halamanUnit - I Milk and Milk ProductsSabiha TabassumBelum ada peringkat

- Group 4 Cheese and YogurtDokumen28 halamanGroup 4 Cheese and YogurtmoniqueBelum ada peringkat

- Chemistry and Biochemistry of FermentedDokumen19 halamanChemistry and Biochemistry of Fermentedgaroasenti44Belum ada peringkat

- Comparision of Rate OfferDokumen10 halamanComparision of Rate Offerl gnaneshuBelum ada peringkat

- Fermented MilkDokumen13 halamanFermented Milkhtc587uyBelum ada peringkat

- Yeast Article FinalDokumen2 halamanYeast Article Finalapi-275184165Belum ada peringkat

- Cheese Making How-To'sDokumen33 halamanCheese Making How-To'snikoskassBelum ada peringkat

- Chemistry Investigatory ProjectDokumen22 halamanChemistry Investigatory ProjectAnurag Mishra100% (1)

- Soy Milk: Nutrition and Health InformationDokumen8 halamanSoy Milk: Nutrition and Health InformationRahul JadhavBelum ada peringkat

- Practica #1 Elaboración de Yogur Batido I. Resumen: Industria LácteaDokumen15 halamanPractica #1 Elaboración de Yogur Batido I. Resumen: Industria LácteaGretel CRBelum ada peringkat

- Chemistry ProjectDokumen10 halamanChemistry ProjectAbhey Gupta100% (3)

- Food Analysis ManualDokumen70 halamanFood Analysis ManualRishad KalappurakkalBelum ada peringkat

- Food Chemistry (Cheese) FullDokumen11 halamanFood Chemistry (Cheese) FullAlia CameliaBelum ada peringkat

- Fermentis Tips TricksDokumen20 halamanFermentis Tips TricksAntonio Imperi100% (4)

- Chemistry ProjectDokumen12 halamanChemistry ProjectAmit Kumar50% (2)

- b4 Cheese ProductionDokumen10 halamanb4 Cheese Productionguide ngobeniBelum ada peringkat

- National Experimental University of TáchiraDokumen9 halamanNational Experimental University of TáchiraOrladys RoaBelum ada peringkat

- CheesemakingDokumen2 halamanCheesemakingsyifa salsabilaBelum ada peringkat

- Lyoto, Lyofast, Cryostart, Cryofast SHL and SHDokumen2 halamanLyoto, Lyofast, Cryostart, Cryofast SHL and SHResources100% (1)

- Chemistry ProjectDokumen13 halamanChemistry ProjectSakthivelayudhamganesanBelum ada peringkat

- Biology ProjectDokumen10 halamanBiology ProjectMaha SBelum ada peringkat

- Milk Adulteration and Milk PropertiesDokumen22 halamanMilk Adulteration and Milk PropertiesNagaraj KhBelum ada peringkat

- Food Microbiology 4Dokumen26 halamanFood Microbiology 4Jefsy YyBelum ada peringkat

- Food MicrobiologyDokumen51 halamanFood MicrobiologyAbBelum ada peringkat

- Food and Beverage BiotechnologyDokumen10 halamanFood and Beverage BiotechnologyHayderBelum ada peringkat

- Class 12 Chemistry ProjectDokumen20 halamanClass 12 Chemistry ProjectSupriyaa HejibBelum ada peringkat

- Dairy Products Manufactured With The Aid of MicroorganismsDokumen4 halamanDairy Products Manufactured With The Aid of MicroorganismsVincent KasimbaBelum ada peringkat

- Comparative Study of Rate of Fermentation of Following Material,..Dokumen11 halamanComparative Study of Rate of Fermentation of Following Material,..Aditya Soni25% (12)

- Yeast Production - General DiscussionDokumen8 halamanYeast Production - General DiscussionDonesh VarshneyBelum ada peringkat

- Wa0052.Dokumen20 halamanWa0052.Riya SharmaBelum ada peringkat

- Fermented Milk Products - Cheese by R. K. KuhiteDokumen100 halamanFermented Milk Products - Cheese by R. K. KuhiteRakeshkuhiteBelum ada peringkat

- Acid Alcohol Fermented Dairy ProductsDokumen10 halamanAcid Alcohol Fermented Dairy ProductsRohit PandeyBelum ada peringkat

- Bioessay 1Dokumen3 halamanBioessay 1Nor AmiliaBelum ada peringkat

- PUBLIKASIDokumen23 halamanPUBLIKASIFadi YansyahBelum ada peringkat

- Food Biotechnology Sub Topic: Processing Fermentation TechnologyDokumen2 halamanFood Biotechnology Sub Topic: Processing Fermentation TechnologyNorsyekii Chea-QirRaBelum ada peringkat

- Cheese Technology - 1: Ankara University, Faculty of Veterinary Medicine Department of Food Hygiene and TechnologyDokumen34 halamanCheese Technology - 1: Ankara University, Faculty of Veterinary Medicine Department of Food Hygiene and Technologycrescent moonBelum ada peringkat

- Baking Update: Bakers Yeast Production and CharacteristicsDokumen2 halamanBaking Update: Bakers Yeast Production and CharacteristicsCheu Hann JongBelum ada peringkat

- How A Landfill Works: Gas Utilization PlantDokumen1 halamanHow A Landfill Works: Gas Utilization PlantCheu Hann JongBelum ada peringkat

- What HappensDokumen2 halamanWhat HappensCheu Hann JongBelum ada peringkat

- Baking Update: Bakers Yeast Production and CharacteristicsDokumen2 halamanBaking Update: Bakers Yeast Production and CharacteristicsCheu Hann JongBelum ada peringkat

- Starch-Based Plastics: Olivier Vilpoux & Luc AverousDokumen0 halamanStarch-Based Plastics: Olivier Vilpoux & Luc AverousCheu Hann Jong0% (1)

- Zhao Xueheng 200408 PHDDokumen127 halamanZhao Xueheng 200408 PHDCheu Hann JongBelum ada peringkat

- Swot of AirasiaDokumen13 halamanSwot of AirasiaShirley LinBelum ada peringkat

- AntibicDokumen95 halamanAntibicJameston BostreBelum ada peringkat

- AntibicDokumen95 halamanAntibicJameston BostreBelum ada peringkat

- Zhao Xueheng 200408 PHDDokumen127 halamanZhao Xueheng 200408 PHDCheu Hann JongBelum ada peringkat

- Work SafetyDokumen18 halamanWork SafetyCheu Hann Jong100% (1)

- E CDokumen8 halamanE CCheu Hann JongBelum ada peringkat

- Screening, Isolation and Biochemical Characterization of Novel Lipase Producing Bacteria From Soil SamplesDokumen5 halamanScreening, Isolation and Biochemical Characterization of Novel Lipase Producing Bacteria From Soil SamplesTri Astuti Hanna PBelum ada peringkat

- The Colours of Complex Metal IonsDokumen27 halamanThe Colours of Complex Metal IonsCheu Hann Jong100% (2)

- Acid-Base Def & StrengthsDokumen12 halamanAcid-Base Def & StrengthsCheu Hann JongBelum ada peringkat

- Acid-Base Def & StrengthsDokumen12 halamanAcid-Base Def & StrengthsCheu Hann JongBelum ada peringkat