Bolt Mike III

Diunggah oleh

vrapciudorianDeskripsi Asli:

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Bolt Mike III

Diunggah oleh

vrapciudorianHak Cipta:

Format Tersedia

BOLT TENSION MEASUREMENT

BOLTMIKE III

The StressTel BoltMike III ultrasonically measures tension and clamp load of threaded fasteners. A large, bright, easy-to-read display; rapid calibration and setup; and automatic temperature compensation ensure fast, repeatable, and accurate fastener tension measurements in many diverse applications. Aerospace - Control tightening of bolted engine joints and aircraft wheel assemblies. Automotive - Confirm tension of installed engine headbolts, connecting rod bolts, and main bearing bolts PLUS monitor torque and tensioning tools. Injection Molding Machines - Measure elongation on tiebars and tierods. Power Generation - Verify tension on manway studs and confirm uniform loading of gasketed flange bolts.

Oil/Petrochemical - Measure tension in leg fasteners of offshore platforms, confirm uniform loading of gasketed flange bolts in pipelines, and verify tension of vessel, reactor, and heat exchanger bolts.

Critical fastener and bolting applications require easy, repeatable, and accurate tension measurements. Verify your loads with the BoltMike III. View our products and specifications at http://www.stresstel.com

BOLTMIKE III SPECIFICATIONS

The StressTel BoltMike III ultrasonically measures tension and clamp load of threaded fasteners. A large, bright, easytoread display; rapid calibration and set up; and automatic temperature compensation ensure fast, repeatable, and accurate fastener tension measurements. Key BoltMike III features include: Simultaneous display of fastener

load, stress, and elongation. Long 40 hour life with five standard AA alkaline batteries. High resolution 1/4 VGA LCD display to verify signal and optimize probe placement. LARGE DIGIT and bargraph display with limits for fast testing. Automatic temperature compensation. Builtin probe zero block allows easy exchange of transducers. Regression analysis for custom material calibration. WINDOWS software to download measurements, create reports, and upload test parameters. Direct to printer reports.

ULTRASONIC MEASUREMENT OF FASTENER LOAD

An ultrasonic pulse, generated in the transducer, is transmitted into the fastener. The pulse travels down the length of the fastener and is reflected back from the end. The BoltMike III measures the total pulse transit time.

Fastener Length=(total pulse transit time / 2) X (material constants) Fastener Elongation=(fastener length AFTER tensioning)(fastener length BEFORE tensioning) Fastener Load=(fastener elongation) X (geometric and material constants)

PHYSICAL DESCRIPTION

Width: 7.5 in (191 mm) Height: 5.5 in (140 mm) Depth: 2.2 in (56 mm) Weight: 2.5 lbs (1.14 kg) with batteries Shock resistant plastic case Weather resistant key pad

TEST SPECIFICATIONS

Measurable Fastener Length: 0.75 to 250 in/19 to 6350 mm Fastener and Test Memory: 10,000 fasteners in 512 groups Measurement Modes: Initial to first pulse; multiple echo for short fasteners Units: Load, stress, and elongation in English and Metric units Stored material constants: 12 common fastener materials

DISPLAY

Graphic Waveform LCD: 1/4 VGA Viewing Area (w x h): 3.8 x 2.8 in/ 96 x 71 mm Pixel Density (w x h): 320 x 240 Update Rate: 4 Hz Adjustable contrast and backlight Four level ZOOM for signal enlargement

POWER SUPPLY

5 AA Alkaline or NiCad batteries Interchangeable and easytoaccess Operating time: 40 hours w/o backlight A.C. Power (85 to 260 volt)

StressTel offers a complete range of transducers for fastener tension measurement.

Temp Sensor Connector Test Temperature Transducer Connector Measurement Value (load, stress, or elong) 5. Coupling Indicator 6. Battery Life Indicator 7. Alarm LED 8. Measurement Window 9. RS-232 Connector 10. A.C. Power Connector 11. Measurement Signal 12. GROUP CAL for Custom Material Calibration 13. GAIN Adjustment 14. Zero for Probe Exchange 15. ZOOM Indicator 16. BOLT Increment Keys 17. Navigation Keys 18. Stability Indicator 19. Auto Gain Adjustment 1. 2. 3. 4.

SOFTWARE

STRESSWARE (WINDOWS 95/98/ ME/NT/2000) to download measurements, create reports, and upload test parameters.

OPERATING TEMPERATURE

+10 to +120 F/-10 to + 50 C

WARRANTY

The BoltMike III and StressTel fastener transducers are manufactured in a facility with processes conforming to ISO 9001. All BoltMike IIIs have a full twoyear warranty on parts and labor excluding batteries, transducers, and cables.

Specifications subject to change without notice

Visit our website at http://www.stresstel.com

BoltMike III 06/0110K

2790 West College Avenue, State College, PA 16801-2605 PH: (814) 861-6300 FAX: (814) 861-6330 www.stresstel.com

Anda mungkin juga menyukai

- GE Bolt Mike III User Manual2016051922133 PDFDokumen2 halamanGE Bolt Mike III User Manual2016051922133 PDFBrenno GonçalvesBelum ada peringkat

- M23-9 12Dokumen8 halamanM23-9 12OLuizaBelum ada peringkat

- Online Electronic Instruments ManufacturersDokumen8 halamanOnline Electronic Instruments ManufacturersAnalysis Tech IncBelum ada peringkat

- MFI-9 Specification SheetDokumen3 halamanMFI-9 Specification SheetAkhilesh KumarBelum ada peringkat

- Testing ToolsDokumen5 halamanTesting ToolsbhpBelum ada peringkat

- Turbine Supervisory InstrumentsationDokumen52 halamanTurbine Supervisory InstrumentsationKarthi KeyanBelum ada peringkat

- Turbine Supervisory Instrumentation Selection Guide - RockwellDokumen52 halamanTurbine Supervisory Instrumentation Selection Guide - Rockwellhozipek100% (1)

- OMICRON CPC100 Primary Test System SpecificationDokumen28 halamanOMICRON CPC100 Primary Test System SpecificationEerumaiBelum ada peringkat

- Bolt Mike IIIDokumen1 halamanBolt Mike IIIMarco Antonio MoncerrateBelum ada peringkat

- Brookfield Process CatalogDokumen24 halamanBrookfield Process CatalogenzopandolfiBelum ada peringkat

- Ceiling Fan Laboratory Guidance ManualDokumen35 halamanCeiling Fan Laboratory Guidance ManualSsdssddBelum ada peringkat

- Company Profile PT. Inako PersadaDokumen22 halamanCompany Profile PT. Inako PersadaTiar_Rahman_9553Belum ada peringkat

- Product Specification CT800 T4 38B 1Dokumen4 halamanProduct Specification CT800 T4 38B 1PeterBelum ada peringkat

- Winding Temperature IndicatorDokumen9 halamanWinding Temperature IndicatorTruong Van Quang100% (2)

- Charged Plate Analyzer Model 268A: Make Sure Antistatic Devices Are WorkingDokumen2 halamanCharged Plate Analyzer Model 268A: Make Sure Antistatic Devices Are Workingashwin jacksonBelum ada peringkat

- Echometer Digital Well AnalyzerDokumen5 halamanEchometer Digital Well AnalyzerEliyanto E BudiartoBelum ada peringkat

- CVT Turns Ratio TesterDokumen4 halamanCVT Turns Ratio Testerjoydeep_d3232100% (1)

- 57 58 1 PDFDokumen9 halaman57 58 1 PDFHaikalBelum ada peringkat

- Omicron CP Line CatalogueDokumen32 halamanOmicron CP Line CatalogueShirosh AyeshmanthaBelum ada peringkat

- Daniel Compact Prover: ProversDokumen12 halamanDaniel Compact Prover: ProversCarlos EduardoBelum ada peringkat

- Compact Prover Datasheet PDFDokumen12 halamanCompact Prover Datasheet PDFMary Soledad Huarcaya EspinoBelum ada peringkat

- CPC100 PDFDokumen32 halamanCPC100 PDFDaniel RizzoBelum ada peringkat

- COF-1000 v11Dokumen14 halamanCOF-1000 v11Sarah LinvilleBelum ada peringkat

- DCRM Meggertm1800Dokumen14 halamanDCRM Meggertm1800parmindra2011Belum ada peringkat

- Universal Testing MachineDokumen4 halamanUniversal Testing MachineTomy GeorgeBelum ada peringkat

- UTM Regular CatalogueDokumen12 halamanUTM Regular CatalogueEr Hemant Kumar SahBelum ada peringkat

- Training Ppt16Dokumen28 halamanTraining Ppt16Kirti BhumbeeBelum ada peringkat

- Cortest Proof Ring Information 021716Dokumen5 halamanCortest Proof Ring Information 021716Jose HallenBelum ada peringkat

- 09 Vacuum MeasurementDokumen44 halaman09 Vacuum MeasurementRamakrisnna GunasegaranBelum ada peringkat

- Testing Equipment Manual PDFDokumen114 halamanTesting Equipment Manual PDFSelva MaharajanBelum ada peringkat

- Transformer A To Z Testing-Ready CatalogueDokumen169 halamanTransformer A To Z Testing-Ready CatalogueUna LakBelum ada peringkat

- XFC EspecificacionsDokumen19 halamanXFC Especificacionsadesa2013Belum ada peringkat

- V2KDokumen2 halamanV2KLindgrenBelum ada peringkat

- Flowserve Butterfly ValveDokumen8 halamanFlowserve Butterfly ValveDGWBelum ada peringkat

- EchometerWA 2008Dokumen4 halamanEchometerWA 2008danny1977Belum ada peringkat

- Module 3Dokumen219 halamanModule 3Sourav PoddarBelum ada peringkat

- Extracto ISO 10816Dokumen10 halamanExtracto ISO 10816clroyo9475Belum ada peringkat

- Testing KitDokumen15 halamanTesting KitmonikaBelum ada peringkat

- Deflection Temperature and Vicat Testers: Bulletin 138Dokumen4 halamanDeflection Temperature and Vicat Testers: Bulletin 138Marcelo SánchezBelum ada peringkat

- Equotip Piccolo Portable Hardness TesterDokumen4 halamanEquotip Piccolo Portable Hardness Testersolrac4371Belum ada peringkat

- 6768 D12R D6R D3R Digital Winding TesterDokumen4 halaman6768 D12R D6R D3R Digital Winding Testermoises_romero_12100% (1)

- IececDokumen11 halamanIececHeather HarrisBelum ada peringkat

- B140DDokumen8 halamanB140DMarcelo SánchezBelum ada peringkat

- Siemens SENTRON PAC3200Dokumen17 halamanSiemens SENTRON PAC3200Hüseyin KelkitBelum ada peringkat

- Hamdon Echometer Model E Well Analyzer BrochureDokumen4 halamanHamdon Echometer Model E Well Analyzer BrochurearispriyatmonoBelum ada peringkat

- The Parametric Measurement - KeysightDokumen6 halamanThe Parametric Measurement - KeysightAndré Kiefer FolladorBelum ada peringkat

- Conventional Meter ProverDokumen6 halamanConventional Meter Proverjivajive50% (2)

- Subsea Sensor BrochureDokumen16 halamanSubsea Sensor Brochurealkhwarizmi1968100% (1)

- Approaches On Reliability Estimation - Kiia DizonDokumen6 halamanApproaches On Reliability Estimation - Kiia DizonkiiadizonBelum ada peringkat

- 9816 RKDokumen8 halaman9816 RKtolomeo10Belum ada peringkat

- Posi Test atDokumen5 halamanPosi Test atsudhir5441Belum ada peringkat

- Adts 505Dokumen6 halamanAdts 505mrchoubeyBelum ada peringkat

- c221 E3490d Uh SeriesDokumen20 halamanc221 E3490d Uh SeriesKokYee Chan100% (1)

- Probador PuntialPLT-100Dokumen4 halamanProbador PuntialPLT-100Antonio RamosBelum ada peringkat

- HALT, HASS, and HASA Explained: Accelerated Reliability Techniques, Revised EditionDari EverandHALT, HASS, and HASA Explained: Accelerated Reliability Techniques, Revised EditionBelum ada peringkat

- Process Control for Sheet-Metal Stamping: Process Modeling, Controller Design and Shop-Floor ImplementationDari EverandProcess Control for Sheet-Metal Stamping: Process Modeling, Controller Design and Shop-Floor ImplementationBelum ada peringkat

- Vibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisDari EverandVibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisPenilaian: 4 dari 5 bintang4/5 (2)

- Thickm W Us NKSVDokumen27 halamanThickm W Us NKSVvrapciudorianBelum ada peringkat

- Management AccountingDokumen37 halamanManagement AccountingvrapciudorianBelum ada peringkat

- GEIT 20058EN USMVision BrochureDokumen2 halamanGEIT 20058EN USMVision BrochurevrapciudorianBelum ada peringkat

- Characterization of Reflectors by Ultrasonic MethodsDokumen10 halamanCharacterization of Reflectors by Ultrasonic MethodsvrapciudorianBelum ada peringkat

- Usm 36 Operation ManualsDokumen306 halamanUsm 36 Operation ManualslenaronBelum ada peringkat

- Examples of Ultrasonic Applications For Nondestructive Testing of PlasticsDokumen6 halamanExamples of Ultrasonic Applications For Nondestructive Testing of PlasticsvrapciudorianBelum ada peringkat

- Mobile Hardness Tester Application GuideDokumen24 halamanMobile Hardness Tester Application Guidem_armoutiBelum ada peringkat

- Selenium 75, Ir 192 and X-RaysDokumen5 halamanSelenium 75, Ir 192 and X-RaysLei LaniBelum ada peringkat

- R Ovver ManualDokumen54 halamanR Ovver ManualvrapciudorianBelum ada peringkat

- Conversion FBH To SDHDokumen10 halamanConversion FBH To SDHvrapciudorianBelum ada peringkat

- Oil&Gas Apps CasesDokumen3 halamanOil&Gas Apps CasesvrapciudorianBelum ada peringkat

- GEIT - ToFD UltrasonicsDokumen51 halamanGEIT - ToFD Ultrasonicsvrapciudorian100% (1)

- Damage Evaluation and NDT: Linhas Aéreas InteligentesDokumen38 halamanDamage Evaluation and NDT: Linhas Aéreas InteligentesChristian OliveiraBelum ada peringkat

- The Ultrasonic Testing of The Spot Welded Different Steel SheetsDokumen4 halamanThe Ultrasonic Testing of The Spot Welded Different Steel SheetsAli IbnBelum ada peringkat

- Digital Solutions For Pipe Testing - BeyerDokumen15 halamanDigital Solutions For Pipe Testing - BeyervrapciudorianBelum ada peringkat

- Visual Perception of Spatial SubjectsDokumen8 halamanVisual Perception of Spatial SubjectsvrapciudorianBelum ada peringkat

- GEIT 65015EN MeasurementDokumen4 halamanGEIT 65015EN MeasurementccoyureBelum ada peringkat

- Geit-40058en Crxvision enDokumen5 halamanGeit-40058en Crxvision envrapciudorianBelum ada peringkat

- US Neutron BackscatterDokumen2 halamanUS Neutron BackscattervrapciudorianBelum ada peringkat

- Apollo Software IntroductionDokumen8 halamanApollo Software IntroductionAnonymous gFcnQ4goBelum ada peringkat

- Manual Apollo AnalysisDokumen114 halamanManual Apollo AnalysisvrapciudorianBelum ada peringkat

- The X-Ray Inspection Booklet v7Dokumen86 halamanThe X-Ray Inspection Booklet v7vrapciudorian100% (1)

- GEIT-20120EN TrueDGS Probes DatasheetDokumen4 halamanGEIT-20120EN TrueDGS Probes DatasheetvrapciudorianBelum ada peringkat

- Battery CapDokumen9 halamanBattery CapvrapciudorianBelum ada peringkat

- Brochure Palm Scanner Single Page 2710Dokumen4 halamanBrochure Palm Scanner Single Page 2710vrapciudorianBelum ada peringkat

- Phasor XS Flange Face PaperDokumen32 halamanPhasor XS Flange Face PapervrapciudorianBelum ada peringkat

- API UT-10 TofdDokumen24 halamanAPI UT-10 TofdvrapciudorianBelum ada peringkat

- Miller TIG HandbookDokumen20 halamanMiller TIG Handbookquiron2010Belum ada peringkat

- Defectoscopie Nedistructiva IndustrialaDokumen514 halamanDefectoscopie Nedistructiva IndustrialaStefan Razvan100% (3)

- Practical MetallographyDokumen23 halamanPractical MetallographyvrapciudorianBelum ada peringkat

- Rate Book - 2011-NCP Building DPTDokumen244 halamanRate Book - 2011-NCP Building DPTthak_raj84Belum ada peringkat

- Kitchen: Library Study MM School of ArchitectureDokumen1 halamanKitchen: Library Study MM School of ArchitectureAteeq RaoBelum ada peringkat

- 09 Counter CellDokumen3 halaman09 Counter CellTana AzeezBelum ada peringkat

- Electronics Y2 PDFDokumen237 halamanElectronics Y2 PDFNebuchadnezzar Buggy Andamon SaysonBelum ada peringkat

- Changing The Pump Seals: (All Pumps Except The G1361A Preparative Pump)Dokumen2 halamanChanging The Pump Seals: (All Pumps Except The G1361A Preparative Pump)sarasaBelum ada peringkat

- High Density Polyethylene - HDPE - Pipe and FittingsDokumen8 halamanHigh Density Polyethylene - HDPE - Pipe and Fittingsnilesh_erusBelum ada peringkat

- API 571 Damage Mechanisms Affecting Fixed Equipment in The Refining Industry PDFDokumen5 halamanAPI 571 Damage Mechanisms Affecting Fixed Equipment in The Refining Industry PDFOrlando19490% (1)

- K-Tron Premier Rep Catalog Dec 2010 PDFDokumen429 halamanK-Tron Premier Rep Catalog Dec 2010 PDFGerardo González33% (3)

- Partition ManualDokumen42 halamanPartition ManualAnonymous SblBDN0Belum ada peringkat

- Supercharging and TurbochargingDokumen23 halamanSupercharging and TurbochargingTrain Placement CellBelum ada peringkat

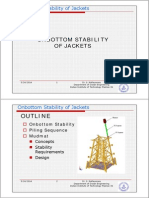

- On Bottom StabilityDokumen25 halamanOn Bottom StabilityhariharanoilgasBelum ada peringkat

- MasterGlenium SKY 8233 v1 PDFDokumen3 halamanMasterGlenium SKY 8233 v1 PDFJaga NathBelum ada peringkat

- E831BDokumen4 halamanE831BDenis JimenezBelum ada peringkat

- List of Activity For HIRA Prep As Per ISO45001Dokumen6 halamanList of Activity For HIRA Prep As Per ISO45001Mohammad ArifBelum ada peringkat

- Product Life Cycle and LifeDokumen3 halamanProduct Life Cycle and LifejoelBelum ada peringkat

- CQ2 New Series PDFDokumen210 halamanCQ2 New Series PDFsumit_waghmareBelum ada peringkat

- ISO 1459 Hots Dip GalvanizingDokumen4 halamanISO 1459 Hots Dip GalvanizingLe Van TamBelum ada peringkat

- Substation Equipment Failure Report October 14 To August 15Dokumen95 halamanSubstation Equipment Failure Report October 14 To August 15Yogendra SwarnkarBelum ada peringkat

- Advanced Planning and SchedulingDokumen7 halamanAdvanced Planning and Schedulingsheebakbs5144100% (1)

- Ansi CodesDokumen3 halamanAnsi CodesMunavwar ProfessBelum ada peringkat

- Base Panther 6x6 Stinger SpecificationDokumen61 halamanBase Panther 6x6 Stinger Specificationфранки штэинBelum ada peringkat

- OrthogonalDokumen4 halamanOrthogonalGuan Ni YeoBelum ada peringkat

- Types of Steam FlowmeterDokumen20 halamanTypes of Steam FlowmeterLidijaSpaseskaBelum ada peringkat

- MBX - Amoladora Quita OxidoDokumen6 halamanMBX - Amoladora Quita OxidoomarBelum ada peringkat

- Front Air Conditioner (2TR-FE, 2KD-FTV) : 268 HIACE (EWD622E)Dokumen10 halamanFront Air Conditioner (2TR-FE, 2KD-FTV) : 268 HIACE (EWD622E)DanielBelum ada peringkat

- Camapana de Humo Sin DuctosDokumen4 halamanCamapana de Humo Sin DuctosBRIAN JULIAN GARCIA ALFONSOBelum ada peringkat

- Pile ReportDokumen14 halamanPile ReportChen E LikBelum ada peringkat

- Seamless VS Welded TubesDokumen1 halamanSeamless VS Welded Tubeshirenkumar patelBelum ada peringkat

- Plastic CollapseDokumen10 halamanPlastic CollapseVijaya Kumar Manikandan100% (1)

- Boge Up To 300kw - PDFDokumen12 halamanBoge Up To 300kw - PDFparsmessengerBelum ada peringkat