Road Recycling 11

Diunggah oleh

Marshall BravestarHak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Road Recycling 11

Diunggah oleh

Marshall BravestarHak Cipta:

Format Tersedia

This digest is one of a series produced by the Aggregates Advisory Service to provide information on aggregates efficiency issues.

The aim of this service, funded by the Department of the Environment, Transport and the Regions, is to assist the Government to achieve its objective of reducing the construction industrys dependence on landwon primary aggregates and increasing the contribution from secondary and recycled materials. Further information on aggregates efficiency issues, whether relating to primary, secondary or recycled materials, can be obtained from the Aggregates Advisory Service on Freephone no. 0800 374 279 or visit the website at http://www.planning.detr.gov.uk/aas/index.htm.

ROAD RECYCLING Ex-situ Road Recycling Why Recycle a Road?

This digest briefly describes one of the methods of road recycling. This digest covers ex-situ recycling. Digest 056 covers in-situ recycling. Two example projects are included. Road reconstruction conventionally consists of the excavation of existing material and its replacement by new. This process results in the requirement for significant quantities of new materials usually from primary sources. dispose Contact Details Walsall Example Address: Roadstone Recycling Ltd Gatherley Road Industrial Estate Brompton on Swale Richmond North Yorkshire DL10 7JQ Telephone: Fax: Contact: A52 Example Address: Staffordshire County Council Development Services Department Highways Northern Area Office Ladder Edge Leek Staffordshire ST13 7AB Telephone: Contact: 01538 483012 Mr P Pytlik Ex-situ recycling consists of the excavation and removal of existing road construction material to a stockpile. From here it is processed by grading and mixing with appropriate binders prior to being recompacted to form a road. 01748 811232 01748 812005 Mr G Cook The recycling of existing materials can result in both cost savings and reduced environmental impacts. of the It is coupled with the need to existing material the and the

environmental

impacts

from

associated

transport operation.

Ex-situ Road Recycling

Recycling can be undertaken either in-situ or exsitu. This digest relates to ex-situ recycling.

In-situ recycling is covered in Digest 056.

Department of the Environment, Transport and the Regions Research Contract MP0623 Symonds

Digest no. 060 (2:1/99)

Ex-situ recycling has the following characteristics: The recycling plant is easily transported and can be established on site in a few hours The plant is smokeless, odourless and is quiet in operation Recycling plant can be located in surroundings appropriate to the nature of the operation where environmental impacts can be mitigated Environmental impacts at the reconstruction site are reduced A wide range of materials can be processed including road planings, crushed concrete and masonry The materials can be crushed and screened to fit a predetermined grading envelope, before being mixed with a binder All materials are processed in a controllable environment resulting in the production of a quality controlled product The graded material can be stockpiled for the later incorporation of a binder Bound material, if correctly stored, can be used for up to four weeks after production The excavation of the road and its replacement can be undertaken using conventional plant and equipment

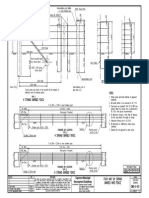

The roads consisted typically of 60-80mm of asphalt covering an unbound stone base consisting of well graded granular slag. Locally concrete was also present within the base materials.

Planing operation to remove existing road surface

Example Project: Estate Roads in Walsall

In a recent operation, Roadstone Recycling Ltd (a joint venture company formed by a partnership between Tarmac and Bruce Cook Road Planing) reconstructed sections of estate roads in central Walsall.

Excavation of existing material in preparation for resurfacing

Department of the Environment, Transport and the Regions Research Contract MP0623 Symonds

Digest no. 060 (2:1/99)

The recycling process incorporated a Foamix binder. Foamix has been widely used for a number of years in Canada and has been particularly successful in areas where indigenous aggregates are of poor quality. The binder was added at approximately 2.2% by weight and the moisture content was adjusted to achieve adequate in-situ density figures. The in-situ density was determined using a nuclear density meter.

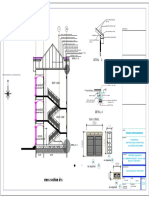

Example Project: A52, Staffordshire

In the summer of 1997, a 0.9km stretch of the A52, which is a heavily trafficked trunk road, was reconstructed using ex-situ recycling techniques.

In this instance, the existing road was planed out to full depth and stockpiled. The resulting material was then graded and, where necessary, crushed to provide material of suitable particle sizes. This was then mixed with 3% lime and 12% pulverised fly ash (PFA). The mixture was recompacted in two 150mm layers as subbase and base course. was topped with new wearing course. It

Where

necessary, small quantities of primary aggregates were brought in to make up volumes. It is believed that this is the first project where a lime/PFA binder has been used in conjunction with recycling of existing road materials. Paving using Foamix macadam

Further Potential

These examples illustrate how recycling techniques can compete successfully with conventional road construction methods.

The grading of the feedstock material was checked on a daily basis. This was undertaken by

thoroughly mixing the stock material prior to wash grading it through a series of sieves. Density checks were undertaken each day and cores were cured and subsequently tested in a laboratory.

The

ex-situ

approach

provides

consistent

construction material and eliminates some of the variables which could occur with direct in-situ

In isolated areas of the site, soft clay was found to exist below the road base level. As this method of repaving is equally as liable to settlement as any other, a number of soft spots were excavated and backfilled with granular material reinforced with a geotextile.

recycling and allows more engineering control during the construction operation. It is anticipated that the performance monitoring can thus be more objective.

An increased use of recycling techniques such as these would reduce demand for primary aggregate,

A wearing course consisting of Masterpave (a Tarmac product) was used as a surfacing layer.

assisting the Government to achieve its aim of sustainable development.

Department of the Environment, Transport and the Regions Research Contract MP0623 Symonds

Digest no. 060 (2:1/99)

Anda mungkin juga menyukai

- Ltu Ex 07239 SeDokumen97 halamanLtu Ex 07239 SeMarshall BravestarBelum ada peringkat

- Engtech, Ieng and Ceng: Uk Standard For Professional Engineering CompetenceDokumen32 halamanEngtech, Ieng and Ceng: Uk Standard For Professional Engineering CompetenceMuhammad ArshadBelum ada peringkat

- CMDG General AllDokumen9 halamanCMDG General AllMarshall BravestarBelum ada peringkat

- 2 Design of Reinforce Concrete BeamsDokumen60 halaman2 Design of Reinforce Concrete BeamsTshepiso NthiteBelum ada peringkat

- Foreword The Need For Land EvaluationDokumen74 halamanForeword The Need For Land EvaluationMarshall BravestarBelum ada peringkat

- 5 Tests That Could Save Your Life: 30 Worst Foods in AmericaDokumen2 halaman5 Tests That Could Save Your Life: 30 Worst Foods in AmericaMarshall BravestarBelum ada peringkat

- BestPracticeGuide4 Issue3 ElectricalDokumen20 halamanBestPracticeGuide4 Issue3 ElectricalMarshall BravestarBelum ada peringkat

- 1foundationsDokumen10 halaman1foundationsMarshall BravestarBelum ada peringkat

- Train Like You Mean It: The Ultimate Performance TreadmillDokumen2 halamanTrain Like You Mean It: The Ultimate Performance TreadmillMarshall BravestarBelum ada peringkat

- Cork Expansion Joint Filler SheetDokumen2 halamanCork Expansion Joint Filler SheetMarshall BravestarBelum ada peringkat

- Diesel Be Stupid CatalogueDokumen15 halamanDiesel Be Stupid CatalogueSaberAYarBelum ada peringkat

- 04 MomentDistribution PDFDokumen88 halaman04 MomentDistribution PDFSimran Radheshyam SoniBelum ada peringkat

- Structural Engineers: The Institution ofDokumen4 halamanStructural Engineers: The Institution ofMarshall BravestarBelum ada peringkat

- Evolution Magazine May 2010Dokumen20 halamanEvolution Magazine May 2010Marshall BravestarBelum ada peringkat

- The Essential Guide To Eurocodes Transition Part-1Dokumen33 halamanThe Essential Guide To Eurocodes Transition Part-1limegreens100% (4)

- STDokumen22 halamanSTMarshall BravestarBelum ada peringkat

- NMTPFDokumen19 halamanNMTPFMarshall BravestarBelum ada peringkat

- Digester FrontDokumen1 halamanDigester FrontMarshall BravestarBelum ada peringkat

- DocDokumen20 halamanDocMarshall BravestarBelum ada peringkat

- Portal FramesDokumen31 halamanPortal FramesMarshall BravestarBelum ada peringkat

- ReadmeDokumen2 halamanReadmeMarshall BravestarBelum ada peringkat

- Welcome To TrinidadRealtor - ComkkDokumen1 halamanWelcome To TrinidadRealtor - ComkkMarshall BravestarBelum ada peringkat

- Institution of Structural Engineers Exam GuideDokumen1 halamanInstitution of Structural Engineers Exam GuideMarshall BravestarBelum ada peringkat

- STDokumen2 halamanSTMarshall BravestarBelum ada peringkat

- Structural Engineers: The Institution ofDokumen2 halamanStructural Engineers: The Institution ofMarshall BravestarBelum ada peringkat

- STDokumen6 halamanSTMarshall BravestarBelum ada peringkat

- Institution of Structural Engineers Exam GuideDokumen1 halamanInstitution of Structural Engineers Exam GuideMarshall BravestarBelum ada peringkat

- STDokumen3 halamanSTMarshall BravestarBelum ada peringkat

- STDokumen12 halamanSTMarshall BravestarBelum ada peringkat

- STDokumen11 halamanSTMarshall BravestarBelum ada peringkat

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5784)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (119)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- ITP For BLOCKWORKDokumen4 halamanITP For BLOCKWORKimkashifsaleemBelum ada peringkat

- Cross Section D-S: Verandah Stair CaseDokumen1 halamanCross Section D-S: Verandah Stair CaseNoble Obeng-AnkamahBelum ada peringkat

- Re Cource Guide 2018Dokumen44 halamanRe Cource Guide 2018Maria PopaBelum ada peringkat

- Prefabricated Asphalt Reservoir, Pond, Canal, and Ditch Liner (Exposed Type)Dokumen3 halamanPrefabricated Asphalt Reservoir, Pond, Canal, and Ditch Liner (Exposed Type)Edmundo Jaita CuellarBelum ada peringkat

- Carpentry 9 Summative TestDokumen9 halamanCarpentry 9 Summative TestJymaer GeromoBelum ada peringkat

- Nudra Villa-Weekly Progress Presentation 11-July-2022Dokumen20 halamanNudra Villa-Weekly Progress Presentation 11-July-2022laraibBelum ada peringkat

- Ns2-Xb02-p0uyq-174247 - Vehicle Repair Shop - Structural Misc Detail - Rev.0Dokumen1 halamanNs2-Xb02-p0uyq-174247 - Vehicle Repair Shop - Structural Misc Detail - Rev.0Doan Ngoc DucBelum ada peringkat

- The National Building Code 2022Dokumen343 halamanThe National Building Code 2022aggrey noahBelum ada peringkat

- Rock Bolt SpecisDokumen1 halamanRock Bolt SpecisZain AbidiBelum ada peringkat

- Arch-Structure-Final-Assessment-Trios-Model 1Dokumen10 halamanArch-Structure-Final-Assessment-Trios-Model 1joyce gayaniloBelum ada peringkat

- Craftsman ManualDokumen28 halamanCraftsman ManualAlex Perez100% (1)

- PreviewpdfDokumen17 halamanPreviewpdfSammy ChanBelum ada peringkat

- Astm F406-08Dokumen22 halamanAstm F406-08Nguyen JamesBelum ada peringkat

- Structural Conceptualization (Pre Board)Dokumen10 halamanStructural Conceptualization (Pre Board)Mavie PerieBelum ada peringkat

- LTC 003-2021 Deauville Beach Resort, 6701 Collins Avenue-UpdateDokumen130 halamanLTC 003-2021 Deauville Beach Resort, 6701 Collins Avenue-Updatethe next miami100% (3)

- Lab 6 Ceramics and GlassDokumen7 halamanLab 6 Ceramics and GlassJawad AhmadBelum ada peringkat

- Technical Specifications: Bullet-ProofDokumen4 halamanTechnical Specifications: Bullet-ProofncakraBelum ada peringkat

- Internal PHE BOQ - R1Dokumen7 halamanInternal PHE BOQ - R1SajeshKumarBelum ada peringkat

- 2 Storey Commercial Building Technical SpecsDokumen8 halaman2 Storey Commercial Building Technical SpecsHarold Valen MagpayoBelum ada peringkat

- List of Building Materials: CatalogsDokumen4 halamanList of Building Materials: CatalogsChristine Marquez RamosBelum ada peringkat

- Carpentry RubricsDokumen2 halamanCarpentry RubricsJymaer GeromoBelum ada peringkat

- Checklist For Tiles FlooringDokumen2 halamanChecklist For Tiles FlooringKishoreBelum ada peringkat

- Ship Construction Sketches and NotesDokumen72 halamanShip Construction Sketches and NotesZainal Arifin100% (3)

- Arch 323 - Theory of StructureDokumen29 halamanArch 323 - Theory of StructureSam garcuaBelum ada peringkat

- CorralesDokumen4 halamanCorralesFrancis Ivan Marie AdelanBelum ada peringkat

- Partition WallsDokumen25 halamanPartition Wallssaransh yadavBelum ada peringkat

- Installation of Exterior Windows, Doors and Skylights: Standard Practice ForDokumen89 halamanInstallation of Exterior Windows, Doors and Skylights: Standard Practice ForJose Antonio FigueroaBelum ada peringkat

- Dispenser Island Civil BoqDokumen3 halamanDispenser Island Civil Boqjay_p_shahBelum ada peringkat

- Checklist Typical Items For Shop Drawing ReviewDokumen11 halamanChecklist Typical Items For Shop Drawing Reviewakram solimanBelum ada peringkat