Alumoweld Overhead Ground Wire

Diunggah oleh

terzaboyHak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Alumoweld Overhead Ground Wire

Diunggah oleh

terzaboyHak Cipta:

Format Tersedia

Wire Products

Alumoweld wire consists of a thick cladding of pure aluminum over a high-strength

steel core. Alumoweld wire offers the advantages of each metal. It is ideal for overhead

ground wire, neutral messengers, line wire and guy strand. Alumoweld wire and strand

is used by power utilities, as well as formed wire and optical ground wire manufacturers. Alumoweld outlasts other options by as much as 200% in corrosive environments,

significantly lowering maintenance and replacement costs. When compared to solid

aluminum wire, Alumoweld offers tremendous savings.

How is Alumoweld made?

Applications

Utility Market

Telecommunications Market

Military

General Industry Applications

The Alumoweld process consists of a continuous application of a pure atomized aluminum

powder to a high strength steel rod. Proper control of heat and pressure refines the cladding and develops a controlled atomic weld. The resulting bimetallic rod is then cold drawn

into finished wire sizes without changing original proportions of aluminum and steel.

Features

Thick Aluminum Covering

Alumoweld wire is produced with the concentric aluminum covering comprising 25% of

the cross-sectional area, with the aluminum thickness 10% minimum of the wire radius.

The high proportion of aluminum offers an excellent degree of electrical conductivity and

permanently protects the high strength steel core.

High Conductivity

Compared to solid aluminum wire of the same diameter, Alumoweld wire has a direct

current conductance of 33%. It has about three times the conductivity of galvanized

steel wire. For high frequency currents where skin effect is a factor, the conductivity

of Alumoweld wire approaches 100% of solid aluminum. When Alumoweld wires are

combined with aluminum wires in composite conductors, a wide range of strength and

conductivity characteristics is possible.

Corrosion Resistance

The thick aluminum cladding of Alumoweld wire provides a high degree of corrosion

resistance, resulting in longer service life and reduced maintenance. Accelerated laboratory tests exposing Alumoweld wire to various types of corrosive conditions have proven

that Alumoweld wires have corrosion resistance comparable to EC grade aluminum. The

conditions simulated in the test included industrial, marine and tropical.

Combines High Strength with Low Weight

Alumoweld wire has a higher strength-to-weight ratio than any other wire commonly

used on overhead lines. Size for size, it has about the same tensile strength as extra high

strength steel wire, but weighs less. It has eight times the strength of solid aluminum wire

of the same diameter and only a little more than twice the weight. This high strength-toweight ratio provides a maximum margin of safety for long-span construction. The strength

of Alumowelds steel core is protected by the thick aluminum covering.

www.AFLglobal.com or 800-866-7385

417

2003, AFL, all rights reserved. Revision 2, 12.10.12

Specifications are subject to change without notice.

A L U M O W E L D

Alumoweld Wire and Strand

Wire Products

Alumoweld Overhead Ground Wire

A L U M O W E L D

Alumoweld wire and strand is used by power utilities, as well as formed wire and optical

ground wire manufacturers. Alumoweld outlasts other options by as much as 200%

in corrosive environments, significantly lowering maintenance and replacement costs.

When compared to solid aluminum wire, Alumoweld offers tremendous savings.

Features

Corrosion Resistance

Alumoweld overhead ground wire has excellent corrosion resistance. Its strength and

conductivity remain unchanged in any atmosphere where aluminum is satisfactory, especially those known to be corrosive from industrial or atmospheric conditions.

Applications

Overhead ground wire

Shield wire protecting transmission lines

against lightning damage

This assurance against corrosion is obtained through the application of a thick covering

of pure aluminum, which provides a substantial barrier of protective metal. The minimum

cladding thickness of Alumoweld is 10% of the radius of the wire. The cladding has a

continuous, strong metallic bond to the steel core that will not crack or flake.

Strength Comparable to Steel

Alumoweld also provides strength greater than or comparable to other overhead ground

wires. For commonly used wire sizes, the tensile strength of the individual wire can

approach 200,000 pounds per square inch. When used in a strand for overhead ground

wire, this high strength permits greater span lengths, less sag, and heavier loads under

storm loading conditions.

Lightweight

Directly related to strength and sag performance is the lighter weight of Alumoweld.

Due to its thick cladding of aluminum, Alumoweld is 15% lighter than a steel strand of

equivalent size. This lighter weight, combined with high strength, permits Alumoweld

to be installed to the same sags as steel with correspondingly lower tensions and lower

stresses on the towers or supporting structures.

www.AFLglobal.com or 800-866-7385

418

2003, AFL, all rights reserved. Revision 2, 12.10.12

Specifications are subject to change without notice.

Wire Products

ALUMOWELD STRAND ASTM B-416

NUMBER &

NOMINAL

NOMINAL STRAND

SIZE OF

WIRE

DIAMETER

WIRES

DIAMETER

BREAKING

LOAD

CROSS SECTION

OHMS/1000

FT@68F

0.05356

0.06754

0.08516

0.10740

0.13540

0.08224

0.10370

0.13080

0.16490

0.20790

0.26220

0.22640

0.28030

0.35350

0.44580

0.56210

0.70880

0.89380

1.12700

0.51770

0.65280

0.82320

1.03800

1.30900

1.65100

OHMS/

KM@20C

0.1757

0.2216

0.2794

0.3523

0.4443

0.2698

0.3402

0.4290

0.5409

0.6821

0.8601

0.7426

0.9198

1.1600

1.4630

1.8440

2.3250

2.9320

3.6970

1.6990

2.1420

2.7010

3.4060

4.2940

5.4150

SQ IN

MM2

54,500

45,690

38,190

30,290

24,020

33,270

27,990

23,460

19,610

15,550

12,330

12,260

10,310

8,645

7,226

5,729

4,545

3,604

2,858

5,547

4,663

3,910

3,269

2,592

2,056

KG/

KM

3307.0

2623.0

2080.0

1649.0

1308.0

2129.0

1688.0

1339.0

1062.0

842.0

667.7

781.1

619.5

491.1

389.6

308.9

245.1

194.4

154.2

334.1

265.0

210.1

166.7

132.2

104.8

0.76264

0.60509

0.47984

0.38032

0.30174

0.49438

0.39163

0.31073

0.24641

0.19530

0.15495

0.18193

0.14435

0.11448

0.09077

0.07198

0.05708

0.04527

0.03590

0.07796

0.06185

0.04905

0.03890

0.03085

0.02446

492.20

390.30

309.50

245.50

194.70

318.70

252.70

200.40

158.90

126.10

99.96

117.40

93.10

73.87

58.56

46.44

36.83

29.21

23.16

50.32

39.90

31.65

25.10

19.90

15.78

2,305

1,946

1,637

1,372

1,147

909

721

572

454

93.63

74.25

58.88

46.69

37.03

29.37

23.29

18.47

14.65

139.3

110.5

87.6

69.5

55.1

43.7

34.7

27.5

21.8

1.222

1.541

1.943

2.450

3.089

3.896

4.912

6.194

7.811

4.009

5.056

6.375

8.038

10.130

12.780

16.120

20.320

25.630

0.03278

0.02599

0.02062

0.01635

0.01297

0.01028

0.00816

0.00647

0.00513

21.15

16.77

13.30

10.55

8.37

6.63

5.26

4.17

3.31

IN

MM

IN

MM

LB

KG

37 No. 6

37 No. 7

37 No. 8

37 No. 9

37 No.10

19 No. 5

19 No. 6

19 No. 7

19 No. 8

19 No. 9

19 No.10

7 No. 5

7 No. 6

7 No. 7

7 No. 8

7 No. 9

7 No.10

7 No.11

7 No.12

3 No. 5

3 No. 6

3 No. 7

3 No. 8

3 No. 9

3 No.10

0.1620

0.1443

0.1285

0.1144

0.1019

0.1819

0.1620

0.1443

0.1285

0.1144

0.1019

0.1819

0.1620

0.1443

0.1285

0.1144

0.1019

0.0907

0.0808

0.1819

0.1620

0.1443

0.1285

0.1144

0.1019

4.115

3.665

3.264

2.906

2.588

4.620

4.115

3.665

3.264

2.906

2.588

4.620

4.115

3.665

3.264

2.906

2.588

2.304

2.052

4.620

4.115

3.665

3.264

2.906

2.588

1.130

1.010

0.899

0.801

0.713

0.910

0.810

0.721

0.642

0.572

0.509

0.546

0.486

0.433

0.385

0.343

0.306

0.272

0.242

0.392

0.349

0.311

0.277

0.247

0.220

28.80

25.70

22.90

20.30

17.90

23.10

20.60

18.30

16.30

14.50

12.90

13.90

12.40

11.00

9.78

8.71

7.76

6.91

6.16

9.96

8.87

7.90

7.03

6.26

5.58

120,200

100,700

84,200

66,770

52,950

73,350

61,700

51,730

43,240

34,290

27,190

27,030

22,730

19,060

15,930

12,630

10,020

7,945

6,301

12,230

10,280

8,621

7,206

5,715

4,532

109.0

116.0

123.0

130.1

137.1

137.1

137.1

137.1

137.1

5,081

4,290

3,608

3,025

2,529

2,005

1,590

1,261

1,000

115

165

175

185

195

195

195

195

195

RESISTANCE

LB/1000

FT

2222.00

1762.00

1398.00

1108.00

879.00

1430.00

1134.00

899.50

713.50

565.80

448.70

524.90

416.30

330.00

261.80

207.60

164.70

130.60

103.60

224.50

178.10

141.20

112.00

88.81

70.43

AWG

ALUMOWELD STRAND ASTM B-415

No. 4

0.2043 5.189

No. 5

0.1819 4.620

No. 6

0.1620 4.115

No. 7

0.1443 3.665

No. 8

0.1285 3.264

No. 9

0.1144 2.906

No.10

0.1019 2.588

No.11

0.0907 2.304

No.12

0.0808 2.052

WEIGHT

Modulus of Elasticity: Strand 23,000,000; Solid Wire 23,500,000. Coefficient of Linear Expansion: 0.000,007,2 per degree F.

Modulus of Elasticity: Strand 16,200 kg/mm2; Solid Wire 16,500 kg/mm2. Coefficient of Linear Expansion: 0.000,013 per degree C.

www.AFLglobal.com or 800-866-7385

419

2003, AFL, all rights reserved. Revision 2, 12.10.12

Specifications are subject to change without notice.

A L U M O W E L D

Alumoweld Overhead Ground Wire (cont.)

Anda mungkin juga menyukai

- High Output: Industrial VRS Magnetic Speed SensorsDokumen8 halamanHigh Output: Industrial VRS Magnetic Speed SensorsDr Zeljko DespotovicBelum ada peringkat

- 3030AN Magnetic Pick-Up Operation ManualDokumen1 halaman3030AN Magnetic Pick-Up Operation ManualDr Zeljko DespotovicBelum ada peringkat

- Application of Mobile Solar OFF-grid Generator in Irrigation System - Case Study PDFDokumen6 halamanApplication of Mobile Solar OFF-grid Generator in Irrigation System - Case Study PDFDr Zeljko DespotovicBelum ada peringkat

- Voith ReliabilityDokumen8 halamanVoith ReliabilityDr Zeljko DespotovicBelum ada peringkat

- 215 Nastavnik Radovi M CasDokumen2 halaman215 Nastavnik Radovi M CasDr Zeljko DespotovicBelum ada peringkat

- Put Ka JahoriniDokumen1 halamanPut Ka JahoriniDr Zeljko DespotovicBelum ada peringkat

- Rad Odrziva Energetika 2017Dokumen11 halamanRad Odrziva Energetika 2017Dr Zeljko DespotovicBelum ada peringkat

- CENOVNIKDEVDokumen1 halamanCENOVNIKDEVDr Zeljko DespotovicBelum ada peringkat

- Low - Frequency - Igbt - Converter For Control Excitin Force of EvcDokumen5 halamanLow - Frequency - Igbt - Converter For Control Excitin Force of EvcDr Zeljko DespotovicBelum ada peringkat

- E Kapija Intervju ENGDokumen7 halamanE Kapija Intervju ENGDr Zeljko DespotovicBelum ada peringkat

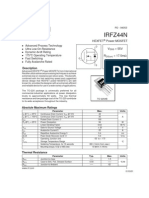

- Irfz 44 NDokumen9 halamanIrfz 44 Nmadhuvariar100% (6)

- Ee2017 Preliminary Program 7Dokumen12 halamanEe2017 Preliminary Program 7Dr Zeljko DespotovicBelum ada peringkat

- E Kapija Intervju ENGDokumen7 halamanE Kapija Intervju ENGDr Zeljko DespotovicBelum ada peringkat

- IR2301 Data Sheet High-Low Side DriverDokumen18 halamanIR2301 Data Sheet High-Low Side DriverDr Zeljko DespotovicBelum ada peringkat

- LM 2574Dokumen38 halamanLM 2574Dr Zeljko DespotovicBelum ada peringkat

- Online Integral Calculator - Find Integrals and Antiderivatives!Dokumen2 halamanOnline Integral Calculator - Find Integrals and Antiderivatives!Dr Zeljko DespotovicBelum ada peringkat

- Imp MRSG LeafletDokumen4 halamanImp MRSG LeafletDr Zeljko DespotovicBelum ada peringkat

- 2017 PERUN Technologies OverviewDokumen28 halaman2017 PERUN Technologies OverviewDr Zeljko DespotovicBelum ada peringkat

- Rad Odrziva Energetika 2017Dokumen11 halamanRad Odrziva Energetika 2017Dr Zeljko DespotovicBelum ada peringkat

- AR100 1000 Deplian Template 2013Dokumen8 halamanAR100 1000 Deplian Template 2013Dr Zeljko DespotovicBelum ada peringkat

- Invited Lecture IEEE - PES DR Zeljko Despotovic Dipl - IngDokumen104 halamanInvited Lecture IEEE - PES DR Zeljko Despotovic Dipl - IngDr Zeljko DespotovicBelum ada peringkat

- Rad Odrziva Energetika 2017Dokumen11 halamanRad Odrziva Energetika 2017Dr Zeljko DespotovicBelum ada peringkat

- 4 2008Dokumen152 halaman4 2008Dr Zeljko DespotovicBelum ada peringkat

- Rad EP 2008 Pre StampeDokumen13 halamanRad EP 2008 Pre StampeDr Zeljko DespotovicBelum ada peringkat

- LM2825 Integrated Power Supply 1A DC-DC Converter: Literature Number: SNVS127BDokumen17 halamanLM2825 Integrated Power Supply 1A DC-DC Converter: Literature Number: SNVS127BDr Zeljko DespotovicBelum ada peringkat

- InTech-Vibration Energy Harvesting Machinery Vibration Human Movement and Flow Induced VibrationDokumen30 halamanInTech-Vibration Energy Harvesting Machinery Vibration Human Movement and Flow Induced VibrationDr Zeljko DespotovicBelum ada peringkat

- IMP ARodic MVujovic ZDespotovic TARA2016Dokumen33 halamanIMP ARodic MVujovic ZDespotovic TARA2016Dr Zeljko DespotovicBelum ada peringkat

- DR Zeljko Despotovic - VIII Forum NS 2014Dokumen50 halamanDR Zeljko Despotovic - VIII Forum NS 2014Dr Zeljko DespotovicBelum ada peringkat

- LM2825 Integrated Power Supply 1A DC-DC Converter: Literature Number: SNVS127BDokumen17 halamanLM2825 Integrated Power Supply 1A DC-DC Converter: Literature Number: SNVS127BDr Zeljko DespotovicBelum ada peringkat

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5782)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (587)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (72)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (344)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (119)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- Metallic Material Specification for 2.25 Cr-1 Mo Alloy with 85 KSI Yield StrengthDokumen6 halamanMetallic Material Specification for 2.25 Cr-1 Mo Alloy with 85 KSI Yield StrengthReginaldo SantosBelum ada peringkat

- NFR Emissions Reporting FrameworkDokumen6 halamanNFR Emissions Reporting FrameworkgeorgianaBelum ada peringkat

- Attachment-8 - Approved Vendor List - Signed Thai OilDokumen29 halamanAttachment-8 - Approved Vendor List - Signed Thai OilNikhil VermaBelum ada peringkat

- Measurement of Water Quality-QuizDokumen3 halamanMeasurement of Water Quality-QuizRaymund DullaBelum ada peringkat

- Liquid Penetrant Testing ProcedureDokumen10 halamanLiquid Penetrant Testing ProcedureirfanBelum ada peringkat

- Armacell Product Catalogue 2011Dokumen153 halamanArmacell Product Catalogue 2011SofijaLaptosevicBelum ada peringkat

- Essentials of Welding: Carbon Steel Plate WeldingDokumen22 halamanEssentials of Welding: Carbon Steel Plate WeldingMARCOE ALONZO ACAIN100% (2)

- Marine Boiler Steam DistributionDokumen21 halamanMarine Boiler Steam DistributionAlyanna AngelesBelum ada peringkat

- NCEM 1.62.002 - EN-merged PDFDokumen244 halamanNCEM 1.62.002 - EN-merged PDFCK ChioBelum ada peringkat

- Orkot Marine Bearings Manual enDokumen40 halamanOrkot Marine Bearings Manual enVadim BlyatBelum ada peringkat

- Wood Staining With Aniline Dye - Dye Stain ApplicationDokumen4 halamanWood Staining With Aniline Dye - Dye Stain ApplicationBobBelum ada peringkat

- How To Choise Refractory For Metallurgy FurnacesDokumen15 halamanHow To Choise Refractory For Metallurgy FurnacesGuilherme Dos Santos MoreiraBelum ada peringkat

- Materials Selection for Rockets Under Extreme ConditionsDokumen17 halamanMaterials Selection for Rockets Under Extreme ConditionsAdithya ShripathiBelum ada peringkat

- Unit 4 Balancing Equations - No Mole - GizmoDokumen4 halamanUnit 4 Balancing Equations - No Mole - GizmoRhys Brown100% (1)

- Product Data: CompositionDokumen2 halamanProduct Data: Compositionsriatul2006Belum ada peringkat

- Asodur - D2: Schomburg SchomburgDokumen2 halamanAsodur - D2: Schomburg SchomburgIbrahim SahinBelum ada peringkat

- Talc - Food Grade - Imperial 1825L FCC / BC: Typical Physical Properties Typical Chemical PropertiesDokumen1 halamanTalc - Food Grade - Imperial 1825L FCC / BC: Typical Physical Properties Typical Chemical PropertiesHaveBelum ada peringkat

- Material Board: - Kadambari KarmalkarDokumen5 halamanMaterial Board: - Kadambari KarmalkarKADAMBARI KARMALKARBelum ada peringkat

- Assignment No.1 - Types and Costs of Materials in The Civil Engineering IndustryDokumen17 halamanAssignment No.1 - Types and Costs of Materials in The Civil Engineering Industryvarun100% (1)

- RockwoolDokumen40 halamanRockwoolMimin Proyek ApaajaBelum ada peringkat

- Ex.2 CHM 3 Sec.1 Fall 2020 (PRB.)Dokumen3 halamanEx.2 CHM 3 Sec.1 Fall 2020 (PRB.)Sn CarbonelBelum ada peringkat

- Spec Cross Reference PassivateDokumen1 halamanSpec Cross Reference PassivateSivaramSubramanianBelum ada peringkat

- Mine Legislation and Safety - TPDokumen4 halamanMine Legislation and Safety - TPReman PatelBelum ada peringkat

- Paper 6 Notes ChemistryDokumen3 halamanPaper 6 Notes ChemistryWuttoxki100% (1)

- Section 03350-Concrete FinishingDokumen3 halamanSection 03350-Concrete FinishingMØhãmmed ØwięsBelum ada peringkat

- Tds Tangit Henkel AlgerieDokumen6 halamanTds Tangit Henkel AlgerieanissmokraniBelum ada peringkat

- Classifying Matter and Its FormsDokumen27 halamanClassifying Matter and Its FormsLiz EvermoreBelum ada peringkat

- Turcite Sheet TrueslideDokumen5 halamanTurcite Sheet TrueslideHaitham MohammadBelum ada peringkat

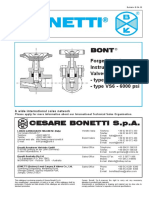

- Vs Instrumentation ValvesDokumen2 halamanVs Instrumentation ValvesAlberto DiazBelum ada peringkat

- Chemical Quantities FullDokumen85 halamanChemical Quantities FullGennelle GabrielBelum ada peringkat