A Synchronization Approach To Trajectory Tracking of Multiple Mobile Robots While Maintaining Time-V-JL0

Diunggah oleh

9999igiJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

A Synchronization Approach To Trajectory Tracking of Multiple Mobile Robots While Maintaining Time-V-JL0

Diunggah oleh

9999igiHak Cipta:

Format Tersedia

1074 IEEE TRANSACTIONS ON ROBOTICS, VOL. 25, NO.

5, OCTOBER 2009

A Synchronization Approach to Trajectory Tracking

of Multiple Mobile Robots While Maintaining

Time-Varying Formations

Dong Sun, Senior Member, IEEE, Can Wang, Wen Shang, and Gang Feng, Fellow, IEEE

AbstractIn this paper, we present a synchronization approach

to trajectory tracking of multiple mobile robots while maintaining

time-varying formations. The main idea is to control each robot

to track its desired trajectory while synchronizing its motion with

those of other robots to keeprelative kinematics relationships, as re-

quired by the formation. First, we pose the formation-control prob-

lemas a synchronization control problemand identify the synchro-

nization control goal according to the formation requirement. The

formation error is measured by the position synchronization error,

which is dened based on the established robot network. Second,

we develop a synchronous controller for each robots translation to

guarantee that both position and synchronization errors approach

zero asymptotically. The rotary controller is also designed to ensure

that the robot is always oriented toward its desired position. Both

translational and rotary controls are supported by a centralized

high-level planer for task monitoring and robot global localization.

Finally, we perform simulations and experiments to demonstrate

the effectiveness of the proposed synchronization control approach

in the formation control tasks.

Index TermsFormation, multiple mobile robots, synchroni-

zation.

I. INTRODUCTION

S

TUDYon the formation control of swarms of mobile robots

has received increasing attention in recent years. Examples

of formation-control tasks include assignment of feasible forma-

tions, moving into a formation, maintenance of formation shape,

and switching between formations. In this paper, we will focus

on how to maintain the networked robots in a time-varying for-

mation while performing a group task as a whole. The relevant

applications include exploration [1], cooperative robot recon-

naissance [2] and manipulation [3], formation ight control [4],

satellite clustering [5], and control of groups of unmanned ve-

hicles [6], [7].

Numerous approaches to the formation control of multiple

mobile robots have been reported in the literature, such as

Manuscript received January 21, 2009; revised May 5, 2009 and July 2, 2009.

First published August 4, 2009; current version published October 9, 2009. This

paper was recommended for publication by Associate Editor G. Antonelli and

Editor L. Parker upon evaluation of the reviewers comments. This work was

supported in part by the Research Grants Council of the Hong Kong Special

Administrative Region, China, under Grant CityU 119907 and in part by the

City University of Hong Kong under Grant 7002461.

The authors are with the Department of Manufacturing Engineering and

Engineering Management, City University of Hong Kong, Kowloon, Hong Kong

(e-mail: medsun@cityu.edu.hk; cwang2@cityu.edu.hk; wenshang@cityu.edu.

hk; megfeng@cityu.edu.hk).

Color versions of one or more of the gures in this paper are available online

at http://ieeexplore.ieee.org.

Digital Object Identier 10.1109/TRO.2009.2027384

behavior-based control, virtual structure approach, and leader-

following strategy, to name a few. In the behavior-based con-

trol [2], [8][11], several desired behaviors are prescribed for

each agent, and the nal control is derived from a weighting of

the relative importance of each behavior. With this method, it

might be difcult to describe the dynamics of the group and guar-

antee the stability of the whole system [12]. In the virtual struc-

ture approach [13][16], the entire formation is treated as a sin-

gle entity. The desired motion is assigned to the virtual structure

that traces out the trajectory for each member of the formation

to follow. However, the controller is not in decentralized archi-

tecture and may encounter difculty in some applications [12].

With the leader-following strategy [3], [12], [17][20], some

robots are designed as leaders, while others are designed as fol-

lowers. This strategy is easily implemented by using two con-

trollers only and is suitable to describe the formation of robots,

but it is hard to take into account the functioning capabilities

of different robots, i.e., ability gap of a robot [12]. There also

exist some other approaches, such as articial-potential-based

methods [21], [22] and graph-theory-based methods [23][29].

A recent approach to convex optimization strategies for coordi-

nating large-scale robot formations was reported in [30], where

shape transitions were discussed for mobile robot teams, albeit

from a high-level planner perspective.

In this paper, we propose to use a synchronization control

strategy to address the multirobot formation control problem,

thus utilizing the concept of cross-coupling approach [31]. Our

basic idea, which was rst reported in [32], is that a team of

mobile robots track each individuals desired trajectory while

synchronizing motions among the robots to keep relative kine-

matics relationship for maintaining the desired, and perhaps

time-varying, formation. A relevant work was reported in [33],

where a group of mobile agents stays connected while achiev-

ing some performance objective. Traditionally, the control loop

of each robot receives only local feedback from the controlled

robot and aims to achieve the desired tracking task without

responding to any other robots. With the proposed synchroniza-

tion control, the control loop of each robot receives feedback

from itself, as well as the others in trajectory tracking, which

is termed as the rst task; meanwhile, it takes care of the other

robots to meet the formation requirement, which is termed as the

second task. In other words, under the synchronization control,

not only the convergence of the position errors to zero but how

these position errors converge to zero will also be considered at

the same time. A pure position control without synchronization

may succeed in the rst task of the trajectory tracking but, in

1552-3098/$26.00 2009 IEEE

SUN et al.: SYNCHRONIZATION APPROACH TO TRAJECTORY TRACKING OF MULTIPLE MOBILE ROBOTS 1075

general, cannot guarantee accomplishment of the second task

of formation maintenance during the motion, due to the lack

of effort in synchronizing the robots motions. A pure position

control can only achieve the desired formation when the posi-

tion errors converge to zero but not during the whole motion.

In many applications, the robots are required to maintain the

desired formation during the whole motion period rather than

at the nal time only. The proposed synchronization control

strategy is ideally suited to the formation tasks of underlying

trajectory controls of multiple mobile robots while following

desired time-varying formations.

The cross-coupling control technology provides advantages

and opportunities to design such a synchronized controller. Over

the past decades, the cross-coupling concept has been widely

used in multiaxis motion applications, such as reducing con-

touring errors of computer numerically controlled (CNC) ma-

chines [34][39]. The concept was also incorporated into adap-

tive control architecture to solve position synchronization of

multiple axes [40], [41]. The cross-coupling technology has

been used in robotics, such as controls of mobile robots [42]

and robot manipulators [43]. Very recently, a combined synchro-

nization and tracking control law was reported in [44] and [45]

for multiple Lagrangian systems in a general setup that includes

complex congurations and different coupling links, such as di-

rectional couplings. To avoid the usage of the system dynamic

models, model-free cross-coupling controllers were introduced

in [46] and [47]. The effort to examine the stability and robust-

ness of the cross-coupled control system was reported in [48].

This paper has made the following contributions.

First, we successfully extend the synchronization approach to

formation control applications and pose the formation control

problem as a motion synchronization problem. As in [43], a

synchronization control goal is determined rst, based on the

formation requirement in the established robot network. Then,

we divide the motion control of each robot into two parts: One

is to drive the robot along the desired trajectory to achieve the

tracking control goal, which is dened as the rst task, and

the other is to synchronize each robots motion with that of

two nearby robots to achieve the synchronization goal, which

is dened as the second task. To measure the synchronicity of

the networked robots, the concept of the synchronization error is

introduced as in [41] and [43], which is dened as the differential

position error between every pair of two neighboring robots.

Second, we develop a decentralized cross-coupled controller

for each robot to achieve its position tracking while synchro-

nizing its motion with those of other robots for the desired

formation. The control algorithm utilizes feedback of both posi-

tion and synchronization errors, requires the information of the

two neighboring robots only, and responds to all linked robots

via the group network. It is proven that the proposed controller

can guarantee asymptotic convergence to zero of both position

and synchronization errors.

Third, simulations and experiments are performed on swarms

of mobile robots to demonstrate the effectiveness of the pro-

posed approach. A generalized superellipse with varying pa-

rameters is utilized to present a range of curves and, therefore,

establish a useful mathematic model to dene time-varying for-

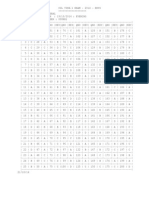

Fig. 1. Group of two-wheel mobile robots.

mations. The result for a skewed superellipse formation was

also reported in [49].

The advantages of applying our proposed synchronization

approach to the formation control are threefold. First, the syn-

chronization control goal is determined based on the desired

formation and is then divided into a number of subgoals for

each individual robot, without discrimination in job assignment.

The potential of robots capability is not overlooked. Also, the

formation strategy can be well prescribed. Second, a synchro-

nization controller can be constructed to guarantee asymptotic

convergence to zero of both position tracking and formation

errors in a decentralized architecture for time-varying forma-

tions. The controller consists of two parallel actions for both

trajectory tracking and formation, and the weighting of the two

actions is adjustable via tuning the control parameter. Third, the

synchronization controller can be simplied by synchronizing

the motion of each robot with that of two neighboring robots. In

other words, the control of each robot requires the information

of two nearby robots only.

II. MULTIROBOT FORMATION VIA SYNCHRONIZATION

Fig. 1 illustrates a group of two-wheel mobile robots, where

q

i

= [ x

i

y

i

]

T

denotes the position coordinate of the ith robot

in xy plane, and

i

denotes the heading angle. To simplify the

analysis, we assume that the center of the mass of each robot

locates at the geometrical center of the robot. In this way, the

centripetal and Coriolis effects are not considered in the robot

dynamics, and the robot is further simplied as a point mass

robot with the following dynamics:

M

i

q

i

=

qi

, I

i

i

=

i

(1)

where M

i

and I

i

denote the inertia of the robot with xed terms,

and

qi

and

i

are torque control inputs with respect to q

i

and

i

, respectively.

Consider the control problem of guiding and positioning a

group of nmobile robots, as shown in Fig. 1, along the boundary

(curve) of a 2-D compact set. In a similar manner to [50], we

introduce a time-varying desired shape for each robot, which

is denoted by S(, t), where denotes a 2-D position vector

and t the time. The boundary of S(, t) is parameterized by a

2-D planar curve, which is denoted by S(, t) = 0. Assign the

target position q

d

i

to the ith robot, and q

d

i

must be located on

1076 IEEE TRANSACTIONS ON ROBOTICS, VOL. 25, NO. 5, OCTOBER 2009

the curve such that S(q

d

i

, t) = 0. Our objective is to determine

the appropriate control inputs for dynamics (1) such that the

ith robot converges to its target position q

d

i

while maintaining

its position in the desired shape S(, t). Note that although

only the position q

i

is explicitly controlled in the formation,

the orientation

i

affects the formation implicitly. In this study,

the desired heading

d

i

of the ith robot is dened such that the

robot is always oriented toward the robots desired position q

d

i

.

d

i

keeps updated during the motion. When the robot is exactly

located at its desired position, the desired heading

d

i

is the same

as the actual heading

i

, and no update is needed.

Dene the position and heading errors of the ith robot as

e

i

= q

d

i

q

i

and

i

=

d

i

i

, respectively. Besides the tra-

ditional robot control goal of e

i

0 and

i

0 as time

t , the robots here are also required to achieve a formation

control goal of maintaining on the desired curve, which can be

formulated as q

i

, S(q

i

, t) = 0, where i = 1, . . . , n.

In this paper, we propose to utilize the synchronization control

concept to solve the formation control problem. The basic idea

of the synchronization control is to regulate the motions of the

robots while they track the desired positions q

d

i

to ensure the

robots to maintain in the required boundary (curve) such that

S(q

i

, t) = 0. Note that a pure position control for q

i

q

d

i

cannot guarantee the formation control goal to be achieved,

because the curve S(q

i

, t) = 0 is dependent on not only the

position q

i

but on the relative relationship of q

i

as well, with

respect to the others at time t.

To measure the synchronicity of the robots, we introduce the

concept of the position synchronization error, which arises from

the synchronization constraint, as required by the formation

goal. The following example will showhowthis synchronization

constraint is determined based on the formation control goal

S(q

i

, t) = 0. Another example was reported in [51].

ExampleConsider that n robots are required to maintain in

an ellipse curve during the motions. The coordinate q

i

of the

ith robot is required to meet the following constraint:

S(q

i

, t) = 0 :

_

q

i

(t) =

_

x

i

(t)

y

i

(t)

_

=

_

cos

i

(t)

sin

i

(t)

_ _

a(t)

b(t)

_

= A

i

(t)

_

a(t)

b(t)

__

(2)

where a and b denote the longest and the shortest radii of

the ellipse, respectively, and

i

= tanh (b sin

i

/a cos

i

), with

i

= tanh [y

i

/x

i

], denotes the angle of the robot lying on the

ellipse with respect to the center of the ellipse. Assume that the

robots are not located in the longest or the shortest axis of the

ellipse such that the inverse of A

i

exists. Then, the synchroniza-

tion constraint to q

i

can be derived as follows:

A

1

1

q

1

= A

1

2

q

2

= = A

1

n

q

n

=

_

a

b

_

. (3)

Fromthe aforementioned example, it is seen that the synchro-

nization constraint can be generally represented in the form

c

1

q

1

= c

2

q

2

= = c

n

q

n

(4)

where c

i

denotes the coupling parameter of the ith robot, and its

inverse exists based on (3). Further, (4) holds at all the desired

coordinates q

d

i

, namely

c

1

q

d

1

= c

2

q

d

2

= = c

n

q

d

n

. (5)

Subtracting (4) from (5) yields the following synchronization

goal:

c

1

e

1

= c

2

e

2

= = c

n

e

n

. (6)

Implicitly, (6) represents the formation control goal, which

can be further divided into n subgoals of c

i

e

i

= c

i+1

e

i+1

. Note

that when i = n, we denote n+1 as 1.

Then, the position synchronization errors can be dened as

a subset of all possible pairs of two neighboring robots in the

following way [52]:

1

= c

1

e

1

c

2

e

2

2

= c

2

e

2

c

3

e

3

.

.

.

n

= c

n

e

n

c

1

e

1

(7)

where

i

denotes the synchronization error of the ith robot. Ob-

viously, if the synchronization error

i

= 0 for all i = 1, . . . , n,

the synchronization goal (6) is achieved automatically.

It is worth noting that the synchronization error is used to mea-

sure the formation effect and is not equivalent to the position-

tracking error. For systems having closed-loop chain structures,

employment of the synchronization error provides each robot

with motion information both from itself and from the other

robots, and hence, the motions of all robots in the group are

coordinated.

Remark 1: The topology of the networked robots is designed

in terms of the robots physical positions in the group when

performing the group task. A principle that may be followed is

that the two physically close robots are coded as two neighbors

for easy sensorial connection. As a result, all robots in one group

are linked, either directly or indirectly, as a whole. The necessary

requirement for the applied shape S(, t) is that the shape can

be represented mathematically such that the synchronization

constraint (4) can be given.

Remark 2: In some formations, the two neighborly coded

robots may be spatially far and, hence, not sensorially con-

nected. This usually happens when the formation shape is not

geometrically closed, e.g., in a line formation, the rst robot

(robot 1) and the last robot (robot n) are far apart but coded

as two neighbors. In case there exists a sensorial problem be-

tween these two robots, we can utilize a high-level planner (as

seen in Fig. 2) to globally localize the two robots such that

the two robots can know the information between each other.

Alternatively, we can also simply remove the direct synchro-

nization request between these two robots, since the two robots

synchronize with the other robots, respectively, and the whole

group of the robots are still linked as a whole. Removal of the

synchronization between the two robots can be mathematically

achieved by setting the synchronization error between these two

SUN et al.: SYNCHRONIZATION APPROACH TO TRAJECTORY TRACKING OF MULTIPLE MOBILE ROBOTS 1077

Fig. 2. Block diagram of the overall control architecture.

robots to zero. In the relevant work [33], sensorial connection

was analytically studied.

Now, the control problem becomes to drive both the position

error e

i

and the synchronization error

i

to zero. The ith robot

can be designed to approach its desired position q

d

i

while syn-

chronizing its motion with those of its two connected robots

i 1 and i + 1. In this way, the control of each robot does not

require the information of all robots except for its neighbors,

and hence, the implementation is simplied.

III. CONTROL DESIGN

Fig. 2 illustrates a block diagram of a two-level control ar-

chitecture used for the formation control. In level 1, there is

a centralized high-level planer for task command generation,

task monitoring (such as detecting malfunctioned robots and

responding), and global localization of the robots. In level 2,

there are decentralized servo controls of the robots and senso-

rial connection among them. Between the two levels is a data

server. Obviously, these two levels have different functions in

accomplishing complex formation control tasks.

This section will focus on the decentralized servo controls of

the robots in level 2. A synchronous tracking controller for the

robots translation is developed. The robots orientation is con-

trolled to be always oriented toward the robots desired position.

The issue of how the robot group responds to the malfunctioned

robot will also be discussed briey at the end of this section.

Without loss of generality, we assume that each robot can obtain

the position information of its two nearby robots, via global or

local localization in the two-level control frame, as shown in

Fig. 2. The relevant works on localization (such as ours [53])

have been reported in the literatures.

A. Synchronous Formation Controller

To make the position and synchronization errors e

i

and

i

both converge to zero, we dene a coupled position error E

i

that links these two errors into one equation, i.e.,

E

i

= c

i

e

i

+

_

t

0

(

i

i1

) d (8)

where is a diagonal positive gain matrix. As is seen from (7)

and (8), this coupled position error for robot i feeds back the

information of the two neighboring robots i 1 and i + 1. Note

that when i = 1, we denote i 1 as n.

Differentiating E

i

with respect to time yields

E

i

= c

i

e

i

+ c

i

e

i

+ (

i

i1

) . (9)

To achieve E

i

0 and

E

i

0, we introduce a command

vector u

i

that leads to a combined position and velocity error,

which is expressed as follows:

u

i

= c

i

q

d

i

+ c

i

e

i

+ (

i

i1

) + E

i

(10)

where is a diagonal positive gain matrix. Denition of u

i

in

(10) leads to the following position/velocity vectors:

r

i

= u

i

c

i

q

i

= c

i

e

i

+ c

i

e

i

+ (

i

i1

) + E

i

=

E

i

+ E

i

. (11)

We then design a controller to drive r

i

to zero, such that

the coupled errors E

i

and

E

i

tend to zero as well. For easy

implementation, such a controller is ideally designed in a de-

centralized architecture, thus considering the synchronization

between each robot and its two neighbors only.

We nally design a torque input for controlling the robots

translation as follows:

qi

=M

i

c

1

i

( u

i

c

i

q

i

) +K

ri

c

1

i

r

i

+c

T

i

K

(

i

i1

) (12)

where K

ri

and K

are positive feedback control gains. The last

term in (12) is used to compensate for the effect due to addition

of the cross-coupling control to the overall system dynamics.

The necessity of introducing this term will be shown in the

stability analysis.

Substituting (12) into the robot translational dynamics in (1)

yields the following closed-loop dynamics:

M

i

c

1

i

r

i

+ K

ri

c

1

i

r

i

+ c

T

i

K

(

i

i1

) = 0. (13)

Theorem 1: The proposed synchronous controller (12) leads

to asymptotic convergence of both the position tracking and syn-

chronization errors to zero, namely, e

i

0 and

i

0 as time

t , under the conditions that the control gain K

ri

is large

enough to satisfy

min

(K

ri

)

max

_

M

i

(d/dt)

_

c

1

i

_

c

i

_

,

where

min

() and

max

() denote the minimum and maximum

eigenvalues of the matrices, respectively.

Proof: Dene a Lyapunov function candidate as

V =

n

i=1

_

1

2

_

c

1

i

r

i

_

T

M

i

c

1

i

r

i

+

1

2

T

i

K

i

_

+

n

i=1

1

2

__

t

0

(

i

i1

) d

_

T

K

_

t

0

(

i

i1

) d.

(14)

Differentiating V with respect to time yields

V =

n

i=1

_

_

c

1

i

r

i

_

T

M

i

c

1

i

r

i

+

_

c

1

i

r

i

_

T

M

i

d

dt

_

c

1

i

_

r

i

+

T

i

K

i

_

+

n

i=1

(

i

i1

)

T

K

_

t

0

(

i

i1

) d. (15)

1078 IEEE TRANSACTIONS ON ROBOTICS, VOL. 25, NO. 5, OCTOBER 2009

Multiplying both sides of (13) by

_

c

1

i

r

i

_

T

yields

_

c

1

i

r

i

_

T

M

i

c

1

i

r

i

+

_

c

1

i

r

i

_

T

K

ri

c

1

i

r

i

+r

T

i

K

(

i

i1

)

= 0. (16)

Substituting (16) into (15) yields

V =

n

i=1

_

_

c

1

i

r

i

_

T

_

K

ri

M

i

d

dt

_

c

1

i

_

c

i

_

c

1

i

r

i

_

i=1

_

r

T

i

K

(

i

i1

)

+

n

i=1

T

i

K

i

+

n

i=1

(

i

i1

)

T

K

_

t

0

(

i

i1

) d. (17)

We now analyze the term

n

i=1

r

T

i

K

(

i

i1

) in (17). It

directly follows that

n

i=1

r

T

i

K

(

i

i1

)

= r

T

1

K

1

r

T

1

K

n

+r

T

2

K

2

r

T

2

K

1

+ r

T

n

K

n

r

T

n

K

n1

= r

T

1

K

1

r

T

2

K

1

+r

T

2

K

2

r

T

3

K

2

+ r

T

n

K

n

r

T

1

K

n

=

n

i=1

(r

i

r

i+1

)

T

K

i

. (18)

Utilizing (7)(9) and (11), we have

r

i

r

i+1

=

E

i

+ E

i

E

i+1

E

i+1

= c

i

e

i

+c

i

e

i

c

i+1

e

i+1

c

i+1

e

i+1

+ (2

i

i1

i+1

)

+ (c

i

e

i

c

i+1

e

i+1

) +

_

t

0

(2

i

i1

i+1

) d

=

i

+ (2

i

i1

i+1

) +

i

+

_

t

0

(2

i

i1

i+1

) d. (19)

Then, substituting (19) into (18) yields

n

i=1

r

T

i

K

(

i

i1

)

=

n

i=1

T

i

K

i

+

n

i=1

T

i

K

i

+

n

i=1

(

i

i+1

)

T

K

(

i

i+1

)

+

n

i=1

(

i

i+1

)

T

K

_

t

0

(

i

i1

) d. (20)

In (20), we utilize the result that

n

i=1

(2

i

i1

i+1

)

T

i

=

n

i=1

(

i

i+1

)

T

(

i

i+1

).

Finally, substituting (20) into (17) and utilizing the condition

of Theorem 1, we have

V

n

i=1

_

_

c

1

i

r

i

_

T

_

min

(K

r

)

max

_

M

i

d

dt

_

c

1

i

_

c

i

__

c

1

i

r

i

_

i=1

T

i

K

i

n

i=1

_

i

i+1

_

T

K

(

i

i+1

)

0. (21)

It is thus concluded that the dened Lyapunov function (14)

has negative semidenite time derivative. From (21), we know

that r

i

and

i

are bounded. From (13), we know that r

i

is

bounded. From (19), we know that

i

is bounded. Therefore, r

i

and

i

are uniformly continuous since r

i

and

i

are bounded.

Then, from Barbalats lemma, r

i

0 and

i

0 as time t

. The synchronization goal (6) is achieved.

We now prove e

i

= 0 when r

i

= 0 and

i

= 0. From (11),

r

i

= 0 implies E

i

= 0 when t . Combining all equations

in (8) from 1 to n, we have

c

1

e

1

+ c

2

e

2

+ + c

n

e

n

= 0. (22)

Substituting (6) into (22) yields c

1

e

1

= c

2

e

2

= =

c

n

e

n

= 0. Since the inverse of c

i

exists, e

i

= 0. Therefore,

Theorem 1 is proved.

It appears that the control parameters in (8) and K

in (12)

dominate the control of the synchronization error. As seen in

(8), the value of determines the weight of the synchroniza-

tion error

i

in the coupled position error E

i

and, thus, affects

the synchronization effort in the whole control action. As

increases, the synchronization will be enhanced. In practical

applications, should be chosen by taking a balance between

position and synchronization controls. The parameter K

, ac-

companied by

i

i1

in (12), ensures the stability of the

system when adding the cross-coupling control with to the

overall system dynamics. It will be further discussed how to

get the desired boundedness of the synchronization error by

adjusting K

in Section III-B.

To control the robots heading, we propose to utilize a general

computed torque approach to design of the control input

i

, i.e.,

i

= I

i

_

d

i

+ k

vi

i

+ k

pi

i

_

(23)

where k

vi

and k

pi

are computed torque control gains. The de-

sired heading

d

i

, as said before, is dened such that the robot is

always oriented toward its desired position. In other words, the

orientation control serves to achieve the robots translation.

Substituting (23) into the robot rotational dynamics in (1)

yields the closed-loop dynamics as follows:

i

+ k

vi

i

+ k

pi

i

= 0. (24)

SUN et al.: SYNCHRONIZATION APPROACH TO TRAJECTORY TRACKING OF MULTIPLE MOBILE ROBOTS 1079

This directly yields

i

= 0 and

i

= 0 as time t

and guarantees the stability properties of the rotation.

Remark 3: If robot i malfunctions, e.g., lags much behind

on its trajectory, the other robots will respond under the syn-

chronization control. The centralized high-level planar in level

1 will monitor the task and make the decision whether robot i is

still suitable to remain in the team. The decision making will be

based on the facts whether the robot loses capabilities to execute

the task (i.e., drive the position error to zero) and communicate

with the other robots. If robot i has to be abandoned by the

team, the other robots will treat robot i as a virtual robot and

assume its position error to be zero in the follow-on motion.

In this way, the remaining robots can still follow the previous

network topology.

B. Discussions

Two issues are further discussed in this section. One is the

boundedness on the formation error. Another is the robustness

achieved by adaptive synchronization control.

1) Boundedness: We nowanalyze the boundedness through-

out the transient response. Given a upper bound on the formation

error, in the following, we will discuss the lower bound on the

control parameter that achieves the desired upper bound on the

error.

Since the system is asymptotically stable, as concluded from

Theorem 1, given an upper bound

i

on

i

, there exists a nite

time T > 0 such that after t > T, one has

i

(t)

i

. In

addition, at t = T

V (T) =

n

i=1

_

1

2

_

c

1

i

(T)r

i

(T)

_

T

M

i

c

1

i

(T)r

i

(T)

_

+

n

i=1

_

1

2

T

i

(T)K

i

(T)

_

+

n

i=1

1

2

__

T

0

(

i

i1

) d

_

T

K

_

T

0

(

i

i1

) d (25)

which is bounded. If we dene the rst term on the right-hand

side of (25) as A, it then follows from (25) that

V (T) A

=

n

i=1

_

1

2

T

i

(T)K

i

(T)

_

+

n

i=1

1

2

__

T

0

(

i

i1

) d

_

T

K

_

T

0

(

i

i1

) d

i=1

_

1

2

K

2

_

+

n

i=1

_

1

2

K

(2

i

T)

2

_

= K

_

1

2

+ 2 T

2

_

n

i=1

_

2

_

. (26)

Finally, the lower bound for K

can be determined as

K

V (T) A

_

1

2

+ 2 T

2

_

n

i=1

(

i

2

)

. (27)

2) Adaptive Control for Robustness: In the controller (12),

the robot inertia M

i

is assumed to be known. In practice, the

inertia M

i

may be uncertain. Dene

M

i

(t) as the estimate of

the robot inertia M

i

. An adaptive control can be designed as

qi

=

M

i

(t)c

1

i

( u

i

c

i

q

i

) + K

ri

c

1

i

r

i

+ c

T

i

K

(

i

i1

).

(28)

The estimated inertia

M

i

(t) is subject to the adaptation law

M

i

(t) =

i

c

1

i

( u

i

c

i

q

i

)c

1

i

r

i

(29)

where

i

is a diagonal positive-denite control gain. Dene the

estimation error as

M

i

(t) = M

i

M

i

(t). (30)

Then, the adaptive control law can be rewritten as

M

i

(t) =

i

c

1

i

( u

i

c

i

q

i

)c

1

i

r

i

. (31)

Substituting the controller (28) into the robot dynamics model

leads to the following closed-loop dynamics:

M

i

c

1

i

r

i

+ K

ri

c

1

i

r

i

+ c

T

i

K

(

i

i1

)

=

M

i

(t)

_

c

1

i

( u

i

c

i

q

i

)

_

. (32)

In a similar manner to Theorem 1 and [43], we can prove that

the aforementioned adaptive control law leads to asymptotic

convergence to zero of both the position tracking and synchro-

nization errors.

The aforementioned analysis indicates that an adaptive con-

trol can be well incorporated into the developed synchronization

scheme. Although only inertia uncertainty is discussed here, the

method can be extended to the cases with more complex mod-

eling uncertainty and/or some external disturbances.

IV. SIMULATIONS

Simulations were performed rst to verify the effectiveness

of the proposed synchronization control approach. It is assumed

that all the required formations are composed of regular closed,

smooth, and simple planar curves. A generalized superellipse

with varying parameters, as seen later, is used to represent dif-

ferent kinds of formation curves

x

i

a

2/m

+

y

i

b

2/m

= 1 (33)

which can also be represented as

_

x

i

= a cos

m

i

y

i

= b sin

m

i

(34)

where m denotes the exponent index that may be time-varying,

and a, b, and

i

have been dened in (2). In the simulations,

i

is xed, and its value can be known at the beginning. Based

1080 IEEE TRANSACTIONS ON ROBOTICS, VOL. 25, NO. 5, OCTOBER 2009

Fig. 3. Switch from an ellipse to a rounded rectangle.

on

i

, each robot can be indexed. Besides the exponent m, the

variation of radii a and b also affects the curve signicantly. A

study on switch between two different ellipses with exchanged

radii a and b was reported in [32].

With different exponent m, (33) and (34) represent a range

of shapes including rectangles, ovals, ellipses, and diamonds, in

categories of hyperellipses (m < 1) and hypoellipses (m > 1).

The following simulation study will consider a switch from an

ellipse (m

0

= 1) to a rounded rectangle (m

f

= 1/8), as seen in

Fig. 3, where a and b are xed.

In the simulation, there are in total 20 mobile robots, which

are denoted by little squares in Fig. 3, all located on an ellipse

curve at the beginning time. During the switch, all the robots

are required to maintain in a desired time-varying hyperellipse

curve, with the exponent index changed in the following way:

m(t) = m

0

+ (m

f

m

0

)

_

1 e

t

_

(35)

where m

0

= 1 and m

f

= 1/8 denote the initial and nal values

of the exponent index. All the 20 robots have different inertia

M

i

, which is expressed by M

i

= diag{0.5 + 0.075i, 0.5 +

0.075i}, where i = 1, . . . , 20.

The desired trajectory of the ith robot is designed according

to the required formation task (34) and is given as

q

d

i

(t) =

_

x

d

i

(t)

y

d

i

(t)

_

=

_

cos

m(t)

i

sin

m(t)

i

_ _

a

b

_

= A

i

(t)

_

a

b

_

. (36)

The coupling parameter matrix was then dened as

c

i

(t) = A

1

i

(t) =

_

cos

m(t)

i

sin

m(t)

i

_

1

. (37)

The sampling period was set to 0.005 s in the simulation.

Two control algorithms were applied in the simulation for

comparison purpose: One was the proposed synchronous con-

Fig. 4. Formation switch froman ellipse to a rounded rectangle and trajectories

of robots, with synchronous control.

trol (12), and the other was the nonsynchronous control by re-

moving all kinds of coupling among the robots in the controller,

which was equivalent to a standard feedforward plus a feedback

control. The control parameters of the synchronous controller

(12) were chosen as = diag{15, 15}, = diag{35, 35},

K

= diag{10, 10}, and K

ri

= diag{120, 120}. To implement

the nonsynchronous control, the control parameters were chosen

as = diag{0, 0}, = diag{35, 35}, K

= diag{0, 0}, and

K

ri

= diag{120, 120}. Note that the same coupling parameter

matrix c

i

was used to calculate the synchronization error in both

cases for a fair comparison.

Fig. 4 illustrates the actual formation shapes and the trajec-

tories of the robots in the switch from the initial ellipse to the

nal rounded rectangle under the synchronous control. Fig. 5(a)

and (b) illustrates the position and synchronization errors in x-

and y-direction of the 20 robots under the proposed synchronous

control. Both the position and synchronization errors growfrom

zero up to some nonzero values and, subsequently, decrease and

converge tozerouponreachingthe nal desiredformation. Fig. 6

illustrates the results of the nonsynchronous control. It is seen

that the robots have large transient synchronization errors under

nonsynchronous control, which degrades the performance of

the formation. With the proposed synchronous control, the syn-

chronization errors are greatly reduced, and therefore, a better

formation can be achieved.

We further study how the robot group responds to a particular

robot that is observed to malfunction. Assume that robot 18 was

found to lag much behind its desired trajectory soon after the

task started. Due to the use of synchronization control, all the

other robots had to slow down to wait for this robot to catch the

team. After recognizing that robot 18 could not resume working

properly, the group decided to abandon this robot at 0.75 s. The

remaining 19 robots then continued the movement and treated

robot 18 as a virtual robot with an assumption that its position

error was zero. Fig. 7(a) and (b) illustrates the position and

synchronization errors of the case. It is seen that due to failure

of robot 18, the position and synchronization errors of all the

SUN et al.: SYNCHRONIZATION APPROACH TO TRAJECTORY TRACKING OF MULTIPLE MOBILE ROBOTS 1081

Fig. 5. Results of synchronous control. (a) Position errors. (b) Synchronization

errors.

robots in the group increased signicantly until robot 18 was

abandoned after 0.75 s.

V. EXPERIMENTS

We further carried out experiments on a group of three mobile

robots to verify the proposed synchronous control method. The

three robots are P3DX mobile robots, as shown in Fig. 8. The

control inputs

qi

and

i

were obtained by the inputs acting

on the left and the right driving wheels, which are denoted by

li

and

ri

, as given in the Appendix. The experiments were

performed in two cases.

A. Case 1: Triangle Formation

In this case, the three robots were controlled to maintain a se-

ries of equilateral triangles. The three robots were located at the

three vertices of the equilateral triangle. Dene a circumcircle

that connects the three vertices of the triangle. The center of the

circumcircle locates at the geometrical central point of the tri-

angle. The switch among the equilateral triangles was modeled

as the switch among the circumcircles with time-varying radius

and orientation, as shown in Fig. 9. Taking reference of (2), the

coordinate q

i

of the ith robot, where i = 1, . . . , 3, was subject

Fig. 6. Results of nonsynchronous control. (a) Position errors. (b) Synchro-

nization errors.

to the following constraint:

S(q

i

, t) = 0 :

_

q

i

(t) =

_

x

i

(t)

y

i

(t)

_

=

_

cos

i

(t)

sin

i

(t)

_ _

R(t)

R(t)

_

= A

i

(t)

_

R(t)

R(t)

__

(38)

where R(t) is the time-varying radius of the circumcircle, and

i

(t) was dened in (2). Since a = b = R(t),

i

(t) =

i

.

In the experiment, both the size and the orientation of the

triangle were changed by varying R(t) and

i

(t), respectively.

R(t) was scheduled to change in the following way:

R(t) = R

0

+ (R

f

R

0

)

t

t + e

1t

(39)

where R

0

and R

f

denote the initial and the nal radii of the

circumcircle and were chosen as R

0

= 2.4 m and R

f

= 4.8 m,

respectively.

i

(t) was scheduled to change as

i

(t) =

i0

+ (

if

i0

)

t

t + e

1t

(40)

where

i0

and

if

are the initial and the nal values for the

ith robot and were chosen as

10

= 0

,

1f

= 120

,

20

= 0

2f

= 120

, and

30

= 0

,

3f

= 0

. After system calibra-

tion, the inertia of each robot was estimated as 1.8 kgm

2

.

1082 IEEE TRANSACTIONS ON ROBOTICS, VOL. 25, NO. 5, OCTOBER 2009

Fig. 7. Results when dealing with the failed robot. (a) Position errors.

(b) Synchronization errors.

Fig. 8. Three mobile robots in the experiment.

Dene the coupling parameter matrix as

c

i

(t) = A

1

i

(t) =

_

cos

i

(t)

sin

i

(t)

_

1

.

Fig. 9. Switch among triangle formations.

The sampling time period was chosen as 200 ms. The control

parameters used in the synchronous controller are

= diag{1, 1}, = diag{2, 2}, K

= diag{5, 5}

K

r1

= diag{5, 5}, K

r2

= diag{5, 5}, K

r3

= diag{5, 5}.

As in the simulations, two control algorithms of the pro-

posed synchronous control (12) and the nonsynchronous con-

trol were implemented, respectively. To implement the non-

synchronous controller, the coupling among the robots was re-

moved, and the parameters were chosen as = diag{0, 0} and

K

= diag{0, 0}, and and K

ri

were the same as in the syn-

chronous case. Note that the same coupling parameter c

i

was

used to calculate the synchronization error for both the syn-

chronous and nonsynchronous cases. The robots were localized

based on their initial positions and the moving distances mea-

sured by the motor encoders.

The right-hand side of Fig. 9 illustrates the legend of the tri-

angle formation change in the experiment. Fig. 10 illustrates

the position and synchronization errors of the three robots in

x- and y-direction, respectively, under the proposed synchro-

nization control (12). Fig. 11 illustrates the position and syn-

chronization errors of the robots under the nonsynchronous

control. It is seen that both the control methods could ensure

good convergence of the robot position errors. The synchro-

nization errors under the synchronous controller were much

smaller than those under the nonsynchronous controller. The

synchronization errors actually represent the formation errors.

Fig. 12 illustrates the heading angle errors of the three robots

under the computed torque controller (23), where the control

gains were K

p1

= diag{10, 10}, K

p2

= diag{10, 10}, K

p3

=

diag{10, 10}, K

v1

= diag{10, 10}, K

v2

= diag{10, 10}, and

K

v3

= diag{10, 10}. Fig. 13 illustrates the control inputs

li

and

ri

on the two wheels of each robot, respectively, under the

synchronous control.

B. Case 2: Ellipse Formation

To further verify the robustness of the proposed adaptive

synchronization control (28) and (29) to the model uncertainty,

the three robots were controlled to form a part of ellipse (see

Fig. 14) and then switch among a series of ellipse formations.

At the beginning, the robots were in a straight line with the

same heading angle, as shown on the left-hand side of Fig. 15.

Then, the robots spread out to explore a series of formations

SUN et al.: SYNCHRONIZATION APPROACH TO TRAJECTORY TRACKING OF MULTIPLE MOBILE ROBOTS 1083

Fig. 10. Synchronous control results. (a) Position errors. (b) Synchronization

errors.

that are all part of ellipses. The coordinate q

i

of the ith robot is

subject to (2). The longest and the shortest radii of the ellipse

were changed as

a(t) = a

0

+ (a

f

a

0

)

t

t + e

1t

(41)

b(t) = b

0

+ (b

f

b

0

)

t

t + e

1t

(42)

where a

0

= 3 m and a

f

= 5 m are the initial and the nal de-

sired longest radii of the ellipse, and b

0

= 1 m and b

f

= 3 m

are the initial and the nal desired shortest radii of the ellipse.

In the experiment, let

i

[as dened in (2)] change to

i

(t) =

i0

+ (

if

i0

)

t

t + e

1t

(43)

where we chose

10

= 30

,

1f

= 75

,

20

= 0

,

2f

= 25

,

and

30

= 30

,

3f

= 75

. All inertias of the robots were

estimated to be zero at the beginning. Dene the same cou-

pling coefcient as in case 1. The control gains were chosen as

Fig. 11. Nonsynchronous control results. (a) Position errors. (b) Synchroniza-

tion errors.

Fig. 12. Heading angle errors of the three robots.

1084 IEEE TRANSACTIONS ON ROBOTICS, VOL. 25, NO. 5, OCTOBER 2009

Fig. 13. Control torques.

Fig. 14. Three robots in an ellipse.

Fig. 15. Switch among formations.

Fig. 16. Adaptive synchronous control results. (a) Position errors. (b) Syn-

chronization errors.

follows:

= diag{1, 1}, = diag{1.3, 1.3}, K

= diag{1, 1}

K

r1

= diag{10, 10}, K

r2

= diag{10, 10}

K

r3

= diag{10, 10},

i

= diag{0.1, 0.1}.

The sampling time period was 200 ms.

The right-hand side of Fig. 15 illustrates the legend of the

ellipse formation change in the experiment. Fig. 16 illustrates

good convergence of the position and synchronization errors

of the three robots under the proposed adaptive synchronous

control, although all inertias of the robots were assumed to be

unknown. These results demonstrate the validity of incorpora-

tion of adaptive control into synchronization approach to solve

the model uncertainty problem.

SUN et al.: SYNCHRONIZATION APPROACH TO TRAJECTORY TRACKING OF MULTIPLE MOBILE ROBOTS 1085

VI. CONCLUSION

This paper presents a synchronization control approach to

controlling swarms of mobile robots to track the desired trajec-

tories while synchronizing the motions among them to maintain

relative kinematics relationships, as required by the formation.

The formation control problem is successfully posed as a syn-

chronization control problem. The concept of the position syn-

chronization error, which is dened as differential position error

between every pair of two neighboring robots, is introduced to

measure the performance of the formation. The proposed syn-

chronous controller guarantees asymptotic convergence to zero

of both position and synchronization errors of each robot in

translation. A rotary controller drives the robot to always be

oriented toward its desired position. Both simulation and ex-

perimental studies are nally performed to demonstrate the ef-

fectiveness of the proposed approach. The future work includes

incorporation of the robot nonholonomic dynamics into the syn-

chronization control, topology design of the networked robots,

and a study on robustness to the environmental uncertainties.

APPENDIX

Dene the torque inputs acting on the left and the right driving

wheels of the ith robot as

li

and

ri

. The transformation matrix

from (

li

,

ri

) to (

qi

,

i

) is expressed as

B

i

(

i

) =

1

d

_

_

cos

i

cos

i

sin

i

sin

i

R R

_

_ (44)

where d and R have been shown in Fig. 1. Based on B

i

(

i

),

qi

and

i

can be derived as

qi

=

_

qi

(x)

qi

(y)

_

=

_

_

cos

r

(

li

+

ri

)

sin

r

(

li

+

ri

)

_

_

(45)

i

=

R

r

(

li

ri

). (46)

The inverse relationship from (

qi

,

i

) to (

li

,

ri

) can be

obtained by

li

=

r

2

_

qi

(x)

cos

+

i

R

_

ri

=

r

2

_

qi

(x)

cos

i

R

_

(47)

or

li

=

r

2

_

qi

(y)

sin

+

i

R

_

ri

=

r

2

_

qi

(y)

sin

i

R

_

. (48)

To avoid singularity, (47) should be used when

i

is around

zero or 180

, and (48) should be used when

i

is around 90

or

270

.

REFERENCES

[1] D. Fox, W. Burgard, H. Kruppa, and S. Thrun, A probabilistic approach

to collaborative multi-robot localization, Auton. Robots, vol. 8, no. 3,

pp. 325344, Jun. 2000.

[2] T. Balch and R. Arkin, Behavior-based formation control for multi-robot

systems, IEEE Trans. Robot. Autom., vol. 14, no. 6, pp. 926939, Dec.

1998.

[3] H. G. Tanner, S. G. Loizou, and K. J. Kyriakopoulos, Nonholonomic

navigation and control of multiple mobile manipulators, IEEE Trans.

Robot. Autom., vol. 19, no. 1, pp. 5364, Feb. 2003.

[4] M. Mesbahi and F. Hadaegh, Formation ying of multiple spacecraft via

graphs, matrix inequalities, and switching, AIAA J. Guid., Control, Dyn.,

vol. 24, pp. 369377, Mar. 2001.

[5] C. R. McInnes, Autonomous ring formation for a planar constellation of

satellites, AIAA J. Guid., Control, Dyn., vol. 18, no. 5, pp. 12151217,

1995.

[6] F. Giulietti, L. Pollini, and M. Innocenti, Autonomous formation ight,

IEEE Control Syst. Mag., vol. 20, no. 6, pp. 3444, Jun. 2000.

[7] D. J. Stilwell and B. E. Bishop, Platoons of underwater vehicles, IEEE

Control Syst. Mag., vol. 20, no. 6, pp. 4552, Dec. 2000.

[8] J. R. T. Lawton, R. W. Beard, and B. J. Young, A decentralized approach

to formation maneuvers, IEEE Trans. Robot. Autom., vol. 19, no. 6,

pp. 933941, Dec. 2003.

[9] L. E. Parker, ALLIANCE: An architecture for fault tolerant multirobot

cooperation, IEEE Trans. Robot. Autom., vol. 14, no. 2, pp. 220240,

Apr. 1998.

[10] S. Berman, Y. Edan, and M. Hamshidi, Navigation of decentralized au-

tonomous automatic guided vehicles in material handling, IEEE Trans.

Robot. Autom., vol. 19, no. 4, pp. 743749, Aug. 2003.

[11] M. Long, A. Gage, R. Murphy, and K. Valavanis, Application of the

distributed eld robot architecture to a simulated deming task, in Proc.

IEEE Int. Conf. Robot. Autom., Barcelona, Spain, Apr. 2005, pp. 3204

3211.

[12] H. Takahashi, H. Nishi, and K. Ohnishi, Autonomous decentralized con-

trol for formation of multiple mobile robots considering ability of robot,

IEEE Trans. Ind. Electron., vol. 51, no. 6, pp. 12721279, Dec. 2004.

[13] M. A. Lewis and K. H. Tan, High precision formation control of mobile

robots using virtual structures, Auton. Robot., vol. 4, pp. 387403, 1997.

[14] M. Egerstedt and X. Hu, Formation constrained multi-agent control,

IEEE Trans. Robot. Autom., vol. 17, no. 6, pp. 947951, Dec. 2001.

[15] R. W. Beard, H. Lawton, and F. Y. Hadaegh, A coordination architecture

for spacecraft formation control, IEEE Trans. Control Syst. Technol.,

vol. 9, no. 6, pp. 777790, Nov. 2001.

[16] W. Kang, N. Xi, and A. Sparks, Formation control of autonomous agents

in 3D workspace, in Proc. IEEE Int. Conf. Robot. Autom., San Francisco,

CA, Apr. 2000, pp. 17551760.

[17] J. P. Deasi, V. Kumar, and P. Ostrowski, Modeling and control of for-

mations of nonholonomic mobile robots, IEEE Trans. Robot. Autom.,

vol. 17, no. 6, pp. 905908, Dec. 2001.

[18] A. K. Das, R. Fierro, V. Kumar, J. P. Ostrowski, J. Spletzer, and C. J.

Taylor, A vision-based formation control framework, IEEE Trans.

Robot. Autom., vol. 18, no. 5, pp. 813825, Oct. 2002.

[19] J. Huang, S. M. Farritor, A. Qadi, and S. Goddard, Localization and

follow-the-leader control of a heterogeneous group of mobile robots,

IEEE/ASME Trans. Mechatron., vol. 11, no. 2, pp. 205215, Apr. 2006.

[20] J. Chen, D. Sun, J. Yang, and H. Chen, A leader-follower formation

control of multiple nonholonomic mobile robots incorporating receding-

horizon scheme, Int. J. Robot. Res., vol. 28, 2009.

[21] P. Ogren, E. Fiorelli, and N. E. Leonard, Cooperative control of mobile

sensor networks: Adaptive gradient climbing in a distributed environ-

ment, IEEE Trans. Autom. Control, vol. 40, no. 8, pp. 12921302, Aug.

2004.

[22] R. Sepulchre, D. Paley, and N. E. Leonard, Stabilization of planar col-

lective motion: All-to-all communication, IEEE Trans. Autom. Control,

vol. 52, no. 5, pp. 811824, May 2007.

[23] J. A. Fax and R. M. Murray, Information ow and cooperative control

of vehicle formations, IEEE Trans. Autom. Control, vol. 49, no. 9,

pp. 14651476, Sep. 2004.

[24] A. Jadbabaie, J. Lin, and A. S. Morse, Coordination of groups of mobile

autonomous agents using nearest neighbor rules, IEEE Trans. Autom.

Control, vol. 48, no. 9, pp. 9881001, Sep. 2003.

[25] L. Moreau, Stability of multiagent systems with time-dependent commu-

nication links, IEEE Trans. Autom. Control, vol. 50, no. 2, pp. 169182,

Feb. 2005.

1086 IEEE TRANSACTIONS ON ROBOTICS, VOL. 25, NO. 5, OCTOBER 2009

[26] R. Olfati-Saber and R. M. Murray, Consensus problems in networks of

agents with switching topology and time-delays, IEEE Trans. Autom.

Control, vol. 49, no. 9, pp. 101115, Sep. 2004.

[27] R. Olfati-Saber, Flocking for multi-agent dynamic systems: Algorithms

and Theory, IEEE Trans. Autom. Control, vol. 51, no. 3, pp. 401420,

Mar. 2006.

[28] W. Ren and R. W. Beard, Consensus seeking in multi-agent systems

under dynamically changing interaction topologies, IEEE Trans. Autom.

Control, vol. 50, no. 5, pp. 655661, May 2005.

[29] C. Belta and V. Kumar, Optimal motion generation for groups of robots:

A geometric approach, ASME J. Mech. Des., vol. 126, pp. 6370, 2004.

[30] J. C. Derenick and J. R. Spletzer, Convex optimization strategies for

coordinating large-scale robot formations, IEEE Trans. Robot., vol. 23,

no. 6, pp. 12521259, Dec. 2007.

[31] Y. Koren, Cross-coupled biaxial computer controls for manufacturing

systems, ASME J. Dyn. Syst., Meas., Control, vol. 102, pp. 265272,

1980.

[32] D. Sun and C. Wang, Controlling swarms of mobile robots for switching

between formations using synchronization concept, in Proc. IEEE Int.

Conf. Robot. Autom., Rome, Italy, Apr. 2007, pp. 23002305.

[33] M. Ji and M. Egerstedt, Distributed coordination control of multi-agent

systems while preserving connectedness, IEEE Trans. Robot., vol. 23,

no. 4, pp. 693703, Aug. 2007.

[34] A. Rodriguez-Angeles and H. Nijmeijer, Mutual synchronization of

robots via estimated state feedback: Acooperative approach, IEEETrans.

Control Syst. Technol., vol. 12, no. 4, pp. 542554, Jul. 2004.

[35] Q. Zhong, Y. Shi, J. Mo, and S. Huang, A linear cross coupled control

system for high speed machining, Int. J. Adv. Manuf. Technol., vol. 19,

pp. 558563, 2002.

[36] S. S. Yeh and P. L. Hsu, Estimation of the contouring error vector for the

cross-coupled control design, IEEE/ASME Trans. Mechatron., vol. 7,

no. 1, pp. 4451, Mar. 2002.

[37] M. T. Yan, M. H. Lee, and P. L. Yen, Theory and application of a combined

self-tuning adaptive control and cross coupling control in a retrot milling

machine, Mechatron., vol. 15, no. 2, pp. 193211, Mar. 2005.

[38] T. C. Chiu and M. Tomizuka, Contouring control of machine tool feed

drive systems: A task coordinate frame approach, IEEE Trans. Control

Syst. Technol., vol. 9, no. 1, pp. 130139, Jan. 2001.

[39] D. Sun and M. C. Tung, Asynchronization approach for the minimization

of contouring errors of CNC machine tools, IEEE Trans. Autom. Sci.

Eng., vol. 6, no. 4, Oct. 2009.

[40] M. Tomizuka, J. S. Hu, and T. C. Chiu, Synchronization of two motion

control axes under adaptive feedforward control, ASME J. Dyn. Syst.,

Meas., Control, vol. 114, no. 2, pp. 196203, 1992.

[41] D. Sun, Position synchronization of multiple motion axes with adaptive

coupling control, Automatica, vol. 39, no. 6, pp. 9971005, Jun. 2003.

[42] L. Feng, Y. Koren, and J. Borenstein, Cross-coupling motion controller

for mobile robots, IEEE Control Syst., vol. 13, no. 6, pp. 3543, Dec.

1993.

[43] D. Sun and J. K. Mills, Adaptive synchronized control for coordination

of multi-robot assembly tasks, IEEE Trans. Robot. Autom., vol. 18, no. 4,

pp. 498510, Aug. 2002.

[44] S. J Chung and J. J. E. Slotine, Cooperative robot control and concurrent

synchronization of Lagrangian systems, IEEE Trans. Robot., vol. 25,

no. 3, pp. 686700, Jun. 2009.

[45] S. J. Chung, U. Ahsun, and J. J. E. Slotine, Application of synchronization

to formation ying spacecraft: Lagrangian approach, AIAA J. Guid.,

Control Dyn., vol. 32, no. 2, pp. 512526, Sep. 2008.

[46] Y. Koren and C. C. Lo, Variable-gain cross-coupling controller for con-

touring, Ann. CIRP, vol. 40, no. 1, pp. 371374, 1991.

[47] D. Sun, X. Y. Shao, and G. Feng, A model-free cross-coupled control for

position synchronization of multi-axis motions: Theory and Experiments,

IEEETrans. Control Syst. Technol., vol. 15, no. 2, pp. 306314, Mar. 2007.

[48] S. Yeh and P. Hsu, Analysis and design of integrated control for multi-

axis motion systems, IEEE Trans. Control Syst. Technol., vol. 11, no. 3,

pp. 375382, May 2003.

[49] D. A. Paley, N. E. Leonard, and R. Sepulchre, Stabilization of symmetric

formations to motion around convex loops, Syst. Control Lett., vol. 57,

pp. 209215, 2008.

[50] M. Y. Hsieh and V. Kumar, Pattern generation with multiple robots, in

Proc. IEEE Int. Conf. Robot. Autom., May 2006, pp. 24422447.

[51] Y. Su, D. Sun, L. Ren, and J. K. Mills, Integration of saturated PI syn-

chronous control and PD feedback for control of parallel manipulators,

IEEE Trans. Robot., vol. 22, no. 1, pp. 202207, Feb. 2006.

[52] D. Sun, L. Ren, J. K. Mills, and C. Wang, Synchronous tracking control

of parallel manipulators using cross-coupling approach, Int. J. Robot.

Res., vol. 25, no. 11, pp. 11371148, Nov. 2006.

[53] H. Chen, D. Sun, and J. Yang, Global localization of multirobot forma-

tions using ceiling vision SLAM strategy, Mechatron., vol. 19, no. 5,

pp. 618628, Aug. 2009.

Dong Sun (S95M00SM08) received the Bach-

elors and Masters degrees in mechatronics and

biomedical engineering from Tsinghua University,

Beijing, China, and the Ph.D. degree in robotics and

automation from the Chinese University of Hong

Kong, Hong Kong.

He was a Postdoctoral Researcher with the Uni-

versity of Toronto, Toronto, ON, Canada, where he

is currently an Adjunct Professor. He was a Research

and Development Engineer in Ontario industry. Since

2000, he has been with the Department of Manufac-

turing Engineering and Engineering Management, City University of Hong

Kong, Kowloon, Hong Kong, where he is currently a Full Professor. His current

research interests include robotics manipulation, multirobot systems, motion

controls, and biological processing automation.

Prof. Sun is a Professional Engineer in the province of Ontario. From 2004

to 2008, he was an Associate Editor of the IEEE TRANSACTIONS ON ROBOTICS.

Can Wang received the B.S. degree from the De-

partment of Electrical Engineering, Zhejiang Uni-

versity, Hangzhou, China, in 2001, the M.S. de-

gree in system-on-chip from Lund University, Lund,

Sweden, in 2005, and the Ph.D. degree with the De-

partment of Manufacturing Engineering and Engi-

neering Management, City University of Hong Kong,

Kowloon, Hong Kong, in 2009.

His current research interests include coordination

of multiple robot systems, synchronization control,

and neural networks.

Wen Shang received the B.Sc. degree in automation

from Shandong University, Jinan, China, in 1999 and

the Ph.D. degree in automatic control from Southeast

University, Nanjing, China, in 2005.

She is currently a Senior Research Associate with

Suzhou Research Center, City University of Hong

Kong, Kowloon, Hong Kong. Her current research

interests include mobile robots, multirobot learning

control, and multirobot coordination.

Gang Feng (S90M92SM95F09) received the

B.Eng. and M.Eng. degrees in automatic control

from Nanjing Aeronautical Institute, Nanjing, China,

in 1982 and 1984, respectively, and the Ph.D. de-

gree in electrical engineering from the University of

Melbourne, Melbourne, Vic., Australia, in 1992.

Since 2000, he has been with the City University

of Hong Kong, Kowloon, Hong Kong, where he is

currently a Chair Professor and an Associate Provost.

During 19921999, he was a Lecturer/Senior Lec-

turer with the School of Electrical Engineering, Uni-

versity of New South Wales, Sydney, N.S.W., Australia. He was an Associate

Editor of the Journal of Control Theory and Applications. He is an Associate

Editor of Mechatronics. His current research interests include piecewise linear

systems, robot networks, and intelligent systems and control.

Prof. Feng received an Alexander von Humboldt Fellowship during 1997

1998 and the IEEE TRANSACTIONS ON FUZZY SYSTEMS Outstanding Paper

Award in 2007. He was an Associate Editor of the IEEE TRANSACTIONS ON

SYSTEMS, MAN, AND CYBERNETICS, PART C and was a member of the Confer-

ence Editorial Board of the IEEE Control Systems Society. He is an Associate

Editor of the IEEE TRANSACTIONS ON AUTOMATIC CONTROL and the IEEE

TRANSACTIONS ON FUZZY SYSTEMS.

Anda mungkin juga menyukai

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- CSAT - Logical Reasoning - Analytical Ability (Shashidthakur23.wordpress - Com) PDFDokumen99 halamanCSAT - Logical Reasoning - Analytical Ability (Shashidthakur23.wordpress - Com) PDF9999igiBelum ada peringkat

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (895)

- Key Hindrances To Good Governance - General Knowledge TodayDokumen2 halamanKey Hindrances To Good Governance - General Knowledge Today9999igi100% (1)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- Agriculture India Year Book 2015Dokumen6 halamanAgriculture India Year Book 2015misfitmedicoBelum ada peringkat

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (399)

- 5 Months Study Plan For Prelims 2017 - UnacademyDokumen5 halaman5 Months Study Plan For Prelims 2017 - Unacademy9999igiBelum ada peringkat

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (266)

- KEY1910EDokumen8 halamanKEY1910EAvinash YadavBelum ada peringkat

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- Climate Violence - EJ AtlasDokumen2 halamanClimate Violence - EJ Atlas9999igiBelum ada peringkat

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- Current Analyst June 2017 IDokumen97 halamanCurrent Analyst June 2017 I9999igiBelum ada peringkat

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- Page Charge Questionnaire: Transactions On Plasma ScienceDokumen2 halamanPage Charge Questionnaire: Transactions On Plasma Science9999igiBelum ada peringkat

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (588)

- Issue Based Questions and AnswersDokumen2 halamanIssue Based Questions and Answers9999igiBelum ada peringkat

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- Jemaa 2013012317203852Dokumen4 halamanJemaa 20130123172038529999igiBelum ada peringkat

- Census 2011 Gender CompositionDokumen20 halamanCensus 2011 Gender CompositiongnanasambathBelum ada peringkat

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- Government of India's Resolution Setting Up The Planning CommissionDokumen4 halamanGovernment of India's Resolution Setting Up The Planning Commissionvivek kumar singhBelum ada peringkat

- UPSC: Civil Services (M) Exam Final Result 2011Dokumen20 halamanUPSC: Civil Services (M) Exam Final Result 2011TrcStaffBelum ada peringkat

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2259)

- THZ Imager SpecsDokumen1 halamanTHZ Imager Specs9999igiBelum ada peringkat

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (73)

- 1204 0966Dokumen4 halaman1204 09669999igiBelum ada peringkat

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (344)

- Bridge For The Terahertz GapDokumen2 halamanBridge For The Terahertz Gap9999igiBelum ada peringkat

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- Quinstar 2009 CatalogDokumen216 halamanQuinstar 2009 Catalog9999igiBelum ada peringkat

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- DFT TablesDokumen6 halamanDFT TablesgalaxystarBelum ada peringkat

- Hyperbolic Metamaterials: Nonlocal Response Regularizes Broadband Super-SingularityDokumen5 halamanHyperbolic Metamaterials: Nonlocal Response Regularizes Broadband Super-Singularity9999igiBelum ada peringkat

- Maurice Nicoll The Mark PDFDokumen4 halamanMaurice Nicoll The Mark PDFErwin KroonBelum ada peringkat

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- Tabla de Transformadas de FourierDokumen5 halamanTabla de Transformadas de FourierIvan MorenoBelum ada peringkat