Alcolyzer Beer Analyzing System

Diunggah oleh

Andrés MárquezHak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Alcolyzer Beer Analyzing System

Diunggah oleh

Andrés MárquezHak Cipta:

Format Tersedia

Alcolyzer

Beer Analyzing System

::: Unique Density & Concentration Meters

Highly Accurate Results for all Beers

The Alcolyzer Beer Analyzing System is the successor of the Alcolyzer Plus Beer Analyzing System. It consists of an Alcolyzer Beer ME module, DMA M density meter and Xsample 122 sample changer or Xsample 22 filling unit. The system measures all types of beers, including non-alcoholic beers, beer mixtures, RTD (ready to drink) alcoholic beverages, fermenting beers, and also cider and molasses (bioethanol). The patented near infrared (NIR) measuring method (US 6,690,015, AT 406711) of the Alcolyzer Beer ME module eliminates the influence of other sample ingredients on the alcohol measurement, therefore guaranteeing highly accurate results. The Xsample 122 sample changer automatically fills up to 24 samples into the measuring system. For routine work, the DMA 4500 M density meter is the right choice. DMA 5000 M is suitable for research work due to its even higher accuracy. The whole system is operated via a touchscreen on the DMA M master instrument.*

One Sample - All Parameters

The Alcolyzer Beer Analyzing System determines the alcohol content, and further parameters such as density, original extract, real extract, degree of fermentation, calorie content and optionally also color, viscosity, pH and turbidity - all in one measuring cycle, all from one single sample. The modular concept enables the easiest and most reliable measurements and adjustments. You always have the option to upgrade your system step-by-step by adding all the parameters you need - now and in the future.

Equipped for the future Anton Paar has longstanding experience in the brewing industry and works closely with customers to meet their needs. Teams of researchers are dedicated to improving existing Anton Paar products and developing new ones. This means you will benefit from your Alcolyzer Beer Analyzing System as an innovative and modular product for many years to come.

*DMA density meters developed in cooperation with Labor fr Messtechnik Dr. H. Stabinger GmbH, Graz

Standardized, Accurate and Easy to Use

The heart of the system is the patented, selective alcohol measurement: A narrow, highly alcohol-specific range of the NIR spectrum is evaluated with a specially developed, highly stable high-resolution spectrometer and suitable algorithms. In this particular spectral range the influence of other beer ingredients is so small that Alcolyzer Beer ME obtains extremely accurate alcohol results. Due to its selectivity and linearity, the measuring method only requires adjustment with water and an alcohol/water solution. One single adjustment is valid for all sample types. The time and work required for adjustment is therefore minimal. The measuring method has been checked and approved by MEBAK and corresponds to the EBC and ASBC standards.

User-friendly All Anton Paar's Generation M instruments provide highly reliable measurement combined with state-of-theart features. You can connect USB instruments such as a keyboard, mouse, printer, bar code reader or external touchscreen. The Alcolyzer Beer Analyzing System has a LIMS connection. Data can be exported via a USB flash drive, printer, RS-232 or Ethernet (LAN); reports can be created in common formats such as PDF, TXT and XLS. Each user logs on to a defined user level and documents work steps as required. The special features of DMAM (U-ViewTM, FillingCheckTM) ensure traceable documentation. Sources of error are recognized early.

Everything Under Control

A new generation as the master 4 DMA M as the master instrument 4 Full control: U-View, FillingCheck, ThermoBalanceTM 4 User interface in more than 10 languages including Chinese and Japanese

So easy 4 Fully automatic sample changer 4 Easy adjustment 4 Practically maintenance-free 4 Secure due to different user levels 4 LIMS connection

Everything covered 4 All standards: MEBAK, EBC and ASBC 4 Methods for alcohol measurement when manufacturing bioethanol (molasses) and whisky (wash)

More at any time 4 Color, pH, viscosity and turbidity 4 Bar code reader 4 CO2 and O2 4 Xsample 510 automated package sampler for 18 different glass bottles, PET bottles and cans

Technical Data

Measuring range

Alcohol content Original extract Extract content Density Color (optional) pH (optional) Viscosity (optional) Turbidity (optional)

0 %v/v to 12 %v/v 0 Plato to 30 Plato 0 %w/w to 20 %w/w 0 g/cm3 to 3 g/cm3 0 EBC to 120 EBC 0 pH to 14 pH 0.3 mPa.s to 10.000 mPa.s 0 EBC to 100 EBC

(values up 200 EBC are displayed)

Repeatability s.d.

Alcohol content Original extract Extract content Density Color (optional) pH (optional) Viscosity (optional) Turbidity (optional)

0.01 %v/v 0.03 Plato 0.01 %w/w 0.00001 g/cm3 (DMA 4500 M) 0.000001 g/cm3 (DMA 5000 M) 0.1 EBC 0.02 pH (in the range 3 pH to 7 pH) 0.1 % 0.02 EBC Integrated Peltier thermostat

Temperature control

Temperature control, turbidity

0.01 C Repeatability s.d. in the range -5 C to +40 C

Sample volume

approx. 30 mL degassed sample per measurement

Typical measuring duration per sample

approx. 4 minutes (incl. lling)

Sample throughput

approx. 15 samples per hour

Dimensions (L x W x H)

482 mm x 730 mm x 446 mm (19 in x 28.7 in x 17.6 in)

Weight

35.7 kg (78.7 lbs)

Power supply

AC 100 to 240 V; 50 to 60 Hz; 50 to 80 VA

Interfaces

4 x USB, Ethernet, VGA, CAN, RS-232

Fotos: Croce & Wir

Anton Paar GmbH Anton-Paar-Str. 20 A-8054 Graz Austria - Europe Tel: +43 (0)316 257-0 Fax: +43 (0)316 257-257 E-mail: info@anton-paar.com Web: www.anton-paar.com

Instruments for: Density and concentration measurement Rheometry Viscometry Sample preparation Microwave synthesis Colloid science X-ray structure analysis Refractometry Polarimetry Petroleum testing High-precision temperature measurement Specifications subject to change without notice 01/13 C83IP001EN-C

Anda mungkin juga menyukai

- CarboQC, CboxQC, OxyQC Lab and At-Line BrochureDokumen16 halamanCarboQC, CboxQC, OxyQC Lab and At-Line BrochureRégis OngolloBelum ada peringkat

- Densimetro Digital Portatil DMA 35Dokumen4 halamanDensimetro Digital Portatil DMA 35dguerrero696Belum ada peringkat

- Catalogo L Dens 4X7Dokumen8 halamanCatalogo L Dens 4X7Xavier ArévaloBelum ada peringkat

- All in One Solution For BeerDokumen7 halamanAll in One Solution For BeerTank Top 2Belum ada peringkat

- Pcd03 ManualDokumen44 halamanPcd03 ManualLeidy Diana Cifuentes AriasBelum ada peringkat

- AquaLabSeries3 3TEDokumen112 halamanAquaLabSeries3 3TEstinoskiBelum ada peringkat

- Cleaning Recommendations For Dma 35Dokumen2 halamanCleaning Recommendations For Dma 35Rafael ArreguiBelum ada peringkat

- Anton Paar 620Dokumen70 halamanAnton Paar 620Veronica VertucciBelum ada peringkat

- Datos TecnicosDokumen2 halamanDatos TecnicosCeleynes RTBelum ada peringkat

- CTD 450 Service ManualDokumen38 halamanCTD 450 Service ManualDiego BouBelum ada peringkat

- Datacolor 650-600-400 Users Guide 4230-0395M Rev1 PDFDokumen54 halamanDatacolor 650-600-400 Users Guide 4230-0395M Rev1 PDFAlex Juarez Castillo100% (2)

- Vol 4ge Version 3 0x B64is79 DDokumen32 halamanVol 4ge Version 3 0x B64is79 DSylwia MaciakBelum ada peringkat

- XPAIB006EN I RefGuide InstrSW WebDokumen41 halamanXPAIB006EN I RefGuide InstrSW WebXavier ArévaloBelum ada peringkat

- C73IB001EN U OT ROT RefGuideDokumen93 halamanC73IB001EN U OT ROT RefGuideJosemiguel FernandezBelum ada peringkat

- B43ib20c e Cobrix3 ServicebookDokumen90 halamanB43ib20c e Cobrix3 Servicebookfrank02130% (1)

- Density Meter ManualDokumen152 halamanDensity Meter ManualJoyce Marian BelonguelBelum ada peringkat

- DLC32 Wiring ManualDokumen14 halamanDLC32 Wiring ManualPaulo F CunhaBelum ada peringkat

- Density Meter ManualDokumen152 halamanDensity Meter ManualyogiBelum ada peringkat

- Microwave Digestion System With Pressurized Digestion CavityDokumen5 halamanMicrowave Digestion System With Pressurized Digestion CavityTank TopBelum ada peringkat

- L-Sonic Sound Velocity SensorsDokumen21 halamanL-Sonic Sound Velocity Sensorsping dengBelum ada peringkat

- Litesizer 500 Instruction ManualDokumen66 halamanLitesizer 500 Instruction ManualWilson OyolaBelum ada peringkat

- Stabinger Viscometer:::: Viscometry at Its BestDokumen8 halamanStabinger Viscometer:::: Viscometry at Its BestMohamed Mosbah0% (1)

- Multiwave PRO Microwave Reaction System BrochureDokumen16 halamanMultiwave PRO Microwave Reaction System BrochureMuchlas AkbarBelum ada peringkat

- Abbemat 350/550: Measure What Is Measurable and Make Measurable That Which Is NotDokumen42 halamanAbbemat 350/550: Measure What Is Measurable and Make Measurable That Which Is NotXavier Arévalo100% (2)

- Aco-8 Maintainace Manual 1.02Dokumen45 halamanAco-8 Maintainace Manual 1.02Farouq ShakerBelum ada peringkat

- Acessorios FTIRDokumen52 halamanAcessorios FTIRanagabriela12Belum ada peringkat

- Alcolyzer Plus Beer Reference ManualDokumen131 halamanAlcolyzer Plus Beer Reference ManualThanh Nguyen Van DangBelum ada peringkat

- Anton Paar Manual PDFDokumen34 halamanAnton Paar Manual PDFSadegh SoltaniBelum ada peringkat

- User Guide PDFDokumen113 halamanUser Guide PDFHanaBelum ada peringkat

- DPRN 427S (I) & DSRN 427S: Instruction ManualDokumen73 halamanDPRN 427S (I) & DSRN 427S: Instruction ManualMBOBelum ada peringkat

- Xdlie041en K PDL Dma M ScuDokumen23 halamanXdlie041en K PDL Dma M ScuMauricio CruzBelum ada peringkat

- Interfacial Tension of Oil Against Water by The Ring Method: Standard Test Method ForDokumen3 halamanInterfacial Tension of Oil Against Water by The Ring Method: Standard Test Method ForShaker QaidiBelum ada peringkat

- Anton Paar MCRDokumen12 halamanAnton Paar MCRIvona IvkovicBelum ada peringkat

- B47ib34e e Carbo2100 TransducerDokumen40 halamanB47ib34e e Carbo2100 Transducerhailatey100% (1)

- Anton-Paar - Multiwave ProDokumen14 halamanAnton-Paar - Multiwave ProKhổngMinhBelum ada peringkat

- Guide To Set Up RheometerDokumen7 halamanGuide To Set Up RheometerMattia RosaBelum ada peringkat

- CO2 VolumesDokumen14 halamanCO2 VolumesACBBelum ada peringkat

- SpectrophotometerDokumen46 halamanSpectrophotometerSivakumar KBelum ada peringkat

- Agilent (2010) Maintaining Your Agilent GC and GC-MS Systems - CatalogueDokumen172 halamanAgilent (2010) Maintaining Your Agilent GC and GC-MS Systems - Catalogueruirui_ahsamBelum ada peringkat

- VLB Labotech Delivery Programme enDokumen78 halamanVLB Labotech Delivery Programme enbajricaBelum ada peringkat

- Bruker Tensor Ftir InstructionsDokumen47 halamanBruker Tensor Ftir InstructionsJorge Luis VazquezBelum ada peringkat

- SVM 300Dokumen8 halamanSVM 300Abe KobBelum ada peringkat

- Automated ELISA System: Operator's ManualDokumen88 halamanAutomated ELISA System: Operator's ManualAbdalazeez AlsayedBelum ada peringkat

- Knit 4Dokumen124 halamanKnit 4adnanBelum ada peringkat

- Biohit M-Line Service Manual, Version3Dokumen42 halamanBiohit M-Line Service Manual, Version3Marko Ivanda100% (1)

- Color Fastness M228B&C Rotawash Manual (Rev1.1)Dokumen22 halamanColor Fastness M228B&C Rotawash Manual (Rev1.1)sayeed hossenBelum ada peringkat

- Expertise in Process Analytics: Product Name Process SensorsDokumen17 halamanExpertise in Process Analytics: Product Name Process SensorsSuresh KumarBelum ada peringkat

- Ben ColourDokumen12 halamanBen ColourAnonymous 0CnvpxSBelum ada peringkat

- Xpsib005en G Refguide Lims BridgeDokumen25 halamanXpsib005en G Refguide Lims BridgeAhmad AbunassarBelum ada peringkat

- Pure FinishDokumen4 halamanPure FinishJubaidurRahmanBelum ada peringkat

- Take Up Factor - FEFCO 102Dokumen2 halamanTake Up Factor - FEFCO 102shere kowiraBelum ada peringkat

- LCH Brew Brochure PDFDokumen28 halamanLCH Brew Brochure PDFvansangfBelum ada peringkat

- Carbo 520 Optical - BrochureDokumen8 halamanCarbo 520 Optical - BrochureAndrés MárquezBelum ada peringkat

- From Basic To Advanced, The OHAUS MB Series Offers Superior Performance and Great ValueDokumen4 halamanFrom Basic To Advanced, The OHAUS MB Series Offers Superior Performance and Great ValuefajarBelum ada peringkat

- Especificaciones Tecnicas - DIST-984 - SPEC PDFDokumen1 halamanEspecificaciones Tecnicas - DIST-984 - SPEC PDFCarlos MatallanaBelum ada peringkat

- Endress-Hauser Liquiline System CA80AL ENDokumen4 halamanEndress-Hauser Liquiline System CA80AL ENandreBelum ada peringkat

- Refractometers - CatalogDokumen5 halamanRefractometers - Catalogdéborah_rosalesBelum ada peringkat

- GC 7800 Gas Chromatograph With AutosamplerDokumen5 halamanGC 7800 Gas Chromatograph With Autosamplerqualityc711Belum ada peringkat

- Mettler Toledo C20-C30 Coulometric Titrator DatasheetDokumen2 halamanMettler Toledo C20-C30 Coulometric Titrator DatasheethuckschweehotmailcomBelum ada peringkat

- Product Line Review: Oakton 700Dokumen8 halamanProduct Line Review: Oakton 700Jorge David Rojas CardenasBelum ada peringkat

- BUCHI Original-Glassware LowDokumen42 halamanBUCHI Original-Glassware LowAndrés MárquezBelum ada peringkat

- Multivapor Solvent List 0Dokumen2 halamanMultivapor Solvent List 0Andrés MárquezBelum ada peringkat

- Multivapor en 1101Dokumen8 halamanMultivapor en 1101Andrés MárquezBelum ada peringkat

- Multivapor Adapder Guide Since April 2011Dokumen4 halamanMultivapor Adapder Guide Since April 2011Andrés MárquezBelum ada peringkat

- Sample Preparation, Gas Chromatography-Mass Spectrometry, and Data AnalysisDokumen2 halamanSample Preparation, Gas Chromatography-Mass Spectrometry, and Data AnalysisAndrés MárquezBelum ada peringkat

- HPLC Sample Prep Workflow Automated Evaporation WP71175 enDokumen7 halamanHPLC Sample Prep Workflow Automated Evaporation WP71175 enAndrés MárquezBelum ada peringkat

- BR Rocket Evaporator BR70315 EDokumen8 halamanBR Rocket Evaporator BR70315 EAndrés MárquezBelum ada peringkat

- 44 171792BRO - Altus HPLC 012040 - 01Dokumen8 halaman44 171792BRO - Altus HPLC 012040 - 01Andrés MárquezBelum ada peringkat

- AP Instruments RheolabQCDokumen6 halamanAP Instruments RheolabQCAndrés MárquezBelum ada peringkat

- Carbo 520 Optical - BrochureDokumen8 halamanCarbo 520 Optical - BrochureAndrés MárquezBelum ada peringkat

- K-425 K-436 Data Sheet en C 0Dokumen7 halamanK-425 K-436 Data Sheet en C 0Andrés MárquezBelum ada peringkat

- APP FAMEbyGCinB100BiodieselDokumen4 halamanAPP FAMEbyGCinB100BiodieselAndrés MárquezBelum ada peringkat

- APP FAMEbyGCinB100BiodieselDokumen4 halamanAPP FAMEbyGCinB100BiodieselAndrés MárquezBelum ada peringkat

- 44-74432BRO DSCFamilyBrochureDokumen14 halaman44-74432BRO DSCFamilyBrochureAndrés MárquezBelum ada peringkat

- Barley MuleDokumen77 halamanBarley MuleHaile KebedeBelum ada peringkat

- Sierra Nevada Pale Ale CloneDokumen2 halamanSierra Nevada Pale Ale Cloneantonio alberto gutierrez suarezBelum ada peringkat

- Mapping of Spent Brewers Grain Supplychain in Eth-Wageningen University and Research 506451Dokumen28 halamanMapping of Spent Brewers Grain Supplychain in Eth-Wageningen University and Research 506451zemedkunAklewegBelum ada peringkat

- Training Course - Part 1: by Heru Setiawan The Edge, 17 May 2012Dokumen77 halamanTraining Course - Part 1: by Heru Setiawan The Edge, 17 May 2012Roopak AgrawalBelum ada peringkat

- Sweetwater Tavern's MenuDokumen4 halamanSweetwater Tavern's Menuchrisban35Belum ada peringkat

- Pellettieri, Mary - Quality Management - Essential Planning For Breweries-Brewers Publications (2015)Dokumen196 halamanPellettieri, Mary - Quality Management - Essential Planning For Breweries-Brewers Publications (2015)Gonzalo Benavides67% (3)

- Greyhogg's Guide To Grog Craft Brewing & RevelryDokumen18 halamanGreyhogg's Guide To Grog Craft Brewing & RevelryxyzBelum ada peringkat

- MUMBAI Alcohol RatesDokumen6 halamanMUMBAI Alcohol RatesStephen Sequeira0% (1)

- MRP List - 01-10-2019 Beer PDFDokumen3 halamanMRP List - 01-10-2019 Beer PDFSagari Nallagopula0% (1)

- Analytica-Microbiologica-EBC 05 Neu PDFDokumen291 halamanAnalytica-Microbiologica-EBC 05 Neu PDFFousseyni TRAORE100% (2)

- Portable Co2 O2 Tpo Meter C DGM Haffmans Leaflet v2048 enDokumen2 halamanPortable Co2 O2 Tpo Meter C DGM Haffmans Leaflet v2048 entayachewendayehuBelum ada peringkat

- US Caramel in Brewing-WebDokumen2 halamanUS Caramel in Brewing-WebSolcan Mircea100% (1)

- Beer BusterDokumen20 halamanBeer Busteramksingh69Belum ada peringkat

- Business Analysis - MTHR BreweryDokumen13 halamanBusiness Analysis - MTHR Brewerydimitris_tsagkosBelum ada peringkat

- Principles of Marketing Act 3Dokumen8 halamanPrinciples of Marketing Act 3kazmer haranyiBelum ada peringkat

- NOISE & COLOR: Volume 1 Issue 2Dokumen23 halamanNOISE & COLOR: Volume 1 Issue 2James Dean HickmanBelum ada peringkat

- Palmers Water Adj Liters 4pt0Dokumen5 halamanPalmers Water Adj Liters 4pt0steve_milenBelum ada peringkat

- 0-1 M Alcoholic Beverages - Drinks - CaliforniaDokumen346 halaman0-1 M Alcoholic Beverages - Drinks - CaliforniaPon KamaleshBelum ada peringkat

- I.H.M, Kolkata: B. SC (H & H.A) BHM 202 F&B (S) Operations 2021-2022 Fermented Beverage - Beer Page 1 of 14Dokumen15 halamanI.H.M, Kolkata: B. SC (H & H.A) BHM 202 F&B (S) Operations 2021-2022 Fermented Beverage - Beer Page 1 of 14Souvik SenBelum ada peringkat

- Beer Priming Sugar Calculator: Brew Your Best Beer EVER. Save 10% On Brewer's Friend Premium Today. Use Code TAKE10Dokumen5 halamanBeer Priming Sugar Calculator: Brew Your Best Beer EVER. Save 10% On Brewer's Friend Premium Today. Use Code TAKE10Carlos CrisostomoBelum ada peringkat

- HeinekenDokumen4 halamanHeinekenIonuţ Tudor UrdéşBelum ada peringkat

- Marketing Mix of CarlsbergDokumen9 halamanMarketing Mix of CarlsbergPraveen MechBelum ada peringkat

- Obatzda Recipe (German Beer Cheese Dip)Dokumen5 halamanObatzda Recipe (German Beer Cheese Dip)muroslavBelum ada peringkat

- BrewZilla 65L - Instruction ManualDokumen30 halamanBrewZilla 65L - Instruction ManualWladimir EncaladaBelum ada peringkat

- LECO Approved MethodologiesDokumen5 halamanLECO Approved MethodologiesAntony ThanosBelum ada peringkat

- Brewing Industry SWOT AnalysisDokumen3 halamanBrewing Industry SWOT Analysisno1remfan78% (9)

- Top 25 Breweries - Twin Cities Business - B.I.GDokumen3 halamanTop 25 Breweries - Twin Cities Business - B.I.GoofterBelum ada peringkat

- Asia Brewery Inc vs. CADokumen2 halamanAsia Brewery Inc vs. CAjaymcapinpinBelum ada peringkat

- The Science of Drinking - How Alcohol Affects Your Body and Mind PDFDokumen277 halamanThe Science of Drinking - How Alcohol Affects Your Body and Mind PDFSanjeev Choudhary100% (1)

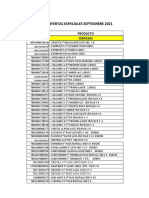

- Ofertas Bebidas, Licores y Snacks SeptiembreDokumen18 halamanOfertas Bebidas, Licores y Snacks SeptiembreHans Henry SeguelBelum ada peringkat