KSB Valvula Diafragma SISTO10

Diunggah oleh

Sarah PerezDeskripsi Asli:

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

KSB Valvula Diafragma SISTO10

Diunggah oleh

Sarah PerezHak Cipta:

Format Tersedia

type series booklet 8641.

1/13-10

- 10

Maintenance-free Diaphragm valves lined and unlined

PN 10 DN 15 - 300

flanged

Fields of application

chemical an industrial process engineering general industries power plants Suitable for water, air, oil as well as abrasive and aggressive media.

Materials

Body Bonnet Compressor Stem Diaphragm Handwheel grey cast iron grey cast iron grey cast iron zinc alloy stainless steel JL-1040 GJL-250 JL-1040 GJL-250 JL-1040 GJL-250 GD-ZnAl4Cu1 2.2141 X12CrMoS17 1.4104 EPDM +140C

Operating data

- operating temperature range from -10C up to +160C - operating pressure range from vacuum up to 10 bar

cast iron/plastic JL-1030/ABS

Variants

Body nodular cast iron JS-1049 stainless steel NR-H IIR ECTFE IIR NBR CSM GJS-400-18U-LT Ebonite Butyl Halar -20C -20C +100C +120C +90C +120C +90C +100C +160C G-X6CrNiMo1810 1.4408

Design

Soft sealing valve, weir type. Sealing in the passage and towards the outside by a diaphragm with a supporting spiral spring (starting with DN 065). Position indicator with integrated stem protection.

Body Lining Body Coating Diaphragm Material

Specification

valve flange - manufactured and tested EN 13397 - designated DIN/EN 19 (ISO 5209) - dimensions - surface

PTFE/EPDM 2layer

face-to-face length On all inquiries / orders please specify - flange EN 558-1 R1 (ISO 5752/1) 1 - type 7 - medium 2 - PN 8 - pipe connection Inspection 3 DN 9 - variants certificate - material EN 10204 2.2 4 - working pressure 10 - certificate EN 10204 3.1 5 - differential pressure 11 - type series booklet -number - final inspection EN 10204 3.1 6 - operating temperature

SISTO valves comply with the safety requirements of the Pressure Equipment Directive 97/23/EG, fluid group 1+2, modul H. SISTO valves have no own potential ignition source and can therefore, according to ATEX 94/9/EG, be used in hazardous locations of the group II, category 2 (zone 1+21) and category 3 (zone 2 +22)

Bonnet nodular cast iron JS-1049 GJS-400-18U-LT DIN EN 1092-2 (BS 4504) These data are given as a guide only and do not apply to DIN EN 1092-2 Form B all operating conditions.

- 10

design DN 015-020

design DN 025-050

design PTFE-diaphragm

Item no. Designation 100 body

Material

JL-1040 JL-1040 1.4104 EPDM EPDM PTFE A2 (1.4301) PTFE/graphite JL-1040 St A2E ABS Luran ABS Luran A2 A2 9S20K A2 A2 St 2K BK JL-1030 data sheet

Note

standard, DN 200 - 300 JS-1025 standard standard on DN 025 - 300 on DN 025 - 300 GD-ZnAlCu1 on DN 015 - 020 on DN 025 - 300 on DN 015 - 065 on DN 080 - 300 on DN 025 - 300 on DN 025 - 300 on DN 080 - 300 on DN 065 - 300 on DN 015 - 020 ABS Luran 0570.821 8630.165

165 bonnet 200 stem 443* diaphragm 443.1* backing diaphragm 443.2* diaphragm 550.1 bearing disc 550.2 disc 553 compressor 554 disc 621.1 upper opening indicator 621.2 lower opening indicator 901 hexagon screw 902 stud 920.1 nut 920.2 hexagon nut 920.3 hexagon nut 951 support spiral spring 961 handwheel *recommended spare part Operating instructions material limitations

- 10

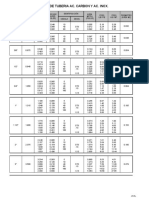

flow values DN 015 020 025 032 040 050 Kv-value DN m/h 5,0 7,9 12,0 19,0 30,0 55,0 87,0 080 100 125 150 200 250 300 Kv-value m/h 126 216 311 414 1120 -

max. permissible operating pressure 10 8 pressure bar 6 4 2

-40

-20

+20

+40

+60

+80

+100

+120

+140

+160

065

temperature C There is no need to reduce the max. permissible operating pressure in relation to temperature and valve size. The temperature limit is determined by the applied material.

stroke

h1

D MD

nominal size DN 015* 020* 025 032 040 050 065 080 100 125 150 200 250 300

diaphragm face-to-face flange valve stroke height handwheel handwheel MD length diameter turns l D stroke h* d approx. AxB 58 x 62 130 95 8 108 63 3 58 x 62 150 105 8 108 63 3 68 x 72 160 115 11 140 100 4 90 x 100 180 140 18 165 100 6 90 x 100 200 150 18 165 100 6 107 x 124 230 165 26 200 125 7 132 x 144 290 185 34 245 200 9 157 x 187 310 200 40 265 200 10 226 350 220 56 340 200 11 258 400 250 72 405 250 15 303 480 285 81 450 400 14 415 600 340 115 595 400 20 415 730 395 115 645 400 20 415 850 445 115 645 400 20

manual valves

weight height kg h1* 2,5 213 3,0 213 4,0 217 5,5 227 8,0 227 11,5 242 19 312 25 320 39 363 53 395 78 485 162 550 190 600 210 600

actuated valves

actuator flanges F10

F10/F14

*diaphragm valves in material 1.4408 with diaphragm dimension 68 x 72 SISTOMAT-P SISTOMAT-E, MTAE/LAE SISTOMAT-PC type series booklet 9210.1 on request type series booklet 8641.1PC all dimensions in mm *with rubber lining add. 5 mm

- 10

all moving parts are seperated from the medium by the diaphragm

thrust bearing reduces the required closing torques diaphragm support (DN 065 - 300) increases the reliability during the operation, the service life and the pressure limit of the diaphragm

opening indicator with integrated stem protection increases the reliability of operation balanced diaphragm suspension increases life time of the diaphragm

no entrapment areas only diaphragm and body are in contact with the medium

body on request - without lining - with rubber lining - with plastic coating

8641.1/13-10 / 08.07.2010

Manufacturing Company SISTO Armaturen S.A.

Zone Industrielle L-6468 Echternach

Tel.:+352 - 32 50 85-1 Fax:+352 - 32 89 56

This document is not contractual and may be amended without notice.

Anda mungkin juga menyukai

- Designing anchor reinforcement for seismic shear loadsDokumen38 halamanDesigning anchor reinforcement for seismic shear loadsSarah Perez100% (1)

- Rigid PavementDokumen100 halamanRigid PavementJAY GANDHI100% (1)

- Business Analyst TrainingDokumen3 halamanBusiness Analyst TrainingMuniswamaiah Mohan100% (1)

- Anneaux Levage CATDokumen13 halamanAnneaux Levage CATA100% (1)

- Autodesk Educational Product DocumentDokumen1 halamanAutodesk Educational Product DocumentEdduardo BadilloBelum ada peringkat

- WPS PQR CompressedDokumen5 halamanWPS PQR CompressedBalaje MantravadiBelum ada peringkat

- Tabla de EquivalenciasDokumen1 halamanTabla de EquivalenciasyamilmrBelum ada peringkat

- 2015 WestwardDokumen16 halaman2015 WestwardmngopherBelum ada peringkat

- AdvancesDokumen328 halamanAdvanceshanumsj123Belum ada peringkat

- What Is Rack Chock SystemDokumen7 halamanWhat Is Rack Chock SystemSarah Perez100% (1)

- Sihi lph75000Dokumen10 halamanSihi lph75000Hernando SalamancaBelum ada peringkat

- Science8 Q2 Module3 (Week6)Dokumen30 halamanScience8 Q2 Module3 (Week6)Mary Grace Lemon100% (1)

- Pipeline Profile Import From AutocadDokumen15 halamanPipeline Profile Import From AutocadSarah PerezBelum ada peringkat

- BHEL Turbine ManualDokumen58 halamanBHEL Turbine Manualnivasssv75% (4)

- Thermo Fisher Scientif 5201 - D20700Dokumen63 halamanThermo Fisher Scientif 5201 - D20700Daniel ArmasBelum ada peringkat

- Ultra Fine Grinding - A Practical Alternative To OxidativeDokumen21 halamanUltra Fine Grinding - A Practical Alternative To OxidativeSarah PerezBelum ada peringkat

- HAVER & BOECKER NIAGARA Vibrating Screen Exciter ModelsDokumen5 halamanHAVER & BOECKER NIAGARA Vibrating Screen Exciter ModelsAliBelum ada peringkat

- Itc Te210eDokumen2 halamanItc Te210ezliang100% (2)

- Galigher 100-2100 SeriesDokumen10 halamanGaligher 100-2100 SeriesSarah Perez100% (1)

- Galigher 100-2100 SeriesDokumen10 halamanGaligher 100-2100 SeriesSarah Perez100% (1)

- Durco 1K 1.5 X 1-82Dokumen9 halamanDurco 1K 1.5 X 1-82jame11inBelum ada peringkat

- Coordinated Interference Management (Low-Frequency TDD) (5G RAN6.1 - Draft A)Dokumen28 halamanCoordinated Interference Management (Low-Frequency TDD) (5G RAN6.1 - Draft A)VVLBelum ada peringkat

- Dome Valve BrochureDokumen8 halamanDome Valve Brochureitang100% (1)

- Medidas y Pesos de CañeriasDokumen2 halamanMedidas y Pesos de Cañeriasmaguirreville100% (1)

- Manual de Tuerca Hidraulica-Desbloqueado-editadoDokumen37 halamanManual de Tuerca Hidraulica-Desbloqueado-editadomauriciojjBelum ada peringkat

- Timken Conicos Catalogo GeralDokumen826 halamanTimken Conicos Catalogo Geralninologin22Belum ada peringkat

- L-1850-2078 PARTS MANUAL Tool GroupDokumen1 halamanL-1850-2078 PARTS MANUAL Tool GroupMarcel BaqueBelum ada peringkat

- C50L Huck BoltDokumen8 halamanC50L Huck BoltEduardo Granados SánchezBelum ada peringkat

- Tabla de Pesos de Tuberia Ac. Carbon Y Ac. InoxDokumen24 halamanTabla de Pesos de Tuberia Ac. Carbon Y Ac. InoxEnrique Barajas100% (2)

- Rockwool Rti-Prorox-Sl-980 - ExpDokumen1 halamanRockwool Rti-Prorox-Sl-980 - Expdedy setiawanBelum ada peringkat

- Norma AISIDokumen21 halamanNorma AISImaria elena castañedaBelum ada peringkat

- Falk Reductor Paralelo CatalogoDokumen118 halamanFalk Reductor Paralelo CatalogoHenry DelgadoBelum ada peringkat

- Starrett 3811ADokumen24 halamanStarrett 3811Acdokep100% (1)

- Nano Ceramic Lubricating GreaseDokumen1 halamanNano Ceramic Lubricating Greasemans2014Belum ada peringkat

- TurningDokumen64 halamanTurningSerhat DoğandemirBelum ada peringkat

- Mi Ether CatalogDokumen76 halamanMi Ether CatalogcirclelineBelum ada peringkat

- Acoples CouplingsDokumen13 halamanAcoples Couplingspablo coroBelum ada peringkat

- BZC 14Dokumen1 halamanBZC 14jkhgvdj mnhsnjkhgBelum ada peringkat

- TruPunch 1000 Prime Edition Technical DataDokumen3 halamanTruPunch 1000 Prime Edition Technical DataNachoLarreaBelum ada peringkat

- BRIDASDokumen1 halamanBRIDASLuis CarlosBelum ada peringkat

- Henfel Bearing Housing Technical InformationDokumen52 halamanHenfel Bearing Housing Technical Informationkrlos_SW2009Belum ada peringkat

- Data Sheets FajasDokumen12 halamanData Sheets FajasGonzalo Rosales JuarezBelum ada peringkat

- Ficha Técnica Eli-FlexDokumen2 halamanFicha Técnica Eli-FlexGhislaine SousaBelum ada peringkat

- Especificaciones Valvula Well MarkDokumen4 halamanEspecificaciones Valvula Well Markmiguel mendozaBelum ada peringkat

- Diseño de Maquinas - Estabilidad 2Dokumen451 halamanDiseño de Maquinas - Estabilidad 2Rodrii RoblesBelum ada peringkat

- Driven End Driving End: HF20 Gear Coupling Mount (With Delay Fill Chamber)Dokumen1 halamanDriven End Driving End: HF20 Gear Coupling Mount (With Delay Fill Chamber)war machineBelum ada peringkat

- 14 MPT San Ei Winch CatalogDokumen48 halaman14 MPT San Ei Winch Catalogtiensy buiBelum ada peringkat

- Equivalencias Balero Autolineable de RodillosDokumen26 halamanEquivalencias Balero Autolineable de RodillosAlfred Hernandez MendozaBelum ada peringkat

- Erapol EHP95ADokumen2 halamanErapol EHP95AMohammad Doost MohammadiBelum ada peringkat

- DownloadDokumen20 halamanDownloadkeyur1109Belum ada peringkat

- Rovalve PDFDokumen4 halamanRovalve PDFWilliam ValenciaBelum ada peringkat

- Nucleotec 2222Dokumen2 halamanNucleotec 2222Marco MorenoBelum ada peringkat

- Eaton AirflexDokumen12 halamanEaton AirflexagusBelum ada peringkat

- Supresor de PolvoDokumen10 halamanSupresor de Polvoluisgalvez60Belum ada peringkat

- Bomba NT-2 Ou NT-3...Dokumen3 halamanBomba NT-2 Ou NT-3...Lucas Vinícius CostaBelum ada peringkat

- Ficha Tecnica ArnesDokumen1 halamanFicha Tecnica Arnesalex roBelum ada peringkat

- Intermittent Rail Support Soleplates - GantrexDokumen2 halamanIntermittent Rail Support Soleplates - GantrexErc Nunez VBelum ada peringkat

- Universal Drill & Cutter Grinder: ORDER NO - VDG-32N CODE NO.8001-010Dokumen1 halamanUniversal Drill & Cutter Grinder: ORDER NO - VDG-32N CODE NO.8001-010Cristian Fuentes0% (1)

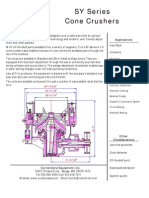

- SY Series Cone CrushersDokumen2 halamanSY Series Cone CrushersOrlando MelipillanBelum ada peringkat

- 110 CFM To 260 CFM QXD - ENDokumen2 halaman110 CFM To 260 CFM QXD - ENJamal HabbasBelum ada peringkat

- Linatex Impact BarDokumen3 halamanLinatex Impact BarNaveenBelum ada peringkat

- Plano de ChancadoraDokumen3 halamanPlano de ChancadoraNilson Cieza Zamora100% (1)

- FalkDokumen8 halamanFalkjmartinezmoBelum ada peringkat

- Socket Head ScrewDokumen12 halamanSocket Head ScrewIgnatiusAbbyBelum ada peringkat

- Kinamatic GEA - 18864 Brochure (GE Catalog)Dokumen6 halamanKinamatic GEA - 18864 Brochure (GE Catalog)Joako TorresBelum ada peringkat

- Msds SC 4000Dokumen9 halamanMsds SC 4000Cristián RojasBelum ada peringkat

- Welding Procedures Package-Gas Line Replacement JobDokumen11 halamanWelding Procedures Package-Gas Line Replacement JobFeroz KhanBelum ada peringkat

- Datasheet Sisto-Kbs Valve - KSBDokumen4 halamanDatasheet Sisto-Kbs Valve - KSBSarah PerezBelum ada peringkat

- Wafer Type Butterfly Valve Z 611-A Wafer Type Butterfly Valve Z 611-ADokumen4 halamanWafer Type Butterfly Valve Z 611-A Wafer Type Butterfly Valve Z 611-ARadu GanciuBelum ada peringkat

- KWP Non-Clogging Centrifugal Pump: Automation Products AvailableDokumen16 halamanKWP Non-Clogging Centrifugal Pump: Automation Products Availablefedeparamos5030100% (1)

- 2Dokumen14 halaman2WormInchBelum ada peringkat

- Valvula Borboleta Lug z411 ADokumen6 halamanValvula Borboleta Lug z411 AWellington S. FrançaBelum ada peringkat

- Butterfly Valve Technical Data SheetDokumen6 halamanButterfly Valve Technical Data SheetMr. ABelum ada peringkat

- Manual: For The Installation of The LineDokumen23 halamanManual: For The Installation of The LineSarah PerezBelum ada peringkat

- Pipe Span ChartDokumen1 halamanPipe Span ChartcoyuncoBelum ada peringkat

- PortaPump Service ManualDokumen5 halamanPortaPump Service ManualSarah PerezBelum ada peringkat

- Brochure Od Insite Ig FluorescenciaDokumen2 halamanBrochure Od Insite Ig FluorescenciaSarah PerezBelum ada peringkat

- Nº 02 - TAG 135 PU 007-008-009 - Modelo 3409 S 6x10-22 - MOTORDokumen11 halamanNº 02 - TAG 135 PU 007-008-009 - Modelo 3409 S 6x10-22 - MOTORSarah PerezBelum ada peringkat

- 9355 40kVA Manual ENG 1025358 Rev D.483Dokumen56 halaman9355 40kVA Manual ENG 1025358 Rev D.483Asim KaleemBelum ada peringkat

- Air Dryer SVC ManDokumen2 halamanAir Dryer SVC ManSarah PerezBelum ada peringkat

- Plan, Foundation 39894472 5: ExhaustDokumen1 halamanPlan, Foundation 39894472 5: ExhaustSarah PerezBelum ada peringkat

- NDP-80 Data SheetDokumen9 halamanNDP-80 Data SheetSarah PerezBelum ada peringkat

- Fotos Helices Mpi, A - 315, y Tk-MixerDokumen1 halamanFotos Helices Mpi, A - 315, y Tk-MixerSarah PerezBelum ada peringkat

- 22kw Motor DataDokumen2 halaman22kw Motor DataSarah PerezBelum ada peringkat

- Half Inch FRL Service ManualDokumen2 halamanHalf Inch FRL Service ManualSarah PerezBelum ada peringkat

- Yamada Corrosion Resistance GuideDokumen48 halamanYamada Corrosion Resistance Guideioan1946Belum ada peringkat

- 130-PU-003 - 004 300 (END SUCTION - REC 1.5x2.5-5 REC)Dokumen1 halaman130-PU-003 - 004 300 (END SUCTION - REC 1.5x2.5-5 REC)Sarah PerezBelum ada peringkat

- VGS Linear Power Drier: Series 29126 "3D" Double Deck DrierDokumen2 halamanVGS Linear Power Drier: Series 29126 "3D" Double Deck DrierSarah PerezBelum ada peringkat

- Brochure Posicionador 6aDokumen0 halamanBrochure Posicionador 6aSarah PerezBelum ada peringkat

- Brochure New 2010Dokumen10 halamanBrochure New 2010Sarah PerezBelum ada peringkat

- Eductor JergusonDokumen12 halamanEductor JergusonSarah PerezBelum ada peringkat

- Datasheet Sisto-Kbs Valve - KSBDokumen4 halamanDatasheet Sisto-Kbs Valve - KSBSarah PerezBelum ada peringkat

- SteelDokumen5 halamanSteelSarah PerezBelum ada peringkat

- Modelo de Prueba Con M20 ISAMILLDokumen13 halamanModelo de Prueba Con M20 ISAMILLSarah PerezBelum ada peringkat

- Neptuno Pumps® World Pumps Magazine - August 2012 - Water Management For Copper MiningDokumen4 halamanNeptuno Pumps® World Pumps Magazine - August 2012 - Water Management For Copper MiningSarah Perez100% (1)

- SMB Determination Help PDFDokumen100 halamanSMB Determination Help PDFSarah Perez100% (1)

- Flow Chart SymbolsDokumen7 halamanFlow Chart SymbolsAbhishekBelum ada peringkat

- CFA Level II 3 Topics - High Yield List of QuestionsDokumen4 halamanCFA Level II 3 Topics - High Yield List of QuestionsCatalinBelum ada peringkat

- Inductive Proximity Sensors: Brett Anderson ECE 5230 Assignment #1Dokumen27 halamanInductive Proximity Sensors: Brett Anderson ECE 5230 Assignment #1Rodz Gier JrBelum ada peringkat

- Math Tutoring Announcement for 4th Year Literary StudentsDokumen5 halamanMath Tutoring Announcement for 4th Year Literary Studentsabed azzamBelum ada peringkat

- Presentation On Power Grid InertiaDokumen47 halamanPresentation On Power Grid InertiajorjijonBelum ada peringkat

- Timer Counter ArduinoDokumen8 halamanTimer Counter ArduinoKietDangBelum ada peringkat

- PT32 12Dokumen3 halamanPT32 12sergiuserbanBelum ada peringkat

- Maintenance Recommendations: Operation and Maintenance ManualDokumen10 halamanMaintenance Recommendations: Operation and Maintenance ManualAmy Nur SBelum ada peringkat

- Ee242 Lect06 TwoportsDokumen32 halamanEe242 Lect06 TwoportsZyad IskandarBelum ada peringkat

- Splunk Skills Assessment-UpdatedDokumen14 halamanSplunk Skills Assessment-Updatedtsegay.csBelum ada peringkat

- Westminster Academy, Islamabad: Physics (0625) Topic Test:Sound WavesDokumen5 halamanWestminster Academy, Islamabad: Physics (0625) Topic Test:Sound Wavessaimee77Belum ada peringkat

- Forrester Roi StudyDokumen30 halamanForrester Roi StudymcgettsBelum ada peringkat

- JACOB ThirdDokumen16 halamanJACOB ThirdWendell ReyesBelum ada peringkat

- Social Media and Loneliness - Why An Instagram Picture May Be Worth More Than A Thousand Twitter WordsDokumen13 halamanSocial Media and Loneliness - Why An Instagram Picture May Be Worth More Than A Thousand Twitter WordsCarlos Leite Filho100% (1)

- BS 2995-1966 PDFDokumen15 halamanBS 2995-1966 PDF윤규섭Belum ada peringkat

- MCB and ELCB PDFDokumen35 halamanMCB and ELCB PDFChris AntoniouBelum ada peringkat

- GSM Modem XM1510S-B00-103 ManualDokumen19 halamanGSM Modem XM1510S-B00-103 ManualPaul MaposaBelum ada peringkat

- Differential Analysis of Fluid FlowDokumen42 halamanDifferential Analysis of Fluid FlowAmr Faisal RaghebBelum ada peringkat

- Multi-Band Booster With HRLB - In-Band Routed DCN Solution GuideDokumen26 halamanMulti-Band Booster With HRLB - In-Band Routed DCN Solution GuideAchintha AluthmanageBelum ada peringkat

- WCS1400 / WCS1400S: FeaturesDokumen7 halamanWCS1400 / WCS1400S: FeaturesbahrowiadiBelum ada peringkat

- Operation & Service Manual For Cable Tensiometer: SeriesDokumen28 halamanOperation & Service Manual For Cable Tensiometer: SeriesJonatan BernalBelum ada peringkat

- Ice o Matic - Cim0436faDokumen2 halamanIce o Matic - Cim0436faJean RamosBelum ada peringkat

- Daikin RXS-K - Technical DataDokumen21 halamanDaikin RXS-K - Technical DataPrestoneKBelum ada peringkat