1935 - 2 - 0202

Diunggah oleh

seafire47Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

1935 - 2 - 0202

Diunggah oleh

seafire47Hak Cipta:

Format Tersedia

i8o

FLIGHT.

AUGUST 15,

1935.

greatest enemies of the parachute is battery acid, the

effects of which are slow-acting but far-reaching. The fabric and harness webbing is not discoloured but may l>e weakened to such an extent as to be readily pulled to pieces with the fingers. Russell parachutes are well known to visitors to aerial "circuses" in this country- It was learned during a recent visit to the makers' factory at Stoke Newington that no fewer than 638 jumps have been made in this country this year. The Russell, incidentally, is used by the Chinese Air Force. For the past three years experiments have been conducted in this country by the Pak Parachute Co., Ltd., whose works are at Mitcham. This company is now offering a range of parachutes of seat, " quick connector " and back types. Henlow tests were successfully completed in the Autumn of 1934. Pak parachutes originated in Czechoslovakia (they are standard equipment in the Air Forces of that country and Finland), but over here they are being made, under patents, from British materials. The Pak model which departs farthest from conventional design is probably the observer's detachable or "quick connector" equipment. This embodies singlepoint connection, the ends of the lift webs terminating in a ,'iingk snaphnok. The silk harness, which may embody a quick release attachment if required, is adjustable to the person. As in other models produced by the company, a "skeleton v e s t " is incorporated. This fits snugly to the body distributing the pressure of the webbing over a large area. It also protects the webbing from wear and prevents possible entanglement. The pack itself also embodies some unusual features. The elastic which assists opening, for instance, is in one piece, and is held in place by a simple leather attachment on the bottom of the pack, doing away with hooks and metal fittings. It will be noted on inspecting a Pak that no silk whatever is visible when the pack is folded. This is due to the fact that special corner flaps are provided at the opening for the lift webs. Another interesting detail refinement is to be found in the pilot 'chute, the spring coils of which are enclosed in a smooth egg-shaped duralumin box.

It will be realised that when the rip cord of a parachute is pulled, escape of the canopy must be instantaneous and infallible. Pak parachutes employ a universal ball-swivel locking cone which receives the rip cord pin. Under no circumstances is it possible for the cone to " sieze " the pin. Either a single rip cord released manually or by a static line or a dual rip cord may be piovided, the latest development being a dual manual rip cord to meet the demand for a release which may be operated by exther hand. There is a possibility, of course, that in war time a hand may sustain injury. One of the latest developments by the company is a duralumin quick release box which may be operated by a twist in either direction. A demonstration of a quick release harness revealed that when the box was operated, the wearer still sat in his harness and did not tumble forward on his face. On raising his hands above his head, however, and exerting himself, he was completely and immediately released. All loads in the quick release box are carried across a nickel chrome steel " s p i d e r " and not through the box itself.

The Back Pak

A back pack, available with either standard T quick release harness, also contains some interesting points. There is an articulated metal frame which is entirely flexible and follows the movements of the wearer when bending forward. Those who have worn a seat pack parachute will appreciate the thoughtfulness of the designers in providing means permitting the seat pack to be hooked up on the back, while the wearer is walking, like a knapsack. Normally the Pak canopy is of 24 ft. diameter. The circumference and vent are strengthened with woven silk tape. Twelve continuous lengths of silk cord form twentyfour rigging lines, each six being secured to one of the four lift webs. Incidentally, the Pak rigging lines are of " tubular weave" without a central core. This makes for elasticity and ensures that there is no possibility of hidden defects.

AIRSCREW BRAKES

HE last few years have seen a definite trend of thought on the part of leading aeronautical engineers toward airscrew brakes on multi-engined machines. Mr. Raymond B. Quick, who is at present an engineering inspector for the American Bureau of Air Commerce, has carried out a very intensive study of propeller brakes, and has taken out a number of lxisic airscrew brake patents. Mr. Quick recently proposed a very simple brake design to the engineers of Sikorsky Aircraft, which resulted in their collaboration in the development and construction of a hydraulic airscrew brake. Such brakes were subsequently tested on the Sikorsky S.42, and recently place*! in service on that machine by Pan American Airways. This is thought to be the first time that airscrew brakes have been used in a commercial operation in this country. The entire brake installation on the Sikorsky .42, involving four propellers, weighs only 55H1. 1 he following reveals some of the advantages attendant ii]>oii airscrew brakes. Upon making a normal landing the pilot clows the throttles. However, the airscrews continue to windmill, causing an air turbulence over the adjacent portion of wing, thus spoiling the lift. If, however, tb<? propeller is braked and stopped, the flow of air over that section of the wing will be smooth, resulting in higher lift. Secondly the device scores in the event of engine failure. During lest it was found that by stopping an outboard engine on the S \i it w.is possible to correct for the loss of power by the use nl the ruddi-r instead of with both rudder and ailerons. This, ot cotiisi-. \wis due to a smoother flow of air over the portion ot the wing near the engine, creating a greater lilt than would be tin case if the airscrew continued to " windmill,"

The resultant lift proved sufficient on the S.42 to cornet for the loss of power. Disagreeable vibrations set up by the rotating airscrew of a " dead " engine are also eliminated. In case of engine failure caused by a broken part the airscrew may lie stopped at once, preventing further breakage or complete destruction of the engine. The operation of the brakes as installed on the Sikorsky S.42 for Pan American Airways is as follows :Arista oil is pumped manually from a two-quart tank through a check valve into a pressure accumulator, thence to a shut-off yalve. Pressure is increased by the pump and maintained in the accumulator, which works against springs. The accumulator has a capacity of 2,ooolb. sq. in. When the shut-off valve is opened the oil passes through the main line to the four control valves for the four airscrews. Any or all control valves may be o[>tned to brake the airscrews singly or collectively. When a control valve is opened the oil passes into a cylinder bracketed by four bolts on to the engine nose section. The cylinder contains two petrol- and oil-proof pistons; these are expanded by the oil, which has an operating pressure of i,ooo-2,ooolb. sq. in., forcing the brake bands against the drum. The brake drum is machined from a steel forging, and has cooling fins. It is connected to six hub bolts on the three-bladed airscrew by welded steel fittings. The brake shoe is hinged by six lx)lts to the nose section. A spring, which is attached to the brake I>ands at the cylinder, returns the piston to a neutral position when oil pressure is released. The oil then returns to the tank. Sikorsky Aircraft has had such great success with these propeller brakes that it contemplates testing a set on the new S.43 amphibian, and will undoubtedly include them as standard equipment on all future models.

Anda mungkin juga menyukai

- PH - Carolina's Chorizo Carbonara With Garden SaladDokumen2 halamanPH - Carolina's Chorizo Carbonara With Garden Saladseafire47Belum ada peringkat

- Short S.20 Mercury SDokumen3 halamanShort S.20 Mercury Sseafire47Belum ada peringkat

- PH - Almond & Garlic Crusted Chicken With Cherry Tomato SaladDokumen2 halamanPH - Almond & Garlic Crusted Chicken With Cherry Tomato Saladseafire47Belum ada peringkat

- East To West Record: 13% HOURSDokumen1 halamanEast To West Record: 13% HOURSseafire47Belum ada peringkat

- Shor BRQS.: of RochesterDokumen1 halamanShor BRQS.: of Rochesterseafire47Belum ada peringkat

- Gtsac : Flight Engineering SectionDokumen1 halamanGtsac : Flight Engineering Sectionseafire47100% (1)

- 1938 - 2869Dokumen1 halaman1938 - 2869seafire47Belum ada peringkat

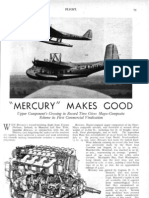

- "Mercury" Makes GoodDokumen1 halaman"Mercury" Makes Goodseafire47Belum ada peringkat

- 1937 - 3485Dokumen1 halaman1937 - 3485seafire47Belum ada peringkat

- Commercial Aviation and Airlines Updates in 1935Dokumen1 halamanCommercial Aviation and Airlines Updates in 1935seafire47Belum ada peringkat

- Flight.: Final Gliding Contest ResultsDokumen1 halamanFlight.: Final Gliding Contest Resultsseafire47Belum ada peringkat

- Percival Q4,6 1937 - 3486Dokumen1 halamanPercival Q4,6 1937 - 3486seafire47Belum ada peringkat

- 74-A-23 Se5a F938Dokumen4 halaman74-A-23 Se5a F938seafire47Belum ada peringkat

- Second Parting: Short-Mayo Compo-Site Separated "In Public"Dokumen1 halamanSecond Parting: Short-Mayo Compo-Site Separated "In Public"seafire47Belum ada peringkat

- 598 Flight.: DECEMBER I 6, 1937Dokumen1 halaman598 Flight.: DECEMBER I 6, 1937seafire47Belum ada peringkat

- 4 Worlds FairDokumen5 halaman4 Worlds Fairseafire47Belum ada peringkat

- 1937 - 3487Dokumen1 halaman1937 - 3487seafire47Belum ada peringkat

- 203 Sample ArticleDokumen8 halaman203 Sample Articleseafire47Belum ada peringkat

- F4u 4Dokumen8 halamanF4u 4seafire47100% (1)

- 95 Sample ArticleDokumen5 halaman95 Sample Articleseafire47Belum ada peringkat

- 8 Ross RS1 93Dokumen4 halaman8 Ross RS1 93seafire47Belum ada peringkat

- Raid On Regensburg2Dokumen8 halamanRaid On Regensburg2seafire47100% (1)

- Chance Vought F4u CorsairDokumen6 halamanChance Vought F4u Corsairseafire47100% (3)

- 7 Moundsville Lone Eagle 94Dokumen9 halaman7 Moundsville Lone Eagle 94seafire47Belum ada peringkat

- Wright Flyer 1903 EngineDokumen3 halamanWright Flyer 1903 Engineseafire47Belum ada peringkat

- SB2U VindicatorDokumen11 halamanSB2U Vindicatorseafire47100% (1)

- VS-10001 GA 02 F4U-1 CorsairDokumen0 halamanVS-10001 GA 02 F4U-1 Corsairseafire47Belum ada peringkat

- Designation OF USA AIRCRAFTDokumen9 halamanDesignation OF USA AIRCRAFTseafire47Belum ada peringkat

- Splash 1Dokumen4 halamanSplash 1seafire47100% (1)

- b47 v3Dokumen4 halamanb47 v3seafire47100% (1)

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (344)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (587)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (73)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (265)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (119)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- Lecture 1 AMT 113Dokumen42 halamanLecture 1 AMT 113Jaafar SorianoBelum ada peringkat

- Afm Flight Manual Pilatus Pc-9Dokumen246 halamanAfm Flight Manual Pilatus Pc-9Gourav DasBelum ada peringkat

- Tecnam P2008JC Spec SheetDokumen16 halamanTecnam P2008JC Spec SheetRafael RafaelBelum ada peringkat

- Vertical Take Off and Landing Powerplant For AircraftsDokumen5 halamanVertical Take Off and Landing Powerplant For AircraftsLiviu GiurcaBelum ada peringkat

- PropellersDokumen24 halamanPropellersRaul Deonarain100% (1)

- 2 MW Product BrochurepdfDokumen16 halaman2 MW Product BrochurepdfDragan VuckovicBelum ada peringkat

- A RANS-based Analysis Ool For Ducted Propeller Systems in Open Water ConditionDokumen23 halamanA RANS-based Analysis Ool For Ducted Propeller Systems in Open Water ConditionLeonardo Duarte MilfontBelum ada peringkat

- Propeller BalancingDokumen4 halamanPropeller Balancingvishwajeet singhBelum ada peringkat

- 208B Manual de Vuelo PDFDokumen846 halaman208B Manual de Vuelo PDFAbelys Campos100% (1)

- Amm Ata 61 PDFDokumen152 halamanAmm Ata 61 PDFcristianocfs100% (4)

- Cirrus SR22 G2 GTS Specs and PerformanceDokumen3 halamanCirrus SR22 G2 GTS Specs and PerformanceAldoBelum ada peringkat

- Design and Manufacturing of QuadcopterDokumen47 halamanDesign and Manufacturing of QuadcopterDebashish Behera100% (3)

- Handbook: Overhaul InstructionsDokumen30 halamanHandbook: Overhaul InstructionsJacksonBelum ada peringkat

- Aircraft Noise Assessment, Prediction and ControlDokumen433 halamanAircraft Noise Assessment, Prediction and ControlN DevaBelum ada peringkat

- Kiwiprop K4 Boss Assembly v2.4Dokumen15 halamanKiwiprop K4 Boss Assembly v2.4adul sungkatinBelum ada peringkat

- Brochure o P CPP Propeller Systems PDFDokumen8 halamanBrochure o P CPP Propeller Systems PDFOliver CelestialBelum ada peringkat

- Chapater FourDokumen12 halamanChapater Fourmohmed4731Belum ada peringkat

- Pratt & Whitney The Aircraft Engine and Its Operation - Rev1949 - BZDokumen213 halamanPratt & Whitney The Aircraft Engine and Its Operation - Rev1949 - BZarizonaflyer100% (4)

- C-172N Specs and PerformanceDokumen9 halamanC-172N Specs and PerformanceRoel MendozaBelum ada peringkat

- Introduction - Role of Precision Engineering in ManufacturingDokumen7 halamanIntroduction - Role of Precision Engineering in ManufacturingjishnuBelum ada peringkat

- The Quadrotor Platform: From A Military Point of ViewDokumen62 halamanThe Quadrotor Platform: From A Military Point of Viewmuhammed sirac erenBelum ada peringkat

- Manual Hélice Hartzell 139-0000-A PDFDokumen202 halamanManual Hélice Hartzell 139-0000-A PDFjojo4761Belum ada peringkat

- An Introduction To The Design and Survey of Marine PropellersDokumen54 halamanAn Introduction To The Design and Survey of Marine PropellersMd. Shahjada TarafderBelum ada peringkat

- Operation Manual: Turboprop EngineDokumen42 halamanOperation Manual: Turboprop EngineBeka KarumidzeBelum ada peringkat

- Pilot's Manual for the B-17 Flying FortressDokumen106 halamanPilot's Manual for the B-17 Flying Fortressalexbiguet100% (2)

- Catalogue Havells Consumer Industrial FansDokumen148 halamanCatalogue Havells Consumer Industrial Fansyash12312Belum ada peringkat

- Handbook PDFDokumen71 halamanHandbook PDFCarlos Navarro PalominoBelum ada peringkat

- Study On Aerodynamic Characteristics of Light Convertible Aircraft ModelDokumen10 halamanStudy On Aerodynamic Characteristics of Light Convertible Aircraft ModelГригорий ОмельченкоBelum ada peringkat

- Copia de Lista de Aplicacion MacCauley 3014631 PDFDokumen640 halamanCopia de Lista de Aplicacion MacCauley 3014631 PDFgianorbegozoBelum ada peringkat

- Piper Seneca Pa-34 Questions by Capt JP SharmaDokumen10 halamanPiper Seneca Pa-34 Questions by Capt JP SharmaOxygen SolutionsBelum ada peringkat