Interlab Test On Polymers Determination of Antioxidants in Polyolefins

Diunggah oleh

rajdewaanJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Interlab Test On Polymers Determination of Antioxidants in Polyolefins

Diunggah oleh

rajdewaanHak Cipta:

Format Tersedia

Polymer Testing 24 (2005) 498506 www.elsevier.

com/locate/polytest

Interlaboratory Tests

Interlaboratory test on polymers: determination of antioxidants in polyolens

Axel Rittera,*, Elisabeth Michela, Manfred Schmida, Samuel Affolterb

a

EMPA (Swiss Federal Laboratories for Materials Testing and Research), Lerchenfeldstrasse 5, CH-9014 St Gallen, Switzerland b r Technik Buchs NTB, Werdenbergstr. 4 CH-9470 Buchs, Switzerland Interstaatliche Hochschule fu Received 6 October 2004; accepted 23 November 2004

Abstract This report presents results obtained from two interlaboratory tests performed in 2000 and 2002. Up to 13 participants, mainly from industry and research institutes analysed two different antioxidants in four polymer matrices. The measured data were collected by EMPA and evaluated using a robust statistical method. Repeatability (r) and reproducibility data (R) were of special interest, as well as the combined uncertainty of measurements (uc). Samples of non-stabilised polyolens were homogeneously doped with accurate well-known quantities of Irgaphos 168 and Irganox 1010. Since no generally valid and universal standard methods for the determination of antioxidants in plastics exist, the interlaboratory test participants were permitted to select an analysis technique of their choice. Almost all laboratories determined the antioxidant contents with HPLC after different pre-treatments. As a result, the most precise HPLC methods could be identied and will be described in this article. The relative repeatability of the determinations was between 1.3 and 5.5%, and the relative reproducibility was in-between 12 and 28% for both antioxidants. No matrix or analyte dependence was observed. The combined calculated uncertainty of measurement (uc) in all laboratories was between 36 and 86%. Therefore analysts in different laboratories have to expect large variations in results when comparing the results of antioxidant analysis on the same polymer. q 2005 Elsevier Ltd. All rights reserved.

Keywords : Interlaboratory test; Antioxidant analysis; Robust statistical method; Repeatability; Reproducibility; Combined uncertainty; Irgaphos 168; Irganox 1010

1. Interlaboratory tests The Swiss Federal Laboratories for Materials Testing and Research (EMPA) organises interlaboratory tests on polymeric materials on a biennial basis. The participants are usually industrial or private laboratories and laboratories at institute that test, research and develop polymeric materials. The present interlaboratory tests took place in 2000 and 2002. ISO 5725 (1994) describes the procedures for interlaboratory tests. The present interlaboratory tests were

statistically analysed using the robust statistical method described by Lischer [1]. The exact procedure used for the evaluation of our Interlaboratory Tests and a detailed description of the statistical parameters is described elsewhere [2]. Some important statistical expressions for a common comprehension of the applied statistical parameters are listed in Table 1. 2. Antioxidants in polyolens 2.1. Introduction

* Corresponding author. Tel.: C41 71 274 7782; fax: C41 71 274 7788. E-mail address: axel.ritter@empa.ch (A. Ritter). 0142-9418/$ - see front matter q 2005 Elsevier Ltd. All rights reserved. doi:10.1016/j.polymertesting.2004.11.012

Non-stabilised polymers usually undergo reactions with oxygen causing degradation and aging readily. Such oxidation reactions negatively inuence the properties of

A. Ritter et al. / Polymer Testing 24 (2005) 498506 Table 1 Statistical expressions sr sr,relative sR sR,relative uc Result with 99.7% condence interval Standard deviation of repeatability absolute Standard deviation of repeatability relative Standard deviation of reproducibility absolute Standard deviation of reproducibility relative Combined uncertainty of measurement ucZ3sR

499

The intention of this laboratory test was, beside an exact statistic evaluation, to compare the different analytical methods used for quantication of antioxidants, because many different determination and sample preparation methods are commonly used. 2.2. Preparation of the samples Due to the fact, that no polymeric reference materials with known antioxidant content are commercially available, EMPA decided to prepare some special samples for this interlaboratory test in-house, in order to be sure about the exact additive content. Thus, two samples (samples 1 and 2) based on polypropylene (PP) were produced in laboratory scale by compounding non-stabilised PP with known amounts of additives by extrusion. The resulting polymer was cut into pieces, powdered in a mill under cooling with liquid nitrogen and sieved with a 1 mm wide meshed sieve, in order to produce homogeneous samples. The second two samples (samples 3 and 4) based on of PP and PE-LLD were produced by Ciba Specialty Chemicals (Basel). The amount of the added additives was disclosed to EMPA. Some details of sample compositions are described in Table 2. The homogeneity of the doped polymer samples was controlled by EMPA with HPLC before mailing and delivering the samples to the participants of the Interlaboratory Test. 2.3. Used antioxidants The antioxidants intended for identication in the Interlaboratory Test was a radical scavenger (Irganox 1010 as proton donor) and a hydro peroxide decomposer (Irgaphos 168 as a oxidizable phosphite). These two

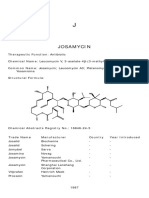

polymers even at very low conversion rates. The oxidative sensitivity of polyolens, e.g. polyethylene, is apparent at room temperature. The use of suitable stabilizers (antioxidants) is one possible solution to overcome this problem. Antioxidants are used in almost all commercial polymers in small amounts up to 2%, w/w (20,000 mg/kg or ppm). They should provide efcient protection of the polymer during processing and end use for the given environmental exposure conditions. Fig. 1 shows the general pathway (circle) of the process of polymer autoxidation and the mode of action of antioxidants [3]. The polymer RH decays under the inuence of shear strain (t), temperature (D), light (hn) or traces of redox active metals (MnC) into free radicals. These radicals can be disposed of by antioxidants. Antioxidants can be divided into two different groups: radical scavengers and hydro peroxide decomposers. The type and quantity of an antioxidant or a combination of different antioxidants used in a polymer compound depend on the intended application and is a determining factor for the long-term behaviour of a polymer. Therefore, one important question of all polymer producers is: how much antioxidant is in my polymer? This is a question, which should be answered by analysts with accuracy. An overview of tools and techniques available for analyzing additives is provided and summarized by Zweifel [3].

Fig. 1. General scheme of action of antioxidants.

500

A. Ritter et al. / Polymer Testing 24 (2005) 498506

Table 2 Description of the samples, number of participants per sample Sample 1 2 3 Polymer PP, nature PP, nature PP, nature State Powder Powder Granulate Added additives 500 mg/kg Irganox 1010 2000 mg/kg Irgaphos 168 1500 mg/kg Irganox 1010 500 mg/kg Irgaphos 168 800 mg/kg Irgaphos 168 400 mg/kg Irganox 1010 110 mg/kg Irganox 1076 (not to be determined) 520 mg/kg Irgaphos 168 170 mg/kg Irganox 1010 Participants 6 9 6 9 13 13

PE-LLD, nature

Granulate

13 13

antioxidants were chosen due to their widespread usage in many recipes for the production of commercial polymers. Chemical details of both antioxidants are described in Table 3. 2.4. Determination 2.4.1. Available methods There are only a few normative standards governing the chemical analysis of antioxidants in polymers (see Table 4). There are many possible analytical methods currently in use, briey described in Table 5, which can be separated into direct and indirect methods. For the indirect methods suitable sample preparation to dissolve the antioxidants

Table 3 Description of the antioxidants Irganox 1010 Synonyms Pentaerythritol tetrakis(3-(3 0 ,5 0 -di-tertbutyl-4 0 -hydroxyphenyl)) Benzenepropanoic acid, 3,5-bis (1,1-dimethylethyl)-4-hydroxy-, 2,2-bis[[3-[3,5-bis(1,1-dimethylethyl)-4-hy-droxyphenyl]-1-oxoPropoxy] methyl]-1,3-propanediylester [6683-19-8] 1177.6 C73H108O12

homogeneously precedes the analytical determination. Extraction according to Soxhlet, dissolving/reprecipitation and swelling of a polymer are widespread methods for sample pretreatment. The most important determinations are based on chromatography, mass spectrometry and spectroscopy methods, whereby GC and HPLC are the most commonly used analytical methods. 2.4.2. Used methods In most cases the participants applied HPLC for the analysis in principle, but with great variations in the analysis parameters. Gas chromatography, photometry and X-ray uorescence were only rarely used as described in Table 6.

Irganox 1076 Octadecyl-3-(3,5-di-tert.butyl-4-hydroxyphenyl)-propionate

Irgaphos 168 Phenol, 2,4-bis(1,1dimethyl-ethyl)-, phosphite (3:1) Tris(2,4-di-tert-butylphenyl) Phosphite

CAS-number Molecular weight (g/mol) Formula Structure

[2082-79-3] 531.0 C35H62O3

[31570-04-4] 646.9 C42H63O3P

A. Ritter et al. / Polymer Testing 24 (2005) 498506 Table 4 Actual standards for determination of antioxidants in polyolens Country GB Standard BS 2782-4: Method 434B: 1977 Title

501

GB GB GB US US

BS 2782-4: Method 434D: 1975 BS 6630: 1985 ISO 4645-1984 BS 7164-31.1:1997 ISO 11089:1997 ASTM D 5524 ASTM D 5815

Methods of testing plastics. Chemical properties. Determination of antioxidants in polyolen compounds by ultra-violet absorption of the chloroform extract Methods of testing plastics. Chemical properties. Determination of antioxidants in polyolen compounds by a spectrophotometric method Method for identication of antidegradants in rubber and rubber products by thin layer chromatography Chemical tests for raw and vulcanized rubber. Determination of antidegradants. High-performance liquid chromatography Test method for determination of phenolic antioxidants in high density polyethylene using liquid chromatography Test method for determination of phenolic antioxidants and erucamide slip additives in linear low density polyethylene using liquid chromatography

HPLC is one of the indirect methods. As sample preparation is needed for HPLC analysis; most participants performed a process starting with dissolving the sample followed by reprecipitation of the polymer. Extraction by Soxhlet was also used in some cases. Microwave and accelerated solvent extraction and stirring in a solvent were used once. 2.5. Results 2.5.1. Determination of Irganox 1010 Fig. 2 shows a representation for all polyolens investigated, including the results of the Irganox 1010 determination in sample 3. This type of comparison sheet is one of the possible results of the interlaboratory tests and is revealed to the participants. From such plots, the participants can estimate their position in the whole eld of results and assess their reliability (e.g. nding a systematic error during the measurement). This gure shows the median values of all participants, the theoretical gravimetric value of Irganox 1010 in sample 3 and the repeatability and reproducibility standard deviation for this determination. The results of the determination of Irganox 1010 in all samples are shown in Table 7 in detail. Absolute and relative statistical terms of repeatability and reproducibility (sr, sR, sr,relative, sR,relative,) are listed. All samples show a lower median value than theoretically predicted (true value). This difference, ranging between 2.2 and 28.6%, could most likely be explained by a partial loss of antioxidants resulting from the compounding process or the analysis procedure. The data of sr,relative were between ca. 2.2 and 5.5%, and therefore the repeatability and precision were considered acceptable and in the expected range. The standard deviations of the reproducibility sR,relative were quite large between ca. 12.3 and 26.6%. This demonstrates the problems that arise in comparing the results between different laboratories.

The ratio sR/sr is a measure of the quality of a determination and should be in a range about 23 for good interlaboratory tests. This is not fullled by this determination with a ratio sR/srZ4.99.0 and therefore the results seem to be a little bit uncertain.

Table 5 Possible methods for determination of antioxidants in polyolens Direct methods Determination with pyrolysis/gas chromatography/mass spectrometry (e.g. using the commercial system of Shimadzu) Time of ight secondary ion mass spectrometry (TOF-SIMS) Matrix assisted mass spectrometry (MALDI) Direct probe insert mass spectrometry (DIP-MS) Indirect methods Determination with gas chromatography (also high temperature GC is possible) Determination with liquid chromatography (HPLC) Determination with thin layer chromatography (DC) Determination with spectrometric methods In case of Irgaphos 168, determination of phosphorus content by photometry or emission spectrometry Antecedent one has to carry out a suitable sample preparation in order to separate the antioxidants from the polymer matrix and to dissolve them homogeneously. The following methods are theoretically possible: Sample preparation for indirect methods Extraction according to Soxhlet with a suitable solvent (typically for several hours) Accelerated solvent extraction (ASE) Dissolving the polymer and reprecipitation Hot or cold swelling of polymer and diffusion of additives into the solvent Disaggregation of the system with microwaves (determination of phosphorus) Disaggregation according to Parr with oxygen (determination of phosphorus) The suitability of the indirect methods depends strongly on the optimization of the extraction methods. Only a high retrieval rate indicates that the extraction method is trustworthy.

502 Table 6 Applied methods by the participants Analysis method GC/MS GC Pyrolysis/GC/MS XRF Photometry of phosphate HPLC HPLC HPLC HPLC HPLC HPLC HPLC HPLC HPLC HPLC HPLC HPLC HPLC HPLC Analyte

A. Ritter et al. / Polymer Testing 24 (2005) 498506

Sample preparation Soxhlet extraction, 8 h Soxhlet extraction None None niger digestion Scho Solution and precipitation Solution and precipitation Solution and precipitation Solution and precipitation Solution and precipitation Solution and precipitation Microwave extraction Soxhlet extraction Soxhlet extraction, 8, 16 h Soxhlet extraction, 1.5 h Soxhlet extraction, 2,18, 48 h Soxhlet extraction, 6 h 24 h, 40 8C by stirring ASE

Used solvent for extraction Dichloromethane Dichloromethane/cyclohexane (3:1) None None None Xylene (S), acetonitrile (P) Cyclohexane/THF/xylene (1:1:1) (S), ethanol (P) Xylene (S), methanol (P) Toluene (S), methanol (P) p-Xylene (S), acetonitrile (P) Toluene (S), chloroform (P) Heptane/acetone Dichloromethane/cyclohexane (3:1) Dichloromethane Ethylacetate Chloroform Acetone Isooctane Unknown

Irgaphos 168 Irgaphos 168 Irganox 1010, Irgaphos 168 Irgaphos 168 Irgaphos 168 Irganox 1010, Irgaphos 168 Irganox 1010, Irgaphos 168 Irganox 1010, Irgaphos 168 Irganox 1010, Irgaphos 168 Irganox 1010 Irganox 1010, Irgaphos 168 Irganox 1010, Irgaphos 168 Irganox 1010 Irganox 1010, Irgaphos 168 Irganox 1010, Irgaphos 168 Irganox 1010, Irgaphos 168 Irganox 1010 Irganox 1010, Irgaphos 168 Irganox 1010, Irgaphos 168

S, solution; P, precipitation; ASE, accelerated solvent extraction; XRF, X-ray uorescence analysis.

The combined uncertainty of measurement (uc) in a laboratory is strongly affected by standard deviation of reproducibility (sR). Within a 99.7% condence interval the combined uncertainty of measurement (uc) is the threefold reproducibility (sR). At this interpretation the combined uncertainty was calculated between 36.9 and 79.8%, which is considered as a rather high value.

2.5.2. Determination of Irgaphos 168 As a representative for all polyolens investigated, the results of the Irgaphos 168 determination in sample 4 are shown in Fig. 3. The median values of all participants, the theoretical gravimetric value of Irgaphos 168 and the repeatability and reproducibility standard deviation for this determination are visualized in such plots. All results of

Fig. 2. Content of Irganox 1010 in mg/kg in sample 3.

A. Ritter et al. / Polymer Testing 24 (2005) 498506 Table 7 Data of interlaboratory test, determination of Irganox 1010 Parameter Type of polymer True value (mg/kg) Content av. (median) (mg/kg) Relative underestimate (%) sr (repeatability) (mg/kg) sr,relative (%) sR (reproducibility) (mg/kg) sR,relative (%) sR/sr uc (99.7% condence interval) Z3sR (mg/kg) uc (99.7% c.i., relative) (%) No. of labs Sample 1 PP 500 357 K28.6 19.5 5.46 95 26.6 4.9 285 79.8 6 Sample 2 PP 1500 1253 K16.5 29.8 2.37 154.6 12.3 5.2 464 36.9 6 Sample 3 PP 400 371.3 K7.2 8.3 2.2 74.7 20.1 9.0 224 60.3 12 Sample 4 LLDPE 170 166.2 K2.2 5.19 3.1 38.2 23.0 7.5 115 69 12

503

the statistical evaluation of the measurements of Irgaphos 168 are shown in detail in Table 8, where all absolute and relative statistical terms of repeatability and reproducibility (sr, sR) are listed. All Irgaphos 168 samples show similar results as the aforementioned value for Irganox 1010, having a similar difference between median values measured and the theoretically predicted, true value. The discrepancies were between 7.0 and 25.9%. The data of sr,relative were about 1.34.05%, so the repeatability and precision were again considered acceptable as they were in the expected range. The standard deviations of the reproducibility sR,relative were quite large, between 12.1 and 28.6%. Also the comparison of results amongst different

laboratories seems to be critical again, as it was with Irganox 1010. The ratio sR/sr is about 5.321 and therefore very high, which leads to the assumption that the results are not very reliable. Furthermore, the combined uncertainty of measurement (uc) was calculated between 36.3 and 85.8%, which are also rather high values. 2.5.3. Comparison of the results The most important results are listed in Table 9. For both Irganox 1010 and Irgaphos 168, considerable differences

Fig. 3. Content of Irgaphos 168 in mg/kg in sample 4.

504

A. Ritter et al. / Polymer Testing 24 (2005) 498506

Table 8 Data of interlaboratory test, determination of Irgaphos 168 Parameter Type of polymer True value (mg/kg) Content av. (median) (mg/kg) Relative underestimate (%) sr (repeatability) (mg/kg) sr,relative (%) sR (reproducibility) (mg/kg) sR,relative (%) sR/sr uc (99.7% condence interval)Z3sR (mg/kg) uc (99.7% c.i., relative) (%) No. of labs Sample 1 PP 2000 1482 K25.9 33.7 2.27 179.1 12.1 5.3 537 36.3 9 Sample 2 PP 500 401 K19.8 16.2 4.05 108.8 27.1 6.7 326 81.3 9 Sample 3 PP 800 743.9 K7.0 10.7 1.4 106.1 14.3 10 318 42.9 13 Sample 4 PE-LLD 520 441.3 K15.1 5.9 1.3 126.3 28.6 21 379 85.8 13

between measured and true contents were detected. The reasons are as follows: 1. During the compounding process parts of the antioxidants can degrade by thermal stress or will be vaporized. The chemical compounds are sensitive to air at elevated temperature and react, e.g. by cleavage, to undened oxidised end products. 2. During the analysis procedure, especially the extraction and clean-up steps, parts of antioxidants can be lost or remain in the matrix. These parts of the analyte cannot be detected by the analysis procedure. The standard deviation of the reproducibility sR between the analytes and samples are displayed in Figs. 4 and 5. . There is no signicant trend observable with these data; the reproducibility seems to be neither depending on the kind of analyte nor on the kind of polymer matrix. All values were found to be in a range between 12 and 28%. Therefore, the accuracy of determination of antioxidants in polymers lies in this range. The ratios sR/sr of different kinds of interlaboratory tests are compared in Table 10. Ratios sR/sr!3 are a performance gure of a reliable interlaboratory test, but often

Table 9 Comparison of the results Irganox 1010 Relative underestimate of determinations Relative combined uncertainty of measurement sR/sr 229% Irgaphos 168 726% Comment Probably lost during the take-up to the polyolen or the procedure of analysis Large uncertainty for an analytical method

the numbers are greater. In this test the range of ratios was between 5 and 20, so the comparability between different laboratories is not very good. The combined uncertainty of measurement of this interlaboratory test is very large as compared to other analytical methods. The reason is most likely the complexity of the determination, the extensive sample preparation and the analysis of potentially unstable compounds. 2.6. Conclusions The present report indicates what repeatability and reproducibility standard deviations must be taken into consideration when the amount of antioxidants are determined in plastic matrices. An overview of all the different analytical methods applied by the participants is summarized in Table 11, illustrating that only two methods gave reliable results. Methods of pyrolysis, photometry, XRF and GC/MS were proven to be uncertain methods. The quantitative results were either too high or to low and so these methods cannot be recommended. HPLC was the method of choice when the pre-treatment was optimised, which is very important to get reliable results.

3780%

3686%

59

520

High value, low comparison between laboratories

Fig. 4. Comparison of sR,relative between the analytes.

A. Ritter et al. / Polymer Testing 24 (2005) 498506 Table 10 Ratio sR/sr in interlaboratory tests Literature Interlaboratory test of determination of metals in stabilised water, internal report EMPA, Nr. 840203, 1999 Interlaboratory test: analysis of wood and wood ash, internal report EMPA, Nr. 46011, 1998 Interlaboratory test: eluate test of concrete, internal report EMPA, Nr. 46003, 1996 Analytical quality assurance, interlaboratory test Nr. 8, heavy metals, r WasserBayerisches Landesamt fu wirtschaft, 1997 Antioxidants in polyolens Analytes 8 heavy metals Matrix Water Number of independent tests 24 Range sR/sr 0.96.5

505

Average sR/sr 2.7

24 heavy metals

Ash of wood Water

24

1.78.9

5.4

8 heavy metals and 2 anions 24 heavy metals

214

2.577

18.7

Water

24

1.94.3

3.0

2 antioxidants in 4 samples

Polyolens

520

8.7

HPLC analysis after microwave extraction was the most successful method when a mixture of heptanes and acetone was used for extraction. The second method, also a HPLC method, is preceded by another sample preparation. The polymer was dissolved in an aromatic solvent like xylene and then precipitated by methanol under intensive stirring. This method is recommended and is easy to execute. 2.7. The Horwitz graph In 1980, Horwitz rst described the relation between the concentration of an analyte and the standard deviation of the reproducibility of interlaboratory tests [4]. By plotting the relative standard deviation of reproducibility versus the concentration of the analyte in a x,y-plot (graph see Fig. 6), Horwitz assessed, that the value of reproducibility is almost doubled when the concentration is decreased a hundred times. Today an interlaboratory test is regarded as valid

when the relative standard deviation of the reproducibility is in-between 0.5 and 2 times the predicted value [5]. Fig. 6 shows the typical coherence between concentration of the analyte and the reproducibility sr (thick line), as well as the results of this interlaboratory test with the regression curve (dotted line). Important analytical methods, like doping or food analysis, usually obey the common Horwitz curve. For the antioxidants analysis the law does not apply because the values of sR are three times higher than the Horwitz graph. The reason is that polymer analysis is more imprecise due to the complex polymer matrix,

Table 11 Assessment of the analytical methods Method Pyrolysis/GC/MS Irganox 1010 Too low and too high values change; the method is uncertain Irgaphos 168 Too low and too high values change; the method is uncertain Too low values Too high values Too low and too high values change; the method is uncertain Reliable values when heptane/ acetone used for extraction Too low values

Photometry XRF GC/MS after Soxhlet extraction

HPLC after microwave extraction

Fig. 5. Comparison of sR,relative between the samples.

HPLC after accelerated solvent extraction HPLC after solution and precipitation HPLC after Soxhlet extraction

Reliable values when heptane/ acetone used for extraction Too low values

Reliable values by using aromatic solvents and methanol Too low values

Reliable values by using aromatic solvents and methanol Too low values

506

A. Ritter et al. / Polymer Testing 24 (2005) 498506

Acknowledgements The authors wish to thank Dr M. Weber who handled the statistical software and evaluated the statistical data and Ciba Specialities, Basel, for the preparation of some samples. We would also like to thank all our colleagues at the Institute who made the interlaboratory tests possible and the companies and institutes that supported the project nancially or supplying test materials free of charge.

References

[1] P. Lischer, Robust statistical methods in interlaboratory analytical studies in: H. Rieder (Ed.), Robust Statistics, Data Analysis, and Computer Intensive Methods, Lecture Notes in Statistics (109), Springer, New York, 1996, pp. 251265. [2] A. Ritter, E. Michel, M. Schmid, S. Affolter, Polym. Test. 23/4 (2004) 467474. [3] H. Zweifel (Ed.), Plastics Additives Handbook, Hanser, Munich, 2000, ISBN: 1-56990-295-X. [4] W. Horwitz, L.R. Kamps, K.W. Boyer, J. AOAC 63 (1980) 13441354. [5] M. Thompson, P.J. Lowthian, J. AOAC Int. 80 (1997) 676680.

Fig. 6. Horwitz curve.

which is inhomogeneous and difcult to prepare. Therefore, when comparing different laboratories one must take into consideration that the combined uncertainty of measurement is greater than that of many common analytical techniques.

Anda mungkin juga menyukai

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (895)

- Kinetics of Azo DyesDokumen6 halamanKinetics of Azo DyesrajdewaanBelum ada peringkat

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- Chemical Affects of Ultrasound PDFDokumen8 halamanChemical Affects of Ultrasound PDFrajdewaanBelum ada peringkat

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- Fast Throughput, Highly Sensitive Determination of Allergenic Disperse Dyes in Textile Products by Use of Sample CompositionDokumen9 halamanFast Throughput, Highly Sensitive Determination of Allergenic Disperse Dyes in Textile Products by Use of Sample CompositionrajdewaanBelum ada peringkat

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- Annurev Virology COVID 19 PDFDokumen28 halamanAnnurev Virology COVID 19 PDFrajdewaanBelum ada peringkat

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- Substance Id en PDFDokumen127 halamanSubstance Id en PDFrajdewaanBelum ada peringkat

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (266)

- Dyeing of Polyamide FibersDokumen19 halamanDyeing of Polyamide FibersrajdewaanBelum ada peringkat

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (400)

- Analysis of Sulphonated DyesDokumen11 halamanAnalysis of Sulphonated DyesrajdewaanBelum ada peringkat

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- Ninety Years of Using Azo Compounds of The Pyridine SeriesDokumen5 halamanNinety Years of Using Azo Compounds of The Pyridine SeriesrajdewaanBelum ada peringkat

- Chemistry in CourtDokumen7 halamanChemistry in CourtrajdewaanBelum ada peringkat

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- Solubility of FormaldehydeDokumen16 halamanSolubility of FormaldehyderajdewaanBelum ada peringkat

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (588)

- HPLC Method Devolopment and Validation For EverolimusDokumen20 halamanHPLC Method Devolopment and Validation For EverolimusthesisBelum ada peringkat

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- (J. Throck Watson, O. David Sparkman) IntroductionDokumen253 halaman(J. Throck Watson, O. David Sparkman) IntroductionAntonio Carlos da SilvaBelum ada peringkat

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- HPLCDokumen82 halamanHPLCRatna Wahyu NoviasariBelum ada peringkat

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (74)

- Original Paper Fast HPLC Method For The Determination of Glimepiride, Glibenclamide, and Related Substances Using Monolithic Column and Flow ProgramDokumen7 halamanOriginal Paper Fast HPLC Method For The Determination of Glimepiride, Glibenclamide, and Related Substances Using Monolithic Column and Flow ProgramAdelia DinayantiBelum ada peringkat

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (344)

- Chlorine in AirDokumen5 halamanChlorine in AirZahra Debrian PutriBelum ada peringkat

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- Protein and Amino Acid Chemistry By: Dr. Hena Alcantara: BiochemistryDokumen7 halamanProtein and Amino Acid Chemistry By: Dr. Hena Alcantara: BiochemistryRay Emmanuel Enriquez DomingoBelum ada peringkat

- Josamycin: YosamicinaDokumen2 halamanJosamycin: YosamicinaJulcon Avanceña AraizBelum ada peringkat

- Determination of Total Ion Concentration Using Ion Exchange ChromatographyDokumen3 halamanDetermination of Total Ion Concentration Using Ion Exchange ChromatographyBulawan LaNeref OremseBelum ada peringkat

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- 2003 - Synthesis and Physical Properties of Estolide-Based Functional Fluids PDFDokumen14 halaman2003 - Synthesis and Physical Properties of Estolide-Based Functional Fluids PDFSoodooNavindraBelum ada peringkat

- Release and Permeation of IndomethaDokumen11 halamanRelease and Permeation of IndomethaWedja VieiraBelum ada peringkat

- Quality Profile Determination of Palm OleinDokumen12 halamanQuality Profile Determination of Palm OleinNestor Armando Marin SolanoBelum ada peringkat

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2259)

- ACM-Penentuan Retinoic Acid (Tretinon)Dokumen5 halamanACM-Penentuan Retinoic Acid (Tretinon)febri supriyoBelum ada peringkat

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- Aromatic Effects of Immobilized Enzymatic Oxidation of Chicken Fat On Flaxseed (Linum Usitatissimum L.) Derived Maillard Reaction ProductsDokumen12 halamanAromatic Effects of Immobilized Enzymatic Oxidation of Chicken Fat On Flaxseed (Linum Usitatissimum L.) Derived Maillard Reaction ProductsSara Ávila BlanquicetBelum ada peringkat

- Scientific Laboratory ReportDokumen5 halamanScientific Laboratory ReportClairmejoy Pingol SuhianBelum ada peringkat

- Exp 7 ChromatographyDokumen10 halamanExp 7 ChromatographyNur AidaBelum ada peringkat

- Densitometry and Image AnalysisDokumen11 halamanDensitometry and Image AnalysisAdhia DekaBelum ada peringkat

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (121)

- FPLC y CromatografiaDokumen9 halamanFPLC y CromatografiaDavid García DíazBelum ada peringkat

- RP-HPLC Method For The Quantitative Determination of Fexofenidine HCL in Coated Tablets and HumanDokumen13 halamanRP-HPLC Method For The Quantitative Determination of Fexofenidine HCL in Coated Tablets and HumanchiralicBelum ada peringkat

- Oxido Etileno para EspeciasDokumen4 halamanOxido Etileno para EspeciasAlexander Nieto VelaBelum ada peringkat

- Indoor Air: BSI Standards PublicationDokumen40 halamanIndoor Air: BSI Standards PublicationRobert100% (3)

- Decoding The Perplexing Mystery of Para-Chloroaniline Formation: A Systematic ReviewDokumen6 halamanDecoding The Perplexing Mystery of Para-Chloroaniline Formation: A Systematic ReviewHllerdBelum ada peringkat

- Practice Exam Forensic ChemistryDokumen5 halamanPractice Exam Forensic ChemistryRaechelle GilmourBelum ada peringkat

- Separation of Amino Acids by Paper Chromatography: Biol. 261Dokumen4 halamanSeparation of Amino Acids by Paper Chromatography: Biol. 261Jeff LinksBelum ada peringkat

- Best Practices Guide For Extractables Testing April 2020 PDFDokumen26 halamanBest Practices Guide For Extractables Testing April 2020 PDFHECHUANBelum ada peringkat

- Exp5 chm260Dokumen7 halamanExp5 chm260Syfkh Nsr100% (2)

- D4124 26071Dokumen8 halamanD4124 26071Diana Catalina Palacio LBelum ada peringkat

- Ezchrom Elite Manual EspañolDokumen1 halamanEzchrom Elite Manual EspañolYrvin Narro Lucano0% (3)

- Electro ChromatographyDokumen17 halamanElectro ChromatographySagar Maney100% (1)

- Amino Acids, Peptides, and ProteinsDokumen75 halamanAmino Acids, Peptides, and ProteinskaleijaBelum ada peringkat

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)