Material 6 - Distribucion Planta

Diunggah oleh

Emmanuel Cervantes VelázquezDeskripsi Asli:

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Material 6 - Distribucion Planta

Diunggah oleh

Emmanuel Cervantes VelázquezHak Cipta:

Format Tersedia

14.4.

PLANT LAYOUT

1069

5. Fire stations and other emergency services; 6. Utilities: steam boilers, compressed air, power generation, refrigeration, transformer stations; 7. Efuent disposal plant: waste water treatment, solid and or liquid waste collection; 8. Ofces for general administration; 9. Canteens and other amenity buildings, such as medical centers; 10. Parking lots. When the preliminary site layout is roughed out, the process units are normally sited rst and arranged to give a smooth ow of materials through the various processing steps, from raw material to nal product storage. Process units are normally spaced at least 30 m apart; greater spacing may be needed for hazardous processes. The location of the principal ancillary buildings should then be decided. They should be arranged so as to minimize the time spent by personnel in traveling between buildings. Administration ofces and laboratories, in which a relatively large number of people will be working, should be located well away from potentially hazardous processes. Control rooms are normally located adjacent to the processing units, but those with potentially hazardous processes may have to be sited at a safer distance. The siting of the main process units determines the layout of the plant roads, pipe alleys, and drains. Access roads to each building are needed for construction and for operation and maintenance. Utility buildings should be sited to give the most economical run of pipes to and from the process units. Cooling towers should be sited so that, under the prevailing wind, the plume of condensate spray drifts away from the plant area and adjacent properties. The main storage areas should be placed between the loading and unloading facilities and the process units they serve. Storage tanks containing hazardous materials should be sited at least 70 m (200 ft) from the site boundary. A typical plot plan is shown in Figure 14.1. A comprehensive discussion of site layout is given by Mecklenburgh (1985); see also House (1969), Kaess (1970), and Meissner and Shelton (1992).

14.4.

PLANT LAYOUT

The economic construction and efcient operation of a process unit will depend on how well the plant and equipment specied on the process owsheet is laid out. A detailed account of plant layout techniques cannot be given in this short section. A fuller discussion can be found in the book edited by Mecklenburgh (1985) and in articles by Kern (1977, 1978), Meissner and Shelton (1992), Brandt et al. (1992), and Russo and Tortorella (1992). The principal factors to be considered are 1. Economic considerations: construction and operating costs; 2. The process requirements;

1070

CHAPTER 14

GENERAL SITE CONSIDERATIONS

Emergency water

Rail siding Tank farm Expansion

Fire station

Plant area 2

Workshops Stores Laboratory

Pipe bridge

Canteen Plant utilities Change house

Plant area 1

Expansion Roads Offices

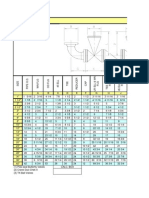

Figure 14.1. 3. 4. 5. 6. 7. Convenience of operation; Convenience of maintenance; Safety; Future expansion; Modular construction.

Typical site plan.

Costs

The cost of construction can be minimized by adopting a layout that gives the shortest run of connecting pipe between equipment and the least amount of structural steel work; however, this will not necessarily be the best arrangement for operation and maintenance.

Process Requirements

An example of the need to take into account process considerations is the need to elevate the base of columns to provide the necessary net positive suction head to a pump (see Chapter 5) or the operating head for a thermosiphon reboiler (see Chapter 12).

Operation

Equipment that needs to have frequent operator attention should be located convenient to the control room. Valves, sample points, and instruments should be located at convenient positions and heights. Sufcient working space and headroom must be

14.4.

PLANT LAYOUT

1071

provided to allow easy access to equipment. If it is anticipated that equipment will need replacement, then sufcient space must be allowed to permit access for lifting equipment.

Maintenance

Heat exchangers need to be sited so that the tube bundles can be easily withdrawn for cleaning and tube replacement. Vessels that require frequent replacement of catalyst or packing should be located on the outside of buildings. Equipment that requires dismantling for maintenance, such as compressors and large pumps, should be placed under cover.

Safety

Blast walls may be needed to isolate potentially hazardous equipment and conne the effects of an explosion. At least two escape routes for operators must be provided from each level in process buildings.

Plant Expansion

Equipment should be located so that it can be conveniently tied in with any future expansion of the process. Space should be left on pipe racks for future needs, and service pipes should be oversized to allow for future requirements.

Modular Construction

In recent years there has been a move to assemble sections of a plant at the plant manufacturers site. These modules include the equipment, structural steel, piping, and instrumentation. The modules are then transported to the plant site, by road or sea. The advantages of modular construction are 1. 2. 3. 4. 1. 2. 3. 4. Improved quality control; Reduced construction cost; Less need for skilled labor on site; Less need for skilled personnel on overseas sites. Higher design costs; More structural steel work; More anged connections; Possible problems with assembly, on site;

Some of the disadvantages are

A fuller discussion of techniques and applications of modular construction is given by Shelley (1990), Hesler (1990), and Whittaker (1984).

General Considerations

Open, structural-steelwork buildings are normally used for process equipment. Closed buildings are used for process operations that require protection from the

1072

CHAPTER 14

GENERAL SITE CONSIDERATIONS

weather, for small plants, or for processes that require ventilation with scrubbing of the vent gas. The arrangement of the major items of equipment often follows the sequence given on the process owsheet: with the columns and vessels arranged in rows and the ancillary equipment, such as heat exchangers and pumps, positioned along the outside. A typical preliminary layout is shown in Figure 14.2.

14.4.1.

Techniques Used in Site and Plant Layout

Cardboard cutouts of the equipment outlines can be used to make trial plant layouts. Simple models, made up from rectangular and cylindrical blocks, can be used to study alternative layouts in plan and elevation. Cutouts and simple block models can also be used for site layout studies. Once the layout of the major pieces of equipment has been

Compressor house

Control room

C2 E7 V3 E6 F1 C4 E5 E3 C1 Road Process equipment Pumps pipe alley over P2 P5 P4 P8 P7 P12

P9

Figure 14.2.

A typical plant layout.

14.4.

PLANT LAYOUT

1073

decided, the plan and elevation drawings can be made and the design of the structural steelwork and foundations undertaken. Large-scale models, to a scale of at least 1:30, are normally made for major projects. These models are used for piping design and to decide the detailed arrangement of small items of equipment, such as valves, instruments, and sample points. Piping isometric diagrams are taken from the nished models. The models are also useful on the construction site and for operator training. Proprietary kits of parts are available for the construction of plant models. Computer-aided design (CAD) tools are being increasingly used for plant layout studies, and computer models are complementing, if not yet replacing, physical models. Several proprietary programs are available for the generation of three-dimensional models of plant layout and piping. Present systems allow designers to zoom in on a section of a plant and view it from various angles. Developments of computer technology will soon enable engineers to virtually walk through the plant. A typical computergenerated model is shown in Figure 14.3.

Figure 14.3.

Computer-generated layout model. (Courtesy: Babcock Construction Ltd.)

1074

CHAPTER 14

GENERAL SITE CONSIDERATIONS

Some of the advantages of computer graphics modeling compared with actual scale models are 1. The ease of electronic transfer of information. Piping drawings can be generated directly from the layout model. Bills of quantities: materials, valves, instruments, etc. are generated automatically. 2. The computer model can be part of an integrated project information system, covering all aspects of the project from conception to operation. 3. It is easy to detect interference between pipe runs and pipes and structural steel that occupy the same space. 4. A physical model of a major plant construction can occupy several square meters. The computer model is contained on a single CD. 5. The physical model has to be transported to the plant site for use in the plant construction and operator training. A computer model can be instantly available in the design ofce, the customers ofces, and at the plant site. 6. Expert systems and optimization programs can be incorporated in the package to assist the designer to nd the best practical layout; see Madden et al. (1990).

14.5.

UTILITIES

The word utilities is used for the ancillary services needed in the operation of any production process. These services are normally supplied from a central site facility and include 1. 2. 3. 4. 5. 6. 7. 8. 9. Electricity; Steam, for process heating; Cooling water; Water for general use; Demineralized water; Compressed air; Inert-gas supplies; Refrigeration; Efuent disposal facilities.

Electricity

The power required for electrochemical processes, motor drives, lighting, and general use may be generated on site, but will more usually be purchased from the local supply company. The economics of power generation on site are discussed in Section 6.4.3. The voltage at which the supply is taken or generated will depend on the demand. In the United States, power is usually transmitted over long distances at 135, 220, 550, or 750 kV. Local substations step the power down to 35 to 69 kV for medium voltage transmission and then to 4 to 15 kV local distribution lines. Transformers at the plant are used to step down the power to the supply voltages used on site. Most motors and other process equipment run on 208 V 3-phase power, while 120/240 V single phase power is used for ofces, labs, and control rooms.

Anda mungkin juga menyukai

- Isa 95.00.02-2001Dokumen104 halamanIsa 95.00.02-2001Alexander Dueñas Salazar100% (4)

- Project phases and deliverablesDokumen1 halamanProject phases and deliverablesEmmanuel Cervantes VelázquezBelum ada peringkat

- Basis Estimate TemplateDokumen2 halamanBasis Estimate TemplateEmmanuel Cervantes VelázquezBelum ada peringkat

- ANEXOS TÉCNICOS DE LAS BASES DE LICITACIÓNDokumen23 halamanANEXOS TÉCNICOS DE LAS BASES DE LICITACIÓNEmmanuel Cervantes VelázquezBelum ada peringkat

- Conceptual Plant LayoutDokumen6 halamanConceptual Plant LayoutEmmanuel Cervantes VelázquezBelum ada peringkat

- Ansi Isa-95.00.01-2000Dokumen142 halamanAnsi Isa-95.00.01-2000Alexander Dueñas Salazar100% (9)

- Integrated Manufacturing SolutionsDokumen15 halamanIntegrated Manufacturing SolutionsEmmanuel Cervantes VelázquezBelum ada peringkat

- Case Study Plant Layout 1Dokumen22 halamanCase Study Plant Layout 1Gaurav ModiBelum ada peringkat

- Engineering Drawing Symbols v2Dokumen98 halamanEngineering Drawing Symbols v2shaikh_nazarBelum ada peringkat

- P&ID LegendDokumen29 halamanP&ID LegendEmmanuel Cervantes VelázquezBelum ada peringkat

- Ansi Isa-95.00.01-2000Dokumen142 halamanAnsi Isa-95.00.01-2000Alexander Dueñas Salazar100% (9)

- Enterprise Control System Integration Part 3: Activity Models of Manufacturing Operations ManagementDokumen104 halamanEnterprise Control System Integration Part 3: Activity Models of Manufacturing Operations ManagementJeff HekmatiBelum ada peringkat

- S 990001 Part 1 DraftDokumen97 halamanS 990001 Part 1 DraftandhrimnirBelum ada peringkat

- Symbolece PDFDokumen12 halamanSymbolece PDFEmmanuel Del RosarioBelum ada peringkat

- Flanged and dished head dimensionsDokumen10 halamanFlanged and dished head dimensionssnehal.deshmukhBelum ada peringkat

- Diplomado en Desarrollo de Proyectos de Ingenier+¡a IVDokumen15 halamanDiplomado en Desarrollo de Proyectos de Ingenier+¡a IVEmmanuel Cervantes VelázquezBelum ada peringkat

- ANEXOS TÉCNICOS DE LAS BASES DE LICITACIÓNDokumen23 halamanANEXOS TÉCNICOS DE LAS BASES DE LICITACIÓNEmmanuel Cervantes VelázquezBelum ada peringkat

- Sample 5 CalcsDokumen24 halamanSample 5 CalcsEmmanuel Cervantes Velázquez100% (2)

- Anexo 2 Ejemplo Relación InterdisciplinariaDokumen1 halamanAnexo 2 Ejemplo Relación InterdisciplinariaEmmanuel Cervantes VelázquezBelum ada peringkat

- Steel Pipe VesselDokumen279 halamanSteel Pipe VesselAhmadreza AminianBelum ada peringkat

- Detailed Engineering Design PhaseDokumen8 halamanDetailed Engineering Design Phaserenjithv_494% (18)

- Anexo 1 - Atividades Disciplinas Basicas 1Dokumen9 halamanAnexo 1 - Atividades Disciplinas Basicas 1Emmanuel Cervantes VelázquezBelum ada peringkat

- Solid Works Model For The Pressure VesselDokumen16 halamanSolid Works Model For The Pressure VesselkarthikeashwarBelum ada peringkat

- Universal Nozzle Calculator Ver 3 0Dokumen10 halamanUniversal Nozzle Calculator Ver 3 0madodandembeBelum ada peringkat

- Solid Works Model For The Pressure vessel-IIDokumen1 halamanSolid Works Model For The Pressure vessel-IIkarthikeashwarBelum ada peringkat

- Sample 5 B&WDokumen1 halamanSample 5 B&WEmmanuel Cervantes VelázquezBelum ada peringkat

- Content 24Dokumen13 halamanContent 24Sutthiroj PeeraBelum ada peringkat

- Sample 4 ColorDokumen1 halamanSample 4 ColorEmmanuel Cervantes VelázquezBelum ada peringkat

- Sample 3 Color Page1Dokumen1 halamanSample 3 Color Page1Emmanuel Cervantes VelázquezBelum ada peringkat

- ASME VIII-1 pressure vessel design code and operating conditionsDokumen1 halamanASME VIII-1 pressure vessel design code and operating conditionsNomi KhanBelum ada peringkat

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (894)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (399)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (265)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (73)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2219)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (119)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- Sime Darby R&D Advances Oil Palm GenomeDokumen4 halamanSime Darby R&D Advances Oil Palm GenomeAhmad Zubair Hj YahayaBelum ada peringkat

- 58 GS KPSC 30082015 PDFDokumen40 halaman58 GS KPSC 30082015 PDFrpsirBelum ada peringkat

- (Biology of Horticultural Crops) Pinchas Spiegel-Roy - Eliezer E Goldschmidt-Biology of Citrus-Cambridge University Press (1996)Dokumen235 halaman(Biology of Horticultural Crops) Pinchas Spiegel-Roy - Eliezer E Goldschmidt-Biology of Citrus-Cambridge University Press (1996)CesarLauterioBelum ada peringkat

- Proximate, Phytochemical and Nutrient Compositions of Some Fruits, Seeds and Leaves of Some Plant Species at Umudike, NigeriaDokumen10 halamanProximate, Phytochemical and Nutrient Compositions of Some Fruits, Seeds and Leaves of Some Plant Species at Umudike, NigeriaIloveBaobabBelum ada peringkat

- LKPD Narrattive TextDokumen5 halamanLKPD Narrattive TextFakhri MukaromahBelum ada peringkat

- The Tragedy of "La Josefina": by Alexander Paute and Cristian AtehortuaDokumen8 halamanThe Tragedy of "La Josefina": by Alexander Paute and Cristian AtehortuaAlexander Paute MatuteBelum ada peringkat

- A Statistical Manual For Forestry ResearchDokumen234 halamanA Statistical Manual For Forestry Researchskjournals100% (1)

- Cell Biology Notes: Prokaryotes vs EukaryotesDokumen6 halamanCell Biology Notes: Prokaryotes vs Eukaryotessaadc786100% (1)

- Soil Testing and Adjusting pH, Nutrients for Vegetable GardenDokumen3 halamanSoil Testing and Adjusting pH, Nutrients for Vegetable GardenAnonymous 1VhXp1Belum ada peringkat

- Moyaney (Molasses, Yakult and Honey) : An Alternative Natural Fertilizer and Pesticide For Allium CepaDokumen5 halamanMoyaney (Molasses, Yakult and Honey) : An Alternative Natural Fertilizer and Pesticide For Allium CepaTitusBelum ada peringkat

- Low Concentrations of Humic Substances Significantly Enhanced Plant GrowthDokumen4 halamanLow Concentrations of Humic Substances Significantly Enhanced Plant GrowthShailendra RajanBelum ada peringkat

- White Spots On Skin - Possible Causes and 15 Home Remedies - HomDokumen11 halamanWhite Spots On Skin - Possible Causes and 15 Home Remedies - HomSandip FirkeBelum ada peringkat

- Important Questions For CBSE Class 7 Science Chapter 11Dokumen7 halamanImportant Questions For CBSE Class 7 Science Chapter 11Atabuddin MondalBelum ada peringkat

- Utilization of Pineapple Subgrade as Pineapple LeatherDokumen11 halamanUtilization of Pineapple Subgrade as Pineapple LeatherNcy KimBelum ada peringkat

- Herbs Magical Properties For Protection, Healing and PovertyDokumen18 halamanHerbs Magical Properties For Protection, Healing and PovertyTom ChordBelum ada peringkat

- Maruthamalai Hills of Western Ghats, Coimbatore District, Tamil Nadu - A Potential Ecosystem For Medicinal Plants.Dokumen15 halamanMaruthamalai Hills of Western Ghats, Coimbatore District, Tamil Nadu - A Potential Ecosystem For Medicinal Plants.researchplantscienceBelum ada peringkat

- Stenochlaena PalustrisDokumen1 halamanStenochlaena Palustrist_h_e-scientistBelum ada peringkat

- Crop Rotation Leaflet-1Dokumen4 halamanCrop Rotation Leaflet-1mradulescuBelum ada peringkat

- Angiosuppressive Activity of Winged BeanDokumen14 halamanAngiosuppressive Activity of Winged BeanGlenn SiachuaBelum ada peringkat

- Menu ProjectDokumen1 halamanMenu Projectapi-357256089Belum ada peringkat

- May 2011 Binnaway Bush TelegraphDokumen28 halamanMay 2011 Binnaway Bush TelegraphBinnawayBelum ada peringkat

- C1 Biodiversity 2023 2AEDokumen35 halamanC1 Biodiversity 2023 2AEHana Farzana ErynaBelum ada peringkat

- Common Core Worksheet Ri.1.7Dokumen1 halamanCommon Core Worksheet Ri.1.7ayeh7880Belum ada peringkat

- Veratrum VirideDokumen11 halamanVeratrum VirideNanda S RBelum ada peringkat

- Classification IGCSEDokumen55 halamanClassification IGCSEelizabethBelum ada peringkat

- Botrytis Bunch Rot of Grape (Botrytis Cinerea) - Pest Management - B.C. Ministry of AgricultureDokumen4 halamanBotrytis Bunch Rot of Grape (Botrytis Cinerea) - Pest Management - B.C. Ministry of AgricultureSiva KumarBelum ada peringkat

- Anthurium Micropropagation From Shoot Tip Explants PDFDokumen5 halamanAnthurium Micropropagation From Shoot Tip Explants PDFBrij Mohan SinghBelum ada peringkat

- HISTORICAL BEGINNINGSDokumen13 halamanHISTORICAL BEGINNINGSMhermina MoroBelum ada peringkat

- How To Care For A CalatheaDokumen17 halamanHow To Care For A CalatheaColeen AlidoBelum ada peringkat

- BE GOING TO Holiday PlansDokumen1 halamanBE GOING TO Holiday PlansIvana Jurić100% (2)