QAQC Manager, Authorized API

Diunggah oleh

عصمت ضيف اللهDeskripsi Asli:

Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

QAQC Manager, Authorized API

Diunggah oleh

عصمت ضيف اللهHak Cipta:

Format Tersedia

Esmat Deif Allah Abdel Malek

QA/QC Manager, Authorized CSWIP3.1 and API 570, 510 Inspector

Egypt, Alexandria

E-mail:

diaeesmat@gmail.com Website: http://www.linkedin.com/profile/view? id=48282955&trk=nav_responsive_tab_profile Phone: 00201281704687 00201012483250

OBJECTIVE

Has 15 years of experience within O i l /Gas & Petrochemical and Power Plants industry as QA/QC Manager, A/QC Engineer and Welding Inspector for on shore and offshore Production facilities for several petroleum companies and power generation companies including: Saudi Aramco - PID Senior Inspector ( Saudi Arabia ) Seimens PG - site QA/QC manager ( Saudi Arabia ) CCC ( Consolidated contractors company.) - QA/QC piping engineer (Saudi Arabia) GUPCO (Gulf of Suiz Pet r ol eum Company -QA/QC Engineer (Egypt) PETROBEL ( Balyim P e t r o l e u m Company) -QA/QC Engineer (Egypt) FREMSS V P (the American Egyptian Manufacture steel structure)(Egypt) Has conversant with International codes such as Saudi Aramco Standard , ASME IX/ VIII Div.1/ IIA/ IIC/ I / V, ASME B31.1/ B31.3/B31.8 B16.5 , AWS D1.1, ASTM, API 570 , API510 , API650, API 577 , API 571 , API 572 , API 574 , API 576 , API 1104, DNV 2000 , etc

QUALIFICATIONS

API 510 Authorized pressure vessel inspector (waiting Certificate) API 570 Authorized piping inspector (Certificate No: 49112) CSWIP 3.1 Quality Management System (Auditor/Lead auditor) (IRCA) Professional program for Welding engineering from (American University in Cairo) Radiographic testing ASNT Level II Ultrasonic testing ASNT Level II Magnetic testing ASNT Level II Dye penetrant testing ASNT Level II Menoufia University 1995 Attend pre-construction meetings (kick-off meetings). Attend Weekly Project Progress and QC Meetings. Follow up and assist QA/QA inspector's performance and data entry. Review the Contractor's look-ahead schedule to assist in the planning of coverage of the work activities.

DUTIES AND RESPONSIBILITIES

Es m at D e i f Al l ah Ab d e l M al e k

Attend as an observer both the Contractor's Internal Quality Audit and the closing meeting. Interview Contractor's proposed QC and NDT candidates and may also disqualify any individual or agency on technical grounds or unsatisfactory performance. Monitor the Contractor training program to ensure that all Contractor and SubContractor personnel are familiar with the project quality requirements for Their area of responsibility. Reviewing and Preparation of Inspection and Test Plans (ITP) as per Specification and client requirement. Review of Mill test certificates as per the specifications. Issuing and reviewing WPS & PQR. Witnessing and Certifying the Welder Performance Qualifications Test (WPQT). Conducting Visual Inspection on Welds and parent material. Co-ordination with NDE works as per requirements. Conducting PT, MT for Surface checks and Sub surface Checks. Radiography film Interpretations. Issue NCRs for violation found during inspection. Preparation of Hydrostatic Test Packages and Pneumatic Test reports. Reviewing all specific QA/QC procedures related to fabrication/welding operations to maintain consistent, reliable and repeatable quality & Method Statements .

WORK EXPERIENCE

Aramco (through CTSA)

Aramco PID Senior inspector (SAP No. 70011848)

Feb.2010 Present

QA-4 A pipe line extended from Qa t i f area to Abqaiq area (approximately 200 KM Long) MGS Eastern Region Expansion SRG-2 for sales gas filtration stations. Stations are located at BARRI Area. SHY-1 A pipe lines Extended from Sh edgum area at Arabian gulf to Yanboa a t red sea aproximately120K long) UBTG-4 A pipe lines Extended from Sh edgum area to Barri ar ea . (Approximately 200 KM long Pipeline Projects starting between Dharan, RasTanura, Juaymah and Qatif up to Khafif.

Siemens PG

Site QA/AC Manager .Shuaibah Integrated Water & Power Plant (IWPP) Project

Feb.2007 July 2007

CCC (Consolidated contractors company)

Feb.2007 July 2007

Es m at D e i f Al l ah Ab d e l M al e k

QA/QC Engineer Rabigh Independent Water Steam Power Project

GUPCO (Gulf of Suiz Petroleum Company)

QA/QC Engineer

Jan.2005 Feb.2007

HAPY West Harbour Plant new LTS Train Project. Maintenance and construction welding activities for on/off shore facilities including : 1. Separator#2 mechanical repair @ July 10 platform. 2. Separator # a mechanical repair @ Badri #C platform. 3. Vessel #2610 mechanical repair @ FWKO Plant. 4. Desalter train #4 mechanical repair@ process plant. 5. Vessel #2605 mechanical repair @FWKO plant. 6. New glycol pump @ October

Petrobel (Belayim Petroleum Company)

QA/QC Engineer

Sep.2000 Jan 2005

24" pipe line from t em sah # 4 platform to temsah #N platform. 26" pipe line from Nour a s #a platform to subsea PLEM @Barboni platform. 8" pipeline (submarine line and land portion) from Sh or e to AMER #4 platform. 8" riser and AMER #4 hook up. MWP5 platform hook up (piping) and f i r e f i g h t i n g . 26" pipe line (Land Portion) . 36"" Slug Catcher. 8" Early Production Line. 26" submarine pipeline from Dar fe el platform to PLEM. 18" Submarine Pipeline from sh or e to MWP5 platform. Belayim Tank Batteries up Grading Project. Temsah Field Development project.

FREMS VP Steel structure

Welding & NDT inspector Steel Structure Fabrication

Sep 1998 Sep. 2000

Es m at D e i f Al l ah Ab d e l M al e k

Anda mungkin juga menyukai

- CV 2023Dokumen5 halamanCV 2023AmitBelum ada peringkat

- Bs Tech: Electrodes Issue and Return RegisterDokumen1 halamanBs Tech: Electrodes Issue and Return RegisterRhannie GarciaBelum ada peringkat

- NDT Request (Template)Dokumen4 halamanNDT Request (Template)Bethel NdifonBelum ada peringkat

- SAIC W 2069 in Process Welding InspectionDokumen8 halamanSAIC W 2069 in Process Welding InspectionAbdul Gafoor ShaikhBelum ada peringkat

- 8 Inspection and Testing PersonnelDokumen2 halaman8 Inspection and Testing PersonnelelmiraBelum ada peringkat

- ACG 22 Requirements For Lifting Equipment Inspection BodiesDokumen14 halamanACG 22 Requirements For Lifting Equipment Inspection BodiesramodBelum ada peringkat

- Welding Procedure Specification (WPS) : Chip Back To The Sound Metal and Re-WeldDokumen2 halamanWelding Procedure Specification (WPS) : Chip Back To The Sound Metal and Re-WeldAbdulmecit YetisBelum ada peringkat

- Inspection and Test Plan ReviewDokumen7 halamanInspection and Test Plan Reviewel_sharkawy2011Belum ada peringkat

- Procedure For WeldingDokumen7 halamanProcedure For WeldingMecon Hyderabad100% (1)

- Welding Inspector Job and ResponsilbilitiesDokumen5 halamanWelding Inspector Job and ResponsilbilitiesFelix GomintongBelum ada peringkat

- CV QAQC Manager-W.DORRI PDFDokumen6 halamanCV QAQC Manager-W.DORRI PDFMoaatazz NouisriBelum ada peringkat

- VT QB S4 Pro Wiyh KeyDokumen12 halamanVT QB S4 Pro Wiyh KeykingstonBelum ada peringkat

- Itp GRPDokumen4 halamanItp GRPJo FrancescBelum ada peringkat

- Linde Rates For Welding Test Services-2018Dokumen2 halamanLinde Rates For Welding Test Services-2018Hoque AnamulBelum ada peringkat

- Process Validation 1Dokumen1 halamanProcess Validation 1tayyabBelum ada peringkat

- A106 Seamless Carbon Steel Pipe: Hydrostatic TestingDokumen7 halamanA106 Seamless Carbon Steel Pipe: Hydrostatic TestingTan Chee MingBelum ada peringkat

- Rdb-Elseif Company LTD.: Job DescriptionDokumen1 halamanRdb-Elseif Company LTD.: Job DescriptionAsif ChahudaryBelum ada peringkat

- 30a100dbqb23010 - Exde06 - 77 Project Quality PlanDokumen81 halaman30a100dbqb23010 - Exde06 - 77 Project Quality Plansamuel madisonBelum ada peringkat

- Equipment Calibration LogDokumen5 halamanEquipment Calibration Logkero keropiBelum ada peringkat

- IQWQ-CE1092-QPQAC-00-0008 - 0 -QUALITY CONTROL PROCEDURE FOR STEEL STRUCTURE钢结构安装质量控制程序 PDFDokumen11 halamanIQWQ-CE1092-QPQAC-00-0008 - 0 -QUALITY CONTROL PROCEDURE FOR STEEL STRUCTURE钢结构安装质量控制程序 PDFAli MajeedBelum ada peringkat

- 4260Dokumen10 halaman4260Lipika GayenBelum ada peringkat

- Liquid Penetrant Examination ProcedureDokumen15 halamanLiquid Penetrant Examination ProcedureANH TAI MAI100% (1)

- VT & PT - NotesDokumen10 halamanVT & PT - Notessanjeev sahota100% (1)

- GE Energy Management Visual Inspection RequirementsDokumen10 halamanGE Energy Management Visual Inspection RequirementsKarthik P MuraliBelum ada peringkat

- Material Receiving Inspection Report: Project TitleDokumen2 halamanMaterial Receiving Inspection Report: Project TitleGomathyselviBelum ada peringkat

- A106 Pipe Spec SheetDokumen7 halamanA106 Pipe Spec SheetyanurarzaqaBelum ada peringkat

- Visual Inspection ReportDokumen2 halamanVisual Inspection ReportAlfian ImaduddinBelum ada peringkat

- WPQR Sample FormDokumen1 halamanWPQR Sample FormshwayeBelum ada peringkat

- 10.LPI. Report FormatDokumen1 halaman10.LPI. Report FormatEr Sumant Kumar SinghBelum ada peringkat

- Company Logo Added to QAP DocumentDokumen4 halamanCompany Logo Added to QAP Documentmanoj thakkar100% (1)

- Industry & Facilities Inspection ReportDokumen10 halamanIndustry & Facilities Inspection Reportkbpatel123Belum ada peringkat

- Shell Rolling Report 1Dokumen6 halamanShell Rolling Report 1Hanuman RaoBelum ada peringkat

- Welding Procedure Specification (Conform Cu /according To) : Specificatia Preliminara A Procedurii de SudareDokumen2 halamanWelding Procedure Specification (Conform Cu /according To) : Specificatia Preliminara A Procedurii de SudareStoian ValentinBelum ada peringkat

- PQR - WPQ Witness ReportDokumen1 halamanPQR - WPQ Witness Reportsdkeskar40Belum ada peringkat

- NCR Tracking Log AAILDokumen5 halamanNCR Tracking Log AAILssenthil04Belum ada peringkat

- Welding & NDE Summary Sheet (BE)Dokumen12 halamanWelding & NDE Summary Sheet (BE)MulPXBelum ada peringkat

- JD QAQC Engineer Mech 2016Dokumen2 halamanJD QAQC Engineer Mech 2016Sebastian Rajesh100% (1)

- Welder Performace Qualification Report 2014..Dokumen132 halamanWelder Performace Qualification Report 2014..Kayra Riri ChirulBelum ada peringkat

- Wps PQR FormatDokumen1 halamanWps PQR FormatVarun MalhotraBelum ada peringkat

- General Specification For Welding and Weld Inspection EIL PDFDokumen19 halamanGeneral Specification For Welding and Weld Inspection EIL PDFValesh MonisBelum ada peringkat

- LV Switch Board 1.1.2 - Test Report For Visual Check Report: ClientDokumen1 halamanLV Switch Board 1.1.2 - Test Report For Visual Check Report: ClientsameershahzanBelum ada peringkat

- PreheatDokumen2 halamanPreheatScott TrainorBelum ada peringkat

- Al-Kifah: Company ProfileDokumen32 halamanAl-Kifah: Company ProfileShiju BhaiBelum ada peringkat

- Hyundai Electrode CATALOG - 7thDokumen134 halamanHyundai Electrode CATALOG - 7tharianaseri100% (1)

- Inspection Flash Report: RFI NO & Date: 1.0 Type of VisitDokumen3 halamanInspection Flash Report: RFI NO & Date: 1.0 Type of VisitFahad AhmadBelum ada peringkat

- X-Ray Room Setup Method StatementDokumen19 halamanX-Ray Room Setup Method StatementJervino RuahBelum ada peringkat

- CV Mechanical Engineer with Extensive Experience in Oil & Gas ProjectsDokumen3 halamanCV Mechanical Engineer with Extensive Experience in Oil & Gas Projectshamza brahmiBelum ada peringkat

- CPVC ChecklistDokumen1 halamanCPVC Checklistchakravarthi kanugulaBelum ada peringkat

- Welding Procedure Specification For GTAWDokumen9 halamanWelding Procedure Specification For GTAWraja reyhanBelum ada peringkat

- WFP 2-01 ASME B31 Piping Welding ProcedureDokumen8 halamanWFP 2-01 ASME B31 Piping Welding Procedureleodavid87Belum ada peringkat

- 1 Imran Piping QC CVDokumen4 halaman1 Imran Piping QC CVkazim MirzaBelum ada peringkat

- B H e L Limited RTDokumen13 halamanB H e L Limited RTbhavin17850% (2)

- JIMT Visual Inspection ReportDokumen1.913 halamanJIMT Visual Inspection Reportgomathyselvi100% (1)

- Welders Continuity Log: Name Welder ID ProcessDokumen4 halamanWelders Continuity Log: Name Welder ID ProcessMacelBelum ada peringkat

- Welder Performance Qualification WPQDokumen3 halamanWelder Performance Qualification WPQramzi5ben5ahmed100% (1)

- Guidance To Prepare Wps PQR For WeldingDokumen1 halamanGuidance To Prepare Wps PQR For WeldingHamid MansouriBelum ada peringkat

- Industrial radiography A Complete Guide - 2019 EditionDari EverandIndustrial radiography A Complete Guide - 2019 EditionBelum ada peringkat

- C.V. Summary of QA/QC Manager with 17+ Years ExperienceDokumen8 halamanC.V. Summary of QA/QC Manager with 17+ Years Experienceعصمت ضيف اللهBelum ada peringkat

- Technofac: Welding Inspector CSWIP 3.1 Non Destructive Examination (NDE), ASNT Level-IIDokumen9 halamanTechnofac: Welding Inspector CSWIP 3.1 Non Destructive Examination (NDE), ASNT Level-IIElankumaran PeriakaruppanBelum ada peringkat

- APIINSPECTORDokumen10 halamanAPIINSPECTORdada khalandarBelum ada peringkat

- Temporary Repair RegisterDokumen6 halamanTemporary Repair Registerعصمت ضيف اللهBelum ada peringkat

- Asset Integrity Daily ReportDokumen1 halamanAsset Integrity Daily Reportعصمت ضيف اللهBelum ada peringkat

- ASSET INTEGRITY SECTION DAILY REPORTDokumen1 halamanASSET INTEGRITY SECTION DAILY REPORTعصمت ضيف اللهBelum ada peringkat

- Answer of Cswip-2015Dokumen2 halamanAnswer of Cswip-2015عصمت ضيف اللهBelum ada peringkat

- Pmbok 5thDokumen5 halamanPmbok 5thfloayzav5684Belum ada peringkat

- Pmbok 5thDokumen5 halamanPmbok 5thfloayzav5684Belum ada peringkat

- Welder MatrixDokumen12 halamanWelder Matrixعصمت ضيف اللهBelum ada peringkat

- Cswip 2015 Q& ADokumen61 halamanCswip 2015 Q& ANaga Jothi50% (2)

- Tanks - Specification For Tank Hydrotest PDFDokumen24 halamanTanks - Specification For Tank Hydrotest PDFعصمت ضيف اللهBelum ada peringkat

- FFS SheetDokumen28 halamanFFS Sheetعصمت ضيف الله50% (2)

- PMP FormulasDokumen3 halamanPMP FormulasMohyuddin A MaroofBelum ada peringkat

- C.V. Summary of QA/QC Manager with 17+ Years ExperienceDokumen8 halamanC.V. Summary of QA/QC Manager with 17+ Years Experienceعصمت ضيف اللهBelum ada peringkat

- 01 Introductiontoframework 101018053825 Phpapp01Dokumen52 halaman01 Introductiontoframework 101018053825 Phpapp01Uma KandukuriBelum ada peringkat

- Inspection HandbookDokumen126 halamanInspection Handbooksteffy18295% (21)

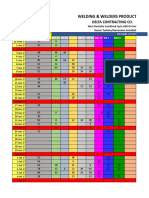

- Welding & Welders ActivitiesDokumen4 halamanWelding & Welders Activitiesعصمت ضيف اللهBelum ada peringkat

- ASME VIII Div. 1 - 6 Pressure TestingDokumen26 halamanASME VIII Div. 1 - 6 Pressure Testingعصمت ضيف الله75% (4)

- Mandatory Minimum NondestructiveDokumen1 halamanMandatory Minimum Nondestructiveعصمت ضيف اللهBelum ada peringkat

- Pressure Vessel InterviewDokumen4 halamanPressure Vessel Interviewعصمت ضيف اللهBelum ada peringkat

- Slides Project Management Professional (Pmi) Study GuideDokumen270 halamanSlides Project Management Professional (Pmi) Study Guideapi-27145250100% (7)

- PMP CH 6-1 (Time Management)Dokumen109 halamanPMP CH 6-1 (Time Management)عصمت ضيف اللهBelum ada peringkat

- PMP CH 5-2Dokumen76 halamanPMP CH 5-2عصمت ضيف اللهBelum ada peringkat

- Piping Interview QuestionsDokumen22 halamanPiping Interview Questionsmsaad288% (34)

- PMP CH 4 IntegrationDokumen102 halamanPMP CH 4 Integrationعصمت ضيف اللهBelum ada peringkat

- Welder and Procedure QualificationDokumen26 halamanWelder and Procedure Qualification'Izzad AfifBelum ada peringkat

- PMP FormulasDokumen3 halamanPMP FormulasMohyuddin A MaroofBelum ada peringkat

- ASME VIII Div. 1 - 5 External PressureDokumen32 halamanASME VIII Div. 1 - 5 External Pressureعصمت ضيف الله100% (2)

- 01 Introductiontoframework 101018053825 Phpapp01Dokumen52 halaman01 Introductiontoframework 101018053825 Phpapp01Uma KandukuriBelum ada peringkat

- Asme Viii Div. 1 - 3 StaticheadDokumen35 halamanAsme Viii Div. 1 - 3 Staticheadعصمت ضيف الله100% (2)

- ASME VIII Div. 1 - 2 Joint EfficiencyDokumen28 halamanASME VIII Div. 1 - 2 Joint Efficiencyعصمت ضيف الله89% (9)

- TransistorDokumen1 halamanTransistorXhaBelum ada peringkat

- B. Ing Kls 6Dokumen5 halamanB. Ing Kls 6siskaBelum ada peringkat

- Symmetry (Planes Of)Dokumen37 halamanSymmetry (Planes Of)carolinethami13Belum ada peringkat

- 10 Slides For A Perfect Startup Pitch DeckDokumen6 halaman10 Slides For A Perfect Startup Pitch DeckZakky AzhariBelum ada peringkat

- ASTM D256-10 - Standard Test Methods For Determining The Izod Pendulum Impact Resistance of PlasticsDokumen20 halamanASTM D256-10 - Standard Test Methods For Determining The Izod Pendulum Impact Resistance of PlasticsEng. Emílio DechenBelum ada peringkat

- 2.4 Avogadro's Hypothesis+ Equivalent MassesDokumen12 halaman2.4 Avogadro's Hypothesis+ Equivalent MassesSantosh MandalBelum ada peringkat

- Practical Research 2: Self-Learning PackageDokumen3 halamanPractical Research 2: Self-Learning PackagePrinces BaccayBelum ada peringkat

- Jazan Refinery and Terminal ProjectDokumen3 halamanJazan Refinery and Terminal ProjectkhsaeedBelum ada peringkat

- Practice Like-Love - Hate and PronounsDokumen3 halamanPractice Like-Love - Hate and PronounsangelinarojascnBelum ada peringkat

- Lecture 1 Family PlanningDokumen84 halamanLecture 1 Family PlanningAlfie Adam Ramillano100% (4)

- Reservoir Rock TypingDokumen56 halamanReservoir Rock TypingAffan HasanBelum ada peringkat

- Impolitic Art Sparks Debate Over Societal ValuesDokumen10 halamanImpolitic Art Sparks Debate Over Societal ValuesCarine KmrBelum ada peringkat

- PW CDokumen4 halamanPW CAnonymous DduElf20OBelum ada peringkat

- Laws of MotionDokumen64 halamanLaws of MotionArnel A. JulatonBelum ada peringkat

- Job Description Support Worker Level 1Dokumen4 halamanJob Description Support Worker Level 1Damilola IsahBelum ada peringkat

- NOTE CHAPTER 3 The Mole Concept, Chemical Formula and EquationDokumen10 halamanNOTE CHAPTER 3 The Mole Concept, Chemical Formula and EquationNur AfiqahBelum ada peringkat

- Russian Tea Market Growth and Brand PreferenceDokumen6 halamanRussian Tea Market Growth and Brand PreferenceKing KhanBelum ada peringkat

- Planview Innovation Management Maturity Model PDFDokumen1 halamanPlanview Innovation Management Maturity Model PDFMiguel Alfonso Mercado GarcíaBelum ada peringkat

- S2 Retake Practice Exam PDFDokumen3 halamanS2 Retake Practice Exam PDFWinnie MeiBelum ada peringkat

- Conceptual FrameworkDokumen24 halamanConceptual Frameworkmarons inigoBelum ada peringkat

- Desert Power India 2050Dokumen231 halamanDesert Power India 2050suraj jhaBelum ada peringkat

- BMS Technical ManualDokumen266 halamanBMS Technical Manualiago manziBelum ada peringkat

- Mechanics of Deformable BodiesDokumen21 halamanMechanics of Deformable BodiesVarun. hrBelum ada peringkat

- Paradigm Shift Essay 2Dokumen17 halamanParadigm Shift Essay 2api-607732716Belum ada peringkat

- NGPDU For BS SelectDokumen14 halamanNGPDU For BS SelectMario RamosBelum ada peringkat

- Guide to Fair Value Measurement under IFRS 13Dokumen3 halamanGuide to Fair Value Measurement under IFRS 13Annie JuliaBelum ada peringkat

- AE-Electrical LMRC PDFDokumen26 halamanAE-Electrical LMRC PDFDeepak GautamBelum ada peringkat

- Hawk Technology Systems v. NCLDokumen6 halamanHawk Technology Systems v. NCLPriorSmartBelum ada peringkat

- Report Daftar Penerima Kuota Telkomsel Dan Indosat 2021 FSEIDokumen26 halamanReport Daftar Penerima Kuota Telkomsel Dan Indosat 2021 FSEIHafizh ZuhdaBelum ada peringkat

- PC November 2012Dokumen50 halamanPC November 2012bartekdidBelum ada peringkat