Assignment 1 Mechanics of Machine

Diunggah oleh

Ir Mohammad FirdausHak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Assignment 1 Mechanics of Machine

Diunggah oleh

Ir Mohammad FirdausHak Cipta:

Format Tersedia

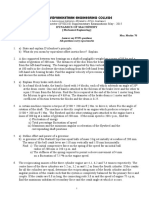

1) An elevator is driven by an electric motor through two gears set.

Motor produces maximum torque of 1000Nm and the transmission efficiency of each contact between gear is 90%. Find the mass M2 (buffer load) required if the lift has to moves up with an acceleration of 0.5m/s2 with 2000kg load (including the mass of the elevator). Elevator movement and buffer load is effected by a constant force 500N. Data system used is as follows. N1 (Number of teeth of gear 1) = 80 N3(Number of teeth of gear 3) = 20 Ih (Inertia of hoist shaft) = 50kgm2 Im (Inertia of motor shaft) = 2kgm2 N2 (Number of teeth of gear 2) = 100 N4 (Number of teeth of gear 4) = 40 It(Inertia of middle shaft) = 20kgm2

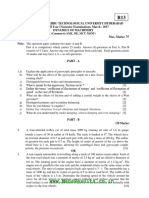

2) A mass of M kg load has to raised on a platform with slope of 1 in 20. The total torque at the drum resulting the load is accelerated with an acceleration of 0.8m/s2 is 3800Nm and the

resistance force on track is 1500N. The drum has a diameter of 0.8m and is driven by an electric motor through a reduction gear system. The efficiency is 95% between gear contact and frictional torque is equal to 10Nm torque at the motor shaft and 20Nm on the drum shaft shaft. If the motor speed is 477.5 rpm, obtain the mass M and the motor power required. Use Im = 9 kgm2, and Ig = 60 kgm2.

3) Figure below shows side view of planetary gearbox. A1 outer gear is locked. Gear S1 and S2 is attach to drive shaft. Total gear teeth are as follows: A1=80, A2=80, S1=20, S2=40. Find the ratio between the input and output shafts .

4) A drive system with two V-shaped conveyor belts were installed parallel on grooved identical pulleys. Drive system used is an open type with distance between the shaft is 1m.

Beam angle of the pulley is 45 , the coefficient of friction is 0.2 and the cross section area of the belt is 600mm2. The density of the belt material is 1.5Mg/m2 and maximum safe stress of the material is 10MN/m2 . Both pulley diameter is 350mm with speed of 1600rpm. Determine the power transmitted between those shaft. Also determine the speed of shaft when the transmitted power is maximum.

5) A 200mm diameter flat type open drive configuration pulley rotating at 1750rpm driving the other pulley with diameter of 800mm. The shafts are 1 m apart, the mass of the belt is 0.5kg /m and the maximum allowable tension is 800N.

a) If the coefficient of friction on the pulley and the belt' is 0.3, determine the maximum tension different in the belt system. b) If the conveyor belts used had 400mm2 cross-sectional area and modulus of elasticity E of 500MN/mm2, determine the speed pulley and power transmitted in event of maximum power transmitted.

Anda mungkin juga menyukai

- O level Physics Questions And Answer Practice Papers 2Dari EverandO level Physics Questions And Answer Practice Papers 2Penilaian: 5 dari 5 bintang5/5 (1)

- TN75D Ops ManualDokumen302 halamanTN75D Ops ManualСергій Боженко100% (1)

- Reciprocating CompressorDokumen12 halamanReciprocating CompressorKha Mn100% (3)

- CASE 580 Super M Presentation PreliminaryDokumen6 halamanCASE 580 Super M Presentation PreliminaryDian SikumbangBelum ada peringkat

- Scx800 2 CrawlerDokumen64 halamanScx800 2 CrawlerwitonoBelum ada peringkat

- Driver Information Module User ManualDokumen33 halamanDriver Information Module User ManualDJAGBABelum ada peringkat

- PW160 7Dokumen24 halamanPW160 7Baciu SorinBelum ada peringkat

- V7III Tech Manual enDokumen335 halamanV7III Tech Manual enBen MorgenBelum ada peringkat

- Audi A3Dokumen76 halamanAudi A3Borislav100% (2)

- Land Cruiser 100 OZDokumen4 halamanLand Cruiser 100 OZaneshareiBelum ada peringkat

- Assignment (4) Forced Vibration of SDOF Systems PDFDokumen2 halamanAssignment (4) Forced Vibration of SDOF Systems PDFKarim FangaryBelum ada peringkat

- Manual de Partes Hyster Japon B466Dokumen1.154 halamanManual de Partes Hyster Japon B466Ignacio100% (1)

- Psi Max2000 AgitatorsDokumen167 halamanPsi Max2000 Agitatorssaipem880% (1)

- Manual de Partes Toro 0010 Often Required ItemsDokumen57 halamanManual de Partes Toro 0010 Often Required Itemscacoman93100% (1)

- Case 590SL PDFDokumen184 halamanCase 590SL PDFAlexBelum ada peringkat

- PM Checklist Ensures Vehicle SafetyDokumen4 halamanPM Checklist Ensures Vehicle SafetyChino Pacia100% (1)

- About Edm MachineDokumen12 halamanAbout Edm MachineIr Mohammad FirdausBelum ada peringkat

- Study of a reluctance magnetic gearbox for energy storage system applicationDari EverandStudy of a reluctance magnetic gearbox for energy storage system applicationPenilaian: 1 dari 5 bintang1/5 (1)

- BDA 20303 - Mechanics of Machines Assignment 1Dokumen2 halamanBDA 20303 - Mechanics of Machines Assignment 1HakimBelum ada peringkat

- Assignment MomDokumen4 halamanAssignment Momdudescape0% (3)

- Question Paper Code:: (10×2 20 Marks)Dokumen4 halamanQuestion Paper Code:: (10×2 20 Marks)Iyyappan SubramanianBelum ada peringkat

- PVP Siddhartha Mech Engineering III Sem HomeworkDokumen2 halamanPVP Siddhartha Mech Engineering III Sem HomeworkNarayanarao PalagaraBelum ada peringkat

- 9A03502 Dynamics of MachineryDokumen4 halaman9A03502 Dynamics of MachinerysivabharathamurthyBelum ada peringkat

- Previous Questions DomDokumen5 halamanPrevious Questions DomSafeer MBelum ada peringkat

- DOM PortantDokumen6 halamanDOM PortantkannanBelum ada peringkat

- V Belt Drive-ProblemsDokumen1 halamanV Belt Drive-ProblemsLightBelum ada peringkat

- S6 QB MeDokumen18 halamanS6 QB MevenkiteshksBelum ada peringkat

- Physics Components and ForcesDokumen22 halamanPhysics Components and ForcesRed Crazy0% (1)

- 081B52EFAC704D5AB58072B74C443C48Dokumen3 halaman081B52EFAC704D5AB58072B74C443C48yashvantBelum ada peringkat

- Dynamics of Machinery QuestionsDokumen11 halamanDynamics of Machinery Questionslogeshboy0070% (1)

- PBR VISVODAYA ENGINEERING COLLEGE MECHANICAL ENGINEERING UNIT-IDokumen7 halamanPBR VISVODAYA ENGINEERING COLLEGE MECHANICAL ENGINEERING UNIT-Ihod mechBelum ada peringkat

- NR-310304 - Dynamics of MachineryDokumen8 halamanNR-310304 - Dynamics of MachinerySrinivasa Rao GBelum ada peringkat

- 2MID EXAMS ENGINE MODEL QUESTIONSDokumen4 halaman2MID EXAMS ENGINE MODEL QUESTIONSSrimanthula SrikanthBelum ada peringkat

- Design of Machinery Jntua Previous PapersDokumen20 halamanDesign of Machinery Jntua Previous PapersHimadhar SaduBelum ada peringkat

- Forced VibrationsDokumen3 halamanForced VibrationsshethBelum ada peringkat

- DOM2Dokumen7 halamanDOM2ds_shivaBelum ada peringkat

- Machine Theory NumericalsDokumen5 halamanMachine Theory NumericalsSaad FarooqBelum ada peringkat

- Anna University Madras Institute of Technology: 718 R.P.M N 843 R.P.M)Dokumen4 halamanAnna University Madras Institute of Technology: 718 R.P.M N 843 R.P.M)veeyeskay_2006Belum ada peringkat

- ME-311 Belt 2018Dokumen2 halamanME-311 Belt 2018VishnuBelum ada peringkat

- Home Take Individual ExaminationDokumen3 halamanHome Take Individual ExaminationTamrat GezahgneBelum ada peringkat

- Au Qp-Me8594 PDFDokumen18 halamanAu Qp-Me8594 PDFMariappan VBelum ada peringkat

- MEC304 ModelDokumen2 halamanMEC304 ModelKKBelum ada peringkat

- DOM Unit 4 & 5 QBDokumen6 halamanDOM Unit 4 & 5 QBRayleighBelum ada peringkat

- Rr320304 Dynamics of MachinesDokumen8 halamanRr320304 Dynamics of MachinesSrinivasa Rao GBelum ada peringkat

- QB For Mid-IiDokumen3 halamanQB For Mid-Iihod mechBelum ada peringkat

- Mechanism MechanicsDokumen5 halamanMechanism MechanicsEzmel KazimBelum ada peringkat

- Tutorial 02 Turning Moment Diagram and Flywheel - 2Dokumen1 halamanTutorial 02 Turning Moment Diagram and Flywheel - 2snafuxxspartanBelum ada peringkat

- Forced Vibration of 1 DOF Systems ExercisesDokumen12 halamanForced Vibration of 1 DOF Systems ExercisesMohammed Al HelaylBelum ada peringkat

- Forced Vibration123Dokumen4 halamanForced Vibration123Himanshu KhannaBelum ada peringkat

- DOM Model PaperDokumen2 halamanDOM Model PaperRambabuDaraBelum ada peringkat

- Ca - 2Dokumen2 halamanCa - 2balaguru78Belum ada peringkat

- Assignment Questions Dom Me 5004Dokumen5 halamanAssignment Questions Dom Me 5004sharmasweeta927Belum ada peringkat

- Model Question BankDokumen4 halamanModel Question BankVinod BalakrishnanBelum ada peringkat

- DYNAMICS OF MACHINERY EXAMDokumen2 halamanDYNAMICS OF MACHINERY EXAMSoumya BsoumyaBelum ada peringkat

- ME 354 VIBRATION & CONTROL (2018-19) Problems On Single-Degree-of-Freedom SystemsDokumen4 halamanME 354 VIBRATION & CONTROL (2018-19) Problems On Single-Degree-of-Freedom SystemsMukul Chandra0% (1)

- Dom Questions For Mid1Dokumen4 halamanDom Questions For Mid1Sai SmartBelum ada peringkat

- Dynamics of Machinery Question BankDokumen8 halamanDynamics of Machinery Question BankArun ShawnBelum ada peringkat

- MECHANICAL ENGINEERING DYNAMICS OF MACHINERY MODEL QUESTION PAPERDokumen4 halamanMECHANICAL ENGINEERING DYNAMICS OF MACHINERY MODEL QUESTION PAPERNirman ParasharBelum ada peringkat

- ME2302 Dynamics of Machinery Question Bank Part A and BDokumen14 halamanME2302 Dynamics of Machinery Question Bank Part A and BNagendar SelvakumarBelum ada peringkat

- Jntu Question PaperDokumen3 halamanJntu Question Paperrohitchanakya76Belum ada peringkat

- R05320304-Dynamics of MachineryDokumen8 halamanR05320304-Dynamics of MachinerySRINIVASA RAO GANTABelum ada peringkat

- rr320304 Dynamics of MachinesDokumen8 halamanrr320304 Dynamics of MachinesSRINIVASA RAO GANTABelum ada peringkat

- Dynamics of Machines 4 Units New Question BankDokumen4 halamanDynamics of Machines 4 Units New Question BankgbharathreddysBelum ada peringkat

- Belt Drive Assignment Problems SolvedDokumen2 halamanBelt Drive Assignment Problems SolvedNevil ModiBelum ada peringkat

- Mom T2 QPDokumen1 halamanMom T2 QPsutha_me20098282Belum ada peringkat

- Design spur gears transmit powerDokumen3 halamanDesign spur gears transmit powerMohammed YunusBelum ada peringkat

- Single DOF System Excited Vibrations ProblemsDokumen3 halamanSingle DOF System Excited Vibrations ProblemsghulmBelum ada peringkat

- Problemas de Dinamica de Los Accionamientos EléctricosDokumen6 halamanProblemas de Dinamica de Los Accionamientos EléctricosSoath SotoBelum ada peringkat

- DOM Assignment 2022-23Dokumen11 halamanDOM Assignment 2022-23Pratham DakoriaBelum ada peringkat

- Assignment - 1 For 1st Test of DOMDokumen2 halamanAssignment - 1 For 1st Test of DOMHareesha N GBelum ada peringkat

- Possible Exercise On Machine Element Two Flat BeltDokumen4 halamanPossible Exercise On Machine Element Two Flat BeltAbebaw AyeleBelum ada peringkat

- DOM Model QuestionDokumen2 halamanDOM Model QuestionSenthilkumar SubbiahBelum ada peringkat

- Assignment QuestionsDokumen12 halamanAssignment QuestionsPallavi CholkhaneBelum ada peringkat

- JuruteraDokumen2 halamanJuruteraIr Mohammad FirdausBelum ada peringkat

- List of Engineering AssociationDokumen1 halamanList of Engineering AssociationIr Mohammad FirdausBelum ada peringkat

- India's Biomass Energy: Advantages of Biomass PyramidsDokumen22 halamanIndia's Biomass Energy: Advantages of Biomass PyramidsIr Mohammad FirdausBelum ada peringkat

- Biomass EnergyDokumen5 halamanBiomass EnergySurendra BamBelum ada peringkat

- Boyle's LawDokumen10 halamanBoyle's LawIr Mohammad FirdausBelum ada peringkat

- ConxDokumen1 halamanConxIr Mohammad FirdausBelum ada peringkat

- 10 Advantages of Biomass Energy SourcesDokumen3 halaman10 Advantages of Biomass Energy Sourcesgeeturamchandani198877Belum ada peringkat

- Boyle's Law LatestxDokumen6 halamanBoyle's Law LatestxIr Mohammad FirdausBelum ada peringkat

- ConxDokumen1 halamanConxIr Mohammad FirdausBelum ada peringkat

- EdmDokumen12 halamanEdmIr Mohammad Firdaus100% (1)

- Rev Amalie SYN ATF Spec SheetDokumen2 halamanRev Amalie SYN ATF Spec SheetAlejandro Alejandro MoenaBelum ada peringkat

- Helicopter Theory DevelopmentDokumen20 halamanHelicopter Theory Developmentkarthick ram selvamBelum ada peringkat

- Vibratory Soil Compactor CS533E EN PDFDokumen16 halamanVibratory Soil Compactor CS533E EN PDFJuan EstebanBelum ada peringkat

- RX ProcedureDokumen10 halamanRX ProcedureJoko GondrongBelum ada peringkat

- DTC P0711 Transmission Fluid Temperature Sensor "A" PerformanceDokumen2 halamanDTC P0711 Transmission Fluid Temperature Sensor "A" PerformanceluisBelum ada peringkat

- Frameless High Torque Motors: Product BrochureDokumen20 halamanFrameless High Torque Motors: Product Brochurevivekcs11Belum ada peringkat

- 52F5 07 2016Dokumen32 halaman52F5 07 2016mamaligosu1Belum ada peringkat

- F1 W06 Hybrid Technical Specification and InformationDokumen8 halamanF1 W06 Hybrid Technical Specification and InformationBlaze123xBelum ada peringkat

- Synchronous Motors Selection Guide KM - SG - 000183 - en-USDokumen24 halamanSynchronous Motors Selection Guide KM - SG - 000183 - en-USJuan Francisco Marin MendiolaBelum ada peringkat

- Tatra t810 Commercial enDokumen20 halamanTatra t810 Commercial enGerard Piedra GarcíaBelum ada peringkat

- Series A, E, G, H, L, P, SR: Operating InstructionsDokumen24 halamanSeries A, E, G, H, L, P, SR: Operating InstructionsAMIRBelum ada peringkat

- LearingDokumen95 halamanLearingNazmul HassanBelum ada peringkat

- 21 GBDokumen57 halaman21 GBjahzooneBelum ada peringkat

- Automobile Cleaner ReportDokumen24 halamanAutomobile Cleaner ReportHarshal TalsaniaBelum ada peringkat

- Aircraft Engine Types and APU InstallationsDokumen13 halamanAircraft Engine Types and APU InstallationsAbdul MuizzBelum ada peringkat