2949 HSE Risk Register - 2013-06-16 RevD1-VB Free

Diunggah oleh

salic2013Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

2949 HSE Risk Register - 2013-06-16 RevD1-VB Free

Diunggah oleh

salic2013Hak Cipta:

Format Tersedia

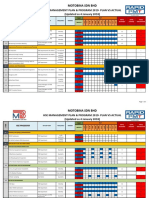

DT HSE Risk Register

Date: 8/3/2013

1 xxx 2

QFM-DT-042 Rev D01 dated 13-06-2013

Register Type:

3 4 5 6

DT / Dept:

7 8 9 10 11 (Base / Inherent Risk) / Impact Significance (without controls) 12 13

Project: FEED

FOR REPLACEMENT OF DIESEL ENGINE DRIVEN IAC PACKAGE

17 18 19 20 21 22 23 24 25 26 Residual Risk / Impact Significance (Post Additional Controls) Environment

14 15 16 Risk / Impact Significance (with Current Controls) Environment

Risk / Significance Zone

Risk / Significance Zone

Environment

Item No.

Unit / Area / Activity

Hazard / Aspect

Hazard / Aspect Description / Scenario

Consequence/ Impact (Result of failure)

Legal / QP Requirement

Current Controls (Physical / Admin)

Planned Additional Implementation Controls required Date

1. Construction HSE plan to include heat stress management plan as per QP procedures. 2. Construction HSE 8/22/2013 plan to include close monitoring of heat stress management by the EPIC contractor

Action Party

Review Date

32

Climate extremes

High temperature/ humidity

Possible heat stress to the construction workers leading to potential injury/ fatality during work at height

Blank

Construction HSE Plan/Restricted working hours during summer/Firstaid/ERP (Emergency Response Plan)

B4

Medium

EPE

B1

32

Climate extremes

High temperature/ humidity

Possible malfunction of equipment/ instrument due to hot and humid weather

Blank

Equipment / instruments are designed for the environmental conditions of the facility as per project specifications Shade provided for outside equipment / instruments Construction HSE Plan/PTW/First-aid/ERP (Emergency Response Plan) Pre-filters with alarms and trip for differential pressure are provided in design and are considered appropriate as the compressor is not on continuous duty. Equipment / instruments are designed for the environmental conditions of the facility as per project specifications. Equipment/ panels / instrument are designed as per IP 65 rating Lifting Plan/Construction HSE Plan/PTW/First-aid/ERP (Emergency Response Plan)

B2

Low

32

Climate extremes

Sand storm/ high winds

Possible injury/ fatality during work at height during high winds

Blank

B4

Medium

3. Construction HSE plan to include close monitoring of high 8/22/2013 wind hazards by the EPIC contractor

EPE

B1

32

Climate extremes

Sand storm/ high winds

Possible damage to the compressor due to dust ingress

Blank

B3

Medium

B1

32

Climate extremes

Sand storm/ high winds

32

Climate extremes

Sand storm/ high winds

Possible equipment / instrument malfunction due to dust ingress Possibility of dropped objects during lifting operations during high winds leading to possible personnel injury/ fatality or asset damage

Blank

B2

Low 4. Construction HSE plan to include close monitoring of lifting 8/22/2013 activities by the EPIC contractor. 5. Recommendations of geotechnical survey shall be 10/22/2013 considered in FEED design

Blank

B4

A0

B3

Medium

EPE

B1

32

Subsidence

Subsidence possibility

Possibility of damage to civil structures

Blank

Design is based on geotechnical survey

B3

Medium

EPE

B1

32

Geographical infrastructure

Possible escalation of Plant lay-out, pipeline routing, emergencies leading to area minimization possible injuries

Blank

Minimum safe distances as per QP fire and safety philosophy are considered in design Design is based on MoE requirements. Appropriate manual sampling provision is considered in design on stack.

B2

Low

32

Continuous plant discharges to air

Diesel engine driven compressor operation (not continuous operation)

Potential damage to environment

Blank

B1

Low

10

32

Waste disposal options

Improper handling of construction waste leading to environmental issues

Possible environmental issues

Blank

B2

Low

6. Ensure CEMP (Construction Environment Management Plan) is 8/22/2013 developed in-line with QP requirements

EPE

11

32

Waste disposal options

Waste generated during maintenance

Possible environmental issues

Blank

Existing QP waste management procedure/ facilities

B1

Low 7. Include the requirement to update the existing plant operating & 8/22/2013 control philosophy in view of this project in EPIC SOW.

12

32

Operations concept

Possible unavailability of Possible mal-operation updated operations philosophy leading to operational in context of additional supply disruption to NGL3 & 4

Blank

Project specific operational philosophy available.

B2

Low

EPE

Risk / Significance Zone

Low Blank Low Low Blank Low Low Blank Blank Blank Blank Blank

Reputation

Reputation

Reputation

People

People

People

Asset

Asset

Asset

Page 1 of 3

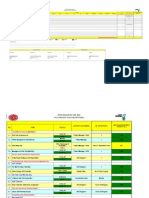

1 xxx

7 8 9 10 11 (Base / Inherent Risk) / Impact Significance (without controls)

12

13

14 15 16 Risk / Impact Significance (with Current Controls) Environment

17

18

19

20

21

22

23 24 25 26 Residual Risk / Impact Significance (Post Additional Controls) Environment

Risk / Significance Zone

Risk / Significance Zone

Environment

Item No.

Unit / Area / Activity

Hazard / Aspect

Hazard / Aspect Description / Scenario

Possible unavailability of updated maintenance philosophy in view of screw type compression and new lifting arrangements in this design

Consequence/ Impact (Result of failure)

Maintenance delays due to unavailability of updated maintenance philosophy

Legal / QP Requirement

Current Controls (Physical / Admin)

Planned Additional Implementation Controls required Date

8. Include the requirement to update the existing 8/22/2013 plant maintenance philosophy in view of this project in EPIC SOW. 9. Ensure that QP design specification ES-5-14-0121 for 10/22/2013 diesel engines are followed to address ignition sources in the FEED design.

Action Party

Review Date

13

32

Maintenance philosophy

Blank

B2

Low

EPE

14

32

Sources of ignition

Spark from diesel engine exhaust and static electricity.

Possible fire leading to personnel injuries and asset damage

Blank

Earthing/ bonding is considered for individual items in design.

B3

B3

Medium

EPE

B1

15

32

Equipment layout

Possible improper location of Compressor air intake

Possible flammable gas ingress in air intake system leading to operational disruption

Blank

Compressor air intake in located in safe area. Air intake flammable gas detection system will trip the compressor.

B2

Low

16

32

Tie-ins (shut down requirements)

Improper tie-in execution

Possible plant operational disruption and possible injury to personnel.

Blank

B3

B4

Medium

10. Ensure that tie-in philosophy / package 10/22/2013 is developed in consultation with QP.

EPE

B1

17

32

Interface shutdown/ blow down/ ESD

Interface requirement with F&G system

Possible wrong interfacing with the existing F&G system may lead to false activation of F&G system

Blank

B4

Medium

11. Ensure that QP approved interface method statement for F&G / ESD interface, is available 8/22/2013 prior to the interface activity. Include OEM involvement along with this requirement in EPIC SOW. 12. Ensure that QP approved method statements and JSAs are available prior to 8/22/2013 the excavation activity. Include this requirement in EPIC SOW.

EPE

B1

18

32

Possible presence of Excavation near underground services at existing cable trench proposed locations

Possible damage to the underground facilities

Blank

Design is based on underground facilities survey. PTW

B2

Low

EPE

19

32

Working hazards

Construction work in high noise Possible health impact on area construction workers Possible overlook on required HSE studies Possible injuries, asset damage due to unidentified hazards

Blank

Construction HSE Plan HAZID/ ENVID/ HAZOP/ SIL assessment are planned for FEED stage

B2

Low 13. Include the requirement of 8/22/2013 HAZID/ HAZOP studies in EPIC SOW 14. Ensure that H&ER is developed and updated during all phases of the project. 8/22/2013 Include this requirement in EPIC SOW. 15. Include in EPIC SOW to provide training to the operation and 8/22/2013 maintenance personnel in new compressor for this project. 7-4-13 (tentative date for EPIC Award)

20

32

Hazard studies

Blank

B3

B3

B3

Medium

EPE

B0

B0

B0

21

32

Hazards and effect register

Possible non-updated H&ER

Possible injuries, asset damage due to nonupdated H&ER

Blank

B3

B3

B3

Medium

EPE

B0

B0

B0

22

32

Training requirements

Possible mal-operation Possible lack of training in new leading to operational compressor to operation and disruption and possible maintenance staff injuries during maintenance

Blank

B2

B2

Low

EPE

23

32

Construction traffic

Generation of dust

Air pollution by dust, deposition of dust on the soil

QP Requirement (QP-STD-V-006, Section 7.6)

A0

High

Stop working activities during strong winds Cover waste loads on tracks Use adequate trucks for demolition waste transport

B2

Low

EPIC

Risk / Significance Zone

Blank Low Blank Low Low Blank Blank Low Low Blank Blank

Reputation

Reputation

Reputation

People

People

People

Asset

Asset

Asset

Page 2 of 3

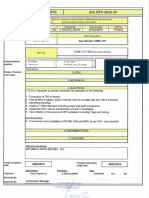

1 xxx

7 8 9 10 11 (Base / Inherent Risk) / Impact Significance (without controls)

12

13

14 15 16 Risk / Impact Significance (with Current Controls) Environment

17

18

19

20

21

22

23 24 25 26 Residual Risk / Impact Significance (Post Additional Controls) Environment

Risk / Significance Zone

Risk / Significance Zone

Environment

Item No.

Unit / Area / Activity

Hazard / Aspect

Hazard / Aspect Description / Scenario

Consequence/ Impact (Result of failure)

Legal / QP Requirement

Current Controls (Physical / Admin)

Minimize duration of vehicles engine work during stay on the site Provide regular maintenance of the vehicles Use high-quality fuel Minimize duration of vehicles engine work during stay on the site Provide regular maintenance of the vehicles Use high-quality fuel Provide protective curtains around the existing compressor during dismantling Provide spraying of working site with water during foundation demolition

Planned Additional Implementation Controls required Date

Action Party

Review Date

24

32

Construction traffic

Combustion gases emission

Air pollution by combustion gases

Executive By-laws of Environment Protection Law Chapter TwoProtection of Air Environment from Pollution & Annex No. (3/first)

High

D1

Low

7-4-13 (tentative date for EPIC Award)

EPIC

25

32

Removal of existing mechanical Existing compressor and electrical equipment, Air pollution by dust dismantling demolition of existing foundations

QP-STD-V-006, Section 7.6

High

C2

Medium

7-4-13 (tentative date for EPIC Award)

EPIC

Risk / Significance Zone

Blank Blank

Reputation

Reputation

Reputation

People

People

People

Asset

Asset

Asset

Page 3 of 3

Anda mungkin juga menyukai

- HSE Capability AssessmentDokumen5 halamanHSE Capability Assessmentsjmpak78% (18)

- Risk Assessment RegisterDokumen8 halamanRisk Assessment RegisterFareeha Waqar100% (10)

- Project Hse Plan Rev2 - ScribdDokumen35 halamanProject Hse Plan Rev2 - ScribdPaulSwinbank94% (36)

- Volkswagen RCD 510 Pin AssignmentsDokumen4 halamanVolkswagen RCD 510 Pin Assignmentssalic2013100% (1)

- HSE ProgramDokumen3 halamanHSE ProgramNadiah Abdul Rahaman100% (16)

- HSE StatisticsDokumen5 halamanHSE Statisticsgiri943100% (1)

- Hse StatisticsDokumen1 halamanHse StatisticsPaul Uwaya100% (5)

- SAMPLE HSE PlanDokumen28 halamanSAMPLE HSE PlanRahmat Adi Saputra100% (4)

- HSE MANAGEMENT PLAN 2019-Rev1Dokumen4 halamanHSE MANAGEMENT PLAN 2019-Rev1Nadiatul Aisyah Mohd Amirul Hakim86% (14)

- SHEQXel Performance Monitoring ToolDokumen105 halamanSHEQXel Performance Monitoring ToolEmil50% (2)

- MOI - Bigbelly Case - RIBARIC 20182109Dokumen4 halamanMOI - Bigbelly Case - RIBARIC 20182109Alizée Ribaric100% (1)

- Final Demo Detailed Lesson PlanDokumen9 halamanFinal Demo Detailed Lesson PlanAngelique Pabillona92% (12)

- Occupational Health, Safety & Environment Management System: Hse Biweekly ReportDokumen3 halamanOccupational Health, Safety & Environment Management System: Hse Biweekly ReportAhmed Hassan SabryBelum ada peringkat

- Hse Statistics Report Pp701 Hse f04 Rev.bDokumen1 halamanHse Statistics Report Pp701 Hse f04 Rev.bMohamed Mouner100% (1)

- Project HSE Performance Monitoring ProcedureDokumen12 halamanProject HSE Performance Monitoring ProcedureWinnie Eldama0% (1)

- HSE Plan Subcontractor # 3Dokumen81 halamanHSE Plan Subcontractor # 3Fauzi Awalludin100% (3)

- Risk Register AllLevelsDokumen5 halamanRisk Register AllLevelsriyaz10100% (4)

- Site Activities Risk AssessmentDokumen50 halamanSite Activities Risk Assessmentjamie542393% (41)

- BGPI - HSSE - 013 Weekly HSE Report FormDokumen10 halamanBGPI - HSSE - 013 Weekly HSE Report Formtimisite2470% (2)

- Volkswagen RNS 510 Pin AssignmentsDokumen4 halamanVolkswagen RNS 510 Pin Assignmentssalic2013Belum ada peringkat

- HSE Statistics Presentation ExampleDokumen23 halamanHSE Statistics Presentation Examplesamirhsqe100% (1)

- HSE Plan - DraftDokumen5 halamanHSE Plan - Draftanjangandak2932100% (5)

- Assessment Profile Sheet: Assessor (S) Labor Posture ActivityDokumen70 halamanAssessment Profile Sheet: Assessor (S) Labor Posture ActivityDave Labberton92% (13)

- Statistic HseDokumen1 halamanStatistic HseAndu WilantaraBelum ada peringkat

- Hse StatisticsDokumen1 halamanHse Statisticskrissregion100% (1)

- Hse Monthly ReportDokumen1 halamanHse Monthly Reportpunnyakumar100% (1)

- HSE Matrix PlanDokumen5 halamanHSE Matrix Planवात्सल्य कृतार्थ100% (1)

- Hse Plan 2016Dokumen9 halamanHse Plan 2016T Bayu Pratama100% (4)

- HSE Statistics (Monthly) - Package I November-2016Dokumen182 halamanHSE Statistics (Monthly) - Package I November-2016makdelBelum ada peringkat

- Brief HSE Procedures ContentsDokumen2 halamanBrief HSE Procedures Contentsarifayee-1Belum ada peringkat

- SafetyDokumen6 halamanSafetyrodrigo_gon57100% (1)

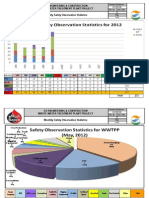

- Monthly Safety Observation Report For 2012Dokumen6 halamanMonthly Safety Observation Report For 2012Ariel Dela Cruz100% (5)

- Master Hazards Risks RegisterDokumen113 halamanMaster Hazards Risks RegisterIvanBelum ada peringkat

- Risk Assessment FormDokumen9 halamanRisk Assessment FormAbu ZahidBelum ada peringkat

- Program HSE Tahun 2015Dokumen1 halamanProgram HSE Tahun 2015Suharto Ari100% (3)

- Weekly HSE Report Feb .2013Dokumen12 halamanWeekly HSE Report Feb .2013sakthivelBelum ada peringkat

- Hse PlanDokumen163 halamanHse PlanEnabulele Osakpamwan100% (10)

- EWAC Safety InductionDokumen14 halamanEWAC Safety InductionPritesh Ramesh BareBelum ada peringkat

- CCAD - Project HSE PlanDokumen187 halamanCCAD - Project HSE Plansergio1234567890100% (7)

- HSE Activities Monthly ReportDokumen1 halamanHSE Activities Monthly Reportneo_chemist100% (2)

- Health, Safety & Environment Management System Health, Safety & Environment Management System (Hsems) (Hsems) Manual ManualDokumen70 halamanHealth, Safety & Environment Management System Health, Safety & Environment Management System (Hsems) (Hsems) Manual ManualQhsef Karmaveer Jyoteendra Vaishnav100% (4)

- Hazard RegisterDokumen135 halamanHazard RegisterChester de Guzman100% (2)

- Appendix P - HSE Management PlanDokumen28 halamanAppendix P - HSE Management PlanSaji Thomas100% (1)

- 2013 HSE Annual Report - Web FINAL PDFDokumen74 halaman2013 HSE Annual Report - Web FINAL PDFarunradBelum ada peringkat

- Environmental Risk RegisterDokumen3 halamanEnvironmental Risk RegisterSiyad SubairBelum ada peringkat

- Environmental Aspect Evaluation FormDokumen4 halamanEnvironmental Aspect Evaluation Form逍逾Belum ada peringkat

- HSE PLAN For UploadDokumen18 halamanHSE PLAN For UploadOladimeji Taiwo71% (7)

- HSE HandbookDokumen53 halamanHSE Handbookmuthuswamy77Belum ada peringkat

- Project: Site / Office: Contractor: Date: Time:: Topics To Be Discussed During HSE InductionDokumen2 halamanProject: Site / Office: Contractor: Date: Time:: Topics To Be Discussed During HSE InductionBashir ArisarBelum ada peringkat

- Ltifr Trir: Target Actual Performance TrendsDokumen2 halamanLtifr Trir: Target Actual Performance TrendsCustomer Service0% (1)

- 2013 Mom Hse 033 PDFDokumen18 halaman2013 Mom Hse 033 PDFebsmsartBelum ada peringkat

- HSE Dashboard For Single SiteDokumen23 halamanHSE Dashboard For Single SiteFOZCAN100% (2)

- Corporate Hse AuditDokumen21 halamanCorporate Hse AuditKukuh Widodo100% (3)

- Assessment Profile Sheet: Assessor (S) Labor Posture ActivityDokumen70 halamanAssessment Profile Sheet: Assessor (S) Labor Posture ActivityAnonymous iI88Lt100% (1)

- Safety Dashboard 2Dokumen4 halamanSafety Dashboard 2victorBelum ada peringkat

- Proj. Management - OverviewDokumen16 halamanProj. Management - Overviewapi-3757629100% (2)

- Health Safety & Environmnetal ChallengesDokumen13 halamanHealth Safety & Environmnetal ChallengesSantosh Mhatre88% (8)

- HSE Action PlanDokumen5 halamanHSE Action PlansantosoBelum ada peringkat

- Supervisor's Investigative Report Form and InsructionsDokumen2 halamanSupervisor's Investigative Report Form and InsructionsRyan FlemingBelum ada peringkat

- HDB Specification A&ADokumen819 halamanHDB Specification A&AJonathan Kok0% (1)

- IRP 22 Hazard and Risk Assessment Register: Column Headings Column LetterDokumen29 halamanIRP 22 Hazard and Risk Assessment Register: Column Headings Column LetterKhuda Buksh100% (2)

- RFP RefDokumen31 halamanRFP RefHicham MedgazBelum ada peringkat

- Confined Spaces & Restricted Work Areas: ObjectiveDokumen5 halamanConfined Spaces & Restricted Work Areas: Objectivemaxine_moonBelum ada peringkat

- Connection: 4xwire +12V GND CAN High Can Low Gateway TPMS ControllerDokumen2 halamanConnection: 4xwire +12V GND CAN High Can Low Gateway TPMS Controllersalic2013Belum ada peringkat

- Valeo Passenger Cars & LCV Security Systems 2012 2013 Catalogue 956216Dokumen40 halamanValeo Passenger Cars & LCV Security Systems 2012 2013 Catalogue 956216salic2013Belum ada peringkat

- PCS 7 APACS OS Symbols and Faceplates V6.1Dokumen66 halamanPCS 7 APACS OS Symbols and Faceplates V6.1salic2013Belum ada peringkat

- Ieh - Chapter 6-9 - Partial-Stroke Testing of Block ValvesDokumen24 halamanIeh - Chapter 6-9 - Partial-Stroke Testing of Block ValvesKareem RasmyBelum ada peringkat

- 111-D-1005 Feed Surge Drum: NotesDokumen1 halaman111-D-1005 Feed Surge Drum: Notessalic2013Belum ada peringkat

- Assessing The Sukhoi PAKDokumen46 halamanAssessing The Sukhoi PAKsalic2013Belum ada peringkat

- HV Induction Motors Technical IEC Catalog FINAL en 092011 LowresDokumen152 halamanHV Induction Motors Technical IEC Catalog FINAL en 092011 LowresSangeet BhandariBelum ada peringkat

- ESD System OperationDokumen53 halamanESD System Operationsalic2013100% (1)

- CAP Short PresentationDokumen12 halamanCAP Short Presentationsalic2013Belum ada peringkat

- INSTRUCALCDokumen1 halamanINSTRUCALCsalic2013Belum ada peringkat

- Saes Z 003Dokumen10 halamanSaes Z 003salic2013Belum ada peringkat

- PMP50 Using This ManualDokumen5 halamanPMP50 Using This Manualsalic2013Belum ada peringkat

- Proforma Invoice: 1) Time of Delivery: 30 Days After Receiving Your Payment 2) Packing: Standard Export CartonDokumen1 halamanProforma Invoice: 1) Time of Delivery: 30 Days After Receiving Your Payment 2) Packing: Standard Export Cartonsalic2013Belum ada peringkat

- 10 Things Deploying Desktops From ImagesDokumen4 halaman10 Things Deploying Desktops From Imagessalic2013100% (1)

- Recycling of Waste PlasticDokumen41 halamanRecycling of Waste Plasticcreativemadhusr100% (2)

- Proyecto SNIP Losas Deportivas PEPRIDokumen50 halamanProyecto SNIP Losas Deportivas PEPRIedartis100% (8)

- Sustainability Report Evoware 2019-2022Dokumen28 halamanSustainability Report Evoware 2019-2022Thành DuyBelum ada peringkat

- MSDS A5Dokumen12 halamanMSDS A5Dicken WongBelum ada peringkat

- Meliseptol MsdsDokumen8 halamanMeliseptol MsdsAgunk IstriBelum ada peringkat

- Standard Operating Procedures For HospitDokumen62 halamanStandard Operating Procedures For HospitThanRMBelum ada peringkat

- An Overview of Covanta Business Model - Market RealistDokumen16 halamanAn Overview of Covanta Business Model - Market Realistam_tanBelum ada peringkat

- Argument Essay 1Dokumen5 halamanArgument Essay 1api-549207860Belum ada peringkat

- DR Krishna Kanth - DSTDokumen19 halamanDR Krishna Kanth - DSTIncubator AIMBelum ada peringkat

- SCIENCE 5 Module 3Dokumen32 halamanSCIENCE 5 Module 3Arnold BaladjayBelum ada peringkat

- Project I-EWAS: (Increasing Electronic Waste Management Awareness in School)Dokumen4 halamanProject I-EWAS: (Increasing Electronic Waste Management Awareness in School)Warren EscapeBelum ada peringkat

- Smart Waste Sorting SystemDokumen4 halamanSmart Waste Sorting Systemvicckyc1100% (1)

- Environmental Management System 8.1.9 Waste Management Operational ProcedureDokumen15 halamanEnvironmental Management System 8.1.9 Waste Management Operational Proceduredhir.ankurBelum ada peringkat

- GE 7 AudioscriptsDokumen27 halamanGE 7 AudioscriptsAli FetohBelum ada peringkat

- ResearchDokumen8 halamanResearchMitchele Piamonte MamalesBelum ada peringkat

- English 6 Q4 L16 ModuleDokumen18 halamanEnglish 6 Q4 L16 Moduleairish catindigBelum ada peringkat

- June 2023 BEVAE-181Dokumen20 halamanJune 2023 BEVAE-181Shivam SainiBelum ada peringkat

- C6 Zero Iowa LLC Information Request 12-19-2022Dokumen14 halamanC6 Zero Iowa LLC Information Request 12-19-2022GazetteonlineBelum ada peringkat

- Hazards and Control Measures of Demolition WorkDokumen6 halamanHazards and Control Measures of Demolition WorkRaja ViswanadaBelum ada peringkat

- DLL - Science 5 - Q2 - W9Dokumen8 halamanDLL - Science 5 - Q2 - W9ChesterBelum ada peringkat

- Ohs-Pr-09-03-F04 (A) Hazard Id & Categories ChecklistDokumen9 halamanOhs-Pr-09-03-F04 (A) Hazard Id & Categories ChecklistSiddiquiBelum ada peringkat

- IG1 Mock Test QPDokumen5 halamanIG1 Mock Test QPzealbalaBelum ada peringkat

- BARITEDokumen6 halamanBARITEsajad gohariBelum ada peringkat

- PTDokumen11 halamanPTGeny AtienzaBelum ada peringkat

- GREEN ED FINAL EXAM ANSWERS - Hisanza - Richard S.Dokumen3 halamanGREEN ED FINAL EXAM ANSWERS - Hisanza - Richard S.Richard HisanzaBelum ada peringkat

- Executive Order No. 04 - BeswmcDokumen4 halamanExecutive Order No. 04 - Beswmckesely esguerraBelum ada peringkat

- 1 s2.0 S0956053X21005663 MainDokumen16 halaman1 s2.0 S0956053X21005663 MainMuhammad MurtazaBelum ada peringkat

- Mabual de Sony Home TheaterDokumen44 halamanMabual de Sony Home TheaterMariana FunesBelum ada peringkat