CLX0039

Diunggah oleh

gazwang478Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

CLX0039

Diunggah oleh

gazwang478Hak Cipta:

Format Tersedia

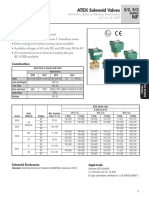

Product Reference Legend (English Units)

For design assistance contact Thermon or visit www.thermon.com and download CompuTrace IT Computer Design Software for Instrument Tubing

Freeze Protection and Temperature Maintenance for the Process Industries

TubeTrace Pre-Insulated & Heat Traced Tubing

Typical Electrically Heat Traced Bundles

SE-4A1-62-7-ATP-035

Bundle Type SE = Single Tube ME = Multiple Tubes Process Tube O.D. 1 = 1/8 2 = 1/4 3 = 3/8 4 = 1/2 5 = 5/8 6 = 3/4 8 = 11 Jacket Type Process Tube Material A = 316 SS Welded B = #122 Copper C = PFA Teon2 D = Monel3 E = Titanium F = 316 SS Seamless G = 304 SS Welded H = 304 SS Seamless J = Alloy C276 K = Alloy 825 L = Alloy 20 M = FEP Teon N = Nylon P = Polyethylene T = TFE Teon X = Special (i.e. passivated, polished, etc.) 30 = 31 = 32 = 33 = 34 = 35 = 36 = 37 = 40 = 41 = 42 = 43 = 44 = 45 = 46 = 47 = Notes . . . 1. Contact factory for availability of 1 O.D. coils. (Not available in all materials.) 2. Teon is a trademark of E.I. du Pont de Nemours & Co., Inc. 3. Monel is a trademark of Inco Alloys International, Inc. 4. Contact factory for design review. 5. Black ATP is standard, other jacket materials include TPU (Urethane). 6. Maximum number of tubes dependent on tube size. 7. Complete line of accessories for TubeTrace and ThermoTube are available. Typical TubeTrace Type ME Typical TubeTrace Type MP Typical ThermoTube Type SL Number of Tubes 6 1 2 3 4 Heat Tracing Type (See Heat Trace Application Below). Contact Thermon for TubeTrace SE/ME instrument tubing bundles with alternative heat trace options such as parallel constant watt and series constant watt including mineral insulated heat tracing. Self-Regulating Heat Trace VSX 5 w/ft. 120 Vac VSX 5 w/ft. 240 Vac VSX 10 w/ft. 120 Vac VSX 10 w/ft. 240 Vac VSX 15 w/ft. 120 Vac VSX 15 w/ft. 240 Vac VSX 20 w/ft. 120 Vac VSX 20 w/ft. 240 Vac BSX 3 w/ft. 120 Vac BSX 3 w/ft. 240 Vac BSX 5 w/ft. 120 Vac BSX 5 w/ft. 240 Vac BSX 8 w/ft. 120 Vac BSX 8 w/ft. 240 Vac BSX 10 w/ft. 120 Vac BSX 10 w/ft. 240 Vac 60 = 61 = 62 = 63 = 64 = 65 = 66 = 67 = 68 = 69 = 70 = 71 = HTSX 3 w/ft. 120 Vac HTSX 3 w/ft. 240 Vac HTSX 6 w/ft. 120 Vac HTSX 6 w/ft. 240 Vac HTSX 9 w/ft. 120 Vac HTSX 9 w/ft. 240 Vac HTSX 12 w/ft. 120 Vac HTSX 12 w/ft. 240 Vac HTSX 15 w/ft. 120 Vac HTSX 15 w/ft. 240 Vac HTSX 20 w/ft. 120 Vac HTSX 20 w/ft. 240 Vac Power-Limiting Heat Trace 50 = HPT 5 w/ft. 120 Vac 51 = HPT 5 w/ft. 240 Vac 52 = HPT 10 w/ft. 120 Vac 53 = HPT 10 w/ft. 240 Vac 54 = HPT 15 w/ft. 120 Vac 55 = HPT 15 w/ft. 240 Vac 56 = HPT 20 w/ft. 120 Vac 57 = HPT 20 w/ft. 240 Vac Heat Trace Option 1 = BN (HPT Only) 3 = OJ (BSX Only) 7 = OJ/Fluoropolymer 8 = Division 1 Approved 4 ATP 5 TPU Process Tube(s) Wall Thickness 028 = .028" 030 = .030" 032 = .032" (Copper Only) 035 = .035" 040 = .040" (Plastic Only) 047 = .047" (Plastic Only) 049 = .049" 062 = .062" (Plastic Only) 065 = .065" 083 = .083" (SS Only) Bundle Type SI = Single Isolated Tube Light Steam Traced MI = Multiple Isolated Tubes Light Steam Traced SP = Single Tube Heavy Steam Traced MP = Multiple Tubes Heavy Steam Traced Process Tube(s) O.D. 1 = 1/8 2 = 1/4 3 = 3/8 4 = 1/2 5 = 5/8 Process Tube(s) Material A = 316 SS Welded C = PFA Teon 2 D = Monel 3 E = Titanium F = 316 SS Seamless G = 304 SS Welded H = 304 SS Seamless J = Alloy C276 K = Alloy 825 L = Alloy 20 M = FEP Teon T = TFE Teon X = Special

Typical Steam Traced Bundles

SP-4F1-3F1-ATP-065/035

Jacket Type ATP 5 Tracer Tube O.D. 2 = 1/4 3 = 3/8 4 = 1/2 Number of Tracer Tube(s) 1 2 TPU Process Tube(s) Wall Thickness 028 = .028" 035 = .035" 040 = .040" (Plastic Only) 047 = .047" (Plastic Only) 049 = .049" 062 = .062" (Plastic Only) 065 = .065" 083 = .083" (SS Only) Tracer Tube(s) Wall Thickness 035 = .035" 049 = .049" 065 = .065" 083 = .083" (SS Only)

Number of Process Tube(s) 6 1 2

Tracer Tube Material A = 316 SS Welded B = 122 Copper F = 316 SS Seamless

ThermoTube Type SL Pre-Insulated Tubing

(Not Heated)

SL-4B135-ATP

Bundle Type SL = Single Tube Tube O.D. 1 = 1/8" 2 = 1/4" 3 = 3/8" 4 = 1/2" 5 = 5/8" 6 = 3/4" 8 = 1"

1

Jacket Type Tube Material A = 316 SS Welded B = #122 Copper C = PFA Teon2 D = Monel3 E = Titanium F = 316 SS Seamless G = 304 SS Welded H = 304 SS Seamless J = Alloy C276 K = Alloy 825 L = Alloy 20 M = FEP Teon N = Nylon P = Polyethylene X = Special Number of Tubes 1 Tube Wall Thickness 30 = 32 = 35 = 49 = 65 = 83 = .030" .032" (Copper Only) .035" .049" .065" .083" (SS Only) ATP 5 TPU

Electrical Heat Trace Application

For Freeze Protection or Maintain 150F (65C) NO STEAM OUTS

Heat Trace Exposure* Limited to 185F (85C) BSX Self-Regulating Heat Tracing (All BSX includes braid & overjacket. Standard overjacket is polyolen, also available with an optional uoropolymer overjacket.) 43 = BSX 5 w/ft. 240 Vac 44 = BSX 8 w/ft. 120 Vac 45 = BSX 8 w/ft. 240 Vac Heat Trace Exposure* to 420F (215C) HTSX Self-Regulating Heat Tracing (All HTSX includes braid & overjacket BNOJ) 60 = 61 = 62 = 63 = HTSX 3 w/ft. 120 Vac HTSX 3 w/ft. 240 Vac HTSX 6 w/ft. 120 Vac HTSX 6 w/ft. 240 Vac 64 = 65 = 66 = 67 = HTSX 9 w/ft. 120 Vac HTSX 9 w/ft. 240 Vac HTSX 12 w/ft. 120 Vac HTSX 12 w/ft. 240 Vac 68 = 69 = 70 = 71 = HTSX 15 w/ft. 120 Vac HTSX 15 w/ft. 240 Vac HTSX 20 w/ft. 120 Vac HTSX 20 w/ft. 240 Vac

For Freeze Protection or Maintain 250F (121C)

Heat Trace Exposure* to 450F (232C) VSX Self-Regulating Heat Tracing (All VSX includes braid & overjacket BNOJ) 30 = VSX 5 w/ft. 120 Vac 31 = VSX 5 w/ft. 240 Vac 32 = VSX 10 w/ft. 120 Vac 33 = VSX 10 w/ft. 240 Vac 34 = VSX 15 w/ft. 120 Vac 35 = VSX 15 w/ft. 240 Vac 36 = VSX 20 w/ft. 120 Vac 37 = VSX 20 w/ft. 240 Vac

For Freeze Protection or Maintain 300F (149C)

Exposure** to 500F (260C) HPT Power-Limiting Heat Tracing (All HPT includes BN braid & may include OJ) 50 = HPT 5 w/ft. 120 Vac 51 = HPT 5 w/ft. 240 Vac 52 = HPT 10 w/ft. 120 Vac 53 = HPT 10 w/ft. 240 Vac 54 = HPT 15 w/ft. 120 Vac 55 = HPT 15 w/ft. 240 Vac 56 = HPT 20 w/ft. 120 Vac 57 = HPT 20 w/ft. 240 Vac

For Freeze Protection or Maintain 400F (205C)

40 = BSX 3 w/ft. 120 Vac 41 = BSX 3 w/ft. 240 Vac 42 = BSX 5 w/ft. 120 Vac

46 = BSX 10 w/ft. 120 Vac 47 = BSX 10 w/ft. 240 Vac

* Exposure temperatures are generally with heat trace de-energized (off). Exceptions are for HTSX and

VSX self-regulating heat trace ratings which allow intermittent exposure, on or off.

** Standard TubeTrace and ThermoTube bundles have a maximum tube temperature rating of 400F

(204C) if outer jacket is to remain below 140F (60C) in a max ambient of 80F (27C) with no wind. Extra insulation (bundle option "XINS") maybe considered if tube temperatures approach HPT Powerlimiting limits of 500F (260C), power off. For higher exposures [up to 1100F (588C)] consider TubeTrace HT or HTX bundles.

100 Thermon Dr.

PO Box 609 San Marcos, TX 78667-0609 Phone: 512-396-5801 Facsimile: 512-396-3627

800-828-HEAT (4328)

www.thermon.com Form CLX0039-1107 Thermon Manufacturing Co. Printed in U.S.A.

Anda mungkin juga menyukai

- Nursing Care Plan For Readiness For Enhanced Sleep NCPDokumen4 halamanNursing Care Plan For Readiness For Enhanced Sleep NCPderic100% (2)

- Materials Data for Cyclic Loading: Low-Alloy SteelsDari EverandMaterials Data for Cyclic Loading: Low-Alloy SteelsPenilaian: 5 dari 5 bintang5/5 (2)

- Combination-Buffer Storage Tank KSEDokumen4 halamanCombination-Buffer Storage Tank KSEZoran DanilovBelum ada peringkat

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsDari EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsBelum ada peringkat

- Fire Alarm SymbolsDokumen6 halamanFire Alarm Symbolscarlos vasquezBelum ada peringkat

- Sample Gas Cooler Data SheetDokumen4 halamanSample Gas Cooler Data Sheetiviji81Belum ada peringkat

- Solenoid Valves 3 - 2 General Service 327 CAT 80402GBDokumen6 halamanSolenoid Valves 3 - 2 General Service 327 CAT 80402GBsaifulBelum ada peringkat

- Swagelok HoseDokumen28 halamanSwagelok HoseRashi Akmal0% (1)

- ASCO SolenoidDokumen10 halamanASCO Solenoidsharib26Belum ada peringkat

- HTTP WWW - Grainger.com Images Catalog 402 4351.PDF Concat True&BaseURL HTTP WWW - GraingerDokumen1 halamanHTTP WWW - Grainger.com Images Catalog 402 4351.PDF Concat True&BaseURL HTTP WWW - GraingerSebastian PVBelum ada peringkat

- Quadrant Ball Valve BrochureDokumen2 halamanQuadrant Ball Valve BrochureHecthor Gomez BelloBelum ada peringkat

- Thermocouple, RTD, and RTD Transmitter Assemblies With ThermowellDokumen2 halamanThermocouple, RTD, and RTD Transmitter Assemblies With ThermowellASPERA2Belum ada peringkat

- MS 02 316Dokumen12 halamanMS 02 316gazwang478Belum ada peringkat

- Econ Gate ValvesDokumen22 halamanEcon Gate ValvesRiyas Udheen100% (1)

- 50 Flarweld Access FlarweldDokumen3 halaman50 Flarweld Access FlarweldMonica EguanBelum ada peringkat

- 31A3AVDokumen2 halaman31A3AVJoseph A. LoeBelum ada peringkat

- Electric Heat Tracing: Installation ProceduresDokumen10 halamanElectric Heat Tracing: Installation ProceduresrajBelum ada peringkat

- p128 22 PDFDokumen3 halamanp128 22 PDFFernando CeballosBelum ada peringkat

- ASCO 327 Solenoid Valves ATEX IECEx Certified For Hazardous Areas2Dokumen4 halamanASCO 327 Solenoid Valves ATEX IECEx Certified For Hazardous Areas2harishBelum ada peringkat

- DeZURIK KCG Knife Gate ValvesDokumen12 halamanDeZURIK KCG Knife Gate ValvesKithkarnonBelum ada peringkat

- TEP0011Dokumen2 halamanTEP0011slygerBelum ada peringkat

- Liebert Intelecool 2Dokumen4 halamanLiebert Intelecool 2JoanLmda100% (1)

- Spirax Sarco Ball Float PDFDokumen12 halamanSpirax Sarco Ball Float PDFchanayireBelum ada peringkat

- Manual Reset Construction 1/4 To 1/2: No Voltage Release (Lever Type)Dokumen6 halamanManual Reset Construction 1/4 To 1/2: No Voltage Release (Lever Type)dharmendrabholeBelum ada peringkat

- Suction Heater - Asphalt & Fuel Oil Applications: SHO Series Starts atDokumen2 halamanSuction Heater - Asphalt & Fuel Oil Applications: SHO Series Starts atJessica Tatiana Muñoz OrtizBelum ada peringkat

- Becon 10Dokumen1 halamanBecon 10harizazrinoordinBelum ada peringkat

- Supertyfon At150-200Dokumen2 halamanSupertyfon At150-200Dimas AnggaBelum ada peringkat

- 61502YDokumen9 halaman61502YbalajivangaruBelum ada peringkat

- Danfoss Expansion ValveDokumen42 halamanDanfoss Expansion ValveLokesh GandhiBelum ada peringkat

- Pulse Valves - Turbocontrols - It PDFDokumen40 halamanPulse Valves - Turbocontrols - It PDFRicardo Ferrari TrevisanBelum ada peringkat

- Swagelok Hose MS 01 167Dokumen28 halamanSwagelok Hose MS 01 167ashok_04meBelum ada peringkat

- American Industrial Liquid Cooled Oil Heat ExchangerDokumen12 halamanAmerican Industrial Liquid Cooled Oil Heat ExchangerAlejandro AguirreBelum ada peringkat

- Condenser Technical DataDokumen3 halamanCondenser Technical DatakawkatrBelum ada peringkat

- SUPERTYFON AT 150-200 With Valve Unit TV 784Dokumen6 halamanSUPERTYFON AT 150-200 With Valve Unit TV 784Dimitry SilinshBelum ada peringkat

- hpr2 Regulator For Model 933 Analyzer PN 300-9478Dokumen7 halamanhpr2 Regulator For Model 933 Analyzer PN 300-9478Jose JohnBelum ada peringkat

- S.No Description Qty Unit Assumed by HWPL: Scope of Work - Supply PSSDokumen14 halamanS.No Description Qty Unit Assumed by HWPL: Scope of Work - Supply PSSASR REDDYBelum ada peringkat

- Catálogo Válvula DirecionalDokumen20 halamanCatálogo Válvula DirecionalcristianoclemBelum ada peringkat

- Electrical Heat Tracing - Master PDFDokumen49 halamanElectrical Heat Tracing - Master PDFmihai085Belum ada peringkat

- ASCO Valve 8345 Spec R2Dokumen2 halamanASCO Valve 8345 Spec R2Calvin HaleyBelum ada peringkat

- Asco Valve 8327Dokumen2 halamanAsco Valve 8327Yorkist100% (1)

- HeatExchanger ReportDokumen5 halamanHeatExchanger ReportNur Izzati KamrulnizamBelum ada peringkat

- 34100Dokumen10 halaman34100Fahrul Songgolangit MangkubumiBelum ada peringkat

- Boiler Pipe Information List - Avantgarde Shipping & Tuff Offshore - FPSO CYRUSDokumen2 halamanBoiler Pipe Information List - Avantgarde Shipping & Tuff Offshore - FPSO CYRUSzarni77Belum ada peringkat

- Opti Flux 4000 Spec SheetDokumen8 halamanOpti Flux 4000 Spec SheetAhmad Adel El TantawyBelum ada peringkat

- Becon 14Dokumen1 halamanBecon 14harizazrinoordinBelum ada peringkat

- ReoTemp Thermocouple & RTD CatalogDokumen18 halamanReoTemp Thermocouple & RTD CatalogIntrave Industrial AutomationBelum ada peringkat

- NeedleValve LT0389Dokumen8 halamanNeedleValve LT0389zkmostafaBelum ada peringkat

- Trampas de Vapor Armstrong, Series880 PDFDokumen2 halamanTrampas de Vapor Armstrong, Series880 PDFLuis Guillermo Gallardo BoscanBelum ada peringkat

- 8735GBDokumen4 halaman8735GBHebert Dacorrégio HeidenreichBelum ada peringkat

- Solenoid Valve Data SheetDokumen14 halamanSolenoid Valve Data SheetGuido Moreno PeredoBelum ada peringkat

- A01CDokumen6 halamanA01CsaravootBelum ada peringkat

- Heat Transfer CompoundDokumen2 halamanHeat Transfer CompoundsusantaBelum ada peringkat

- Ep33411 b11Dokumen9 halamanEp33411 b11salamrefighBelum ada peringkat

- Complressor R134aDokumen2 halamanComplressor R134aHikmat KtkBelum ada peringkat

- STK404 070SDokumen5 halamanSTK404 070SJuan Carlos BarrantesBelum ada peringkat

- Astma 269Dokumen4 halamanAstma 269Raúl TinocoBelum ada peringkat

- Series NF07Dokumen3 halamanSeries NF07riedpecasincosepBelum ada peringkat

- Asco Direct Acting Solenoid Valve - 320Dokumen6 halamanAsco Direct Acting Solenoid Valve - 320SatyamEng100% (1)

- Mangueras Flexibles SwagelokDokumen28 halamanMangueras Flexibles SwagelokCristian OtivoBelum ada peringkat

- 470A Phillybond 6Dokumen1 halaman470A Phillybond 6gazwang478Belum ada peringkat

- Hydroguard Hybrid BreathersDC HG 1 en DC HG 8Dokumen2 halamanHydroguard Hybrid BreathersDC HG 1 en DC HG 8gazwang478Belum ada peringkat

- Dow Corning Corporation Material Safety Data SheetDokumen9 halamanDow Corning Corporation Material Safety Data Sheetgazwang478Belum ada peringkat

- Sealing / Dressing For Existing Gasket Properties Chart: Loctite ProductDokumen1 halamanSealing / Dressing For Existing Gasket Properties Chart: Loctite Productgazwang478Belum ada peringkat

- Sealing / Dressing For Existing Gasket Properties Chart: Loctite ProductDokumen1 halamanSealing / Dressing For Existing Gasket Properties Chart: Loctite Productgazwang478Belum ada peringkat

- Hougen Mag Drill & Annular Cutter GuideDokumen20 halamanHougen Mag Drill & Annular Cutter Guidegazwang478Belum ada peringkat

- 510cb81db643aWB 225 SpecsDokumen9 halaman510cb81db643aWB 225 Specsgazwang478Belum ada peringkat

- Loctite 5699™: Technical Data SheetDokumen3 halamanLoctite 5699™: Technical Data Sheetgazwang478Belum ada peringkat

- 1 004 - 4-Department of Agriculture, 2009 KAR Vol 1Dokumen111 halaman1 004 - 4-Department of Agriculture, 2009 KAR Vol 1gazwang478Belum ada peringkat

- General Catalog (S)Dokumen262 halamanGeneral Catalog (S)gazwang478Belum ada peringkat

- 2014 KAR Supplement Book 2Dokumen649 halaman2014 KAR Supplement Book 2gazwang478Belum ada peringkat

- WARod Brochure v10211Dokumen3 halamanWARod Brochure v10211gazwang478Belum ada peringkat

- 1 005 - 5-Department of Agricultureâ Div of Water Resources, 2009 KAR Vol 1 PDFDokumen174 halaman1 005 - 5-Department of Agricultureâ Div of Water Resources, 2009 KAR Vol 1 PDFgazwang478Belum ada peringkat

- TGX Series: Stainless Flux Cored Filler Rods No Back Purge NecessaryDokumen2 halamanTGX Series: Stainless Flux Cored Filler Rods No Back Purge Necessarygazwang478Belum ada peringkat

- E50001 W410 A105 V1 4A00 - SolarbroschuereDokumen8 halamanE50001 W410 A105 V1 4A00 - SolarbroschueremohantyomBelum ada peringkat

- TGX Series: Stainless Flux Cored Filler Rods No Back Purge NecessaryDokumen2 halamanTGX Series: Stainless Flux Cored Filler Rods No Back Purge Necessarygazwang478Belum ada peringkat

- 05 Sensor-Suite-SST700 SST500 2012 01 PDFDokumen4 halaman05 Sensor-Suite-SST700 SST500 2012 01 PDFgazwang478Belum ada peringkat

- Case Study WTE SST700 F ScreenDokumen2 halamanCase Study WTE SST700 F Screengazwang478Belum ada peringkat

- Steam Power For Solargenix EnergyDokumen8 halamanSteam Power For Solargenix Energygazwang478Belum ada peringkat

- Staineless Steel Wire Flux Cored WireDokumen6 halamanStaineless Steel Wire Flux Cored Wiregazwang478Belum ada peringkat

- Industrial Steam Turbines enDokumen8 halamanIndustrial Steam Turbines engazwang478Belum ada peringkat

- SST-700 Steam Turbine Environmental Product Declaration: According To ISO 14021Dokumen8 halamanSST-700 Steam Turbine Environmental Product Declaration: According To ISO 14021gazwang478Belum ada peringkat

- Latest Steam Turnbine Tecnology For Solar Power Plant in Spain PDFDokumen6 halamanLatest Steam Turnbine Tecnology For Solar Power Plant in Spain PDFgazwang478Belum ada peringkat

- E50001 W410 A105 V1 4A00 - SolarbroschuereDokumen8 halamanE50001 W410 A105 V1 4A00 - SolarbroschueremohantyomBelum ada peringkat

- Swagelok Gaugeable Tube Fittings SAF 2507 Super DuplexDokumen12 halamanSwagelok Gaugeable Tube Fittings SAF 2507 Super DuplextotcsabBelum ada peringkat

- MS 01 107Dokumen16 halamanMS 01 107gazwang478Belum ada peringkat

- Swagelok Gaugeable Tube Fittings Alloy 400Dokumen8 halamanSwagelok Gaugeable Tube Fittings Alloy 400totcsabBelum ada peringkat

- 05 Sensor-Suite-SST700 SST500 2012 01 PDFDokumen4 halaman05 Sensor-Suite-SST700 SST500 2012 01 PDFgazwang478Belum ada peringkat

- Swagelok CatalogDokumen66 halamanSwagelok Catalogfeelmybeat100% (1)

- Man-Arian Flow Cad SoftwareDokumen27 halamanMan-Arian Flow Cad SoftwareDinhnamsgpBelum ada peringkat

- Yume Beauty Price ListDokumen1 halamanYume Beauty Price ListjessicaelaBelum ada peringkat

- Ball Bearing Units Stainless SeriesDokumen5 halamanBall Bearing Units Stainless SeriesRicardo KharisBelum ada peringkat

- Karan Chawla and Joshua Lee November 21, 2016 MEDS 3020 - Fall 2016 Dr. Rosevear, Dr. Cartwright, Dr. LiebermanDokumen2 halamanKaran Chawla and Joshua Lee November 21, 2016 MEDS 3020 - Fall 2016 Dr. Rosevear, Dr. Cartwright, Dr. LiebermanJeremy DelaneyBelum ada peringkat

- Separating Mixtures: Techniques and Applications: Evaporation, Distillation and FiltrationDokumen4 halamanSeparating Mixtures: Techniques and Applications: Evaporation, Distillation and FiltrationAndrea SobredillaBelum ada peringkat

- 084 - ME8073, ME6004 Unconventional Machining Processes - NotesDokumen39 halaman084 - ME8073, ME6004 Unconventional Machining Processes - NotesA. AKASH 4001-UCE-TKBelum ada peringkat

- Colonel SandersDokumen17 halamanColonel SandersAmandaBelum ada peringkat

- Channels of DistributionDokumen101 halamanChannels of DistributionlakshmanlakhsBelum ada peringkat

- Pulverizers: By: G. RamachandranDokumen140 halamanPulverizers: By: G. Ramachandranshivshankar prajapatiBelum ada peringkat

- B1 SpeakingDokumen5 halamanB1 SpeakingHoàng Nam Thắng100% (2)

- Eprubete. Culori. UtilizareDokumen3 halamanEprubete. Culori. UtilizareCuCUBelum ada peringkat

- Startup Time Reduction For Combined Cycle Power PlantsDokumen8 halamanStartup Time Reduction For Combined Cycle Power PlantsEnrique TamayoBelum ada peringkat

- HMPE1 (Catering MGT.)Dokumen17 halamanHMPE1 (Catering MGT.)Rysyl Mae MoquerioBelum ada peringkat

- Bachelor of Physiotherapy (BPT) 2nd YearDokumen17 halamanBachelor of Physiotherapy (BPT) 2nd YearMOHD TAUSIF0% (1)

- Kora 3T 09Dokumen1 halamanKora 3T 09Vаleriy шефBelum ada peringkat

- Assessment in The Affective DomainDokumen19 halamanAssessment in The Affective DomainChano MorenoBelum ada peringkat

- Paracetamol DegradationDokumen9 halamanParacetamol DegradationTruyền Phạm MinhBelum ada peringkat

- Trash Chute-Compliance Sheet Sangir)Dokumen5 halamanTrash Chute-Compliance Sheet Sangir)Li LiuBelum ada peringkat

- Heating Ventilation Air Conditioning Hvac ManualDokumen4 halamanHeating Ventilation Air Conditioning Hvac ManualShabaz KhanBelum ada peringkat

- (VOLKSWAGEN) Manual de Taller Volkswagen Jetta 1999 2006Dokumen4 halaman(VOLKSWAGEN) Manual de Taller Volkswagen Jetta 1999 2006Carlos AntonioBelum ada peringkat

- FCE Writing 14 - ArticleDokumen4 halamanFCE Writing 14 - Articlepingu70Belum ada peringkat

- FALLSEM2021-22 EEE3004 ETH VL2021220100810 Reference Material I 16-Aug-2021 7 Controlled Rectifier NewDokumen51 halamanFALLSEM2021-22 EEE3004 ETH VL2021220100810 Reference Material I 16-Aug-2021 7 Controlled Rectifier NewVAHEESBelum ada peringkat

- Piaget and Preoperational StageDokumen2 halamanPiaget and Preoperational Stageapi-285179229Belum ada peringkat

- Robodrill 01Dokumen298 halamanRobodrill 01vuchinhvdcBelum ada peringkat

- (Complete) BLC 201 Assignment Intro Logistics SCM Sep 2021 - McdonaldDokumen12 halaman(Complete) BLC 201 Assignment Intro Logistics SCM Sep 2021 - McdonaldHf CreationBelum ada peringkat

- Crew Resource Management Phil O'DonnellDokumen39 halamanCrew Resource Management Phil O'DonnellMostafaBelum ada peringkat

- Clack 2983 WS1EE Twin Valve LDokumen2 halamanClack 2983 WS1EE Twin Valve Lmohamed boufasBelum ada peringkat

- LISD LetterDokumen2 halamanLISD LetterAnonymous Pb39klJ100% (1)

- FPSB 2 (1) 56-62oDokumen7 halamanFPSB 2 (1) 56-62ojaouadi adelBelum ada peringkat