Hydrex Revolutionises Underwater Bow Thruster Operations

Diunggah oleh

jiokoijikoJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Hydrex Revolutionises Underwater Bow Thruster Operations

Diunggah oleh

jiokoijikoHak Cipta:

Format Tersedia

Hydrex Revolutionises Underwater Bow Thruster Operations

Posted on Dec 20th, 2013 with tags BOW, europe, Hydrex, interview, News y topic, Operations, !evo"utionises, #u sea, $hruster, %nderwater&

Hydrex was the first company to show that it was possible to remove and then replace thrusters by creating a dry environment underwater. Using the Hydrexdeveloped steel mobdoc s to seal off the thruster tunnel! with an access shaft protruding above the water! wor teams accessed the thruster tunnel and removed or repaired the thruster within the tunnel in complete safety. $his was done in conditions si'i"ar to those a ove water& Hydrex has since then deve"oped this techno"ogy (urther using "ightweight ("exi "e 'o doc)s& $hese 'oderni*ed 'o doc)s, which are designed to e easi"y transported around the wor"d, are used to c"ose o(( the thruster tunne" on oth sides& $his a""ows divers to wor) in a dry environ'ent around the unit& Hydrex Production Executive Dave Bleyenberg ta")s a out the history o( on+site thruster operations and 'entions the ene(its this can have (or shipowners in the shipping as we"" as the o((shore industry& Hydrex" How did it all start#

Dave B"eyen erg, We started off with small repairs on bow thrusters: welding anodes, performing bow thruster blade repairs in the wet, repairing the steel belt, We then began looking into ways to carry out on-site repairs in dry circumstances. Emptying the thruster tunnel of water was the most logical next step. n !""# we started doing this by closing off both sides of the thruster tunnel and blowing air into it. $his created a dry en%ironment in which our di%er&technicians could remo%e a blade or perform a seal repair. 'or its inno%ati%e work in this field (ydrex won the )**) +loyd,s +ist -.. /ward in the category of nno%ation in 0a%al -hipbuilding and .arine $echnology.1 Hydrex" But it did not stop at these smaller repairs! did it# Dave, $he next step was to perform complex repairs to the thruster unit itself. $he easiest way to do this was to remo%e the unit in its entirety. $he difficult part was to find a way of lowering the unit into the thruster tunnel without water coming in through the hole connecting the tunnel to the engine room. f the air in the tunnel escapes through the hole, the tunnel will fill up with water %ery fast. We needed to find a way the close off the engine room. /fter lots of brainstorm sessions around the drawing table, we found the solution. $hings went %ery fast after that and we started putting the idea into practice soon after. We %isited engine rooms to get a good idea of how we needed to de%elop the concept. / uni%ersal solution was not possible and we had to adapt it to different si2es. 3ood drawings and ideally a pre-inspection 4of the %essel or a sister ship5 is re6uired to perform a full thruster unit replacement.1 (ydrex: What are the typical problems encountered with a thruster unit that result in a need for it to be o%erhauled7 Dave, $here can be a number of causes for a thruster,s malfunction. $he gearing wheels can be worn down so that the unit does not function as it should, one or more hydraulic tubes can be se%ered so that the correct pitch cannot be established or the feedback cable can be broken, pre%enting correct readings. f a thruster does not function correctly, the %essel has to use an extra tugboat when entering port and this raises the cost of entering and lea%ing considerably. f possible we perform on-site repairs inside the tunnel, to pre%ent a complete remo%al of the thruster unit. We recently did a repair of the stainless steel belt on a %essel in 8ort 3entil 43abon5. /n 9:-meter research %essel needed the stainless steel belt in one of its thruster tunnels replaced. $he belt is installed around the perimeter of a thruster tunnel at the location of the thruster blades. $here the impact of the ca%itation caused by the mo%ement of the blades is the most se%ere. Extra protection against ca%itation damage is therefore essential. When the stainless steel belt in the thruster tunnel suffered cracks, the underlying steel was exposed to ca%itation. $he belt needed to be replaced as soon as possible to pre%ent the tunnel from getting damaged too se%erely. $he owner of the %essel

would ha%e had to take his %essel to drydock if no on-site solution was found. / tailormade, open-top cofferdam was designed by our technical department. t was constructed in a local workshop under the super%ision of (ydrex di%er&technicians. /t the same time a regular shaped second cofferdam was also built. $his allowed us to empty all water from the thruster tunnel and descend into it to carry out the repair. ;ur di%er&technicians remo%ed the old damaged belt and replaced it with a new stainless steel belt. $he actual operation was finished in only fi%e days.1 Hydrex" $oes the si%e of the thruster matter# Dave, 0o. We ha%e also performed se%eral offshore thruster operations. We only need a crane with a large enough lifting capability. 'or instance, we ha%e replaced one of the <*-ton, swing-up, a2imuth thrusters of a crane barge stationed in 3abon with the spare on se%eral occasions. ;ne of these operations had to be carried out in a %ery short time frame because the crane barge was scheduled to lea%e for an operation in 0igeria. /ll repairs and other ser%icing work needed to be carried out before the start of this operation. 'or this reason going to drydock was not an option, as the nearest suitable location was -outh /frica and this would ha%e taken the repairs far beyond the a%ailable time frame. When the first a2imuth thruster was replaced, a large mobdock 4measuring " x : x ) meters and weighing o%er )# tons by itself5 was constructed under (ydrex super%ision in =elgium and transported to 3abon. $here it was stored after the repair to be used at short notice whene%er future repairs were re6uired on thrusters. $his allowed for a %ery fast mobili2ation and thruster replacement on the next two occasions. (ydrex has also de%eloped a permanent thruster repair and replacement system. $his system has been de%eloped so it can be tailored to most %essels. t can be included in the planning for a newbuild, installed on a unit going to drydock or constructed and brought on board at any other suitable time. With such a system on standby any repair work to the thruster that may arise can be dealt with much faster and more easily.1 Hydrex" $espite the difficulty of these operations! they can be performed very fast. Dave, $hat is correct. $he remo%al of the unit can be done in the wet, because it is o%erhauled. We only need to remo%e the blades and close the unit off with flanges. $he reinstallation needs to be done in the dry because you need to reinstall the blades without water ingress. >emo%al can be done within )< hours. >einstallation is usually done in <9 hours. We ha%e now taken it e%en a step further. ;n se%eral occasions in )*!? we ha%e remo%ed the old bow thruster unit and reinstalled a new one in a single operation. $his sa%es the customer extra time because we do not need to mobili2e our di%ers and e6uipment twice. / %essel can sail after we remo%e the unit and close off the tunnel from the engine room. $he reinstallation can then be done at a later date on-site or during the next drydock %isit if re6uired. $his sa%es time in dock because they do not need to remo%e the old unit and they can ha%e the o%erhauled or new unit ready when the ship comes in.

'or bow thrusters unit remo%als or blade replacements in Western Europe we ha%e two workboats a%ailable at our head6uarters in /ntwerp. $he transport of the unit to the manufacturer can also be arranged by us if needed. $his is a package we offer to customers. f a @ob comes in we ask if the thruster needs to be o%erhauled and where it needs to go. -pare parts or thruster blades can be stored at our offices so that they are immediately a%ailable when we start the operation. $here is no need to send the %essel to drydock as all operations can be carried out in port or while the %essel is stationary at sea. 0ormal commercial acti%ities can therefore continue without disruption.1

Anda mungkin juga menyukai

- HitchhikerDokumen6 halamanHitchhikerjiokoijikoBelum ada peringkat

- Three Piles StructuresDokumen1 halamanThree Piles StructuresjiokoijikoBelum ada peringkat

- Adult Stem Cell RegulationDokumen3 halamanAdult Stem Cell RegulationjiokoijikoBelum ada peringkat

- Steel Catenary RisersDokumen1 halamanSteel Catenary RisersjiokoijikoBelum ada peringkat

- Jacket Loadout AnalysisDokumen1 halamanJacket Loadout AnalysisjiokoijikoBelum ada peringkat

- Required Civil and Structural EngineerDokumen1 halamanRequired Civil and Structural EngineerjiokoijikoBelum ada peringkat

- Deck & Jacket Load Out AnalysesDokumen1 halamanDeck & Jacket Load Out Analysesjiokoijiko0% (1)

- Fields of ActivityDokumen1 halamanFields of ActivityjiokoijikoBelum ada peringkat

- Naval ArchitectureDokumen1 halamanNaval ArchitecturejiokoijikoBelum ada peringkat

- Technip's Spar Platform LeadershipDokumen1 halamanTechnip's Spar Platform LeadershipjiokoijikoBelum ada peringkat

- Flexible Pipe Systems: France Brazil MalaysiaDokumen2 halamanFlexible Pipe Systems: France Brazil MalaysiajiokoijikoBelum ada peringkat

- Civil EngineeringDokumen1 halamanCivil EngineeringjiokoijikoBelum ada peringkat

- Fixed PlatformsDokumen1 halamanFixed PlatformsjiokoijikoBelum ada peringkat

- Subsea Field Development: Key ReferencesDokumen2 halamanSubsea Field Development: Key ReferencesjiokoijikoBelum ada peringkat

- Dockwise Sets 30,000 ToonesDokumen2 halamanDockwise Sets 30,000 ToonesjiokoijikoBelum ada peringkat

- EngineeringDokumen2 halamanEngineeringjiokoijikoBelum ada peringkat

- How Does Heavy Lift WorkDokumen3 halamanHow Does Heavy Lift WorkjiokoijikoBelum ada peringkat

- Electrical EngineeringDokumen1 halamanElectrical EngineeringjiokoijikoBelum ada peringkat

- PSV - Platform Supply Vessels Transport Goods to Offshore Oil RigsDokumen2 halamanPSV - Platform Supply Vessels Transport Goods to Offshore Oil RigsjiokoijikoBelum ada peringkat

- Structural EngineeringDokumen1 halamanStructural EngineeringjiokoijikoBelum ada peringkat

- Process EngineeringDokumen1 halamanProcess EngineeringjiokoijikoBelum ada peringkat

- Logistical Management: The Dockwise DifferenceDokumen1 halamanLogistical Management: The Dockwise DifferencejiokoijikoBelum ada peringkat

- Offshore ConstructionsDokumen1 halamanOffshore ConstructionsjiokoijikoBelum ada peringkat

- Pressure VesselDokumen1 halamanPressure VesseljiokoijikoBelum ada peringkat

- Onshore/Onsite Services: Engineering Procurement FabricationDokumen1 halamanOnshore/Onsite Services: Engineering Procurement FabricationjiokoijikoBelum ada peringkat

- Offshore ServicesDokumen1 halamanOffshore ServicesjiokoijikoBelum ada peringkat

- NPCCDokumen1 halamanNPCCjiokoijikoBelum ada peringkat

- Transport & Installation: The Dockwise DifferenceDokumen2 halamanTransport & Installation: The Dockwise DifferencejiokoijikoBelum ada peringkat

- Offshore Installation EquipmentDokumen2 halamanOffshore Installation EquipmentjiokoijikoBelum ada peringkat

- Heavy Marine TransportDokumen2 halamanHeavy Marine TransportjiokoijikoBelum ada peringkat

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (344)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (587)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (73)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (265)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (119)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- Tarea 1Dokumen36 halamanTarea 1LUIS RVBelum ada peringkat

- ThiruppavaiDokumen157 halamanThiruppavaiajiva_rts100% (49)

- Focus2 2E Review Test 4 Units1 8 Vocabulary Grammar UoE Reading GroupBDokumen4 halamanFocus2 2E Review Test 4 Units1 8 Vocabulary Grammar UoE Reading GroupBaides1sonBelum ada peringkat

- ECUMINISMDokumen2 halamanECUMINISMarniel somilBelum ada peringkat

- List of Indian Timber TreesDokumen5 halamanList of Indian Timber TreesE.n. ElangoBelum ada peringkat

- 3DO For IPDokumen7 halaman3DO For IPHannah Angela NiñoBelum ada peringkat

- Lived Experiences of Science Teachers of Pangasinan Ii in The New Normal Education: A Phenomenological StudyDokumen10 halamanLived Experiences of Science Teachers of Pangasinan Ii in The New Normal Education: A Phenomenological StudyIJAR JOURNALBelum ada peringkat

- Csd88584Q5Dc 40-V Half-Bridge Nexfet Power Block: 1 Features 3 DescriptionDokumen26 halamanCsd88584Q5Dc 40-V Half-Bridge Nexfet Power Block: 1 Features 3 DescriptionJ. Carlos RGBelum ada peringkat

- Lawson v. Mabrie Lawsuit About Botched Funeral Service - October 2014Dokumen9 halamanLawson v. Mabrie Lawsuit About Botched Funeral Service - October 2014cindy_georgeBelum ada peringkat

- Kristy Gallazin Edte 431 - Assignment 2 Newsletter pdf12Dokumen4 halamanKristy Gallazin Edte 431 - Assignment 2 Newsletter pdf12api-301047467Belum ada peringkat

- GO vs. CA Case DigestDokumen1 halamanGO vs. CA Case Digestunbeatable38100% (4)

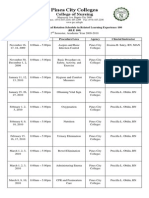

- Pines City Colleges: College of NursingDokumen2 halamanPines City Colleges: College of NursingmagisasamundoBelum ada peringkat

- Council Of Architecture Scale Of ChargesDokumen4 halamanCouncil Of Architecture Scale Of ChargesAshwin RajendranBelum ada peringkat

- FCC TechDokumen13 halamanFCC TechNguyen Thanh XuanBelum ada peringkat

- Rashi - Effusion CytDokumen56 halamanRashi - Effusion CytShruthi N.RBelum ada peringkat

- Ballet Folklórico de MéxicoDokumen3 halamanBallet Folklórico de MéxicoDasikaPushkarBelum ada peringkat

- Official Correspondence in English CompleteDokumen55 halamanOfficial Correspondence in English Completeyadab rautBelum ada peringkat

- SOP For Storage of Temperature Sensitive Raw MaterialsDokumen3 halamanSOP For Storage of Temperature Sensitive Raw MaterialsSolomonBelum ada peringkat

- Sanogo 2019 TFDokumen40 halamanSanogo 2019 TFbassomassi sanogoBelum ada peringkat

- G.R. No. 190583 - People vs FrontrerasDokumen12 halamanG.R. No. 190583 - People vs FrontrerasKaren Faye TorrecampoBelum ada peringkat

- Eng CBLDokumen2 halamanEng CBLMengTangBelum ada peringkat

- MATHS UNDERSTANDINGDokumen15 halamanMATHS UNDERSTANDINGNurul IzzaBelum ada peringkat

- B1 Grammar and VocabularyDokumen224 halamanB1 Grammar and VocabularyTranhylapBelum ada peringkat

- Bible TabsDokumen8 halamanBible TabsAstrid TabordaBelum ada peringkat

- Java Thread Priority in MultithreadingDokumen3 halamanJava Thread Priority in MultithreadingMITALI SHARMABelum ada peringkat

- 2023 Civil LawDokumen7 halaman2023 Civil LawJude OnrubiaBelum ada peringkat

- 100 Commonly Asked Interview QuestionsDokumen6 halaman100 Commonly Asked Interview QuestionsRaluca SanduBelum ada peringkat

- Phonetics Exercises PDFDokumen2 halamanPhonetics Exercises PDFShanti YuliastitiBelum ada peringkat

- Appellate Tribunal Inland Revenue Rules, 2010Dokumen18 halamanAppellate Tribunal Inland Revenue Rules, 2010Shahbaz KhanBelum ada peringkat