What Is Chemical Engineering

Diunggah oleh

talesofseriesJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

What Is Chemical Engineering

Diunggah oleh

talesofseriesHak Cipta:

Format Tersedia

WHAT IS CHEMICAL ENGINEERING?

DEFINITION OF CHEMICAL ENGINEERING

What does the word ‘chemical engineering’ mean? What would a person, who never

heard of these words, think of? From the words, itself let’s try to deduce a definition.

‘Chemical’ is a general word used to refer to a wide variety of substances. Examples of

chemicals are alcohols, acids, bases, powders or any chemical reagent that may be used

in laboratories. ‘Engineering’ is a term associated to applying a specific scientific idea or

mathematical technique to obtain an answer for practical problems. Examples of practical

problems are ‘Determine the mass of a liquid inside a container.’, and ‘How much water

and salt must be added to produce a homogeneous solution of certain composition?’.

Engineering aims to answer these kinds of questions. With these understanding of

‘chemical’ and ‘engineering’, one may think that chemical engineering is all about

finding how to apply specific chemicals and their properties in practical problems.

Being a chemical engineer, that definition is too restrained. According to McCabe,

Smith and Harriot, chemical engineering deals with transforming raw materials to useful

products. Based on how I’ve studied chemical engineering, this is the best definition. The

scope of chemical engineering is mainly on industrial processes and on how these

processes transforms raw materials to useful products. It is all about understanding and

manipulating these processes in order to produce the desired product. This is achieved by

using scientific principles and mathematical techniques.

WHAT AND WHERE THEY WORK

The term ‘industrial’ brings into mind two things: (1) Chemical plant and (2) large

scale production. The chemical engineer therefore resides in a chemical plant and handles

large amounts of materials. This is where all industrial processes take place and process

large amounts of raw material.

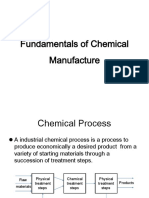

Exactly what are these industrial processes? How do they transform these raw

materials? These industrial processes can be broken down to two types based on their

function: (1) unit operations and (2) unit processes. Unit operations are physical

treatments undergone by raw materials. Its purpose is to separate certain components

from the raw material. Unit processes are in essence chemical reactions. Its main aim is

to produce the useful product. Below is a simplified diagram of a chemical plant.

Raw mat’l Processed

products

Unit Unit Unit

Operations Processes Operations

Unit operations are at the start of the plant because different components are usually

found in the raw material. These components if not removed may cause the succeeding

operation to not function. Various physical treatments are used to separate the different

kinds of components. The treated raw materials become more amenable to the chemical

reaction. Once this is accomplished the next step is unit processes. Unit processes make

the material undergo a chemical reaction thus changing their composition and producing

a useful product. The product from the unit process usually comes out with some

unwanted components and therefore requires further separation. Unit operations are

needed to further separate the exiting material.

DUTIES AND RESPONSIBILITIES

Chemical engineering is all about processing raw materials to finished useful

products. The field requires scientific principles and mathematical techniques applied in

the chemical plant to process large amounts of raw materials. The chemical engineer

must understand each of these physical and chemical processes to efficiently operate the

plant. As a result, chemical engineers are responsible for the production of the wide

variety of products found in society. It is our duty to properly produce these products for

the benefit of society.

Anda mungkin juga menyukai

- Lecture 2 & 3Dokumen22 halamanLecture 2 & 3Ahmed SafiBelum ada peringkat

- Chemical Product Design and EngineeringDokumen35 halamanChemical Product Design and EngineeringArinjayKumarBelum ada peringkat

- English For Chemical EngineerDokumen94 halamanEnglish For Chemical EngineerKresna Thufail ABelum ada peringkat

- Fundamentals of Chemical ManufactureDokumen125 halamanFundamentals of Chemical Manufacturemulugeta damisuBelum ada peringkat

- Lesson 1Dokumen34 halamanLesson 1syaza mohamadBelum ada peringkat

- 1b Introduction Chem Engg DefinitionDokumen25 halaman1b Introduction Chem Engg DefinitionSnow DropBelum ada peringkat

- Roles of Chemical EngineeringDokumen10 halamanRoles of Chemical EngineeringIrawan Setiadi100% (1)

- Fundamentals of Applied Chemistry 11-1Dokumen19 halamanFundamentals of Applied Chemistry 11-1Aaditya K S100% (1)

- Inorganic Industries Engineering هيوضعلايرغ تاعانصلا ةسدنه: Dr.: Sameh Araby El-MekawyDokumen37 halamanInorganic Industries Engineering هيوضعلايرغ تاعانصلا ةسدنه: Dr.: Sameh Araby El-MekawyMohamed AbdelaalBelum ada peringkat

- Chemical Engineering.2Dokumen13 halamanChemical Engineering.2haitham abdelsamadBelum ada peringkat

- Chemical Process IndustriesDokumen14 halamanChemical Process IndustriesRida akhtarBelum ada peringkat

- PE - IntroductionDokumen6 halamanPE - IntroductionprasadparulekarBelum ada peringkat

- Chemical Engineering ReportDokumen4 halamanChemical Engineering ReportAlan SánchezBelum ada peringkat

- Chemical EngineeringDokumen3 halamanChemical EngineeringDianna DayawonBelum ada peringkat

- CHE 410 Chemcal Process Industries Rev (Part 1)Dokumen32 halamanCHE 410 Chemcal Process Industries Rev (Part 1)Benedick Jayson MartiBelum ada peringkat

- Chemical Engineering - Is A Branch ofDokumen17 halamanChemical Engineering - Is A Branch ofAshenafi GebrelibanosBelum ada peringkat

- Engineering Physical Science Chemistry Physics Biology Microbiology Biochemistry Mathematics Materials ChemicalsDokumen6 halamanEngineering Physical Science Chemistry Physics Biology Microbiology Biochemistry Mathematics Materials ChemicalsSelvam VasudevanBelum ada peringkat

- 1 - Introduction To Chemical Process IndustriesDokumen13 halaman1 - Introduction To Chemical Process IndustriesVenus Abigail GutierrezBelum ada peringkat

- Shera Angelista Salsha Bella 21 - Assignment 6Dokumen6 halamanShera Angelista Salsha Bella 21 - Assignment 6Angel ChweBelum ada peringkat

- Module-I: Chemical Technology-V SemDokumen25 halamanModule-I: Chemical Technology-V SemPrashant GiriBelum ada peringkat

- Course Outline - DraftDokumen2 halamanCourse Outline - DraftAki EspaldonBelum ada peringkat

- Chemical Plant Is Required Carry Out Transformation Chemical EngineeringDokumen6 halamanChemical Plant Is Required Carry Out Transformation Chemical EngineeringHans August ARBelum ada peringkat

- Lec 1Dokumen27 halamanLec 1A KhapreBelum ada peringkat

- Role of Chemical Engineer in Chemical ProcessingDokumen4 halamanRole of Chemical Engineer in Chemical ProcessingRowel GanzonBelum ada peringkat

- Industrial Chemistry IDokumen128 halamanIndustrial Chemistry Idebela jufarBelum ada peringkat

- Homework #1Dokumen8 halamanHomework #1Erwin CabangalBelum ada peringkat

- Subject 4. - Product Design OCW PDFDokumen33 halamanSubject 4. - Product Design OCW PDFJose Luis BarradasBelum ada peringkat

- ChE 210 Lecture 1 Introduction To Chemical Engineering CalculationsDokumen18 halamanChE 210 Lecture 1 Introduction To Chemical Engineering CalculationsMay May MagluyanBelum ada peringkat

- CT 1Dokumen69 halamanCT 1Vijaya GosuBelum ada peringkat

- Chemical Engineer ResumeDokumen3 halamanChemical Engineer ResumeRaju JadavBelum ada peringkat

- Design ViabilityDokumen5 halamanDesign Viabilityapi-299000804Belum ada peringkat

- Chemical Process Industries: Lecture 1: IntroductionDokumen13 halamanChemical Process Industries: Lecture 1: IntroductionMaria Eloisa Angelie ArellanoBelum ada peringkat

- Chemical Engineering Thermodynamics: CHD002U2MDokumen9 halamanChemical Engineering Thermodynamics: CHD002U2MSULABH SRIVASTAVABelum ada peringkat

- CHE524Dokumen34 halamanCHE524Precious JamesBelum ada peringkat

- Hemical Lant Esign: Dr. Muhammad Rizwan Assistant Professor Nfc-IetDokumen16 halamanHemical Lant Esign: Dr. Muhammad Rizwan Assistant Professor Nfc-IetOwaisBelum ada peringkat

- Hemical Lant Esign: Dr. Muhammad Rizwan Assistant Professor Nfc-IetDokumen16 halamanHemical Lant Esign: Dr. Muhammad Rizwan Assistant Professor Nfc-IetZarar SaleemBelum ada peringkat

- Ecolizer 2.0 LCA TablesDokumen89 halamanEcolizer 2.0 LCA Tableshieu dongBelum ada peringkat

- Subject 4. - Product Design OCWDokumen33 halamanSubject 4. - Product Design OCWjonas1227Belum ada peringkat

- ChemPlantDesign-Intro To Plant Design EconomicsDokumen29 halamanChemPlantDesign-Intro To Plant Design EconomicsPrabakkaran VelayuthamBelum ada peringkat

- Chemical Process Industries: Introduction: Chemical Engineering Department Universitas Muhammadiyah SurakartaDokumen36 halamanChemical Process Industries: Introduction: Chemical Engineering Department Universitas Muhammadiyah SurakartaLilianaBelum ada peringkat

- POM Unit1 PDFDokumen22 halamanPOM Unit1 PDFShwetha MudireddyBelum ada peringkat

- Plant Performance & Efficiency Monitoring: Introduction & Familiarization Module - Part 1Dokumen19 halamanPlant Performance & Efficiency Monitoring: Introduction & Familiarization Module - Part 1Youcef NasriBelum ada peringkat

- 02 Overview of Plant DesignDokumen37 halaman02 Overview of Plant DesignNadiaBelum ada peringkat

- Chapter 1: General Information of Engineering and Its ApplicationDokumen3 halamanChapter 1: General Information of Engineering and Its ApplicationSOm KAntaBelum ada peringkat

- Assignment 6 DwiDokumen5 halamanAssignment 6 DwiDwi Nur FitrianaBelum ada peringkat

- Chemical EngineeringDokumen2 halamanChemical EngineeringKouame AdjepoleBelum ada peringkat

- Cerd 82 11 1409 52029Dokumen2 halamanCerd 82 11 1409 52029lazarudin azarBelum ada peringkat

- Handout p3k 1 HGNDokumen33 halamanHandout p3k 1 HGNRio SanjayaBelum ada peringkat

- Basic Principle in CPIDokumen28 halamanBasic Principle in CPIDion VixBelum ada peringkat

- Process ChemistryDokumen63 halamanProcess ChemistryFiruj AhmedBelum ada peringkat

- Chemical Product DesignDokumen42 halamanChemical Product DesignRanaeshwarBelum ada peringkat

- Mass and Energy Balances Chapter 1,2Dokumen102 halamanMass and Energy Balances Chapter 1,2Ferat BotBelum ada peringkat

- A Comprehensive Framework For Surfactant Selection and Design For Emulsion Based Chemical Product Design PDFDokumen12 halamanA Comprehensive Framework For Surfactant Selection and Design For Emulsion Based Chemical Product Design PDFArley NovaBelum ada peringkat

- 04 - Devices Functional and Formulated ProductsDokumen89 halaman04 - Devices Functional and Formulated ProductsZaki WasitBelum ada peringkat

- Mem Construction 3Dokumen5 halamanMem Construction 3Georgina SuleBelum ada peringkat

- Bab 0 PendahuluanDokumen13 halamanBab 0 PendahuluanRaihan HasbillaBelum ada peringkat

- Unitoperations and ProcessesDokumen19 halamanUnitoperations and ProcessesnirbhaykumarBelum ada peringkat

- Chemical Engineering Design: Principles, Practice and Economics of Plant and Process DesignDari EverandChemical Engineering Design: Principles, Practice and Economics of Plant and Process DesignPenilaian: 4 dari 5 bintang4/5 (16)

- Career Options - Inglés CientíficoDokumen50 halamanCareer Options - Inglés CientíficodianaBelum ada peringkat

- Balance Diet and NutritionDokumen9 halamanBalance Diet and NutritionEuniceBelum ada peringkat

- Comsol ProfileDokumen4 halamanComsol ProfilePrashant KumarBelum ada peringkat

- Namma Kalvi 12th English Slow Learners Study MaterialDokumen28 halamanNamma Kalvi 12th English Slow Learners Study MaterialSTANLEY RAYEN100% (1)

- SURELAM-380,540II (User Manual)Dokumen25 halamanSURELAM-380,540II (User Manual)kamran.sefyaliyevBelum ada peringkat

- 4.5.redistrribution - PBR Quiz AnswersDokumen4 halaman4.5.redistrribution - PBR Quiz AnswersffbugbuggerBelum ada peringkat

- By Beholding We Are ChangedDokumen2 halamanBy Beholding We Are ChangedAdrian EbensBelum ada peringkat

- Roger Ghanem, David Higdon, Houman Owhadi (Eds.) - Handbook of Uncertainty Quantification-Springer International Publishing (2017)Dokumen2.035 halamanRoger Ghanem, David Higdon, Houman Owhadi (Eds.) - Handbook of Uncertainty Quantification-Springer International Publishing (2017)Jaime Andres Cerda Garrido100% (1)

- Teiaiel - Visions of The FutureDokumen2 halamanTeiaiel - Visions of The FutureMarkosBelum ada peringkat

- Elementary Graph Theory: Robin Truax March 2020Dokumen15 halamanElementary Graph Theory: Robin Truax March 2020Jefferson WidodoBelum ada peringkat

- Exam Materials ScienceDokumen10 halamanExam Materials ScienceChimzoe CatalanBelum ada peringkat

- Class VII Half Yearly Maths, M.junaidDokumen4 halamanClass VII Half Yearly Maths, M.junaidmohd junaidBelum ada peringkat

- CHAPTER 48 - Skin Integrity & Wound CareDokumen3 halamanCHAPTER 48 - Skin Integrity & Wound CareABelum ada peringkat

- C8 Flyer 2021 Flyer 1Dokumen7 halamanC8 Flyer 2021 Flyer 1SANKET MATHURBelum ada peringkat

- Seminar 2 of 2021-Multispectral Spectroscopy-Aster Imagery Processing For Mineral ExplorationDokumen15 halamanSeminar 2 of 2021-Multispectral Spectroscopy-Aster Imagery Processing For Mineral Explorationmartin nyakinyeBelum ada peringkat

- 01-15th December, GK Today MagazineDokumen134 halaman01-15th December, GK Today MagazinejohnBelum ada peringkat

- 3rd Quarter PHYSICAL SCIENCE ExamDokumen19 halaman3rd Quarter PHYSICAL SCIENCE ExamZhering RodulfoBelum ada peringkat

- Essay, How Microscopes Have Contributed To Our Understanding of Living OrganismsDokumen2 halamanEssay, How Microscopes Have Contributed To Our Understanding of Living Organismslinanqikiki82% (11)

- Comparative Study of Conventional and Generative Design ProcessDokumen11 halamanComparative Study of Conventional and Generative Design ProcessIJRASETPublicationsBelum ada peringkat

- The Proof of Agricultural ZakatDokumen7 halamanThe Proof of Agricultural ZakatDila Estu KinasihBelum ada peringkat

- Abortion Remedies From A Medieval Catholic Nun (!) - JSTOR DailyDokumen12 halamanAbortion Remedies From A Medieval Catholic Nun (!) - JSTOR DailysiesmannBelum ada peringkat

- ASTM D4852-88 (Reapproved 2009) E1Dokumen3 halamanASTM D4852-88 (Reapproved 2009) E1Sandra LopesBelum ada peringkat

- Amenzade Yu.a. - Theory of Elasticity-Mir (1979)Dokumen284 halamanAmenzade Yu.a. - Theory of Elasticity-Mir (1979)Javier100% (1)

- GNM SyllabusDokumen4 halamanGNM SyllabusVinay SinghBelum ada peringkat

- Exercises PDFDokumen39 halamanExercises PDF910220Belum ada peringkat

- Poems by Cawein, Madison Julius, 1865-1914Dokumen126 halamanPoems by Cawein, Madison Julius, 1865-1914Gutenberg.orgBelum ada peringkat

- Unit 1Dokumen175 halamanUnit 1Karthikeya SharmaBelum ada peringkat

- SRS Cheat CodesDokumen9 halamanSRS Cheat CodesnurhayatiBelum ada peringkat

- LEED v4 For Interior Design and Construction ChecklistDokumen3 halamanLEED v4 For Interior Design and Construction Checklisttarek.abbas8598Belum ada peringkat

- Table of Content and PrefaceDokumen5 halamanTable of Content and PrefaceHaiderEbrahimBelum ada peringkat

- 4200 Magnetometer Interface Manual 0014079 - Rev - ADokumen34 halaman4200 Magnetometer Interface Manual 0014079 - Rev - AJose Alberto R PBelum ada peringkat