PSV Sizing (Liquid)

Diunggah oleh

Saeid Rahimi MofradDeskripsi Asli:

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

PSV Sizing (Liquid)

Diunggah oleh

Saeid Rahimi MofradHak Cipta:

Format Tersedia

PROJECT : PROJ. NO.

: CLIENT : UNIT :

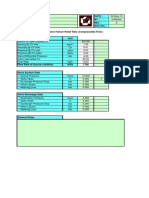

DATE : BY : REV : DOC NO.: PRESSURE SAFETY VALVE CALCULATION SHEET (LIQUID)

3/4/2011 SR A

General Data PSV Tag No. P&ID No. Protected Equipment Cause of Overpressure Flowing Specific Gravity Flowing Viscosity Effective Coefficient of Discharge

PSV-4101 20-DWG-FS-01 20-P-801 BLOCK OUTLET ---0.54 Cp 0.10 ---0.62

Sizing Method With Capacity Certification No Capacity Certification Combination Without Rupture Disk With Rupture Disk

Operating Condition Maximum Operating Pressure Maximum Operating Temperature Max. Allowable Working Pressure

barg O C barg

40.9 40.00 75.00

Relieving Condition Required Relieving Capacity Set Pressure Allowable Overpressure Superimposed Back Pressure (Constant) Superimposed Back Pressure (Variable) Built Up Back Pressure Relieving Temprature

Kg/hr barg % barg bar bar O C

330.0 75.00 10.0 7.00 4.00 0.00 40.0

Calculation Results Recommended Type (Conv./Bellows/Pilot) Total Back Pressure Relieving Pressure Capacity Certification Factor (Kp) Capacity Correction Factor (Kw) Effective Coefficient of Discharge (Kd) Viscosity Correction Factor (Kv) Minimum Required Discharge Area Selected Discharge Area Orifice Designation Inlet Size Outlet Size Actual Relieving Capacity Actual Relieving Capacity No. of PSVs Required

CONVENTIONAL barg 11.00 bara 83.50 ---1.00 ---1.00 ---0.62 ---1.00 mm2 1.68 2 mm 70.97 ---D in 1.0 in 2.0 3 m /hr 26.07 kg/hr 13971.3 ---1

General Notes

www.chemwork.org

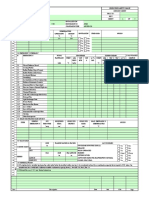

PROJECT : PROJ. NO.: CLIENT : UNIT :

0 0 0 0

DATE : BY : REV : DOC NO.: PSV SUCTION LINE SIZING CALCULATION FORM

40606 SR A

PSV Tag No. : P&ID No. Cause of Overpressure Fluid phase (Liquid/Vapor) Actual Flow Rate Set Pressure Flowing Density Flowing Viscosity

PSV-4101 20-DWG-FS-01 BLOCK OUTLET ---LIQUID kg/hr 330.00 barg 75.00 kg/m3 536.00 Cp 0.1040

Sizing Flow Rate Required Flow Rate Actual Flow Rate

Inlet Line Fitting Data Pipe Length Nominal Pipe Size Pipe Schedule No. Pipe Roughness (DEF.) Fittings Quantity * tee flow thru * tee branch * elbow 90 deg LR * elbow 90 deg screwed * elbow 45 deg LR * elbow 45 deg screwed * close pattern return bend * gate valve * ball valve * globe valve * angle valve * butterfly valve (2" - 8") * butterfly valve (10" - 14") * butterfly valve (16" - 24") * check valve swing * check valve lift * check valve stop lift * check valve tilting disk * foot valve hinged disc * foot valve poppet disc * reducer / expander * entrance (projecting) * entrance (sharp-edged) * entrance (flush) * exit (projecting) * exit (sharp-edged) * exit (rounded)

m inch ---inch no. no. no. no. no. no. no. no. no. no no. no. no. no. no. no. no. no. no. no. no. no. no. no. no. no. no. no.

50 24 40 0.00180 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

Calculation Results Pipe Internal Diameter Velocity Reynolds No. Friction Factor Pipe Pressuer Loss Fitting Pressure Loss Calculated P Allowable P Statement General Notes

mm m/s ------bar bar bar bar OK

574.65 0.001 1953 0.0328 0.000 0.000 0.000 2.250

www.chemwork.org

Anda mungkin juga menyukai

- Control Valve Failure Relief Rate - Liquid ServiceDokumen2 halamanControl Valve Failure Relief Rate - Liquid ServiceSaeid Rahimi MofradBelum ada peringkat

- WPI-KE-1104-SP141-QM5433 (Datasheet)Dokumen4 halamanWPI-KE-1104-SP141-QM5433 (Datasheet)Jèfrì PìnémBelum ada peringkat

- PSV Sizing (Steam)Dokumen2 halamanPSV Sizing (Steam)Saeid Rahimi Mofrad100% (1)

- MPCL Flare KOD Pump 11442-DS-103 - IFC2 18-06-2013Dokumen2 halamanMPCL Flare KOD Pump 11442-DS-103 - IFC2 18-06-2013zohaib_farooqBelum ada peringkat

- Control Valve Failure Relief Rate - Gas ServiceDokumen3 halamanControl Valve Failure Relief Rate - Gas ServiceSaeid Rahimi Mofrad100% (1)

- Control ValveDokumen1 halamanControl ValveAjay TiwariBelum ada peringkat

- Calculation Sheet For Centrifugal Pumps: Excel Program File: Pumpmast - Xls Version: 1.02 / RehDokumen9 halamanCalculation Sheet For Centrifugal Pumps: Excel Program File: Pumpmast - Xls Version: 1.02 / RehCast Ed IvBelum ada peringkat

- Line Sizing - 2PHASEDokumen11 halamanLine Sizing - 2PHASEEbby Onyekwe100% (1)

- Instrument Process Datasheet (IPDS)Dokumen3 halamanInstrument Process Datasheet (IPDS)Vraja KisoriBelum ada peringkat

- Ejector Data SheetDokumen5 halamanEjector Data SheetFatih FıratBelum ada peringkat

- API-12J - Horizontal Seperator Sizing OriginalDokumen2 halamanAPI-12J - Horizontal Seperator Sizing OriginalMichael HaiseBelum ada peringkat

- HX Design v1Dokumen12 halamanHX Design v1mansourotaibiBelum ada peringkat

- Pressure Safety Valve Sizing Calculations Vapour or Gas ReliefDokumen3 halamanPressure Safety Valve Sizing Calculations Vapour or Gas ReliefDhananjay NilkuteBelum ada peringkat

- Steam Pressure DropDokumen8 halamanSteam Pressure DropDavid Muñoz CastroBelum ada peringkat

- Fire Relief Dynamic StudyDokumen2 halamanFire Relief Dynamic StudyImtinan MohsinBelum ada peringkat

- Pump (English) TemplateDokumen1 halamanPump (English) TemplateMichael HaiseBelum ada peringkat

- No Yes No Yes No Yes No Yes No Yes No YesDokumen8 halamanNo Yes No Yes No Yes No Yes No Yes No YesEkundayo JohnBelum ada peringkat

- Breather Valves DatasheetDokumen4 halamanBreather Valves Datasheetmilton1987Belum ada peringkat

- Tube Rupture (Two Phase-Omega Method) PDFDokumen1 halamanTube Rupture (Two Phase-Omega Method) PDFAmin RoisBelum ada peringkat

- Pump CalcDokumen1 halamanPump CalcMoch WildanBelum ada peringkat

- Cepde - Valve Sizing (U16ch036, U16ch037, U16ch083)Dokumen15 halamanCepde - Valve Sizing (U16ch036, U16ch037, U16ch083)VRUSHABHBelum ada peringkat

- Pump Sizing Calculation SheetDokumen20 halamanPump Sizing Calculation Sheetvazzoleralex6884100% (1)

- Relief Valve Sizing - FireDokumen2 halamanRelief Valve Sizing - Firevlcmstne04Belum ada peringkat

- Sizing and Specifying Pumps R2Dokumen27 halamanSizing and Specifying Pumps R2royBelum ada peringkat

- PSV 0764 CD Vent KO Drum Liquid Pump - L03Dokumen3 halamanPSV 0764 CD Vent KO Drum Liquid Pump - L03Ebby OnyekweBelum ada peringkat

- Separator SizingDokumen3 halamanSeparator SizingMaryJane Ayisha Sado-ObahBelum ada peringkat

- Separator (1) Sizing Spread SheetsDokumen21 halamanSeparator (1) Sizing Spread SheetsSteve WanBelum ada peringkat

- Valve SizingDokumen6 halamanValve SizingVaibhav KuraleBelum ada peringkat

- Sonic VelocityDokumen2 halamanSonic Velocityganeshdhage100% (1)

- Line Sizing LiqDokumen12 halamanLine Sizing LiqDana GuerreroBelum ada peringkat

- PSV Sizing - Two Phase (Two-Points)Dokumen2 halamanPSV Sizing - Two Phase (Two-Points)Saeid Rahimi MofradBelum ada peringkat

- Jet Mixing CalculationDokumen3 halamanJet Mixing CalculationRachel FloresBelum ada peringkat

- BDVDokumen3 halamanBDVJason ThomasBelum ada peringkat

- 25nb y StrainerDokumen1 halaman25nb y StrainerKailas NimbalkarBelum ada peringkat

- Cvts - Tag No. Mpt-tv-4161Dokumen2 halamanCvts - Tag No. Mpt-tv-4161biswasdipankar05Belum ada peringkat

- Line SizeDokumen3 halamanLine Sizeintania660% (1)

- 13205-PPE-DS-V-003-1 - DataSheet - CVDokumen7 halaman13205-PPE-DS-V-003-1 - DataSheet - CVAnggun RushBelum ada peringkat

- Blow Off Pipe SizingDokumen13 halamanBlow Off Pipe Sizinggopaltry100% (1)

- Liquid Valve CV CalcDokumen4 halamanLiquid Valve CV Calcamit_kt1973Belum ada peringkat

- Datasheet AcDokumen9 halamanDatasheet AcMohan VarkeyBelum ada peringkat

- PSV Calculation and PhilosophyDokumen33 halamanPSV Calculation and PhilosophysbmmlaBelum ada peringkat

- Tank Vent Sizing - Cheresources - Com CommunityDokumen13 halamanTank Vent Sizing - Cheresources - Com CommunityharmlesdragonBelum ada peringkat

- Line Losses (Fittings) ΔP (ft) ΔP (ft)Dokumen3 halamanLine Losses (Fittings) ΔP (ft) ΔP (ft)ahmadlieBelum ada peringkat

- Valve Sizing CalculationDokumen10 halamanValve Sizing CalculationJayesh Chandran100% (1)

- Vessel - Vertical Sizing - IPunitsDokumen25 halamanVessel - Vertical Sizing - IPunitsAnders FTBelum ada peringkat

- Liquid Orifice SizingDokumen4 halamanLiquid Orifice SizingrmaganBelum ada peringkat

- CN5191 - L2 - A1-Centrifugal Pump Process Data SheetDokumen1 halamanCN5191 - L2 - A1-Centrifugal Pump Process Data SheetMochi CumilinaBelum ada peringkat

- Control Valve Sizing - LiquidDokumen4 halamanControl Valve Sizing - Liquidcharro1623Belum ada peringkat

- Valve Sizing SelectionDokumen15 halamanValve Sizing SelectionbariBelum ada peringkat

- Sizing ExercisesDokumen20 halamanSizing ExercisesfdkaBelum ada peringkat

- Info Calculation Pipe Line SizingDokumen8 halamanInfo Calculation Pipe Line Sizingrasnowmah2012Belum ada peringkat

- PSV Sizing Psv-414 UpdateDokumen7 halamanPSV Sizing Psv-414 UpdateBui Khoi NguyenBelum ada peringkat

- Filter Separator Revised Feb 19 2004Dokumen1 halamanFilter Separator Revised Feb 19 2004motalebyBelum ada peringkat

- Total Length Calcs For Pipes Valves and FittingsDokumen6 halamanTotal Length Calcs For Pipes Valves and FittingsImtinan MohsinBelum ada peringkat

- FlareTot - Total Flare AnalysisDokumen8 halamanFlareTot - Total Flare AnalysisArjun KapoorBelum ada peringkat

- Mechanical Data Sheet For Nitrogen ReceiverDokumen8 halamanMechanical Data Sheet For Nitrogen ReceiversudjonoBelum ada peringkat

- On OFF ValveDokumen30 halamanOn OFF ValveAjay TiwariBelum ada peringkat

- Knockout DrumDokumen9 halamanKnockout Drumgautam_96948069Belum ada peringkat

- Pump CalculationDokumen3 halamanPump CalculationSaeid Rahimi Mofrad100% (1)

- Control Valve CalculationDokumen18 halamanControl Valve CalculationLeonardo Ramirez Guzman100% (1)

- Tube Rupture (Two Phase - API App-D Method)Dokumen5 halamanTube Rupture (Two Phase - API App-D Method)Indra Kurniawan WijayaBelum ada peringkat

- Three Phase Separator Sizing (Double Weir 1)Dokumen3 halamanThree Phase Separator Sizing (Double Weir 1)Saeid Rahimi MofradBelum ada peringkat

- Tube Rupture (Two Phase-Omega Method)Dokumen1 halamanTube Rupture (Two Phase-Omega Method)Saeid Rahimi MofradBelum ada peringkat

- Three Phase Separator Sizing - Overflow WeirDokumen2 halamanThree Phase Separator Sizing - Overflow WeirSaeid Rahimi MofradBelum ada peringkat

- Three Phase Separator Sizing (Double Weir 2)Dokumen3 halamanThree Phase Separator Sizing (Double Weir 2)12377466790% (2)

- Three Phase Separator Sizing - Bucket & PipeDokumen2 halamanThree Phase Separator Sizing - Bucket & PipeSaeid Rahimi MofradBelum ada peringkat

- Three Phase Separator Sizing - No InternalDokumen2 halamanThree Phase Separator Sizing - No InternalSaeid Rahimi MofradBelum ada peringkat

- Three Phase Separator Sizing - Bucket & PipeDokumen2 halamanThree Phase Separator Sizing - Bucket & PipeSaeid Rahimi MofradBelum ada peringkat

- Three Phase Separator Sizing - Boot & WeirDokumen2 halamanThree Phase Separator Sizing - Boot & WeirSaeid Rahimi MofradBelum ada peringkat

- Three Phase Separator Sizing - Submerged WierDokumen2 halamanThree Phase Separator Sizing - Submerged WierSaeid Rahimi MofradBelum ada peringkat

- Three Phase Separator Sizing - Bucket & PipeDokumen2 halamanThree Phase Separator Sizing - Bucket & PipeSaeid Rahimi MofradBelum ada peringkat

- Tank Normal Venting (ISO)Dokumen2 halamanTank Normal Venting (ISO)Saeid Rahimi Mofrad0% (1)

- PSV Sizing - Non Ideal GasesDokumen1 halamanPSV Sizing - Non Ideal GasesSaeid Rahimi MofradBelum ada peringkat

- PVRV Sizing For Atmospheric Storage TanksDokumen2 halamanPVRV Sizing For Atmospheric Storage TanksSaeid Rahimi Mofrad50% (4)

- Tank Normal Venting (API)Dokumen1 halamanTank Normal Venting (API)ام يمنى ايمنBelum ada peringkat

- Tank SizingDokumen1 halamanTank SizingSaeid Rahimi MofradBelum ada peringkat

- Tank Emergency VentingDokumen1 halamanTank Emergency VentingSaeid Rahimi MofradBelum ada peringkat

- Steam Condensate Pot SizingDokumen1 halamanSteam Condensate Pot SizingSaeid Rahimi Mofrad100% (1)

- Supercritical PSV Sizing - Nonfire CaseDokumen1 halamanSupercritical PSV Sizing - Nonfire CaseSaeid Rahimi MofradBelum ada peringkat

- Pump CalculationDokumen3 halamanPump CalculationSaeid Rahimi Mofrad100% (1)

- PSV Sizing (Two Phase - HEM)Dokumen1 halamanPSV Sizing (Two Phase - HEM)Saeid Rahimi MofradBelum ada peringkat

- PSV Sizing - Two Phase (Two-Points)Dokumen2 halamanPSV Sizing - Two Phase (Two-Points)Saeid Rahimi MofradBelum ada peringkat

- Flare Stak Szin PPDDDokumen2 halamanFlare Stak Szin PPDDATUL SONAWANEBelum ada peringkat

- Nitrogen PurgingDokumen4 halamanNitrogen PurgingSaeid Rahimi MofradBelum ada peringkat

- Liquid Thermal ExpansionDokumen2 halamanLiquid Thermal ExpansionSaeid Rahimi MofradBelum ada peringkat

- List of SpreadsheetsDokumen5 halamanList of Spreadsheetsuetian729Belum ada peringkat

- S.Rahimi 0: Two Phase Flow Regime DeterminatorDokumen3 halamanS.Rahimi 0: Two Phase Flow Regime DeterminatorSaeid Rahimi MofradBelum ada peringkat

- Perdarahan Uterus AbnormalDokumen15 halamanPerdarahan Uterus Abnormalarfiah100% (1)

- Analysis of Rates (Nh-15 Barmer - Sanchor)Dokumen118 halamanAnalysis of Rates (Nh-15 Barmer - Sanchor)rahulchauhan7869Belum ada peringkat

- Continuing Professional Development PlanDokumen4 halamanContinuing Professional Development Planvviki50% (2)

- Zomato Restaurant Clustering & Sentiment Analysis - Ipynb - ColaboratoryDokumen27 halamanZomato Restaurant Clustering & Sentiment Analysis - Ipynb - Colaboratorybilal nagoriBelum ada peringkat

- Reference Paper Literature ReviewDokumen5 halamanReference Paper Literature ReviewAani RashBelum ada peringkat

- The Turning Circle of VehiclesDokumen2 halamanThe Turning Circle of Vehiclesanon_170098985Belum ada peringkat

- Img 20150510 0001Dokumen2 halamanImg 20150510 0001api-284663984Belum ada peringkat

- Culture 2007 2013 Projects Overview 2018-03-18Dokumen133 halamanCulture 2007 2013 Projects Overview 2018-03-18PontesDeboraBelum ada peringkat

- Cobol v1Dokumen334 halamanCobol v1Nagaraju BBelum ada peringkat

- XII CS Material Chap7 2012 13Dokumen21 halamanXII CS Material Chap7 2012 13Ashis PradhanBelum ada peringkat

- 4th Sept - Marathon Series Lecture 8 - General AwarenessDokumen208 halaman4th Sept - Marathon Series Lecture 8 - General AwarenessManbir ArinBelum ada peringkat

- Module 5 What Is Matter PDFDokumen28 halamanModule 5 What Is Matter PDFFLORA MAY VILLANUEVABelum ada peringkat

- The Chemistry of The Colorful FireDokumen9 halamanThe Chemistry of The Colorful FireHazel Dela CruzBelum ada peringkat

- 18 Composition Rules For Photos That ShineDokumen20 halaman18 Composition Rules For Photos That Shinemahfuzkhan100% (1)

- Full Project LibraryDokumen77 halamanFull Project LibraryChala Geta0% (1)

- CISF Manual Final OriginalDokumen17 halamanCISF Manual Final OriginalVaishnavi JayakumarBelum ada peringkat

- Invisible CitiesDokumen14 halamanInvisible Citiesvelveteeny0% (1)

- A P P E N D I X Powers of Ten and Scientific NotationDokumen5 halamanA P P E N D I X Powers of Ten and Scientific NotationAnthony BensonBelum ada peringkat

- Hockney-Falco Thesis: 1 Setup of The 2001 PublicationDokumen6 halamanHockney-Falco Thesis: 1 Setup of The 2001 PublicationKurayami ReijiBelum ada peringkat

- Circular ConvolutionDokumen3 halamanCircular Convolutionseeksudhanshu1Belum ada peringkat

- Grammar and Vocabulary TestDokumen5 halamanGrammar and Vocabulary TestLeonora ConejosBelum ada peringkat

- BBL PR Centralizer Rig Crew Handout (R1.1 2-20-19)Dokumen2 halamanBBL PR Centralizer Rig Crew Handout (R1.1 2-20-19)NinaBelum ada peringkat

- PM Jobs Comp Ir RandDokumen9 halamanPM Jobs Comp Ir Randandri putrantoBelum ada peringkat

- Smart Door Lock System Using Face RecognitionDokumen5 halamanSmart Door Lock System Using Face RecognitionIJRASETPublicationsBelum ada peringkat

- JCP4 XDOBursting EngineDokumen13 halamanJCP4 XDOBursting Enginesubhash221103Belum ada peringkat

- Very Narrow Aisle MTC Turret TruckDokumen6 halamanVery Narrow Aisle MTC Turret Truckfirdaushalam96Belum ada peringkat

- Evidence Prove DiscriminationDokumen5 halamanEvidence Prove DiscriminationRenzo JimenezBelum ada peringkat

- Common Core Content and Training Objectives For Basic AIS Training - Phase 2 - SpecialistDokumen82 halamanCommon Core Content and Training Objectives For Basic AIS Training - Phase 2 - SpecialistjlferreiraBelum ada peringkat

- 0012 Mergers and Acquisitions Current Scenario andDokumen20 halaman0012 Mergers and Acquisitions Current Scenario andJuke LastBelum ada peringkat

- EMD Question Bank II 2Dokumen4 halamanEMD Question Bank II 2Soham MisalBelum ada peringkat