Us 60995

Diunggah oleh

asdfasfHak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Us 60995

Diunggah oleh

asdfasfHak Cipta:

Format Tersedia

@uitrit isms. @anni ulffirr.

VWF. BUTTERFIELD, OF MADISON, .WISCONSIN.

Letters Patent No. 60,995, dated January 8, 1867. i

`\

:IMPROVEMENT ni ROTARY PUMPS.

.___

@In .Satanic referat in in time tett?t ndert irritating wt nf its time.

TO ALL WHOM IT MAY CONCERN; '

Be it known vthat I, W. BUTTERFIELD, of Madison, in the county of Dane, and State of Wisconsin, have invented certain new and useful improvements in Rotary Pumps; and I do hereby declare that the following is

a full, clear, and" exact description thereof, reference being had to the accompanying drawings, making part

of this specification, .and to -the letters of reference marked thereon, like letters indicating like parts wherever

they occur. ' '

` Y'lo enable others skilled in :the art ,to ccnstru'ct and use the invention, I will proceed to describe it.

My invention consists in constructing a rotary pump with'achamber'formed on the interior surface of the

casing, as a reservoir, from which the water is forced in a direction opposite tothat in which the cylinder rotates,

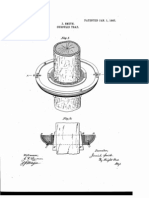

for the purpose of producing a more uniform flow of the water from the dischargel pipe. It further consists in' a novel method of arranging andoperating the valves or buckets. Figure 1 is a longitudinal vertical section of the pump complete.

Figure 2 is "an inside face view of one of the end plates of the case; and

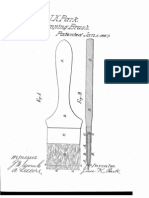

Figure 3 is a view of one of the buckets detached. i

I~ construct my pump with a circular casing, A, and two end plates, H, which, being bolted together, constitute the case of the pump. Crepresents a cylinder, equal in thickness to the width of the casing A, which is mounted

on a shaft, 13 which shaft has its bearings in the holes F of the end plates H. It will he' observed that the hole F is located eccentrically, and that the cylinder C is of such a diameter that when thus located its periph ery on one side shall just touch, or nearlytouch, the `surface of 'the case A, and leave a space on the opposite side, as shown in fig. l. Three transverse slots are cut in the periphery of the cylinder C, into which are fitted the buckets or valves D, as shown in fig. 1, the form of the buckets being shown. in iig. 3. A spring, a, is secured to the under edge of- the bucket D, the ends of which restv upon the outer surface of the projecting ringen, formed concentrically on the inside surface of each of the end plates H, thus serving to keep the

buckets pushed out against the casing A, as represented in iig. 1.l Upon the-upper left-hand side of -the casing

A, a projection is formed, constituting a chamber,- E, internally, as represented in fig. 1. ' This chamber, E, is .Slightly narrower than the casing A, so that the casing on each side `of the chamber forms a bearing forthe outer edge' of the bucket, so-that while the bucket is passing the chamber Eit will occupy the position indicated in red in iig. 1, thereby leaving a space outside ofthe bucket, throughwhich the waterthat fills the space between the outlet pipe I and the shoulder a, at the end of chamberE, will pass out toward the voutlet I, as indicated by the arrow. By these means I construct a pump that is simple and efficient, and from _which the ilow o'f water is more uniform than from the ordinary rotary pumps. Having thus describedmy invention, what I claim, is. 1. A rotary pump,'having a circular cylinder and the chamber E in the _casing so arranged that the valves,

in passing under th'e chamber, shall force the water out in the _opposite direction, as described.

substantially asset forth. -

2. I claim constructing the end plates- H with the concentric rings n, forming a. bearing for the springs a,

3. The combination of the cylinder C, provided with the buckets or valves D, and set eccentrically in the case A, in combination with the chamber E and the side 4'plates H, provided with the rings n, when arranged

and operating as set forth. i ' ' ' -

. W. BUTTERFIELD.

Witnesses: J. C. Scnnrrsn, T. R. HABEL.

Anda mungkin juga menyukai

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (895)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (74)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- FMO ESG Toolkit (AutoRecovered)Dokumen149 halamanFMO ESG Toolkit (AutoRecovered)me.abhishekpBelum ada peringkat

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- 07 EPANET Tutorial-SlidesDokumen26 halaman07 EPANET Tutorial-SlidesTarhata Kalim100% (1)

- T Rex PumpDokumen4 halamanT Rex PumpWong DaBelum ada peringkat

- GunshotDokumen2 halamanGunshotasdfasfBelum ada peringkat

- Patented Jan. 1, I867 V: Z. SperryDokumen3 halamanPatented Jan. 1, I867 V: Z. SperryasdfasfBelum ada peringkat

- Socket Programing GuideDokumen101 halamanSocket Programing GuideAnurag AggarwalBelum ada peringkat

- 01V96 ManualDokumen334 halaman01V96 ManualDario Luna Popunjeni ProfilBelum ada peringkat

- Us 60954Dokumen2 halamanUs 60954asdfasfBelum ada peringkat

- @értitrh .. Tstrs Gaunt @ffirn.: Amor Smith, 0F Cincinnati, OhioDokumen1 halaman@értitrh .. Tstrs Gaunt @ffirn.: Amor Smith, 0F Cincinnati, OhioasdfasfBelum ada peringkat

- US60942 PageDokumen1 halamanUS60942 PageasdfasfBelum ada peringkat

- US60932 Page 1Dokumen1 halamanUS60932 Page 1asdfasfBelum ada peringkat

- Us 60945Dokumen2 halamanUs 60945asdfasfBelum ada peringkat

- Us 60941Dokumen2 halamanUs 60941asdfasfBelum ada peringkat

- Us 60946Dokumen2 halamanUs 60946asdfasfBelum ada peringkat

- Us 60951Dokumen2 halamanUs 60951asdfasfBelum ada peringkat

- Us 60949Dokumen3 halamanUs 60949asdfasfBelum ada peringkat

- Us 60947Dokumen2 halamanUs 60947asdfasfBelum ada peringkat

- Us 60943Dokumen2 halamanUs 60943asdfasfBelum ada peringkat

- Nit2h Giant Gaunt @F?SR.: IMPROVEMENT M Rsrsnsvme BUTTER, MEAT 6mDokumen1 halamanNit2h Giant Gaunt @F?SR.: IMPROVEMENT M Rsrsnsvme BUTTER, MEAT 6masdfasfBelum ada peringkat

- Gems "Tetra GM": Ffinr.: John '1 . Sohenck, JR, or ' Matteawan, New YorkDokumen1 halamanGems "Tetra GM": Ffinr.: John '1 . Sohenck, JR, or ' Matteawan, New YorkasdfasfBelum ada peringkat

- H. K. Smith.: No. 60,950. Y. Patented Jan. L, 1867Dokumen3 halamanH. K. Smith.: No. 60,950. Y. Patented Jan. L, 1867asdfasfBelum ada peringkat

- Us 60953Dokumen3 halamanUs 60953asdfasfBelum ada peringkat

- N. Puckett. - : Centering ToolDokumen2 halamanN. Puckett. - : Centering ToolasdfasfBelum ada peringkat

- Nitrii Tetra Gaunt Ffirr.: Adolphe Roque, of Brire, France, Assignor To Jacques Guedin, ofDokumen1 halamanNitrii Tetra Gaunt Ffirr.: Adolphe Roque, of Brire, France, Assignor To Jacques Guedin, ofasdfasfBelum ada peringkat

- Making Eyelets'.: L. RichardsDokumen3 halamanMaking Eyelets'.: L. RichardsasdfasfBelum ada peringkat

- F. F. Reynolds.: No. 60,938. ' Patented Jan. Ì, - 867Dokumen2 halamanF. F. Reynolds.: No. 60,938. ' Patented Jan. Ì, - 867asdfasfBelum ada peringkat

- Refrigerator.: 2 Sheets Sheet 1.' C. F. Pike"Dokumen5 halamanRefrigerator.: 2 Sheets Sheet 1.' C. F. Pike"asdfasfBelum ada peringkat

- Us 60931Dokumen2 halamanUs 60931asdfasfBelum ada peringkat

- Us 60935Dokumen2 halamanUs 60935asdfasfBelum ada peringkat

- Us 60933Dokumen2 halamanUs 60933asdfasfBelum ada peringkat

- No. 60,932. - Patented Jan: 1, "1867.: S. J . PEETDokumen2 halamanNo. 60,932. - Patented Jan: 1, "1867.: S. J . PEETasdfasfBelum ada peringkat

- No. 60,930. Patented Jan. 1, 1867.:: LllliiilitillllllDokumen2 halamanNo. 60,930. Patented Jan. 1, 1867.:: LllliiilitillllllasdfasfBelum ada peringkat

- Us 60959Dokumen2 halamanUs 60959asdfasfBelum ada peringkat

- Shades Eq Gloss Large Shade ChartDokumen2 halamanShades Eq Gloss Large Shade ChartmeganBelum ada peringkat

- 120 Câu Tìm Từ Đồng Nghĩa-Trái Nghĩa-Dap AnDokumen9 halaman120 Câu Tìm Từ Đồng Nghĩa-Trái Nghĩa-Dap AnAlex TranBelum ada peringkat

- When I Was A ChildDokumen2 halamanWhen I Was A Childapi-636173534Belum ada peringkat

- Genie PDFDokumen264 halamanGenie PDFjohanaBelum ada peringkat

- IBS and SIBO Differential Diagnosis, SiebeckerDokumen1 halamanIBS and SIBO Differential Diagnosis, SiebeckerKrishna DasBelum ada peringkat

- Polyembryony &its ImportanceDokumen17 halamanPolyembryony &its ImportanceSURIYA PRAKASH GBelum ada peringkat

- Lab Report 2Dokumen5 halamanLab Report 2Md jubayer SiddiqueBelum ada peringkat

- Johari WindowDokumen7 halamanJohari WindowSarthak Priyank VermaBelum ada peringkat

- PBPO008E FrontmatterDokumen13 halamanPBPO008E FrontmatterParameswararao Billa67% (3)

- AREMA Shoring GuidelinesDokumen25 halamanAREMA Shoring GuidelinesKCHESTER367% (3)

- Industry and Community Project: Jacobs - Creating A Smart Systems Approach To Future Cities Project OutlineDokumen14 halamanIndustry and Community Project: Jacobs - Creating A Smart Systems Approach To Future Cities Project OutlineCalebBelum ada peringkat

- Portfolio AdityaDokumen26 halamanPortfolio AdityaAditya DisBelum ada peringkat

- GSM Radio ConceptsDokumen3 halamanGSM Radio ConceptsMD SahidBelum ada peringkat

- Sco 8th Class Paper - B Jee-Main Wtm-15 Key&Solutions Exam DT 17-12-2022Dokumen4 halamanSco 8th Class Paper - B Jee-Main Wtm-15 Key&Solutions Exam DT 17-12-2022Udaya PrathimaBelum ada peringkat

- RIBA PoWUpdate 131009 ProbynMiersDokumen28 halamanRIBA PoWUpdate 131009 ProbynMiersYellowLightBelum ada peringkat

- What Is An EcosystemDokumen42 halamanWhat Is An Ecosystemjoniel05Belum ada peringkat

- CBSE Class 10 Science Sample Paper SA 2 Set 1Dokumen5 halamanCBSE Class 10 Science Sample Paper SA 2 Set 1Sidharth SabharwalBelum ada peringkat

- Brachiocephalic Artery: AnteriorDokumen37 halamanBrachiocephalic Artery: AnteriorFarah FarahBelum ada peringkat

- B2B Marketing: Chapter-8Dokumen23 halamanB2B Marketing: Chapter-8Saurabh JainBelum ada peringkat

- BRENTON TarrantDokumen4 halamanBRENTON TarrantSayyidBelum ada peringkat

- Adigrat University: College of Engineering and Technology Department of Chemical EnginneringDokumen39 halamanAdigrat University: College of Engineering and Technology Department of Chemical EnginneringSeid Aragaw100% (1)

- Wordbank 15 Youtube Writeabout1Dokumen2 halamanWordbank 15 Youtube Writeabout1Olga VaizburgBelum ada peringkat

- USA Nozzle 01Dokumen2 halamanUSA Nozzle 01Justin MercadoBelum ada peringkat

- Basic Knowledge About WDM Principle ADokumen92 halamanBasic Knowledge About WDM Principle AJosé LópezBelum ada peringkat

- Conjunctions in SentencesDokumen8 halamanConjunctions in SentencesPunitha PoppyBelum ada peringkat

- Resolution: Owner/Operator, DocketedDokumen4 halamanResolution: Owner/Operator, DocketedDonna Grace Guyo100% (1)

- D15 Hybrid P1 QPDokumen6 halamanD15 Hybrid P1 QPShaameswary AnnadoraiBelum ada peringkat