GE Energy Data Sheets Technical Specifications

Diunggah oleh

Abisholita MecaTronicsDeskripsi Asli:

Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

GE Energy Data Sheets Technical Specifications

Diunggah oleh

Abisholita MecaTronicsHak Cipta:

Format Tersedia

g

GE Energy

11. Data Sheets

11.1 Technical Data

The following technical data is typical for the size and type of unit proposed and except for that information specifically identified as being guaranteed, this data is preliminary in nature and subject to change based on final equipment design and component selection.

11.1.1

Gas Turbine

Measurement Type Stages Configuration Operating speed Maximum tip speed Trip speed Electrical Maximum temperature First stage rotor bucket material Metal Coating Second stage rotor bucket material Metal Coating Third stage rotor bucket material Metal Coating Stator nozzle material First Second and third Rotor wheel material FSX-414 GTD-222 IN-706 GTD-111 GE proprietary coating DS-GTD-111 GE proprietary coating *DS-GTD-111 GE proprietary coating 3960 rpm 2420F Heavy duty 3 Single shaft, 2 bearing 3600 rpm 1615 fps Value

* Directionally solidified casting with serpentine cooling passages

GE PROPRIETARY INFORMATION For Internal GE Use Only

Data Sheets Firm Proposal

Page 11.1 101841G1N1 (02/04) Rev. 0 tt

11.1.2

Compressor

Measurement Type Stages Ratio Maximum tip speed Inlet guide vanes Inlet guide vane material Rotor blade material Stages 0 through 8 Stages 9 through 17 Stator blade material Stages 0 through 8 Stages 9 through 17 Rotor material Stages 0 through 14 Stages 15 through 17 Ni Cr MoV Cr Mo V C-450 AISI-403 C-450 AISI-403 Axial flow 18 15.7 (ISO) 1269 fps Variable-modulating C-450 Value

11.1.3

Bearings

Measurement Radial type (2) Thrust type (1) Tilt Pad Tilt pad Value

11.1.4

Combustion

Measurement Type Number of chambers Materials Liners Transition pieces Igniters (quantity) Flame detectors (quantity) Hastelloy X and HS-188 Nimonic 263 2 4 14 Value Can annular reverse flow

GE PROPRIETARY INFORMATION

Data Sheets Firm Proposal

Page 11.2 101841G1N1 (02/04) Rev. 0 tt

11.1.5

Water Injection

Measurement Required inlet pressure Maximum inlet temperature Minimum inlet temperature 0-20 psig 110F 35F Value

Refer to GEK-101944, Requirements for Water/Steam Purity in Gas Turbines in the Reference Document Chapter for water injection quality.

11.1.6

Natural Gas Fuel

Measurement Pressure required * Maximum * Minimum Fuel gas temperature (minimum) 475 psig site specific 50F of superheat Value

* Fuel gas supply pressure is measured at the inlet connection to the gas fuel valve module, and the pressure value at this point is referenced to site conditions. For typical gas fuel quality information, refer to GEI-41040, Process Specification Fuel Gases for Combustion in Heavy-Duty Gas Turbines in the Reference Document Chapter.

11.1.7

Liquid Fuel

For typical liquid fuel quality information, refer to GEI 41047, Gas Turbine Liquid Fuel Specifications in the Reference Document Chapter.

11.1.8

Lubrication and Hydraulic Control Oil

Measurement Configuration (turbine and generator) Oil type Initial charge Reservoir capacity Retention time Bearing supply pressure nominal Bearing supply temperature (nominal) Mineral oil Reference GEK-32568 7400 gallons 6200 gallons 5 minutes 25 psig 130F

Page 11.3 101841G1N1 (02/04) Rev. 0 tt

Value Common supply

GE PROPRIETARY INFORMATION

Data Sheets Firm Proposal

Main oil pump Type Driver Auxiliary oil pump Type Driver Emergency oil pump Type Driver Lube filter effectiveness Lube cooler Centrifugal DC motor Beta 41 = 200 Plate and frame (stainless) water cooled Centrifugal AC motor Centrifugal AC motor

11.1.9

Inlet Air

Measurement Air filter Normal pressure loss (new) Maximum pressure loss (dirty) 1.5 in. H2O 4.0 in. H2O Value

11.1.10

Exhaust System

Measurement External duct shell and stiffeners Internal flow liner A36 carbon steel Duct walls: 409 stainless steel Silencer panels (if provided): ASTM/A176 TY 409 stainless steel perforated sheet Inorganic zinc Value

External duct primer

11.1.11

Fire Protection

Measurement Type System Detector Detector manufacturer Number of detectors Multi-zone Fixed type temperature sensors Fenwal or equal 22 Value Low presssure CO2

GE PROPRIETARY INFORMATION

Data Sheets Firm Proposal

Page 11.4 101841G1N1 (02/04) Rev. 0 tt

11.1.12

Cooling Water Module

Measurement Nominal heat duty* Supply temperature (maximum) Supply pressure (maximum) Expected system pressure drop Value 200,000 to 317,000 Btu/min (211 to 334 MJ/min) 120F (49C) 130F H2 cooled gen 125 psig (862 KPag) 52 psid (358 KPad)

* Actual value depends on site configuration and conditions.

11.1.13

11.1.13.1

SPEEDTRONICTM Mark VI Hardware and Specifications

Environment The Control Cabinet is designed for operation in an air-conditioned equipment room with convection cooling at a maximum rating of 45C continuous or 50C for a short duration (a few days) to repair the cooling system.

Ambient Temperature: Operating Storage +32 to +113F -40 to +158F 0 to +45C -40 to +70C

Purchased commercial control room equipment such as PCs, monitors, and printers are capable of operating in a control room ambient of 0 to +40 deg C with convection cooling.

Humidity Contaminants: < 10 PPB 5 to 95% non-condensing Reactive Sulfur Reactive Chlorine Hydrogen Sulfide Sulfur Dioxide Chlorine Dioxide Sulfuric Acid Hydrochlori c Acid Hydrogen Chlorine Ammonia

11.1.13.2

Packaging

Item Access: Backplane: Cable Entrance: Front door access only VME Type (VERSA Module Eurocard) Top and / or Bottom

Data Sheets Firm Proposal Page 11.5 101841G1N1 (02/04) Rev. 0 tt

Description

GE PROPRIETARY INFORMATION

Dimensions:

3 Cabinet Lineup with Control Modules in center 13.8 ft wide x 2.0 ft deep x 7.6 ft high 4.2 m wide x 0.6 m deep x 2.32 m high E-coat primed, pebble gray - RAL 7032 Door, rear wall, roof: powder painted 1,000 Watts typical Lockable door Sheet Steel (24) point, barrier type terminal blocks which can be unplugged for maintenance. Each screw can terminate (2) #12 AWG 300 volt insulated wires. 1,200 lbs. (544kg.)

Finish: Heat: Locks: Material: Term. Blocks:

Weight:

11.1.13.3

Power Requirements (typical) The control cabinet is powered from the 125Vdc battery bus and short circuit protected in the motor control center. Both sides of the floating 125Vdc bus are continuously monitored with respect to ground. The 125Vdc is fuse isolated in the Mark VI power distribution module and fed to the internal power supplies for the Control Modules, the termination boards for the field contact inputs, and to the termination boards for the turbine solenoids. Additional 3.2A fuse protection is provided on the termination board for each solenoid. Separate 120Vac feeds are provided from the motor control center for the ignition transformers and to the local operator/maintenance station. Auxiliary 120/240Vac sources can be provided for cabinet power if required.

Control Cabinet Power Steady-State Voltage 125vdc (100 to 145vdc) 120vac (108 to 132vac) 47 53Hz 57 63Hz 240vac (216 to 264vac) 47 53Hz 57 63 Hz Frequency Load 7 A dc 7 A rms 3.5 A rms Comments Ripple <= 5% Note 1 Harmonic distortion < 7% Note 2 Harmonic distortion < 7 % Note 3

Note 1: Add 0.5 A dc continuous for each dc solenoid Note 2: Add 6.0 A RMS for a continuously powered ignition transformer Note 3: Add 3.5 A RMS for a continuously powered ignition transformer

GE PROPRIETARY INFORMATION

Data Sheets Firm Proposal

Page 11.6 101841G1N1 (02/04) Rev. 0 tt

11.1.14

Battery and Accessories

Battery System Features Battery Type Description 56 Cell 125Vdc nominal calcium-alloyed flooded lead/acid type Floated at 129Vdc (2.30 volts/cell) Equalized at 135Vdc (2.41 volts/cell) Batteries shipped in special shipping containers to the site for installation. Mounted in the control compartment Single phase 50 amp charger

Shipping Installation Charger Type

11.2 Component Weights and Dimensions

Item Accessory compartment Turbine and base Generator Length (Ft) 31.00 29.33 37.20 Width (Ft) 11.50 13.25 12.08 Height (Ft) 13.83 14.00 13.80 Weight (Lbs) 80000 377000 540000

GE PROPRIETARY INFORMATION

Data Sheets Firm Proposal

Page 11.7 101841G1N1 (02/04) Rev. 0 tt

Anda mungkin juga menyukai

- Formas Instalacion Turbina 6000Dokumen27 halamanFormas Instalacion Turbina 6000ferrerick100% (1)

- Lm2500 DescripDokumen2 halamanLm2500 DescripDenis Jimenez100% (1)

- List of Illustrations: Lm6000 PD Gek 105061 Ge Industrial Aeroderivative Gas TurbinesDokumen4 halamanList of Illustrations: Lm6000 PD Gek 105061 Ge Industrial Aeroderivative Gas TurbinesJHONNATTAN RODRIGUEZBelum ada peringkat

- Scope of Work Gas TurbineDokumen13 halamanScope of Work Gas TurbinePhong le100% (1)

- LM 2500Dokumen12 halamanLM 2500pramodtryBelum ada peringkat

- Technical Specifications, Fuel Nozzle GR 127 PDFDokumen8 halamanTechnical Specifications, Fuel Nozzle GR 127 PDFMadhan KumarBelum ada peringkat

- MS5002E NewDokumen8 halamanMS5002E Newecs71100% (2)

- GearboxDokumen16 halamanGearboxMehul zareBelum ada peringkat

- LM6000 PC O&M - GEK 105059 CHG 06Dokumen1.988 halamanLM6000 PC O&M - GEK 105059 CHG 06Alejandro J. Vigo50% (2)

- 1 151125221535 Lva1 App6892Dokumen40 halaman1 151125221535 Lva1 App6892Darmawan PutrantoBelum ada peringkat

- LM6000-InD-239 - Improved LPT Coupling NutDokumen9 halamanLM6000-InD-239 - Improved LPT Coupling NutIqbal UsmaniBelum ada peringkat

- MS6001FADokumen14 halamanMS6001FAsureshkumar908Belum ada peringkat

- Oman Energy Conference - World Record Gas Turbine Service ExperiencesDokumen16 halamanOman Energy Conference - World Record Gas Turbine Service ExperiencesabelsgBelum ada peringkat

- 9FA Failures in DabholDokumen10 halaman9FA Failures in Dabholsenthil031277100% (3)

- CatalogoPGT25 PDFDokumen4 halamanCatalogoPGT25 PDFshihabjamaan100% (4)

- DLN 2.0+ Fuel NozzleDokumen1 halamanDLN 2.0+ Fuel NozzleWedneslao LopezBelum ada peringkat

- APA DOC No. 2014 PDFDokumen67 halamanAPA DOC No. 2014 PDFThanapaet RittirutBelum ada peringkat

- 9FA Device SummaryDokumen71 halaman9FA Device SummaryVanchi Nathan100% (1)

- MFS Gas Turbine MaintenanceDokumen34 halamanMFS Gas Turbine MaintenanceThanapaet Rittirut0% (1)

- MHPS D Class GT UpratesDokumen6 halamanMHPS D Class GT Uprateskp pkBelum ada peringkat

- Comp Amp Turbine COURS 9001EDokumen27 halamanComp Amp Turbine COURS 9001Enabil160874100% (1)

- CT Inspection IntervalsDokumen19 halamanCT Inspection IntervalsSantiago67% (3)

- SAC and DLE PDFDokumen29 halamanSAC and DLE PDFMehulkumar PatelBelum ada peringkat

- TIL 1132 2R1 - VIGV Inspection, Thrust WasherDokumen5 halamanTIL 1132 2R1 - VIGV Inspection, Thrust WasherHernan Giraut100% (2)

- GE User QnA 6BDokumen31 halamanGE User QnA 6Bsatyandaru100% (1)

- Til 1213 R1Dokumen6 halamanTil 1213 R1Hernan GirautBelum ada peringkat

- Overview of SCF6 ExchangeDokumen2 halamanOverview of SCF6 Exchangechdi100% (1)

- Gek105054 File0007Dokumen18 halamanGek105054 File0007outilprok22kBelum ada peringkat

- (GAS TURBINE MS 5001 PA) Volume IDokumen159 halaman(GAS TURBINE MS 5001 PA) Volume Ihayder ahmed100% (2)

- Aerosila NPP JSC: Gas Turbine Power PlantsDokumen30 halamanAerosila NPP JSC: Gas Turbine Power PlantsSatish Babu Garikapati100% (2)

- GE Power Systems 7F Users Conference PresentationsDokumen27 halamanGE Power Systems 7F Users Conference Presentationsatfrost4638Belum ada peringkat

- TIL 1108-R1: Cast Segmented Turbine Nozzle Acceptance GuidelinesDokumen10 halamanTIL 1108-R1: Cast Segmented Turbine Nozzle Acceptance GuidelinesAkramBelum ada peringkat

- GEN01A 214 B5 7FA-Gas-Turbine-Major-Inspections Example r1 PFDokumen14 halamanGEN01A 214 B5 7FA-Gas-Turbine-Major-Inspections Example r1 PFsarathkumar100% (1)

- Proven Solutions GE-EvuletDokumen48 halamanProven Solutions GE-EvuletmohamedhasBelum ada peringkat

- 01 Tab01 130916060639 Phpapp02 PDFDokumen36 halaman01 Tab01 130916060639 Phpapp02 PDFajo zinzoBelum ada peringkat

- 3 - Gas Turbine Overview 8.09Dokumen25 halaman3 - Gas Turbine Overview 8.09Sujeet Kumar100% (1)

- GE Gas Turbines Were Basically Divided Into 3 DifferentDokumen3 halamanGE Gas Turbines Were Basically Divided Into 3 Differentsaikrish36Belum ada peringkat

- Volume II Generator-Accessories-Switchgears & Electric Control EquipmentDokumen908 halamanVolume II Generator-Accessories-Switchgears & Electric Control Equipmentdepinfor lusofabril100% (1)

- Technical Information Letter: Ge Power TIL 2445 Product ServiceDokumen4 halamanTechnical Information Letter: Ge Power TIL 2445 Product ServiceMinhajur Rahman100% (1)

- Equipment Definition: Component LiteratureDokumen5 halamanEquipment Definition: Component LiteratureAbbas AkbarBelum ada peringkat

- 04 - Dry Low NOxDokumen15 halaman04 - Dry Low NOxdenmas90Belum ada peringkat

- MS5002C BreakdownDokumen245 halamanMS5002C BreakdownElver Amesquita100% (2)

- Ge MS 5000 5341Dokumen45 halamanGe MS 5000 5341helmybh100% (3)

- 000start CDDokumen1.166 halaman000start CDruben100% (3)

- 04 - LM2500 OverviewDokumen27 halaman04 - LM2500 OverviewLudovic LeroyBelum ada peringkat

- T 2055 R 1Dokumen6 halamanT 2055 R 1srinivasBelum ada peringkat

- TIL 476C - Exhaust Temperature Spread GuidelinesDokumen2 halamanTIL 476C - Exhaust Temperature Spread GuidelinesHernan Giraut100% (1)

- Ansaldo Energia AE94.2 Upgrading ProjectDokumen20 halamanAnsaldo Energia AE94.2 Upgrading Projectvincent8295547100% (1)

- Alstom Gas-Turbines-Technical-Performance PDFDokumen2 halamanAlstom Gas-Turbines-Technical-Performance PDFPoull SteeadyBelum ada peringkat

- LM6000 PC Time Limited ComponentsDokumen7 halamanLM6000 PC Time Limited ComponentsmstaszelBelum ada peringkat

- DLN-1 Heavy Duty Gas Turbines: Improved Secondary Flame Detector SystemDokumen8 halamanDLN-1 Heavy Duty Gas Turbines: Improved Secondary Flame Detector SystemManuel L LombarderoBelum ada peringkat

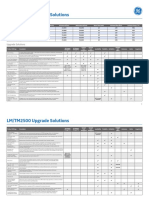

- LM TM2500 Upgrade Solutions PDFDokumen2 halamanLM TM2500 Upgrade Solutions PDFLibyanManBelum ada peringkat

- CBN Blade Tip AbradableDokumen8 halamanCBN Blade Tip Abradablebehtam2407Belum ada peringkat

- 9FA Recommended Parts ListingDokumen1 halaman9FA Recommended Parts Listingalexandr_popov_2Belum ada peringkat

- Advanced Sgt6-5000F Development: 09-IAGT-202Dokumen18 halamanAdvanced Sgt6-5000F Development: 09-IAGT-202Ronald ChavezBelum ada peringkat

- Datasheet of Equipment - ANNAMDokumen8 halamanDatasheet of Equipment - ANNAMhuyly34Belum ada peringkat

- Kohler 150kw Prime Gas OilfieldDokumen4 halamanKohler 150kw Prime Gas OilfieldnathandemBelum ada peringkat

- Kohler 20RES SpecsDokumen4 halamanKohler 20RES Specsginger1951Belum ada peringkat

- Bomba Desaladora AlternativaDokumen6 halamanBomba Desaladora AlternativawaricateBelum ada peringkat

- Horizontal Turbine - G005Dokumen1 halamanHorizontal Turbine - G005Abisholita MecaTronicsBelum ada peringkat

- Horizontal Exhaust FrameDokumen1 halamanHorizontal Exhaust FrameAbisholita MecaTronicsBelum ada peringkat

- Horizontal CompressorDokumen1 halamanHorizontal CompressorAbisholita MecaTronicsBelum ada peringkat

- 7F LABELED DIGITAL CLEARANCE DOCUMENTDokumen25 halaman7F LABELED DIGITAL CLEARANCE DOCUMENTAbisholita MecaTronics100% (1)

- Generator Bolting and TorquesDokumen2 halamanGenerator Bolting and TorquesAbisholita MecaTronics100% (1)

- FIBONACCIDokumen1 halamanFIBONACCIAbisholita MecaTronicsBelum ada peringkat

- Transistor NPN 2n222aDokumen8 halamanTransistor NPN 2n222aRoberto Eduardo Tenorio RamosBelum ada peringkat

- THERMODYNAMICS - Course OutlineDokumen2 halamanTHERMODYNAMICS - Course OutlineNduati JohnBelum ada peringkat

- Aircraft Engine Types and APU InstallationsDokumen13 halamanAircraft Engine Types and APU InstallationsAbdul MuizzBelum ada peringkat

- Switch GearDokumen3 halamanSwitch GearAsifShahzadBelum ada peringkat

- Ethos 24c Maintenance ManualDokumen29 halamanEthos 24c Maintenance Manualdanielteo2008Belum ada peringkat

- Texon Automation ControlsDokumen27 halamanTexon Automation ControlsFede RonchiBelum ada peringkat

- Vapour Compression CycleDokumen16 halamanVapour Compression CycleHrishikesh ShindeBelum ada peringkat

- Final Lab4Dokumen16 halamanFinal Lab4pwint chit thawBelum ada peringkat

- Arctic KiewitDokumen21 halamanArctic KiewitpvisigalliBelum ada peringkat

- Energy Saving Measures and Payback CalculationsDokumen5 halamanEnergy Saving Measures and Payback CalculationsASHUTOSH RANJANBelum ada peringkat

- Assignment EN671 2Dokumen2 halamanAssignment EN671 2Hari Peravali100% (1)

- Hydraulic TurbinesDokumen43 halamanHydraulic TurbinesKarim SayedBelum ada peringkat

- Polymer Electrolyte Membrane Fuel Cells: AuthorsDokumen31 halamanPolymer Electrolyte Membrane Fuel Cells: AuthorsMichelle BrechuBelum ada peringkat

- Perkins 4012-46TWG2-3Dokumen24 halamanPerkins 4012-46TWG2-3Cris_eu09100% (3)

- Energy Storage DeviceDokumen9 halamanEnergy Storage DeviceAbhishek SainiBelum ada peringkat

- Alkali Boilout Procedure for Oil RemovalDokumen4 halamanAlkali Boilout Procedure for Oil RemovalBalaji PillaiBelum ada peringkat

- 6 Electricity - TransmissionDokumen1 halaman6 Electricity - TransmissionMohamad IskandarBelum ada peringkat

- Asset Location ListDokumen421 halamanAsset Location Listanke irenaBelum ada peringkat

- Performance Analysis For Francis Hydraulic Turbine Based On Normalized Operating Condition and Its ApplicationDokumen6 halamanPerformance Analysis For Francis Hydraulic Turbine Based On Normalized Operating Condition and Its Applicationriddhesh gandreBelum ada peringkat

- Activity - 221130 - Exploration Geologist - MKEDokumen8 halamanActivity - 221130 - Exploration Geologist - MKESetia WirawanBelum ada peringkat

- Marioff HI FOG 2342D EN Total Flooding Application Leaflet Web - tcm990 157057Dokumen2 halamanMarioff HI FOG 2342D EN Total Flooding Application Leaflet Web - tcm990 157057Yahia LekouaraBelum ada peringkat

- High-Efficiency Cast Iron Submersible Sewage PumpDokumen16 halamanHigh-Efficiency Cast Iron Submersible Sewage PumptuanBelum ada peringkat

- Brush Dax Generadores Dax - 2 - PoleDokumen4 halamanBrush Dax Generadores Dax - 2 - PoleHernan GirautBelum ada peringkat

- 3.1.1 Overpressure Protection Basic RulesDokumen21 halaman3.1.1 Overpressure Protection Basic RulesFranklin RevillBelum ada peringkat

- REVOMAX ONCE-THROUGH STEAM GENERATORDokumen34 halamanREVOMAX ONCE-THROUGH STEAM GENERATORDuggineni RamakrishnaBelum ada peringkat

- Review of Proposed Installation of Custom Gridmetrix Load Side Voltage Detection Pilot To NPC'S Off Grid SystemDokumen3 halamanReview of Proposed Installation of Custom Gridmetrix Load Side Voltage Detection Pilot To NPC'S Off Grid SystemCatrina FedericoBelum ada peringkat

- AFT Backpack10 2Dokumen2 halamanAFT Backpack10 2Forum PompieriiBelum ada peringkat

- Safe Furnace and Boiler Firing (2012) PDFDokumen96 halamanSafe Furnace and Boiler Firing (2012) PDFFrank Seipel6100% (1)

- Grundfos K_Series Submersible Pumps OverviewDokumen29 halamanGrundfos K_Series Submersible Pumps OverviewMeliaGrina100% (2)

- Refrigeration and Air Conditiong Lab MannualDokumen24 halamanRefrigeration and Air Conditiong Lab MannualCreative 360Belum ada peringkat

- TEZEUS BrochureDokumen10 halamanTEZEUS BrochureAlexandruIonutBelum ada peringkat