Us 4888901 Patent

Diunggah oleh

MSavicJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Us 4888901 Patent

Diunggah oleh

MSavicHak Cipta:

Format Tersedia

United States Patent [191

French et a1.

[54] [75]

FIREARM

Inventors: Kendrick L. French, Lebanon, Me.;

I [56]

[11] [45]

Patent Number: Date of Patent:

References Cited

4,888,901

Dec. 26, 1989

U.S. PATENT DOCUMENTS

Mark C. Laney, New Market, N.H.

158,221 12/1874 3,757,447 9/1973 4,700,499 10/1987

Smith .................................... .. 42/51 Rowe .... .. 42/51 Knight ...... .. 42/51

[73] Assignee: K. W. Thompson Tool Co., Inc.,

Rochester, N.H.

4,715,139 12/1987

Rodney, Jr. .......................... .. 42/51

Primary ExaminerCharles T. Jordan Attorney, Agent, or Firm-Norman S. Blodgett; Gerry A. Blodgett

[21] Appl. No.: 342,998 122] Filed:

[51] [52] 158]

Apr. 25, 1989

[57] ABSTRACT Muzzle-loading ?rearm which ignites the powder by

means of a percussion cap located on a nipple coaxially

of the bore, a venting passage directing gas laterally of

Int. Cl.4 ............................................ .. F41C 21/00 US. Cl. .......................................... .. 42/51; 42/83 Field of Search .................................... .. 42/51, 83

the nipple.

4 Claims, 2 Drawing Sheets

l4

//

25

9'5 5:4

/

I.

49

2,3 W////

{////////(/// __ - 555/455

aB

Y//// /// ////

US. Patent

Dec. 26, 1989

Sheet 1 of 2

4,888,901

NM

i

215::

4,888,901

2

DESCRIPTION OF THE PREFERRED

FIREARM

BACKGROUND OF THE INVENTION

FIG. 5 is a horizontal sectional view of the ?rearm,

showing it during powder burn.

EMBODIMENT It is obvious that minor changes may be made in the form and construction of the invention without depart ing from the material spirit thereof. It is not, however,

desired to con?ne the invention to the exact form herein

0 shown and described, but it is desired to include all such _ as properly come within the scope claimed.

Most of the traditional muzzle-loading guns were ignited by a ?int lock or by a percussion cap; in both

cases, the ignition device was maintained on the side of

the gun and the ignition spark was ?red into a nipple

passage that was directed sideways. When the gun was

?red, the back?re gas was projected out of the nipple passage and laterally of the gun. Recently, however, it

has been suggested that a muzzle-loading ?rearm could be ?red advantageously by a percussion cap mounted

on a nipple located at the rear end of the barrel and

Referring ?rst to FIGS. 1 and 2 there is shown a

?rearm embodying the principles of the present inven tion and generally indicated by the reference numeral

10. The ?rearm 10 is by way of example a muzzle-load

coaxial of the bore. This concept was shown and de scribed in the patent application of French et al Ser. No.

ing, black-powder pistol having a receiver 11, a frame

12, a barrel 14, and a nipple 13 which carries a percus

obviated in a novel manner by the present invention.

254,953 ?led Oct. 7, 1988. One of the problems with this sion cap 15 which is mounted behind the ?ring chamber axial ignition arrangement is that the backfire is directed of the ?rearm. The trigger 16 is pivotally connected to rearwardly around the hammers. These and otherdif? 20 the frame 12 by means of a pivot pin 18 and biased to the culties experienced with the prior art devices have been forward position shown in FIG. 2 by a spring 22. A

hammer 24 is pivotally connected to frame 12 by means

_ of a pivot pin 26. A venting passage 17 exists on the

It is therefore, an outstanding object of the invention to provide a ?rearm of the muzzle-loading, percussion

cap ignited type, in which ignition takes place coaxially

of the barrel, but back?re is directed laterally. Another object of this invention is the provision of a

opposite sides of the receiver. A hammer block 20 is integral with the trigger 16 and

extends upwardly from the pivot 18. The hammer block

20 normally occupies a rearward position when the trigger 16 is in its forward position The hammer block

20 has a rearwardly-facing surface which has a rear

muzzle-loading ?rearm having symmetrical ?ring.

A further object of the present invention is the provi sion of the ?rearm ignited by a percussion cap and

wardly facing notch. The hammer 24 has a forwardly facing striking surface 30 which is in line with the per With these and other objects in view, as will be ap cussion cap 15 and a thumb grip 32 for moving the parent to those skilled in the art, the invention resides in ; hammer 24 about the pivot pin 26 from an intermediate the combination of parts set forth in the speci?cation position to a rearward, cocked positioniWhen the ham and covered by the claims appended hereto. .35 mer 24 is in its intermediate position, it is spaced from the percussion cap 15. . SUMMARY OF THE INVENTION Referring next to FIGS. 3, 4, and 5, it can be seen that

wherein back?re ejection is symmetrical.

In general, the invention consists of a ?rearm having

the barrel 14 is mounted in the receiver 11 and has,

a receiver and a barrel mounted in the receiver and located at its rear end, a chamber element 25 and a t having a bore to receive a projectile. A chamber ele 40 nipple 13. The barrel has a bore 19, while the chamber ment is mounted on the rear end of the barrel and has a element has a cylindrical chamber 27 facing down the

generally cylindrical chamber facing down the barrel

barrel coaxially of the bore. The nipple 13 has a primer

coaxially of the bore. A nipple is mounted at the rear bore 28 that is coaxial of the bore and the chamber. The end of the chamber element and has a primer bore venting passage 17 extends through the chamber ele which is coaxial at the bore and the chamber A venting 45 ment 25 and the receiver 11 to the exterior of the re passage extends through the chamber element and the ceiver, as is evident in FIGS. 1 and 2. receiver to the exterior from the axis of the bore to both A small bore 29 extends axially from the chamber 27 exterior sides of the receiver. into the venting passage and a small bore 31 extends More speci?cally, a small bore extends from the from the primer bore 28 into the venting passage. The chamber into the venting passage and a small bore ex cross-sectional area of the venting passage is substan

tends from the primer bore into the venting passage, the cross-sectional area of the venting passage being sub

stantially greater than that of either of the said small bores.

BRIEF DESCRIPTION OF THE DRAWINGS The character of the invention, however, may be best understood by reference to one of its structural forms, as illustrated by the accompanying drawings, in which:

tially greater than that of either of the said small bores. The venting passage 17 consists of two branches, each of which consists of a ?rst, second, and third section. The ?rst section 33 leaves the axis of the barrel and extends angularly and rearwardly. The second section 34 extends at a right angle to the axis. The third section 35 extends through the wall of the receiver angularly and forwardly to the exterior surface. The ?rst sections 33 of the branches of the venting

FIG. 1 is a side elevational view of a firearm incorpo 60 passage are de?ned by a rearwardly-facing conical re cess 36 having a channel 38 and by a conical projection 37 formed on the nipple 13. The projection 37 ?ts FIG. 2 is a side elevational view of the ?rearm, some snugly in the conical recess 36. what enlarged and with portions broken away, The operation and advantages of the invention will FIG. 3 is a horizontal sectional view of the ?rearm taken on the line III--III of FIG. 1, showing the ?rearm 65 now be readily understood in view of the above discus

rating the principles of the present invention,

in loaded condition,

FIG. 4 is a horizontal sectional view of the ?rearm, showing it at the moment of ignition, and

sion. The charge of black-powder is introduced into the chamber 27 in the usual way and followed by the pro jectile 23. The percussion cap 15 is placed on the nipple

4,888,901

13. The ?rearm 10 is then ready to ?re, as shown in FIG. 3. When the trigger 16 is pulled, the hammer 24 falls on

(b) a barrel mounted in the receiver and having a bore to receive a projectile,

(c) a chamber element mounted on the rear end of the

the cap 15 and the ignition ?ame passes forwardly

through the primer bore 28, through the small bore 31,

across the venting passage 17, and through the small bore 29 into the chamber, whereupon the charge is

ignited, as shown in FIG. 4.

barrel and having a generally cylindrical chamber facing down the barrel coaxially of the bore, and

(d) a nipple mounted at the rear end of the chamber element and having a primer bore which is coaxial of the bore and the chamber, wherein a venting passage extends through the chamber element and the receiver to the exterior from the axis of the bore to both exterior sides of the receiver. 2. A ?rearm as recited in claim 1, wherein a small

As the powder burns, the gas pressure forces the projectile 23 along the bore 19. At the same time, a certain amount of back?re gas is forced through the small bore 29 into the passage 17. The gas is divided into

two parts, each of which ?ows down one of the two

branches of the venting passage 17. The gas emerging from the small bore 29 strikes the conical protuberance 37 of the nipple and ?ows into the ?rst section 33 of the passage 17. The gas passes through the second section 34 and through the third section 35 to the exterior.

While in the ?rst section, the gas flow has a rearward component of direction; in the second section it ?ows directly laterally of the axis; and in the third section it has a foreward component of direction. Very little gas flow enters the small bore 31 and passes rearwardly,

bore extends from the chamber into the venting passage and a small bore extends from the primer bore into the venting passage, the cross-sectional area of the venting

passage being substantially greater than that of either of

the said small bores. 3. A ?rearm as recited in claim 2, wherein the venting passage consists of two branches, each branch having a

?rst section leaving the axis and extending angularly

and rearwardly, a second section extending at a right

angle to the axis, and a third section extending through the receiver angularly and forwardly to the exterior.

4. A ?rearm as recited in claim 3,.wherein the cham since the cross-sectional area of the combined branches 25 ber element is provided with a coaxial conical recess of the venting passage 17 is so much greater than that of facing rearwardly and the nipple is formed with a coax the small bore. ial conical protuberance that ?ts snugly in the said coni The invention having been thus described, what is cal recess, the chamber element having a channel open claimed as new and desired to secure by Letters Patent ing onto the surface of the conical recess, which chan is: 30 nel and protuberance de?ne the said ?rst sections of the

1. A ?rearm, comprising:

(a) a receiver,

35

branches of the venting passage.

it

* *

IIR

45

50

55

65

Anda mungkin juga menyukai

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (587)

- Fermentacija PovrćaDokumen1 halamanFermentacija PovrćaMSavicBelum ada peringkat

- Learn How To MassageDokumen21 halamanLearn How To MassageEskay100% (29)

- AD21 - On Farm Fish CultureDokumen67 halamanAD21 - On Farm Fish CultureKenny CasillaBelum ada peringkat

- Mind Control Conspiracy - Perverted ScienceDokumen31 halamanMind Control Conspiracy - Perverted ScienceMSavicBelum ada peringkat

- Cvorovi Na YoutubeDokumen1 halamanCvorovi Na YoutubeMSavicBelum ada peringkat

- 12x24 Homesteaders Cabin v2Dokumen22 halaman12x24 Homesteaders Cabin v2bercenaru1100% (6)

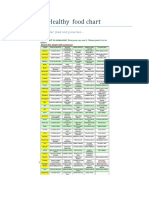

- Healthy Food Guide Chart for Optimal NutritionDokumen2 halamanHealthy Food Guide Chart for Optimal NutritionMSavicBelum ada peringkat

- 500 Real English PhrasesDokumen38 halaman500 Real English PhrasesIon Sava100% (2)

- 25 Healthy Paleo SnacksDokumen56 halaman25 Healthy Paleo SnacksMSavic100% (1)

- 2005-2006 Audio & Speaker Application GuideDokumen0 halaman2005-2006 Audio & Speaker Application GuideMSavicBelum ada peringkat

- United States Patent: CalifDokumen8 halamanUnited States Patent: CalifMSavicBelum ada peringkat

- Swadesh PDFDokumen4 halamanSwadesh PDFMSavicBelum ada peringkat

- Us 4434718 PatentDokumen6 halamanUs 4434718 PatentMSavicBelum ada peringkat

- Small Fishing Boats DesignsDokumen47 halamanSmall Fishing Boats DesignsMSavic100% (2)

- Basic Livestock VettingDokumen3 halamanBasic Livestock VettingMSavicBelum ada peringkat

- Yugo, Zastava PDFDokumen0 halamanYugo, Zastava PDFMSavicBelum ada peringkat

- 6th Central Pay Commission Salary CalculatorDokumen15 halaman6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- 300 Papermaking RecipiesDokumen96 halaman300 Papermaking RecipiesMSavic100% (4)

- Chopper Handbook Tube BenderDokumen20 halamanChopper Handbook Tube Bendermendingojr100% (5)

- 6th Central Pay Commission Salary CalculatorDokumen15 halaman6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Chopper Handbook Tube BenderDokumen20 halamanChopper Handbook Tube Bendermendingojr100% (5)

- DIY Survival Kit from Everyday ItemsDokumen3 halamanDIY Survival Kit from Everyday ItemsMSavicBelum ada peringkat

- CLOVER - Wild Edible SeriesDokumen14 halamanCLOVER - Wild Edible SeriesMSavicBelum ada peringkat

- Upland RiceDokumen44 halamanUpland RiceVictorio RustiaBelum ada peringkat

- Grit USA 2012 05 06Dokumen100 halamanGrit USA 2012 05 06MSavic100% (1)

- Mother Earth News - February & March 2011Dokumen133 halamanMother Earth News - February & March 2011MSavic100% (2)

- Gunsmithing and Tool Making Bible by Harold HoffmanDokumen294 halamanGunsmithing and Tool Making Bible by Harold HoffmanErik Green100% (7)

- Grit July-Aug 2011Dokumen100 halamanGrit July-Aug 2011MSavic100% (1)

- Forager's Harvest Guide To Eating Wild PlantsDokumen368 halamanForager's Harvest Guide To Eating Wild PlantsMSavic100% (4)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (399)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (73)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (265)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (119)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- Ecco ADokumen5 halamanEcco Aouzun852Belum ada peringkat

- ProjectDokumen5 halamanProjectMahi MalikBelum ada peringkat

- Book 3 - Revised 2017-2Dokumen41 halamanBook 3 - Revised 2017-2sales zfBelum ada peringkat

- HP t410 Smart Zero Client: Zero Management. Zero Configuration. Zero CompromiseDokumen5 halamanHP t410 Smart Zero Client: Zero Management. Zero Configuration. Zero Compromisekonan09Belum ada peringkat

- Chlorine (Free or Total) Manual For Test Kits CN-70, CN-70F, CN-70TDokumen6 halamanChlorine (Free or Total) Manual For Test Kits CN-70, CN-70F, CN-70TDemétrius Ivo FernandesBelum ada peringkat

- Axion DatabaseDokumen25 halamanAxion Databasemacy williamsBelum ada peringkat

- EGGAR - Final ReportDokumen8 halamanEGGAR - Final ReportAndrew LeeBelum ada peringkat

- English Test 03Dokumen6 halamanEnglish Test 03smkyapkesbi bjbBelum ada peringkat

- Learn About Steganography TechniquesDokumen11 halamanLearn About Steganography TechniquesashaBelum ada peringkat

- Qc-Sop-0 - Drilling of PoleDokumen7 halamanQc-Sop-0 - Drilling of PoleAmeerHamzaWarraichBelum ada peringkat

- Rexroth HABDokumen20 halamanRexroth HABeleceng1979Belum ada peringkat

- 08 - Truck Driver's Dhobi SinkDokumen3 halaman08 - Truck Driver's Dhobi SinkfebousBelum ada peringkat

- Adv - Student - HandbookDokumen61 halamanAdv - Student - HandbookOmkar BezzankiBelum ada peringkat

- IGNOU FEG-02 (2011) AssignmentDokumen4 halamanIGNOU FEG-02 (2011) AssignmentSyed AhmadBelum ada peringkat

- Properties of Skeletal MuscleDokumen72 halamanProperties of Skeletal MuscleAakash GohilBelum ada peringkat

- DHP UM 015 IHP24 HART User ManualDokumen70 halamanDHP UM 015 IHP24 HART User Manualkumar ambujBelum ada peringkat

- Reynaers Product Overview CURTAIN WALLDokumen80 halamanReynaers Product Overview CURTAIN WALLyantoBelum ada peringkat

- OSRAM LEDriving XENARC Headlamp Brochure For Audi A4 B7Dokumen8 halamanOSRAM LEDriving XENARC Headlamp Brochure For Audi A4 B7Fourtitude.comBelum ada peringkat

- Air Blue E-TicketDokumen1 halamanAir Blue E-TicketMuneeb Ahmed100% (3)

- Let's Mingle Chat Invite ExamplesDokumen22 halamanLet's Mingle Chat Invite ExamplesCarmen BalbuenaBelum ada peringkat

- Starting and Configuring Crontab in CygwinDokumen2 halamanStarting and Configuring Crontab in CygwinSamir BenakliBelum ada peringkat

- Tutorial Quartus II Simulation VHDLDokumen27 halamanTutorial Quartus II Simulation VHDLHeitor B. S. BezerraBelum ada peringkat

- Ternary Phase Diagram Guided Question 1 PDFDokumen1 halamanTernary Phase Diagram Guided Question 1 PDFLuci FernBelum ada peringkat

- Tuomo Summanen Michael Pollitt: Case Study: British Telecom: Searching For A Winning StrategyDokumen34 halamanTuomo Summanen Michael Pollitt: Case Study: British Telecom: Searching For A Winning StrategyRanganath ChowdaryBelum ada peringkat

- Philips 170v7fbDokumen95 halamanPhilips 170v7fbaposticaaBelum ada peringkat

- Mathematics 10 Performance Task 1Dokumen2 halamanMathematics 10 Performance Task 1SnowBelum ada peringkat

- Physics Chapter 2 Original TestDokumen6 halamanPhysics Chapter 2 Original TestJanina OrmitaBelum ada peringkat

- mf8240 160824142620 PDFDokumen698 halamanmf8240 160824142620 PDFArgopartsBelum ada peringkat

- The Reference Frame - Nice Try But I Am Now 99% Confident That Atiyah's Proof of RH Is Wrong, HopelessDokumen5 halamanThe Reference Frame - Nice Try But I Am Now 99% Confident That Atiyah's Proof of RH Is Wrong, Hopelesssurjit4123Belum ada peringkat

- PreviewpdfDokumen50 halamanPreviewpdfMarcosGouvea100% (1)