9952T 1311 F0001 PD2 A C

Diunggah oleh

Barbara Howell0 penilaian0% menganggap dokumen ini bermanfaat (0 suara)

226 tayangan169 halamanJudul Asli

9952T-1311-F0001-PD2-A-C

Hak Cipta

© Attribution Non-Commercial (BY-NC)

Format Tersedia

PDF, TXT atau baca online dari Scribd

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Attribution Non-Commercial (BY-NC)

Format Tersedia

Unduh sebagai PDF, TXT atau baca online dari Scribd

0 penilaian0% menganggap dokumen ini bermanfaat (0 suara)

226 tayangan169 halaman9952T 1311 F0001 PD2 A C

Diunggah oleh

Barbara HowellHak Cipta:

Attribution Non-Commercial (BY-NC)

Format Tersedia

Unduh sebagai PDF, TXT atau baca online dari Scribd

Anda di halaman 1dari 169

ALGIERS REFINERY

REHABILITATION AND ADAPTATION PROJECT

Preliminary Dossier

Vendor Doc Reference : 9952T-1311-F0001-PD2 Revision : A

Requisition Reference : 9952T-000-MR-1311-0102 Purchase Order : 9952T-000-PO-1311-0102-00-0127

A 25/10/13 Issue for Approval RAJA KARTHIK GAUTHAM

Rev Date

DD/MMM/YY

STATUS WRITTEN BY

(name & visa)

CHECKED BY

(name & visa)

APPROVED BY

(name & visa)

DOCUMENT REVISIONS

Sections changed in last revision are identified by a vertical line in the margin

Preliminary Dossier

ALL TAGS

See comments

Section 4/5/6

Material Dept RL

11/12/2013

1) Specify the name of the equipment in the cover page

2) Create a Bookmarks following the ARH preliminary dossier summary PP 0210 rev1 P14/43.

3) Section 4 - Document Code E0004; Check Comments of Mr. Amrani and insert the description

statement corrected according to his comment and approved by Technip (Code 3)

4) Section 5 - Document Code A1003; Insert the design calculation approved by Technip (Code 3).

5) Section 6 - Document Code A2001; Insert the drawing approved by Technip (Code 3)

6) Section 7 - Document Code B1304; Insert the welding procedure approved by Technip (Code 3).

7) Section 8 - Document Code B1201; The heat Treatment is missing, To be provided. (If it is not

applicable then specify it)

8) Section 9 - Document Code E0005; The certificate does not specify that the country of origin is

India.

9) Section 10 - Document Code B1002; Insert the ITP approved by Technip (Code 3)

10) Section 11 - Document Code; The inspection procedure is missing, to be provided.

Leila

Merhfour

2013.12.1

6 15:00:57

+01'00'

SECTION - 1

SECTION - 2

SECTION - 3

SECTION - 4

ALGIERS REFINERY

REHABILITATION AND ADAPTATION PROJECT

Description Statement

Vendor Reference: 9952T-1311-E0004-DS2 Revision : A

Requisition Reference: 9952T-000-MR-1311-0102 Purchase Order : 9952T-000-PO-1311-0102-00-0127

A 09/10/13 Issue for Approval RAJA KARTHIK GAUTHAM

Rev Date

DD/MMM/YY

STATUS WRITTEN BY

(name & visa)

CHECKED BY

(name & visa)

APPROVED BY

(name & visa)

DOCUMENT REVISIONS

Sections changed in last revision are identified by a vertical line in the margin

Description Statement

ALL TAGS

SEE COMMENTS

Etat descriptif de l'quipement

Rfrence de l'quipement

Dsignation de lquipement: 'VCGC8L4DJF1L4FLDL00

Nom et adresse du fabricant: AUDCO INDIA LIMITED, Chennai, Tamil Nadu

Anne de construction: 2013

N de srie: As per annexure

N de plan: As per annexure

Code de construction: BS 1868 -ASME B16.34

Lieu de fabrication: India

Caractristiques techniques de l'quipement:

Type: Valve

Dnomination de l'appareil: Swing Check valve, Flanged Ends

Fluide vhicul: Hydrocarbures, vapeur, autres

Pression de Calcul: 48 bar

Pression max. de service: 48 bar

Pression dpreuve: 72 bar

Temprature de calcul: 46 to +427C

Temprature max. de service: 427C

Temprature d'essai: 46 C

Matriaux utiliss: ASTM A352 Gr. LCB

Epaisseur: As per annexure

Charge limite de rupture: 450 Mpa

Limite minimale d'lasticit: 240 Mpa

Contrainte admissible: 128.3 Mpa

Coefficient de joint: N.A.

Radiographie: As per annexure

Traitement thermique: N.A

Sur-paisseur de corrosion: N.A

Essais non destructifs: ASME B16.34

Diamtre interne: As per annexure

AMBIENT

Annexure to the Description Statement:

Commodity Code: VCGC8L4DJF1L4FLDL00

Size

(inch)

Ident Code Class Qty

Inside Dia

(mm)

Wall thickness

(mm)

Serial

No.

Drawing No.

Radiography

(%)

Calculation Note

06 CKZGACY 300 2 153 16 * 30004603-27 10%

VCGC8L4DJF1L4FLDL00/

CKZGACY

* - Serial number will be allotted at the time of Inspection

Etat descriptif de l'quipement

Rfrence de l'quipement

Dsignation de lquipement: VGAJ3L4DJF1L2KZ7DR00

Nom et adresse du fabricant: AUDCO INDIA LIMITED, Chennai, Tamil Nadu

Anne de construction: 2013

N de srie: As per annexure

N de plan: As per annexure

Code de construction: API 600-ASME B16.34

Lieu de fabrication: India

Caractristiques techniques de l'quipement:

Type: Valve

Dnomination de l'appareil: Gate valve, Flanged Ends

Fluide vhicul: Hydrocarbures, vapeur, autres

Pression de Calcul: 18.4 bar

Pression max. de service: 18.4 bar

Pression dpreuve: 28 bar

Temprature de calcul: 46 to +427C

Temprature max. de service: 427C

Temprature d'essai: 46 C

Matriaux utiliss: ASTM A352 Gr. LCB

Epaisseur: As per annexure

Charge limite de rupture: 450 Mpa

Limite minimale d'lasticit: 250 Mpa

Contrainte admissible: 128.3 Mpa

Coefficient de joint: N.A.

Radiographie: As per annexure

Traitement thermique: N.A

Sur-paisseur de corrosion: N.A

Essais non destructifs: ASME B16.34

Diamtre interne: As per annexure

AMBIENT

Annexure to the Description Statement:

Commodity Code: VGAJ3L4DJF1L2KZ7DR00

Size

(inch)

Ident Code Class Qty

Inside Dia

(mm)

Wall thickness

(mm)

Serial

No.

Drawing No.

Radiography

(%)

Calculation Note

04

CVH2P1X

150 2 102 13.5 * 30004716-04 10%

VGAJ3L4DJF1L2KZ7DR00/

CVH2P1X

08

CVH2P20 150 2 203 15.0 * 30004716-05 10%

VGAJ3L4DJF1L2KZ7DR00/

CVH2P20

* - Serial number will be allotted at the time of Inspection

Etat descriptif de l'quipement

Rfrence de l'quipement

Dsignation de lquipement: VGAJ3L4DJF1L4KZ7DR00

Nom et adresse du fabricant: AUDCO INDIA LIMITED, Chennai, Tamil Nadu

Anne de construction: 2013

N de srie: As per annexure

N de plan: As per annexure

Code de construction: API 600-ASME B16.34

Lieu de fabrication: India

Caractristiques techniques de l'quipement:

Type: Valve

Dnomination de l'appareil: Gate valve, Flanged Ends

Fluide vhicul: Hydrocarbures, vapeur, autres

Pression de Calcul: 48 bar

Pression max. de service: 48 bar

Pression dpreuve: 72 bar

Temprature de calcul: 46 to +427C

Temprature max. de service: 427C

Temprature d'essai: 46 C

Matriaux utiliss: ASTM A352 Gr. LCB

Epaisseur: As per annexure

Charge limite de rupture: 450 Mpa

Limite minimale d'lasticit: 240 Mpa

Contrainte admissible: 128.3 Mpa

Coefficient de joint: N.A.

Radiographie: As per annexure

Traitement thermique: N.A

Sur-paisseur de corrosion: N.A

Essais non destructifs: ASME B16.34

Diamtre interne: As per annexure

AMBIENT

Annexure to the Description Statement:

Commodity Code: VGAJ3L4DJF1L4KZ7DR00

Size

(inch)

Ident Code Class Qty

Inside Dia

(mm)

Wall thickness

(mm)

Serial

No.

Drawing No.

Radiography

(%)

Calculation Note

06

CVFGEVY

300 6 152 18.5 * 30004716-06 10%

VGAJ3L4DJF1L4KZ7DR00/

CVFGEVY

* - Serial number will be allotted at the time of Inspection

SECTION - 5

ALGIERS REFINERY

REHABILITATION AND ADAPTATION PROJECT

Design Calculation (First Submisison Draft For All Items)

Vendor Reference: 9952T-1311-A1003-DC2 Revision : A

Requisition Reference: 9952T-000-MR-1311-0102 Purchase Order : 9952T-000-PO-1311-0102-00-0127

A 26/08/13 Issue for Approval KARTHIK KARTHIK KARTHIK

Rev Date

DD/MMM/YY

STATUS WRITTEN BY

(name & visa)

CHECKED BY

(name & visa)

APPROVED BY

(name & visa)

DOCUMENT REVISIONS

Sections changed in last revision are identified by a vertical line in the margin

Design Calculation (First Submisison Draft For All Items)

ALL TAGS

TO A DIFFERENT NAME FOR

EACH CASE

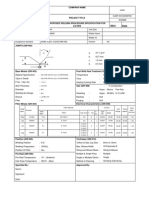

REF. : WT_CH

REVISION : 0

SHEET : 1 OF 1

SWING CHECK

CKZGACY/VCGC8L4DJF1L4FLDL00

6"

300

L&T VALVES LIMITED

Customer M/S TECHNIP FRANCE

ALGIERS REFINERY PROJECT

ASTM A352 Gr.LCB

Psi 35000

Psi 65000

Db Bore Diameter mm 153.0

CA Corrosion Allowance Required mm 0.0

tmin Min. Body Thickness mm 9.7

tact Actual Wall Thickness mm 16.0

Is tact>=tmin+C2)

Dic Neck Inner Diameter mm 181.0

Doc Neck Outer Diameter mm 213.0

t1min Min.Body Neck Thick mm 10.5

t1act Actual Body Neck Thick mm 16.0

Is t1act>=t1min+C2)

Pc Pressure Class Lbs 300

Bolting Material - ASTM A320 Gr.L7

St Tensile strength Psi 125000

Ds Sealing Diameter mm 221

Sa Allowable Bolt Stress at 100

o

F = min(St/5;20000) Psi 20000

Ag

Area bounded by the effective outside periphery of a gasket or O-ring

(p/4 * Ds

2

)

mm

2

38256

Bolts Dimension UNC 3/4"

N No of Bolts Nos. 10

Ar Bolt Tensile stress Area

mm

2

215

Ab Total Effective Bolt Tensile Stress Area (Ar * N)

mm

2

2155

P

c

* A

g

/A

b

5326

0.45 * Sa 9000

P

c

* A

g

/A

b

<=0.45 * S

a

<=9000 OK

PREPARED : MASWOOD AHMED APPROVED : RAMADAS

THUS THE DESIGN IS SATISFACTORY

BODY:

OK

OK

BOLTED BONNET OR COVER JOINTS - (ASME B16.34)

THE ACTUAL WALL THICKNESS IS GREATER THAN THE MINIMUM REQUIREMENT

Project

Body Material

Yield Strength, Sy

Tensile Strength, St

WALL THICKNESS VERIFICATION - (ASME B16.34)

WALL THICKNESS AS PER TABLE-3B

SHELL WALL THICKNESS & COVER JOINT VERIFICATION

Valve Type

Tag No.

Valve Size

Class, Pc

Manufacturer

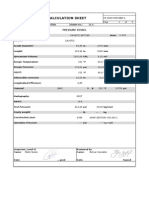

REF. : WT_GT

REVISION : 0

SHEET : 1 OF 1

GATE - Extended Bonnet

VGAJ3L4DJF1L2KZ7DR00/CVH2P1X

4"

150

L&T VALVES LIMITED

Customer M/S TECHNIP FRANCE

ALGIERS REFINERY PROJECT

ASTM A352 Gr.LCB

Psi 35000

Psi 65000

Db Bore Diameter mm 101.6

CA Corrosion Allowance Required mm 0.0

tmin Min. Body Thickness mm 6.6

tact Actual Wall Thickness mm 13.5

Is tact>=tmin+CA)

Dic Neck Inner Diameter mm 142.7

Doc Neck Outer Diameter mm 169.7

t1min Min.Body Neck Thick mm 7.1

t1act Actual Body Neck Thick mm 13.5

Is t1act>=t1min+CA)

Ds Neck Inner Diameter mm 38.6

Dse Neck Outer Diameter mm 53.8

CA Corrosion Allowance Required mm 0.0

t2min Min.Body Neck Thick mm 4.8

t2act Actual Body Neck Thick mm 7.6

Is t2act>=t2min+CA)

Pc Pressure Class Lbs 150

Bolting Material - ASTM A320 Gr.L7

St Tensile strength Psi 125000

Ds Sealing Diameter mm 177

Sa Allowable Bolt Stress at 100

o

F = min(St/5;20000) Psi 20000

Ag

Area bounded by the effective outside periphery of a gasket or O-ring

(p/4 * Ds

2

)

mm

2

24564

Bolts Dimension UNC 1/2"

N No of Bolts Nos. 10

Ar Bolt Tensile stress Area

mm

2

92

Ab Total Effective Bolt Tensile Stress Area (Ar * N)

mm

2

915

P

c

* A

g

/A

b

4025

0.45 * Sa 9000

P

c

* A

g

/A

b

<=0.45 * S

a

<=9000 OK

PREPARED : MASWOOD AHMED APPROVED : RAMADAS

SHELL WALL THICKNESS & COVER JOINT VERIFICATION

Valve Type

Tag No.

Valve Size

Class, Pc

Manufacturer

Project

Body Material

Yield Strength, Sy

Tensile Strength, St

WALL THICKNESS VERIFICATION - (ASME B16.34)

WALL THICKNESS AS PER TABLE-3B

THE ACTUAL WALL THICKNESS IS GREATER THAN THE MINIMUM REQUIREMENT

THUS THE DESIGN IS SATISFACTORY

BODY:

OK

OK

BONNET:

OK

BOLTED BONNET OR COVER JOINTS - (AS PER ASME B16.34 -CLAUSE 6.4.1.1)

REF. : WT_GT

REVISION : 0

SHEET : 1 OF 1

GATE - Extended Bonnet

VGAJ3L4DJF1L2KZ7DR00/CVH2P20

8"

150

L&T VALVES LIMITED

Customer M/S TECHNIP FRANCE

ALGIERS REFINERY PROJECT

ASTM A352 Gr.LCB

Psi 35000

Psi 65000

Db Bore Diameter mm 203.2

CA Corrosion Allowance Required mm 0.0

tmin Min. Body Thickness mm 8.1

tact Actual Wall Thickness mm 15.0

Is tact>=tmin+CA)

Dic Neck Inner Diameter mm 257.0

Doc Neck Outer Diameter mm 287.0

t1min Min.Body Neck Thick mm 8.9

t1act Actual Body Neck Thick mm 15.0

Is t1act>=t1min+CA)

Ds Neck Inner Diameter mm 48.2

Dse Neck Outer Diameter mm 68.1

CA Corrosion Allowance Required mm 0.0

t2min Min.Body Neck Thick mm 5.3

t2act Actual Body Neck Thick mm 10.0

Is t2act>=t2min+CA)

Pc Pressure Class Lbs 150

Bolting Material - ASTM A320 Gr.L7

St Tensile strength Psi 125000

Ds Sealing Diameter mm 260

Sa Allowable Bolt Stress at 100

o

F = min(St/5;20000) Psi 20000

Ag

Area bounded by the effective outside periphery of a gasket or O-ring

(p/4 * Ds

2

)

mm

2

52913

Bolts Dimension UNC 5/8"

N No of Bolts Nos. 12

Ar Bolt Tensile stress Area

mm

2

146

Ab Total Effective Bolt Tensile Stress Area (Ar * N)

mm

2

1750

P

c

* A

g

/A

b

4536

0.45 * Sa 9000

P

c

* A

g

/A

b

<=0.45 * S

a

<=9000 OK

PREPARED : MASWOOD AHMED APPROVED : RAMADAS

SHELL WALL THICKNESS & COVER JOINT VERIFICATION

Valve Type

Tag No.

Valve Size

Class, Pc

Manufacturer

Project

Body Material

Yield Strength, Sy

Tensile Strength, St

WALL THICKNESS VERIFICATION - (ASME B16.34)

WALL THICKNESS AS PER TABLE-3B

THE ACTUAL WALL THICKNESS IS GREATER THAN THE MINIMUM REQUIREMENT

THUS THE DESIGN IS SATISFACTORY

BODY:

OK

OK

BONNET:

OK

BOLTED BONNET OR COVER JOINTS - (AS PER ASME B16.34 -CLAUSE 6.4.1.1)

REF. : WT_GT

REVISION : 0

SHEET : 1 OF 1

GATE - Extended Bonnet

VGAJ3L4DJF1L4KZ7DR00/CVFGEVY

6"

300

L&T VALVES LIMITED

Customer M/S TECHNIP FRANCE

ALGIERS REFINERY PROJECT

ASTM A352 Gr.LCB

Psi 35000

Psi 65000

Db Bore Diameter mm 152.4

CA Corrosion Allowance Required mm 0.0

tmin Min. Body Thickness mm 9.7

tact Actual Wall Thickness mm 18.5

Is tact>=tmin+CA)

Dic Neck Inner Diameter mm 203.2

Doc Neck Outer Diameter mm 240.3

t1min Min.Body Neck Thick mm 11.2

t1act Actual Body Neck Thick mm 18.5

Is t1act>=t1min+CA)

Ds Neck Inner Diameter mm 48.2

Dse Neck Outer Diameter mm 70.1

CA Corrosion Allowance Required mm 0.0

t2min Min.Body Neck Thick mm 6.1

t2act Actual Body Neck Thick mm 11.0

Is t2act>=t2min+CA)

Pc Pressure Class Lbs 300

Bolting Material - ASTM A320 Gr.L7

St Tensile strength Psi 125000

Ds Sealing Diameter mm 230

Sa Allowable Bolt Stress at 100

o

F = min(St/5;20000) Psi 20000

Ag

Area bounded by the effective outside periphery of a gasket or O-ring

(p/4 * Ds

2

)

mm

2

41620

Bolts Dimension UNC 3/4"

N No of Bolts Nos. 12

Ar Bolt Tensile stress Area

mm

2

215

Ab Total Effective Bolt Tensile Stress Area (Ar * N)

mm

2

2586

P

c

* A

g

/A

b

4829

0.45 * Sa 9000

P

c

* A

g

/A

b

<=0.45 * S

a

<=9000 OK

PREPARED : MASWOOD AHMED APPROVED : RAMADAS

SHELL WALL THICKNESS & COVER JOINT VERIFICATION

Valve Type

Tag No.

Valve Size

Class, Pc

Manufacturer

Project

Body Material

Yield Strength, Sy

Tensile Strength, St

WALL THICKNESS VERIFICATION - (ASME B16.34)

WALL THICKNESS AS PER TABLE-3B

THE ACTUAL WALL THICKNESS IS GREATER THAN THE MINIMUM REQUIREMENT

THUS THE DESIGN IS SATISFACTORY

BODY:

OK

OK

BONNET:

OK

BOLTED BONNET OR COVER JOINTS - (AS PER ASME B16.34 -CLAUSE 6.4.1.1)

SECTION - 6

ALGIERS REFINERY

REHABILITATION AND ADAPTATION PROJECT

GENERAL ASSEMBLY DRAWING (GAD)

Vendor Doc Reference : 9952T-1311-A110-GAD2 Revision : A

Requisition Reference : 9952T-000-SR-1311-0102 Purchase Order : 9952T-000-PO-1311-0102-00-0127

A 26/08/13 Issue for Approval KARTHIK KARTHIK KARTHIK

Rev Date

DD/MMM/YY

STATUS WRITTEN BY

(name & visa)

CHECKED BY

(name & visa)

APPROVED BY

(name & visa)

DOCUMENT REVISIONS

Sections changed in last revision are identified by a vertical line in the margin

GENERAL ASSEMBLY DRAWING (GAD)

ALL TAGS

TO A DIFFERENT NAME FOR

EACH CASE

FLOW DIRECTION

SECTION - 7

ALGIERS REFINERY

REHABILITATION AND ADAPTATION PROJECT

WPS / PQR

Vendor Reference: 9952T-1311-B1304-WPS Revision : A

Requisition Reference: 9952T-000-MR-1311-0102 Purchase Order : 9952T-000-PO-1311-0102-00-0127

B 21/06/12 Issue for Approval KARTHIK KARTHIK KARTHIK

A 23/05/12 Issue for Approval KARTHIK KARTHIK KARTHIK

Rev Date

DD/MMM/YY

STATUS WRITTEN BY

(name & visa)

CHECKED BY

(name & visa)

APPROVED BY

(name & visa)

DOCUMENT REVISIONS

Sections changed in last revision are identified by a vertical line in the margin

PP 1 - ANG - rev. 2

WELDING PROCEDURE SPECIFICATION (WPS)

PROCEDURE QUALIFICATION RECORD (PQR)

ALL TAGS

B

Docref:9952T1311B1304WPS

S.No TechnipComment L&T'sReply

1

MissingWPS/WPQRforhardfacingofseats/wedgesofSS

(STL6onausteniticstainlesssteelgrade316L)

Included

2

Maximumthroatthicknessforweldingseatringstovalve

body(sketchinpage27inthedocument).

Throatthicknessforweldingseatringstovalvebodyvaries

withsizeandclassratingofthevalve.Howeverdepthof

weldingshallbefor5060%oftheseatringthickness

3

Forweldsonthebody(bonnetextension),WPSinthe

documentisshowingabackingringusedforwelding,

specifymaterialandwhetherthisringisremovedafter

welding

WPSforbonnetextensionenclosedwhichwasmissed

earlier.Regardingbackingmaterial,asmentionedinthe

page1oftheWPS,Backingmaterialissameasthatofthe

basematerialanditisatemporarybacking,backing

materialshallberemovedafterwelding

CommentReplySheet

Globevalves

Gatevalves Globevalves

WPSPQRforTechnipAlgiersLTCSValvesRev1submittalDate:18.06.2012

Valvesinvolvedinthisproject

Samplesketches

Gatevalves

TypesofWeldinginvolvedinthebelowmentionedvalvetypes

Seal Welding of Body Ring Insitu Hardfacing on body

Stellite / 13% Cr Deposition on Seat Ring & Disc Stellite Deposition on Disc

Sl.No WPS.No PQRNo. BaseMaterial Process FillerMaterial Remarks/Application Typeofweldinginvolved

1 WPS/AIL/525R1DT27.01.2011 PQR/AIL/525R1DT27.01.2011

ASTMA352

GrLCB

SMAW E70181

Fabrication/minorrepair

welidng

Partialpenertationweld(Non

pressurecontainingweld)

2

WPS/AIL/813REV0DT

25.11.2010

PQR/AIL/813REV0

DT25.11.2010

ASTMA352

GrLCB

FCAW E71T1 Bodyseatringwelding

partialpenetrationgroove

weld(Nonpressurecontaining

weld)

3

WPS/AIL/814REV0DT

25.11.2010

PQR/AIL/814REV0DT

25.11.2010

ASTMA352

GrLCB

GMAW ER309L Bodyseatringwelding

partialpenetrationgroove

weld(Nonpressurecontaining

weld)

4

WPS./AIL/452REV0DT

28.06.2010

PQR/AIL/452REV0DT

28.06.2010

ASTMA352

GrLCB

PTAW ERCoCrA

HardfaceoverlayonSeat

ring(Stellite6)

Hardfacingoverlay

5

WPS./AIL/453REV0DT

28.06.2010

PQR/AIL/453REV0DT

28.06.2010

ASTMA352

GrLCB

PTAW ERCoCrA

Hardfaceoverlayonseat

Ring(Stellite6)

Hardfacingoverlay

6

WPS/AIL/701REV0DT

20.10.2010

PQR/AIL/701REV0DT

20.10.2010

ASTMA352

GrLCB

GTAW ERCoCrA

Hardfaceoverlayinsituon

Bodyoronseatring(Stellite

6)

Hardfacingoverlay

7

WPS/AIL/702REV0DT

20.10.2010

PQR/AIL/702REV0DT

20.10.2010

ASTMA352

GrLCB

GTAW ERCoCrA

Hardfaceoverlayinsituon

Bodyoronseatring(Stellite

6)

Hardfacingoverlay

8

WPS/AIL/766REV0DT

10.12.2011

PQR/AIL/766REV0DT

10.12.2011

ASTMA352

GrLCBtoASTMA333

Gr.6

GTAW ER70S2 Extensionbonnetwelding Fullpenetrationweld

9

WPS./AIL/454REV1DT

17.09.2010

PQR/AIL/454REV1DT

17.09.2010

ASTM A351

Gr. CG8M

PTAW ERCoCrA

HardfaceoverlayonSeat

ring(Stellite6)

Trimdeposition(Nonpressure

containingweld)

10

WPS./AIL/455REV1DT

17.09.2010

PQR/AIL/455REV1DT

17.09.2010

ASTM A351

Gr. CG8M

PTAW ERCoCrA

Hardfaceoverlayonseat

Ring(Stellite6)

Trimdeposition(Nonpressure

containingweld)

11 WPS/AIL/717R0DT28.12.2010 PQR/AIL/717R0DT28.12.2010

ASTM A351

Gr. CG8M

GTAW ERCoCrA

Hardfaceoverlayinsituon

Bodyoronseatring(Stellite

6)

Trimdeposition(Nonpressure

containingweld)

12 WPS/AIL/718R0DT28.12.2010 PQR/AIL/718R0DT28.12.2010

ASTM A351

Gr. CG8M

GTAW ERCoCrA

Hardfaceoverlayinsituon

Bodyoronseatring(Stellite

6)

Trimdeposition(Nonpressure

containingweld)

Weldconfigurations

A WS

A

WSAlL

1

CW

1

1

S C

C C 8

WS n WSAlL

AlL WS C8 8

8 8M

AuuCC lnulA L

S 8 W M

C

M

L 8

A 8

LlMl1Lu

WS C8 u

8 S k

SS 8 n 8

u

A WS

A

1

CW

1

1

S C

C C 8

WS n WSAlL

AlL WS C8 8

8 8M

AuuCC lnulA L

C

L 8Lv u1

A 8

LlMl1Lu

WS C8 u

8 S k

SS 8 n 8

u

SCPLMA1lC ulAC8AM

C P S

WS n WSAlL

A WS

8 8M

AuuCC lnulA L

wP5 lOk 8OuY 1O

u

8

8

1 n

1 n

NC1L WLLDING IN A SINGLL

Cl 8Cu? Anu SLA18lnC WLLulnC

S n

L 8

A 8

LlMl1Lu

WS C8 u

O 541 klN6 wLulN6

8

8

L ASS IS kCnI8I1LD

8 S k

SS 8 n 8

u

25.11.2010

Heat No.: M3354, refer TC encl.

Heat No.: M3354, refer TC Encl.

SECTION - 9

SECTION - 10

ALGIERS REFINERY

REHABILITATION AND ADAPTATION PROJECT

INSPECTION AND TEST PLAN

Vendor Reference: 9952T1311-B1002-ITP Revision : C

Requisition Reference: 9952T-000-MR-1311-0102 Purchase Order : 9952T-000-PO-1311-0102-00-0127

C 19/09/12 Issue for Approval RAJA KARTHIK GAUTHAM

B 23/06/12 Issue for Approval RAJA KARTHIK GAUTHAM

A 26/04/12 Issue for Approval RAJA KARTHIK GAUTHAM

Rev Date

DD/MMM/YY

STATUS WRITTEN BY

(name & visa)

CHECKED BY

(name & visa)

APPROVED BY

(name & visa)

DOCUMENT REVISIONS

Sections changed in last revision are identified by a vertical line in the margin

INSPECTION AND TEST PLAN

ALL TAGS

Date

10.09.2012

Vendor AIL Technip ARH Remarks

1.0

Chemical Chemical Analysis All heats Material Specification

Material

Specification

P-100% R R - -

Heat Treatment Performance All heats & Castings Material Specification

Material

Specification

P-100% R R - -

Mechanical Test

Tensile,Yield,Elongation,Ha

rdness

All heats Material Specification

Material

Specification

P-100% R R - -

Mechanical Test* Impact test at -45 Deg.C All heats Material Specification

Material

Specification

P-100% R R

Surface examination &

Markings

Visual AIL Sampling Plan P-100% SI - - -

Maganatic particle test-

LTCS

Wet Prod method 100% MPI Report P-100% R R - -

Radiographic test for

Body & Bonnet

X-Ray /Gamma ray

20% Of Po line

Item for General

service/50% of Po

line item for

Hydrogen service

RT reports P-100% R R - -

Chemical Chemical Analysis All heats Material Specification

Material

Specification

P-100% R R - -

Heat Treatment Performance All heats & Castings Material Specification

Material

Specification

P-100% R R - -

Mechanical Mechanical Test All heats Material Specification

Material

Specification

P-100% R R - -

Surface examination &

Markings

Visual AIL Sampling Plan P-100% SI - - -

Chemical Chemical Analysis All heats Material Specification

Material

Specification

P-100% R R - -

Heat Treatment Performance All heats/lots Material Specification

Material

Specification

P-100% R R - -

Mechanical Mechanical Test All heats Material Specification

Material

Specification

P-100% R R - -

Surface examination Visual AIL Sampling Plan AIL Drawing AIL Drawing P-100% SI - - -

1.4 Bar-Bonnet Bush

Chemical Chemical Analysis

Material

Specification

Material Specification

Material

Specification

Vendor TC or

Lab Report

P-100% R R - -

2.0

Chemical Chemical Analysis

Material

Specification

Material Specification

Material

Specification

P-100% R R - -

Surface examination &

Markings

Visual AIL Sampling Plan AIL Drawing AIL Drawing P-100% SI - - -

BOF ITEMS:

2.1 Fastener (for Body-

Bonnet Joint)

Vendor Test

Certificate

1.2 Casting: Disc

Vendor Test

Certificate

MSS-SP-55 /AIL Drawings

1.3 Forging:

Disc,Stem, Seat Ring

& Hinge pin cover

Vendor TC or

Lab Report

RAW MATERIAL:

1.1 Casting: Body,

Bonnet/Cover

Vendor Test

Certificate

MSS-SP-55 /AIL Drawings

NDE-002 / MSS SP 53

NDE-001 / ASME B16.34

Reference

Document

Acceptance

Norm

Format of

Record

Scope of Inspection

AIL SALE ORDER NO. 30004186

Cus. Order No.: - 9952T-000-PO-1311-0102-0127 Amdt.00 Dt. 21.03.2012

Prepared by:J.BALACHANDRAN

Customer: - TECHNIP FRANCE Approved By: M.VIJAYARANGAN

Sl No

Component &

Operation

Characteristics Method of Check

Quantum of

Check by AIL

AUDCO INDIA LIMITED

INSPECTION TEST PLAN QAP No: 3-4186/GGC/001 Rev: 2

CHENNAI-INDIA

CAST LOW TEMPERATURE CARBON STEEL GATE, GLOBE &

CHECK VALVES

Project : Algiers Refinery Project

Date

10.09.2012

Vendor AIL Technip ARH Remarks

Reference

Document

Acceptance

Norm

Format of

Record

Scope of Inspection

AIL SALE ORDER NO. 30004186

Cus. Order No.: - 9952T-000-PO-1311-0102-0127 Amdt.00 Dt. 21.03.2012

Prepared by:J.BALACHANDRAN

Customer: - TECHNIP FRANCE Approved By: M.VIJAYARANGAN

Sl No

Component &

Operation

Characteristics Method of Check

Quantum of

Check by AIL

AUDCO INDIA LIMITED

INSPECTION TEST PLAN QAP No: 3-4186/GGC/001 Rev: 2

CHENNAI-INDIA

CAST LOW TEMPERATURE CARBON STEEL GATE, GLOBE &

CHECK VALVES

Project : Algiers Refinery Project

2.2 Gasket & Packing

Chemical,Surface

examination &

Dimension Inspection

Review of TC/CC,Visual &

measurement

AIL Sampling Plan

Matl Spec/ AIL

Drawing

Matl Spec/ AIL

Drawing

Vendor TC or CC P-100% SI - - -

3.0

3.1 Machined

Components

Body,Bonnet,Cover,

Stem,Ring,Bush

Surface examination &

Dimension Inspection

Visual & Measurement AIL Sampling Plan AIL Drawing AIL Drawing CSCN - SI - - -

3.2 WPS / PQR Records

qualification

Procedure Qualification ASME IX /Customer spec.

100% for all

grades/types

WPS/PQR Weld

records

- P-100% R - -

3.3 Seatring & Disc

Surface Defect DP (On hardfaced surface) 100% DP Report - P-100% R - -

3.4 POST WELD HEAT

TREATMENT

Hardness

Review of HT

records/Measurements

100%

Hardness

report/ SR

charts

- P-100% RR - -

4.0

Shell Test Hydro

Backseat Test # Hydro

Seat Test Hydro

Seat Test # Air

Functional test

Full Open/Full Close of

valves

Helium Leak Test for H2

service valves ( Shell

Test @25% of allowable

working pressure)

Helium ( Detector Probe

Method)

One valve Per

type/Rating/Size

AIL Report -

W- One

valve Per

type/Rating/

Size

W- One valve

Per

type/Rating/Si

ze

- -

Final Inspection

Visual, Dimension, TC

Verification, Spl Reqmnts &

Markings as per sale order

100%

Stores Credit

Note

- P-100% W-10% - -

4.2 Painting & Packing

Surface examination &

DFT Inspection

Visual & Measurement 100%

Painting &

Packing Report

- P-100% R - -

4.3 Final Documents &

Inspection Release

certificate

Review of Finished Valve

Documents

Review of final documents 100% Packing List - P-100% H - -

1) Hydrogen service castings must be complied with NACE MR0103.

2) Certification as per EN 10204 3.1 for Body/Bonnet/Cover ,EN 10204 2.2 for trim components. *-Impact test to be witnessed by M/s Lloyd/BVIS/DNV/TUV

# For Gate & Globe Valve Only ,W- Witness , R-review , H-Hold,P-Performed ,RR-Random review

Abbreviations: TPI - Third Party Inspection, R - Review, GRN - Goods Receipt Note, TC - Test Certificate, DP -Dye penetrant test

CC - Compliance Certificate, PO - Purchase Order,CSCN - Component stores credit note,NDE - Non Destructive examination.

SI- Sampling Inspection as per ANSI / ASQC Z1.4-1993 Level-II Tightened inspection of AQL 4.0

As per project Spec. /AIL Procedures

As per project spec./ Customer order

NOTES:

P-100%

W-10% Per Po

line Item

Size 4" &

Above - W-

10% Per

PO Line

Item

-

AIL procedure /ASME SEC.V Subsection A

(Article10)

AIL GA Drawing / ASME B16.5/ASME

B16.47

AIL Proc: NDE-003/ASME Sec V/Sec VIII

Div.1 APX.8

As per Customer Spec/ASME Sec. IX

FINAL INSPECTION:

4.1 Valve Assembly

100% AIL Proc:QTS-001/Approved Procedure Test Record -

IN-PROCESS:

As per Customer Spec/ASME Sec. IX

SECTION - 11

Anda mungkin juga menyukai

- Pressure Vessel Inspection ReportDokumen34 halamanPressure Vessel Inspection ReportJinlong SuBelum ada peringkat

- Pressure Vessel Inspection ReportDokumen34 halamanPressure Vessel Inspection ReportJinlong SuBelum ada peringkat

- Pressure Vessel Inspection ReportDokumen34 halamanPressure Vessel Inspection ReportJinlong SuBelum ada peringkat

- Pressure Vessel Inspection ReportDokumen34 halamanPressure Vessel Inspection ReportJinlong SuBelum ada peringkat

- Pressure Vessel Inspection ReportDokumen34 halamanPressure Vessel Inspection ReportJinlong SuBelum ada peringkat

- Pressure Vessel Inspection ReportDokumen34 halamanPressure Vessel Inspection ReportJinlong SuBelum ada peringkat

- Pressure Vessel Inspection ReportDokumen34 halamanPressure Vessel Inspection ReportJinlong SuBelum ada peringkat

- Pressure Vessel Inspection ReportDokumen34 halamanPressure Vessel Inspection ReportJinlong SuBelum ada peringkat

- Pressure Vessel Inspection ReportDokumen34 halamanPressure Vessel Inspection ReportJinlong SuBelum ada peringkat

- Pressure Vessel Inspection ReportDokumen34 halamanPressure Vessel Inspection ReportJinlong SuBelum ada peringkat

- PQR 014 (Qualified Sa 106 GR BDokumen5 halamanPQR 014 (Qualified Sa 106 GR Bersenthil100% (1)

- Pressure Vessel Inspection ReportDokumen33 halamanPressure Vessel Inspection ReportJinlong SuBelum ada peringkat

- Pressure Vessel Inspection ReportDokumen34 halamanPressure Vessel Inspection ReportJinlong SuBelum ada peringkat

- Pressure Vessel Inspection ReportDokumen34 halamanPressure Vessel Inspection ReportJinlong SuBelum ada peringkat

- Pressure Vessel Inspection ReportDokumen34 halamanPressure Vessel Inspection ReportJinlong SuBelum ada peringkat

- Pressure Vessel Inspection ReportDokumen34 halamanPressure Vessel Inspection ReportJinlong SuBelum ada peringkat

- Pressure Vessel Inspection ReportDokumen34 halamanPressure Vessel Inspection ReportJinlong SuBelum ada peringkat

- Pressure Vessel Inspection ReportDokumen33 halamanPressure Vessel Inspection ReportJinlong SuBelum ada peringkat

- Pressure Vessel Inspection ReportDokumen34 halamanPressure Vessel Inspection ReportJinlong SuBelum ada peringkat

- Pressure Vessel Inspection ReportDokumen34 halamanPressure Vessel Inspection ReportJinlong SuBelum ada peringkat

- Pressure Vessel Inspection ReportDokumen33 halamanPressure Vessel Inspection ReportJinlong SuBelum ada peringkat

- Pressure Vessel Inspection ReportDokumen33 halamanPressure Vessel Inspection ReportJinlong SuBelum ada peringkat

- Pressure Vessel Inspection ReportDokumen34 halamanPressure Vessel Inspection ReportJinlong SuBelum ada peringkat

- Pressure Vessel Inspection ReportDokumen34 halamanPressure Vessel Inspection ReportJinlong SuBelum ada peringkat

- Pressure Vessel Inspection ReportDokumen34 halamanPressure Vessel Inspection ReportJinlong SuBelum ada peringkat

- Pressure Vessel Inspection ReportDokumen33 halamanPressure Vessel Inspection ReportJinlong SuBelum ada peringkat

- Pressure Vessel Inspection ReportDokumen33 halamanPressure Vessel Inspection ReportJinlong SuBelum ada peringkat

- Pressure Vessel Inspection ReportDokumen33 halamanPressure Vessel Inspection ReportJinlong SuBelum ada peringkat

- API Tube Thickness Calculation1Dokumen5 halamanAPI Tube Thickness Calculation1pandiangvBelum ada peringkat

- Pt. Bahana Karya Mandiri: Data SheetDokumen8 halamanPt. Bahana Karya Mandiri: Data SheetBowo Edhi WibowoBelum ada peringkat

- Pressure Vessel Inspection ReportDokumen34 halamanPressure Vessel Inspection ReportJinlong SuBelum ada peringkat

- Pressure Vessel Inspection ReportDokumen34 halamanPressure Vessel Inspection ReportJinlong SuBelum ada peringkat

- Above Ground Piping Wall Thickness CalculationsDokumen7 halamanAbove Ground Piping Wall Thickness Calculationslutfi awn100% (1)

- Reaction Tank Design For WWTPDokumen9 halamanReaction Tank Design For WWTPDavid LambertBelum ada peringkat

- Data Sheet Fuel Gas Filter Rev 0Dokumen22 halamanData Sheet Fuel Gas Filter Rev 0Bowo Edhi WibowoBelum ada peringkat

- Datasheet Phe OnwjDokumen1 halamanDatasheet Phe OnwjMamank Ira Sudrajat100% (1)

- DC S3-1301 REV.0 OriginalDokumen93 halamanDC S3-1301 REV.0 OriginalPeja JusohBelum ada peringkat

- Calculation Sheet: Pressure VesselDokumen8 halamanCalculation Sheet: Pressure Vesselbgonzalez1981Belum ada peringkat

- Nozzle Calculation - Primary Reformer Stack-R0Dokumen22 halamanNozzle Calculation - Primary Reformer Stack-R0Aditya Jain100% (1)

- Ibr CalculationsDokumen9 halamanIbr Calculationsaroonchelikani67% (3)

- Vessel Design CalculationDokumen54 halamanVessel Design CalculationPohn Myint Han50% (2)

- Ip060-45!20!02 Orifice Plate Assembly (Buyer's Scope)Dokumen5 halamanIp060-45!20!02 Orifice Plate Assembly (Buyer's Scope)Rahul DevaBelum ada peringkat

- Internal CoilDokumen2 halamanInternal CoilwhngomjBelum ada peringkat

- NCR - SampleDokumen7 halamanNCR - SamplecamycaxBelum ada peringkat

- Nozzle Calculation - Auxiliary Boiler Stack-R0Dokumen13 halamanNozzle Calculation - Auxiliary Boiler Stack-R0Aditya JainBelum ada peringkat

- Appendix 2) : Optional Type Flange (Fig. 2-4 (8) )Dokumen18 halamanAppendix 2) : Optional Type Flange (Fig. 2-4 (8) )hardik5818Belum ada peringkat

- Pressure Vessel Inspection ReportDokumen34 halamanPressure Vessel Inspection ReportJinlong SuBelum ada peringkat

- PV Elite 2013 SP3 Licensee: ISGEC TubeSheet CalcDokumen8 halamanPV Elite 2013 SP3 Licensee: ISGEC TubeSheet CalcMayank MittalBelum ada peringkat

- B 84567 SB Mm2 DSR ST 60 0020 - 1 - Aoc - GTG Fuel Gas Filter CoalescerDokumen11 halamanB 84567 SB Mm2 DSR ST 60 0020 - 1 - Aoc - GTG Fuel Gas Filter CoalescerpragatheeskBelum ada peringkat

- STV SW Project Level Gauge DatasheetDokumen4 halamanSTV SW Project Level Gauge Datasheetnguyenquoc1988Belum ada peringkat

- Secondary superheater stress calculation documentDokumen45 halamanSecondary superheater stress calculation documentbrintopvBelum ada peringkat

- LCP709 TK 003Dokumen41 halamanLCP709 TK 003hgag selimBelum ada peringkat

- WPS FormatDokumen1 halamanWPS FormatAbdullah AnsariBelum ada peringkat

- Informe Inspección V324 REV1Dokumen9 halamanInforme Inspección V324 REV1bgonzalez1981Belum ada peringkat

- Pressure Vessel Inspection ReportDokumen34 halamanPressure Vessel Inspection ReportJinlong SuBelum ada peringkat

- ASME VIII-1 Calculations for Sample Pressure VesselDokumen21 halamanASME VIII-1 Calculations for Sample Pressure VesselTrishul Nath Pallay100% (1)

- All-in-One Manual of Industrial Piping Practice and MaintenanceDari EverandAll-in-One Manual of Industrial Piping Practice and MaintenancePenilaian: 5 dari 5 bintang5/5 (1)

- 3 Human Resource ManagementDokumen10 halaman3 Human Resource ManagementRonaldBelum ada peringkat

- Erasmo WongDokumen3 halamanErasmo WongGabriel GutierrezBelum ada peringkat

- Earth / Ground Test (Version 1) : Za'immul Na'imDokumen4 halamanEarth / Ground Test (Version 1) : Za'immul Na'imMd Rodi BidinBelum ada peringkat

- Difference Between Offer and Invitation To TreatDokumen5 halamanDifference Between Offer and Invitation To TreatBrian Okuku Owinoh100% (2)

- 21 B 53679 Cdae 251 D 88 AeDokumen2 halaman21 B 53679 Cdae 251 D 88 Aeapi-439429931Belum ada peringkat

- 2021.10.06 Boq Facade Civil Works at b10 - 20211129Dokumen24 halaman2021.10.06 Boq Facade Civil Works at b10 - 20211129Irul HimawanBelum ada peringkat

- Ashish Dixit ResumeDokumen2 halamanAshish Dixit Resume9463455354Belum ada peringkat

- Leader in Water Purification Systems RougingDokumen16 halamanLeader in Water Purification Systems RougingtomcanBelum ada peringkat

- Respharma Company BrochureDokumen7 halamanRespharma Company BrochureHiteshi Parekh100% (1)

- Occurrence of Black Soldier Fly HermetiaDokumen2 halamanOccurrence of Black Soldier Fly HermetiaMarcelo Geraldo TeixeiraBelum ada peringkat

- Quickspecs: HP Proliant Dl980 Generation 7 (G7)Dokumen46 halamanQuickspecs: HP Proliant Dl980 Generation 7 (G7)nadiaBelum ada peringkat

- University of BelizeDokumen6 halamanUniversity of BelizeMartin and JennyBelum ada peringkat

- Manual D00125190 1 PDFDokumen114 halamanManual D00125190 1 PDFnimish_845588906Belum ada peringkat

- Disaster Risk Reduction and LivelihoodsDokumen178 halamanDisaster Risk Reduction and LivelihoodsFeinstein International Center100% (1)

- Forces and Motion Chapter ExplainedDokumen11 halamanForces and Motion Chapter ExplainedMaridjan WiwahaBelum ada peringkat

- IAS Physics SB1 Practs CP1 Student SheetDokumen3 halamanIAS Physics SB1 Practs CP1 Student Sheethussain azizBelum ada peringkat

- Torts - Damages by UribeDokumen4 halamanTorts - Damages by UribeJolas BrutasBelum ada peringkat

- Mipspro™ Assembly Language Programmer'S Guide: Document Number 007-2418-001Dokumen129 halamanMipspro™ Assembly Language Programmer'S Guide: Document Number 007-2418-001mr_silencioBelum ada peringkat

- Tybms Sem 5 CCPRDokumen45 halamanTybms Sem 5 CCPROswin DsouzaBelum ada peringkat

- Eaton: Medium Duty Piston PumpDokumen25 halamanEaton: Medium Duty Piston PumprazvanBelum ada peringkat

- 131b0314 - Im Danffos VLT ManualDokumen108 halaman131b0314 - Im Danffos VLT ManualMery Helen Barraza DelgadoBelum ada peringkat

- Berklee Blues Progression in SongwritingDokumen4 halamanBerklee Blues Progression in SongwritingTC Ahmet Ayhan Altunoğlu100% (1)

- Mid-Term Test RemedialDokumen2 halamanMid-Term Test RemedialgaliihputrobachtiarzenBelum ada peringkat

- Manual LubDokumen25 halamanManual LubMota Guine InformaçõesBelum ada peringkat

- Geo 2230 MJ 02Dokumen8 halamanGeo 2230 MJ 02Jason 402Belum ada peringkat

- Book Shop Automation SystemDokumen36 halamanBook Shop Automation SystemThe Tech ExpertBelum ada peringkat

- Data Sheet Sylomer SR 28 ENDokumen4 halamanData Sheet Sylomer SR 28 ENlpczyfansBelum ada peringkat

- Inflammability and Health Risks of Lubricant Oil 5W30 SNDokumen9 halamanInflammability and Health Risks of Lubricant Oil 5W30 SNPerformance Lubricants, C.A.Belum ada peringkat

- Lec4 WWW Cs Sjtu Edu CNDokumen134 halamanLec4 WWW Cs Sjtu Edu CNAUSTIN ALTONBelum ada peringkat

- Appraising and Managing PerformanceDokumen20 halamanAppraising and Managing PerformanceAnushkar ChauhanBelum ada peringkat