Calc

Diunggah oleh

ZoebairHak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Calc

Diunggah oleh

ZoebairHak Cipta:

Format Tersedia

PUMP AND LINE CALCULATION SHEET

Fluid Properties:

Fluid Type =

Temperature (C) =

Density (kg/m) =

Viscosity (mPas) =

Suction Side (s)

Line size DN (mm)

65

1306

0.9

40

=[13s]-[14s]

[1s] Velocity

[2s] Friction loss

[3s] Line length

[4s] Line loss

[5s] Head losses

(Ki)

entrance

1.0

elbows

0.4

valves

0.2

equipment

exit

other

[7s] Total Ki

1.5

[8s] Other losses

[9s] Total losses

[10s] Static liquid head

[10s*] Static pressure head

[11s] Equipment pressure

[12s] Total

[13s] Suction pressure

[14s] Vapour pressure

[15s] NPSHA

[15s]/g*1*103

[16s] NPSHA liquid head

u=flow/(dens*area)

f (Genereaux)

L

fL = [2s]*[3s]

=[5s]*u/2*10-3

Sum Ki

=[4s]+[8s]+[9s]

z

gz

=[10s*]+[11s]

=[12s]-[9s]

Ian Cameron, April 2000

Norm. Flow (kg/s) =

Max Flow (kg/s) =

Hydrocarbon

2.78

3.34

(1.2*Norm)

Name: Ian Cameron

Sheet:1

Date: 25/04/00

Project: Hydrocarbon Processing System

of

centipoise

I.D. (mm) =

Discharge side (d)

Line size DN (mm)

40.94

Normal

1.6

1.0

3.4

3.5

Max

1.9

1.5

1.7

0.6

0.3

0.0

0.0

0.0

2.6

2.5

0.9

0.4

0.0

0.0

0.0

3.7

4.9

6.1

1.5

19.2

100.0

119.2

113.1

0.1

113.0

8.7

19.2

100.0

119.2

110.5

8.8

8.6

110.4

Units

m/s

kPa/m

m

kPa

kPa

kPa

kPa

m

kPa

kPa

kPa

kPa

kPa

kPa

[1d] Velocity

[2d] Friction loss

[3d] Line length

[4d] Line loss

[5d] Head losses

=[5d]*u/2*10-3

entrance

elbows

valves

equipment

exit

Sum Ki

[6d] Total Ki

[7d] Control valve loss

[8d] Other losses

=[4d]+[6d]+[7d]+[8d] [9d] Total losses

z

[10d] Static liquid head

gz

[10d*] Static pressure head

[11d] Equipment pressure

=[10d*]+[11d]

[12d] Total

=[12d]+[9d]

[13d] Discharge pressure

=[13d]-[13s]

[14d] Differential pressure

[14d*] Differential head

=m.dP/e.rho

Pump shaft power

=[6d]/[9d]

Control valve % of total loss

201811419.xls.ms_office

40

I.D. (mm) =

Normal

1.6

1.0

44.5

46.3

40.94

Max

Units

1.9

m/s

1.5

kPa/m

m

64.8

kPa

(Ki)

0.0

2.1

0.5

0.0

0.0

2.6

0.0

3.6

0.9

0.0

0.0

4.5

140.0

85.0

275.8

6.5

83.3

200.0

283.3

559.0

446.0

34.8

1.4

50.8

0.0

5.2

1.3

0.0

0.0

6.4

201.6

122.4

395.2

83.3

200.0

283.3

678.5

567.9

44.3

1.7

kPa

kPa

kPa

kPa

m

kPa

kPa

kPa

kPa

kPa

m

kW

%

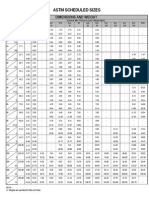

Pipeline Data - Diameters and Wall Thicknesses (mm) ANSI B36.10

Carbon Steel Pipe

Pipe Schedule

DN (mm)

15

20

25

40

50

80

100

125

150

200

250

300

400

500

600

700

800

900

O.D. (mm)

21.3

26.7

33.4

48.3

60.3

88.9

114.3

141.3

168.3

219.1

273.1

323.9

406.4

508

610

711

813

914

40

Stainless Steel Pipe

Pipe Schedule

80

160

5S

10S

40S

80S

wall

I.D.

wall

I.D.

wall

I.D.

wall

I.D.

wall

I.D.

wall

I.D.

2.77

2.87

3.38

3.68

3.91

5.49

6.02

6.55

7.11

8.18

9.27

9.53

9.53

9.53

9.53

9.53

9.53

9.53

15.76

20.96

26.64

40.94

52.48

77.92

102.26

128.2

154.08

202.74

254.56

304.84

387.34

488.94

590.94

691.94

793.94

894.94

3.73

3.91

4.55

5.08

5.54

7.62

8.56

9.53

10.97

12.7

12.7

12.7

12.7

12.7

12.7

12.7

12.7

12.7

13.84

18.88

24.3

38.14

49.22

73.66

97.18

122.24

146.36

193.7

247.7

298.5

381

482.6

584.6

685.6

787.6

888.6

4.78

5.56

6.35

7.14

8.74

11.13

13.49

15.88

18.26

23.01

28.58

33.32

40.49

50.01

59.54

11.74

15.58

20.7

34.02

42.82

66.64

87.32

109.54

131.78

173.08

215.94

257.26

325.42

407.98

490.92

1.65

1.65

1.65

1.65

1.65

2.11

2.11

2.77

2.77

2.77

3.4

3.96

4.19

4.78

5.54

18.0

23.4

30.1

45.0

57.0

84.7

110.1

135.8

162.8

213.6

266.3

316.0

398.0

498.4

598.9

2.11

2.11

2.77

2.77

2.77

3.05

3.05

3.4

3.4

3.76

4.19

4.57

4.78

5.54

6.35

17.1

22.5

27.9

42.8

54.8

82.8

108.2

134.5

161.5

211.6

264.7

314.8

396.8

496.9

597.3

2.77

2.87

3.38

3.68

3.91

5.49

6.02

6.55

7.11

8.18

9.27

9.52

15.76

20.96

26.64

40.94

52.48

77.92

102.26

128.2

154.08

202.74

254.56

304.86

wall

3.73

3.91

4.55

5.08

5.54

7.62

8.56

9.52

10.97

12.7

12.7

12.7

I.D.

13.84

18.88

24.3

38.14

49.22

73.66

97.18

122.3

146.4

193.7

247.7

298.5

Head Loss Data for Valves and Fittings

(Hydraulic Institute, 1961; Perry 4th Edn Table 5-19)

Equivalent number of velocity heads, Ki (u2/2g)

Pipeline fittings

Flanged 45 deg regular elbow

Flanged 45 deg long elbow

Flanged 90 deg regular elbow

Flanged 90 deg long elbow

Flanged 180 deg regular bend

Flanged 180 deg long bend

Pipe inlet

Square edged inlet

Bell shaped inlet

Flanged Tee - through flow

Flanged Tee - branch flow

Gate valve - open

Gate valve - 3/4 open

Gate valve - 1/2 open

Gate valve - 1/4 open

Globe valve - open

Globe valve - 1/2 open

Diaphragm valve - open

Diaphragm valve - 3/4 open

Diaphragm valve - 1/2 open

Diaphragm valve - 1/4 open

Angle valve -open

Butterfly valve - 5 deg

Butterfly valve - 10 deg

Butterfly valve - 20 deg

Butterfly valve - 40 deg

Butterfly valve - 60 deg

Check valve - swing

Strainer - basket

Average

0.35

0.20

0.35

0.25

0.35

0.25

1.00

0.50

0.05

0.16

0.70

0.17

0.90

4.50

24.00

6.40

9.50

2.30

2.60

4.30

21.00

3.00

0.24

0.52

1.54

10.80

118.00

2.00

1.20

Anda mungkin juga menyukai

- D6251D6251MDokumen16 halamanD6251D6251MUriel OlivaresBelum ada peringkat

- Axial Generator Calculator - English VersionDokumen55 halamanAxial Generator Calculator - English VersionMihai ApostoliuBelum ada peringkat

- Horizontal Cylindrical Tank Volume and Level CalculatorDokumen5 halamanHorizontal Cylindrical Tank Volume and Level CalculatorWaleed EmaraBelum ada peringkat

- All-in-One Manual of Industrial Piping Practice and MaintenanceDari EverandAll-in-One Manual of Industrial Piping Practice and MaintenancePenilaian: 5 dari 5 bintang5/5 (1)

- Industrial Plates and Pipes DimensionsDokumen19 halamanIndustrial Plates and Pipes DimensionsGanesh AdityaBelum ada peringkat

- Calculation Sheet For Make - Up Water Tank: #Value!Dokumen4 halamanCalculation Sheet For Make - Up Water Tank: #Value!thanh_79Belum ada peringkat

- ASTM PIPE SCHEDULE SIZES AND WEIGHTSDokumen1 halamanASTM PIPE SCHEDULE SIZES AND WEIGHTSVikasShelkeBelum ada peringkat

- Thk. S.F. K.R.: Dish - Dish 2100Dokumen3 halamanThk. S.F. K.R.: Dish - Dish 2100jayvant jadhavarBelum ada peringkat

- Volume Calculation For Pressure VesselDokumen2 halamanVolume Calculation For Pressure VesselVikas NaikBelum ada peringkat

- Dish EndDokumen5 halamanDish EndalexnomitaBelum ada peringkat

- Copia de Unit Converter Ver1Dokumen15 halamanCopia de Unit Converter Ver1Brian TuckerBelum ada peringkat

- Pipe Dimensions Chart with Nominal Sizes and SchedulesDokumen2 halamanPipe Dimensions Chart with Nominal Sizes and SchedulesAtul JainBelum ada peringkat

- Desuperheater Boiler Feed Water RequirementDokumen2 halamanDesuperheater Boiler Feed Water RequirementMichael HaiseBelum ada peringkat

- Calculator - U Tubes - HSA & QtyDokumen4 halamanCalculator - U Tubes - HSA & QtyRey Fiedacan100% (1)

- Pipe Size CalculationDokumen5 halamanPipe Size CalculationChristoberBelum ada peringkat

- Flange & FittingsDokumen30 halamanFlange & FittingsThiruThirunavukkarasuBelum ada peringkat

- Blank Calc Template - Steel Tools1Dokumen656 halamanBlank Calc Template - Steel Tools1magdy.kamel6528Belum ada peringkat

- PIPE TABLE WIZARD Input Parameters and Component DimensionsDokumen2 halamanPIPE TABLE WIZARD Input Parameters and Component DimensionsBangto YibsipBelum ada peringkat

- No Item: I/D CR KR SF THKDokumen30 halamanNo Item: I/D CR KR SF THKnil100% (1)

- PSVDokumen3 halamanPSVDhananjay NilkuteBelum ada peringkat

- Type k1 (Re 1) NP (Re 10 5) : Anchor 0.7 LaminarDokumen3 halamanType k1 (Re 1) NP (Re 10 5) : Anchor 0.7 LaminarRobinBelum ada peringkat

- Distillation Column Design (Trial and Error)Dokumen29 halamanDistillation Column Design (Trial and Error)AlexandraBarbeConawayBelum ada peringkat

- Asme Pipe Wall ThicknessDokumen3 halamanAsme Pipe Wall ThicknessYoke ShuBelum ada peringkat

- Calculation of time needed to mix liquids with pitch blade impellersDokumen10 halamanCalculation of time needed to mix liquids with pitch blade impellershadiBelum ada peringkat

- Reactor WeightsDokumen2 halamanReactor WeightsleekiangyenBelum ada peringkat

- Round To SQDokumen2 halamanRound To SQalexnomitaBelum ada peringkat

- Friction Loss in Pipe LineDokumen3 halamanFriction Loss in Pipe LineAvinash VasudeoBelum ada peringkat

- Sewer Pumpstation Design Calculations For AlqiDokumen7 halamanSewer Pumpstation Design Calculations For AlqiTahirJabbarBelum ada peringkat

- 2K Method Excess Head Loss in Pipe FittingsDokumen8 halaman2K Method Excess Head Loss in Pipe Fittingsjxd3261Belum ada peringkat

- Global Marketing For Tube & PipeDokumen4 halamanGlobal Marketing For Tube & PipedsyashankaBelum ada peringkat

- V E00B0003B Size-Range MetricDokumen1 halamanV E00B0003B Size-Range MetricopremapodpritisokBelum ada peringkat

- Structural Equivalency SheetDokumen73 halamanStructural Equivalency Sheetboim1234Belum ada peringkat

- Cone Development CalculationsDokumen5 halamanCone Development CalculationssaudimanBelum ada peringkat

- Linear Mixing CalcDokumen12 halamanLinear Mixing CalcClarence AG YueBelum ada peringkat

- Heater Lowers Methanol Temp from 95C to 40CDokumen30 halamanHeater Lowers Methanol Temp from 95C to 40CHamdan ShdBelum ada peringkat

- Calculation Sheet: FittingDokumen6 halamanCalculation Sheet: FittingYhing YingBelum ada peringkat

- 62577A Calculation of Orifice Coefficient Si UnitsDokumen18 halaman62577A Calculation of Orifice Coefficient Si UnitsUary Buza RegioBelum ada peringkat

- Name: - ClassDokumen4 halamanName: - Classozil_72Belum ada peringkat

- Internal CoilDokumen2 halamanInternal CoilwhngomjBelum ada peringkat

- Unit Conversions Between U.S. Customary System & Metric SystemDokumen1 halamanUnit Conversions Between U.S. Customary System & Metric SystemMario Sajulga Dela CuadraBelum ada peringkat

- PV Elite 2020 Licensee: Tubesheet Check CalculationDokumen8 halamanPV Elite 2020 Licensee: Tubesheet Check CalculationAbhishek LadBelum ada peringkat

- Excel Calculator-Surface Area and VolumeDokumen3 halamanExcel Calculator-Surface Area and VolumeEhsaan MirzaBelum ada peringkat

- Established Flow Condition for Orifice JDokumen1 halamanEstablished Flow Condition for Orifice JQuangThai1988100% (1)

- Pipe SpecificationsDokumen5 halamanPipe Specificationsbabar.muetBelum ada peringkat

- Countercurrent Flow: T1 (F) T2 (F) T3 (F) T4 (F)Dokumen32 halamanCountercurrent Flow: T1 (F) T2 (F) T3 (F) T4 (F)Partho GiriBelum ada peringkat

- Tank Calculator: Cylindrical Tank With Domed RoofDokumen22 halamanTank Calculator: Cylindrical Tank With Domed RoofalexnomitaBelum ada peringkat

- Calculate Surface Area for Cylindrical TankDokumen10 halamanCalculate Surface Area for Cylindrical TanksudjonoBelum ada peringkat

- Heat Exchanger Specification SheetDokumen1 halamanHeat Exchanger Specification SheetGreisly MarrugoBelum ada peringkat

- Transverse Strain: Load (G)Dokumen6 halamanTransverse Strain: Load (G)rajaraji33Belum ada peringkat

- Double FdexchangerDokumen8 halamanDouble FdexchangerBoško IvanovićBelum ada peringkat

- Yanbu: Export Refinery ProjectDokumen8 halamanYanbu: Export Refinery ProjectJanakiraman MalligaBelum ada peringkat

- Pipe SizingDokumen2 halamanPipe Sizinggroup2sd1314Belum ada peringkat

- Xtra Strong (XS) Size Steel Pipe Weights TAble CalculatorDokumen1 halamanXtra Strong (XS) Size Steel Pipe Weights TAble CalculatorshownpuBelum ada peringkat

- Formula of Calculation Weight For S.S Sheet, S.S Circle, SDokumen2 halamanFormula of Calculation Weight For S.S Sheet, S.S Circle, SDonald Toledo100% (1)

- Static Pressure Calc.Dokumen29 halamanStatic Pressure Calc.Allada Trinadh RaoBelum ada peringkat

- Helical Coil - With AgitationDokumen3 halamanHelical Coil - With AgitationUmair FareedBelum ada peringkat

- Mechanical Design SpreadsheetDokumen1 halamanMechanical Design SpreadsheetHoney TiwariBelum ada peringkat

- Cone Layout ToolDokumen1 halamanCone Layout ToolSaravanan ManiBelum ada peringkat

- Flange GapDokumen2 halamanFlange GapRamNathanBelum ada peringkat

- Tuberia Fibra de VidrioDokumen0 halamanTuberia Fibra de VidrioFernando Reyes GomezBelum ada peringkat

- RBL Precision Ansi RollerDokumen8 halamanRBL Precision Ansi RollerRingball_GusBelum ada peringkat

- 90 Series (ET1590) InstructionsDokumen24 halaman90 Series (ET1590) InstructionsZoebairBelum ada peringkat

- International Standard: Hydraulic Turbines, Storage Pumps and Pump-Turbines - Model Acceptance TestsDokumen9 halamanInternational Standard: Hydraulic Turbines, Storage Pumps and Pump-Turbines - Model Acceptance TestsZoebairBelum ada peringkat

- 1 12 (End)Dokumen17 halaman1 12 (End)ZoebairBelum ada peringkat

- ENZX TechDokumen30 halamanENZX TechZoebairBelum ada peringkat

- Spring-Supported Thrust BearingsDokumen4 halamanSpring-Supported Thrust BearingsZoebairBelum ada peringkat

- Installation and Operating Procedures: Manual Grease InterceptorsDokumen8 halamanInstallation and Operating Procedures: Manual Grease InterceptorsZoebairBelum ada peringkat

- Structures and Mechanisms Classifications GuideDokumen1 halamanStructures and Mechanisms Classifications GuideminakirolosBelum ada peringkat

- Appendix B - 20100903 - 145453Dokumen25 halamanAppendix B - 20100903 - 145453AkoKhalediBelum ada peringkat

- TurbinesDokumen19 halamanTurbinesSamarakoon BandaBelum ada peringkat

- Type of ThreadDokumen13 halamanType of ThreadVils ArabadzhievaBelum ada peringkat

- Ratle Enm Reply Tecnical Prebid Points 080212Dokumen42 halamanRatle Enm Reply Tecnical Prebid Points 080212ZoebairBelum ada peringkat

- Quality Conference TTL KUDokumen6 halamanQuality Conference TTL KUZoebairBelum ada peringkat

- CA6NMDokumen2 halamanCA6NMjoene3Belum ada peringkat

- 1 Technical Data Sheets TurbineDokumen7 halaman1 Technical Data Sheets TurbineZoebairBelum ada peringkat

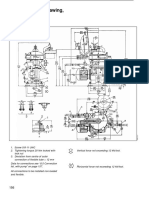

- 8.4 Basic Size Drawing, With Pump: Alfa Laval Ref. 557913 Rev. 0Dokumen1 halaman8.4 Basic Size Drawing, With Pump: Alfa Laval Ref. 557913 Rev. 0ZoebairBelum ada peringkat

- Datasheet TurbineDokumen2 halamanDatasheet TurbineZoebairBelum ada peringkat

- Solutions EngDokumen6 halamanSolutions EngZoebairBelum ada peringkat

- Calculate The Number of Extinguishers Needed in A BuildingDokumen3 halamanCalculate The Number of Extinguishers Needed in A BuildingZoebairBelum ada peringkat

- INDIGENOUS MANUFACTURERS OF SMALL HYDRO TURBINESDokumen6 halamanINDIGENOUS MANUFACTURERS OF SMALL HYDRO TURBINESZoebairBelum ada peringkat

- PJPR0 V 200 Ucturing 0 Data 0 SheetDokumen3 halamanPJPR0 V 200 Ucturing 0 Data 0 SheetZoebairBelum ada peringkat

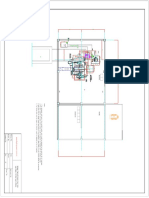

- Scada SystemDokumen1 halamanScada SystemZoebairBelum ada peringkat

- 1 - Layout of H-FrancisDokumen1 halaman1 - Layout of H-FrancisZoebairBelum ada peringkat

- ANDRITZ HYDRO Valves Ensure Lifetime Safety and Reliability in Hydropower PlantsDokumen3 halamanANDRITZ HYDRO Valves Ensure Lifetime Safety and Reliability in Hydropower PlantsZoebairBelum ada peringkat

- Load AcceptanceDokumen2 halamanLoad AcceptanceZoebairBelum ada peringkat

- Construction Specification 71-Water Control Gates: Instructions For UseDokumen2 halamanConstruction Specification 71-Water Control Gates: Instructions For UseZoebairBelum ada peringkat

- CEE 331: Fluid Mechanics, Homework Set 2, SolutionsDokumen7 halamanCEE 331: Fluid Mechanics, Homework Set 2, SolutionsZoebairBelum ada peringkat

- PJPR0 V 200 Ucturing 0 Data 0 SheetDokumen3 halamanPJPR0 V 200 Ucturing 0 Data 0 SheetZoebairBelum ada peringkat

- ANDRITZ HYDRO Valves Ensure Lifetime Safety and Reliability in Hydropower PlantsDokumen3 halamanANDRITZ HYDRO Valves Ensure Lifetime Safety and Reliability in Hydropower PlantsZoebairBelum ada peringkat

- 3DS Net OrthoGen For Intergraph CADWorx Plant ProfessionalDokumen2 halaman3DS Net OrthoGen For Intergraph CADWorx Plant ProfessionalThanadkitBunkaewBelum ada peringkat

- 3 Tables Friction Loss AquacultureDokumen10 halaman3 Tables Friction Loss AquacultureZoebairBelum ada peringkat

- MSDS Mindray M-30 LyseDokumen2 halamanMSDS Mindray M-30 LyseSandra HubayaBelum ada peringkat

- Q1 Science 9 Module 5Dokumen28 halamanQ1 Science 9 Module 5Shiena Lou Tucasan CudadaBelum ada peringkat

- 008x TF-compressed PDFDokumen66 halaman008x TF-compressed PDFJosé Francisco Blanco VillalbaBelum ada peringkat

- Chapter 03 AnnotDokumen4 halamanChapter 03 AnnotNur Amira Mardiana ZulkifliBelum ada peringkat

- Solid, Liquid, Gas Explanation TextDokumen2 halamanSolid, Liquid, Gas Explanation Textnettexts100% (1)

- Astm B495 10 2017Dokumen1 halamanAstm B495 10 2017shokhul lutfiBelum ada peringkat

- Stainless Steel 1.4404 316lDokumen3 halamanStainless Steel 1.4404 316lDilipSinghBelum ada peringkat

- Understanding and Managing Cell Culture Contamination PDFDokumen24 halamanUnderstanding and Managing Cell Culture Contamination PDFPabloski AndreBelum ada peringkat

- Determination of HHV of Diesel FuelDokumen7 halamanDetermination of HHV of Diesel FuelAdrian Soriaga LontocBelum ada peringkat

- ACROLEIN MSDSDokumen6 halamanACROLEIN MSDSzaedmohd50% (2)

- Petromax LanternDokumen9 halamanPetromax LanternbatacurloBelum ada peringkat

- Histamine, Serotonin, and Their Antagonists: Classification and Clinical UseDokumen47 halamanHistamine, Serotonin, and Their Antagonists: Classification and Clinical Usebangkit99Belum ada peringkat

- 1995Dokumen283 halaman1995Robert BataraBelum ada peringkat

- Capillary Viscometer Calculations for Newtonian & Non-Newtonian FluidsDokumen2 halamanCapillary Viscometer Calculations for Newtonian & Non-Newtonian Fluidsgrovestreet1Belum ada peringkat

- Storage ProteinDokumen3 halamanStorage ProteinprincessicyjulietBelum ada peringkat

- Safely Purging Air from Pipelines and VesselsDokumen7 halamanSafely Purging Air from Pipelines and Vesselsgan_raoBelum ada peringkat

- Superlon1 PDFDokumen4 halamanSuperlon1 PDFmohd aliffBelum ada peringkat

- By Sabandi Ismadi WE/ IIW CertifiedDokumen4 halamanBy Sabandi Ismadi WE/ IIW CertifiedStefanus HerriejadyBelum ada peringkat

- Atmospheric Water GeneratorDokumen3 halamanAtmospheric Water GeneratorKhusnil MujibBelum ada peringkat

- GSAP - Shell HelixDokumen16 halamanGSAP - Shell HelixJoseph Rubyanto SudrajadBelum ada peringkat

- Himani Bansal Jayant Negi Ritesh Kumar Uday PratapDokumen7 halamanHimani Bansal Jayant Negi Ritesh Kumar Uday PratapJayant NegiBelum ada peringkat

- Introduction To GFRCDokumen3 halamanIntroduction To GFRCFred VictorBelum ada peringkat

- Lecture 2 - Cellulose Structure PDFDokumen55 halamanLecture 2 - Cellulose Structure PDFpipers10Belum ada peringkat

- Micropitting Can Lead To Macro ProblemsDokumen2 halamanMicropitting Can Lead To Macro ProblemsAnonymous alQXB11EgQBelum ada peringkat

- Venturi TubeDokumen2 halamanVenturi TubeQing JyulyanBelum ada peringkat

- API Standard 614 - Lubrication, Shaft-Sealing, and Control-Oil Systems For Special-Purpose ApplicationDokumen4 halamanAPI Standard 614 - Lubrication, Shaft-Sealing, and Control-Oil Systems For Special-Purpose ApplicationFabioSalaBelum ada peringkat

- Essential Guide to Compressed Air SystemsDokumen35 halamanEssential Guide to Compressed Air SystemsvmramakrishnanBelum ada peringkat

- Parker O-Ring Material Guide-2008Dokumen72 halamanParker O-Ring Material Guide-2008Ian Pillay50% (2)

- HOSTAFORM® C 27021 - POM - Unfilled: DescriptionDokumen5 halamanHOSTAFORM® C 27021 - POM - Unfilled: Descriptionrahul vermaBelum ada peringkat