DS ACC Cooling Element en Us 17070

Diunggah oleh

behnamatgHak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

DS ACC Cooling Element en Us 17070

Diunggah oleh

behnamatgHak Cipta:

Format Tersedia

Diaphragm Seals

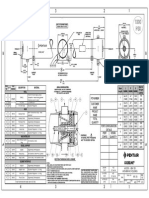

Diaphragm Seal Mounting Options Diaphragm Seal Assembly with Cooling Element

WIKA Datasheet Cooling Element

Applications

Direct mounted system is required High: >212F Process Temperature Low: < -40F Process Temperature

Special Features

Specifically designed heat-sink Works in combination with diaphragm seal Dissipates temperatures up to 300F in normal conditions

Standard Features

Cooling Element Intended to protect the pressure instrument from high or low process temperature. Air flow across heat exchanging fins reduces or increases the temperature of the system fill fluid to protect the pressure measuring instrument. The cooling element is recommended for process temperatures above 212F. It is direct mounted between the pressure instrument and the diaphragm seal. Silicone fill is recommended. Effective temperature reductions of 300F depending upon ambient conditions. All stainless steel construction is back-welded to stainless steel upper housing or flange. Capillary line Stainless steel capillary with stainless steel armor provides a connection between the pressure instrument and the diaphragm seal. It protects the pressure instrument from high or low process temperatures and provides remote reading. The capillary should be selected as short as possible, since changes in ambient temperature conditions may considerably affect the accuracy and response time of the pressure instrument. Standard length is five feet; other lengths 2mm and 0.6mm are available upon request. Installation on mechanical gauges normally requires a gauge support and gauge adaptor or other surface mounting provisions.

WIKA Datasheet Cooling Element 12/2012

Shown with XSEL Process Gauge and M93X.D1 All-Welded System

Diaphragm Seal Assembly with Capillary Line, Gauge Support and Adaptor

Any level difference between pressure instrument and diaphragm seal will cause a pressure indication error. The level difference can be compensated for during calibration of the diaphragm seal assembly if level difference is known. Minor corrections can be made on site by means of an adjustable pointer or zero adjustment of the pressure instrument. Gauge Support and Adaptor Provides wall mounting of pressure instrument by clamping to gauge adaptor. Material: gauge support - aluminum or stainless steel, gauge adaptor - stainless steel.

Page 1 of 4

R

Diaphragm Seal Mounting Option Table

Field No. Code DZZ Description Instrument Mounting To Seal

KZS

Direct assembly

MK0

Cooling element

MK1 ??? ZZ F1 F2

Unarmored stainless steel capillary Armored stainless steel capillary Other - please specify PVC coated, armored stainless steel capillary Capillary Line Length

MK2

5 ft length

Direct Assembly or Cooling Element 10 ft length

F3 ??

F4

15 ft length

20 ft length

Other - please specify " NPT female Connection to Seal

N4 WI 3 ?? A1 F1 E2

N2

Weld-in connection (*offered only for capillary or cooling element mounting to 316 SS seal upper housings) (SS-to-SS only) Other - please specify (SS-to-SS only) KN2 - Silicone oil (50 cSt) KN7 - Glycerine (99.7%) KN8 - Fluorolube FS-5 System Fill Fluid

" NPT female

G1 B1 E1

KN12 - Glycerine/Water (86.5%/13.5%) KN21 - Halocarbon 6.3

KN17 - Low temperature silicone oil (4 cSt)

A2

B2 J2 4 K3 ??

K5

KN32 - High temperature silicone oil KN68 - Silicone oil (10 cSt) KN59 - NEOBEE M20

KN92 - Medicinal white mineral oil KN93 - Food grade silicone oil Other - please specify

ZZZZ ID20 ID10 ID06 SSTW ALMT

Without

Additional Mounting Options

Capillary Internal Diameter 0.079 (standard) Capillary Internal Diameter 0.039 Capillary Internal Diameter 0.024

SSBW 5 SSMT

Tack-weld instrument connection (SS-to-SS only)

Aluminum gauge support with stainless steel adaptor

Back-weld instrument connection (SS-to-SS only)

Stainless steel gauge support with stainless steel adaptor

Mounting Option Table - ___ __ __ __ - ____ ZZZ

Page 2 of 4 WIKA Datasheet Cooling Element 12/2012

4 Cooling Element T X X X weld X weld KEY in. in. in. mm mm mm in. mm A 4.68 119 119 119 119 4.68 4.68 4.68 B 4.05 103 98 3.86 4.05 103 98 3.86 P/N 1600885 1584510 1653512 2081849

4 Cooling Element

Cooling Performance

Gauge Sample

1 2

Transmitter Sample

Food grade fill fluids; for sanitary applications Inert fill fluids; for oxidizing process media applications

WIKA Datasheet Cooling Element 12/2012

Page 3 of 4

Typical Capillary

5 ft

1/4 NPT-F X 1/4 NPT-M 1632540 1030876

10 ft 15 ft

1655752

1030850

1/2 NPT-F X 1/2 NPT-M

50249584

2082152

2080494

Male weld nipple X Male weld nipple

2080141

Gauge Support

KEY in.

A 3.35

B 2.56

C 2.20

D 2.99

F 1.02

G .87

H .55

I 3.94

SS AL

Material

9091882 9091858

P/N

Gauge Adaptor KEY A B C T Y 1 1 1 P/N

2.95 2.35 2.35

1.18 1.18 1.18

1.02 X X

in.

x CPL CONNECTION x CPL CONNECTION

9091416 2084619 50183851

How to Order

Instrument: D/S: Mounting:

Add information

232.34 4.5 200 psi 1/2L DZZZZ-N2-ZZZZ-ZZZ Silicon oil KN2 N/A

Sample:

Reference page* 57-67 229 228

990.FR-A-SM20-1-1B-C2-C2-C2-Z-Z-Z

System fill: *2013 Price List Additional:

Page 4 of 4

WIKA Datasheet Cooling Element 12/2012

R

WIKA Instrument Corporation 1000 Wiegand Boulevard Lawrenceville, GA 30043-5868 Tel: 888-WIKA-USA 770-513-8200 Fax: 770-338-5118 E-Mail: info@wika.com www.wika.com

Anda mungkin juga menyukai

- Salting, Curing and SmokingDokumen36 halamanSalting, Curing and SmokingMonaisa81% (58)

- SARRP Calibration GuideDokumen92 halamanSARRP Calibration Guidemengano perezBelum ada peringkat

- All-in-One Manual of Industrial Piping Practice and MaintenanceDari EverandAll-in-One Manual of Industrial Piping Practice and MaintenancePenilaian: 5 dari 5 bintang5/5 (1)

- WIKA DS TE 60.03 Resistance Thermometer Model TR10-C With Fabricated ThermowellDokumen6 halamanWIKA DS TE 60.03 Resistance Thermometer Model TR10-C With Fabricated ThermowellŽeljko KasunićBelum ada peringkat

- Series 4200: Safety Valves For ASME Code Section I Boiler ApplicationsDokumen16 halamanSeries 4200: Safety Valves For ASME Code Section I Boiler ApplicationsjimycantrellBelum ada peringkat

- SV97Dokumen2 halamanSV97nclogesh_1981Belum ada peringkat

- General Specifications: DFS Diaphragm Seals For Model YA53 Gauge Pressure TransmitterDokumen3 halamanGeneral Specifications: DFS Diaphragm Seals For Model YA53 Gauge Pressure TransmitterJorge GuerreroBelum ada peringkat

- Spirax Sarco BTM-7Dokumen3 halamanSpirax Sarco BTM-7Bambang Agung LaxmonoBelum ada peringkat

- Steam TrapDokumen2 halamanSteam TrapAmpornchai PhupolBelum ada peringkat

- Local Solutions For Individual Customers Worldwide: Accumulators & AccessoriesDokumen20 halamanLocal Solutions For Individual Customers Worldwide: Accumulators & Accessoriesamjed_de_enimBelum ada peringkat

- Diapham Valve PDFDokumen8 halamanDiapham Valve PDFthouche007Belum ada peringkat

- Asco S V7394R5Dokumen16 halamanAsco S V7394R5Jorge Jarpa VBelum ada peringkat

- Swagelok Medium Pressure Fittings Alloy 625Dokumen16 halamanSwagelok Medium Pressure Fittings Alloy 625totcsabBelum ada peringkat

- TD62LM and TD62M Thermodynamic Steam Traps With Replaceable Seats (Screwed /socket Weld)Dokumen2 halamanTD62LM and TD62M Thermodynamic Steam Traps With Replaceable Seats (Screwed /socket Weld)Rupesh DesaiBelum ada peringkat

- Differential Pressure Gauge Model 732.51, Stainless Steel Version, With Diaphragm Element All Welded ConstructionDokumen4 halamanDifferential Pressure Gauge Model 732.51, Stainless Steel Version, With Diaphragm Element All Welded ConstructionClarence AG YueBelum ada peringkat

- Trampa Socket WeldDokumen2 halamanTrampa Socket WeldOscar Nieves ZamoraBelum ada peringkat

- General CatalogueDokumen144 halamanGeneral CataloguePhilipMDMBelum ada peringkat

- OverpressureDokumen2 halamanOverpressureampowersidBelum ada peringkat

- (2012) Complete IELTS Bands 5-6.5 Student's BookDokumen3 halaman(2012) Complete IELTS Bands 5-6.5 Student's BookAhmed Hamdy0% (1)

- Tyco Catalogue NetDokumen34 halamanTyco Catalogue NetAhmad Nasser0% (1)

- As 0201 Gauge Valves and Pressure Gauge Accessories enDokumen36 halamanAs 0201 Gauge Valves and Pressure Gauge Accessories enTomas PinheiroBelum ada peringkat

- DWG REF QTY Number Description Material Shell: Dash Length L IN (MM) P IN (MM) S IN (MM) Approx Weight LB (KG)Dokumen3 halamanDWG REF QTY Number Description Material Shell: Dash Length L IN (MM) P IN (MM) S IN (MM) Approx Weight LB (KG)RamanNegiBelum ada peringkat

- Catálogo FarrisDokumen20 halamanCatálogo FarrissueBelum ada peringkat

- Rosemount 1195 Integral Orifice Primary Element: Product Data SheetDokumen18 halamanRosemount 1195 Integral Orifice Primary Element: Product Data Sheetابزار دقیقBelum ada peringkat

- DCV Spirax PDFDokumen2 halamanDCV Spirax PDFVaitheeswaran PalaniBelum ada peringkat

- SIKA Exhaust Therm 2009Dokumen4 halamanSIKA Exhaust Therm 2009asiantaraBelum ada peringkat

- HDP-Victaulic Estilo 995Dokumen4 halamanHDP-Victaulic Estilo 995hugorubenzBelum ada peringkat

- General Specifications: PI Components Remote Diaphragm Seals For Pressure TransmittersDokumen22 halamanGeneral Specifications: PI Components Remote Diaphragm Seals For Pressure TransmittersSithu ZawBelum ada peringkat

- Ashcroft PI 1259 Duragauge Pressure GaugeDokumen2 halamanAshcroft PI 1259 Duragauge Pressure GaugejplutodBelum ada peringkat

- Codeline, 150 PSI, Drawing - 80S15Dokumen3 halamanCodeline, 150 PSI, Drawing - 80S15RamanNegiBelum ada peringkat

- AE AccessoriesDokumen16 halamanAE AccessoriesmisaelzaBelum ada peringkat

- Api Plan 11Dokumen6 halamanApi Plan 11johnsaballaBelum ada peringkat

- Visilume Standard SightglassDokumen2 halamanVisilume Standard Sightglassgrincheu70Belum ada peringkat

- KVC 01Dokumen35 halamanKVC 01hamidreza_m85Belum ada peringkat

- Watlow AccessoriesDokumen30 halamanWatlow AccessoriesEliasBelum ada peringkat

- RTDDokumen68 halamanRTDMaria DenetBelum ada peringkat

- As 0201 en Gauge Valves and Pressure Gauge AccessoriesDokumen36 halamanAs 0201 en Gauge Valves and Pressure Gauge AccessoriesTache MihaiBelum ada peringkat

- Hoja Tecnica BartonDokumen4 halamanHoja Tecnica BartonjairoBelum ada peringkat

- Autoclave AccessoriesDokumen20 halamanAutoclave Accessoriescmct0819Belum ada peringkat

- Steam TrapsDokumen2 halamanSteam Trapslaxmans20Belum ada peringkat

- V9271 Fivalco 2902eDokumen6 halamanV9271 Fivalco 2902eharenas7Belum ada peringkat

- Pressure Switch CatalogueDokumen0 halamanPressure Switch CatalogueMilosglBelum ada peringkat

- Automatic Valve Gemue DB - 512 - GBDokumen6 halamanAutomatic Valve Gemue DB - 512 - GBTaher Yusuf100% (1)

- DB 650 GBDokumen6 halamanDB 650 GBDenial BasanovicBelum ada peringkat

- APV-LLK-2 Ball Valve BrochureDokumen13 halamanAPV-LLK-2 Ball Valve BrochureHeri SetyantoBelum ada peringkat

- ErmetoDokumen14 halamanErmetoJavier VespaBelum ada peringkat

- FARRIS PSV MODEL 2700 New Cat PDFDokumen20 halamanFARRIS PSV MODEL 2700 New Cat PDFPeter James Castelo0% (1)

- Model"Dc": Dual Chamber Orifice FittingDokumen13 halamanModel"Dc": Dual Chamber Orifice FittingFrankBelum ada peringkat

- Direct Contact Desuperheaters TI-P475-01Dokumen9 halamanDirect Contact Desuperheaters TI-P475-01LucasZanaBelum ada peringkat

- Commercial Gas Water Heaters: Models BTN 120-400 (A)Dokumen4 halamanCommercial Gas Water Heaters: Models BTN 120-400 (A)xukaiauBelum ada peringkat

- DS TM5301 GB 2133Dokumen4 halamanDS TM5301 GB 2133Anonymous 4MwmDaNbBelum ada peringkat

- Catalogo de Presion ReotempDokumen48 halamanCatalogo de Presion Reotempdiuska13Belum ada peringkat

- INSERTION Adapter/Fitting For Analytical Devices: (With Reduction) (Plastic) (Stainless Steel)Dokumen8 halamanINSERTION Adapter/Fitting For Analytical Devices: (With Reduction) (Plastic) (Stainless Steel)Manjit SinghBelum ada peringkat

- Ti 2 516 UsDokumen2 halamanTi 2 516 Uswill_streetBelum ada peringkat

- Drawing 80H30Dokumen3 halamanDrawing 80H30kpranjal15Belum ada peringkat

- SONDA cONDUTIVÍMETRO PDFDokumen8 halamanSONDA cONDUTIVÍMETRO PDFAngeloBelum ada peringkat

- Siba Back UpDokumen48 halamanSiba Back Upadicto001Belum ada peringkat

- Bourdon Tube Pressure Gauges Solid-Front Test Gauge - Direct Drive Type 332.34DDDokumen2 halamanBourdon Tube Pressure Gauges Solid-Front Test Gauge - Direct Drive Type 332.34DDbehnamatgBelum ada peringkat

- Asco Series 327 High Flow Direct Acting CatalogDokumen2 halamanAsco Series 327 High Flow Direct Acting CatalogErnestoBelum ada peringkat

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitDari EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitBelum ada peringkat

- Metal Valves & Pipe Fittings World Summary: Market Values & Financials by CountryDari EverandMetal Valves & Pipe Fittings World Summary: Market Values & Financials by CountryBelum ada peringkat

- PR 00076 enDokumen36 halamanPR 00076 eneddie0042Belum ada peringkat

- OI 2003325 SwitchContacts F 24583Dokumen68 halamanOI 2003325 SwitchContacts F 24583behnamatgBelum ada peringkat

- OI 7x GasThermometer en PT 25431Dokumen40 halamanOI 7x GasThermometer en PT 25431behnamatgBelum ada peringkat

- Pressure Transmitter For High Pressure Applications Up To 15,000 Bar Type HP-2Dokumen3 halamanPressure Transmitter For High Pressure Applications Up To 15,000 Bar Type HP-2behnamatgBelum ada peringkat

- OI 2003325 SwitchContacts F 24583Dokumen68 halamanOI 2003325 SwitchContacts F 24583behnamatgBelum ada peringkat

- High-Performance Submersible Pressure Transmitter For Level Measurement Model LH-20Dokumen6 halamanHigh-Performance Submersible Pressure Transmitter For Level Measurement Model LH-20behnamatgBelum ada peringkat

- Bourdon Tube Caisson Pressure Gauges Room Pressure Gauge Model 232.01, Stainless Steel VersionDokumen2 halamanBourdon Tube Caisson Pressure Gauges Room Pressure Gauge Model 232.01, Stainless Steel VersionbehnamatgBelum ada peringkat

- Special Purpose Thin-Film OEM-Pressure Transducer Type TTF-1Dokumen2 halamanSpecial Purpose Thin-Film OEM-Pressure Transducer Type TTF-1behnamatgBelum ada peringkat

- Sanitary Pressure Transmitter Type SA-11: Special FeaturesDokumen4 halamanSanitary Pressure Transmitter Type SA-11: Special FeaturesbehnamatgBelum ada peringkat

- DS PELevelguard en Us 17083Dokumen2 halamanDS PELevelguard en Us 17083behnamatgBelum ada peringkat

- Unitrans Universal Pressure Transmitters Type Ut-10, Ut-11: ApplicationsDokumen4 halamanUnitrans Universal Pressure Transmitters Type Ut-10, Ut-11: ApplicationsbehnamatgBelum ada peringkat

- Bourdon Tube Pressure Gauges Hinged Ring Test Gauge - Brass Wetted Parts Type 312.25Dokumen2 halamanBourdon Tube Pressure Gauges Hinged Ring Test Gauge - Brass Wetted Parts Type 312.25behnamatgBelum ada peringkat

- Ds Uhp Wuc 1x en Us 20710Dokumen10 halamanDs Uhp Wuc 1x en Us 20710behnamatgBelum ada peringkat

- Worldwide: Diwitherm Digital RTDDokumen4 halamanWorldwide: Diwitherm Digital RTDbehnamatgBelum ada peringkat

- DS PE A 10 Product Profile en Us 52381Dokumen2 halamanDS PE A 10 Product Profile en Us 52381behnamatgBelum ada peringkat

- Worldwide: RTD For Heating, Ventilation and Air-ConditioningDokumen4 halamanWorldwide: RTD For Heating, Ventilation and Air-ConditioningbehnamatgBelum ada peringkat

- Bourdon Tube Pressure Gauges: Cast Aluminum Black Enameled Finish Ni-Span C / Stainless Steel Parts Pressure GaugesDokumen2 halamanBourdon Tube Pressure Gauges: Cast Aluminum Black Enameled Finish Ni-Span C / Stainless Steel Parts Pressure GaugesbehnamatgBelum ada peringkat

- DS UHPHydra Sensor en Us 17011Dokumen4 halamanDS UHPHydra Sensor en Us 17011behnamatgBelum ada peringkat

- Bourdon Tube Pressure Gauges Solid-Front Test Gauge - Direct Drive Type 332.34DDDokumen2 halamanBourdon Tube Pressure Gauges Solid-Front Test Gauge - Direct Drive Type 332.34DDbehnamatgBelum ada peringkat

- Bourdon Tube Pressure Gauge Model 332.34 LM-All Stainless Steel Wetted PartsDokumen2 halamanBourdon Tube Pressure Gauge Model 332.34 LM-All Stainless Steel Wetted PartsbehnamatgBelum ada peringkat

- Bourdon Tube Pressure Gauges Test Gauge With 0.25% Accuracy Type 312.20Dokumen2 halamanBourdon Tube Pressure Gauges Test Gauge With 0.25% Accuracy Type 312.20behnamatgBelum ada peringkat

- DS HP W T 300 6 Differential en Us 17183Dokumen3 halamanDS HP W T 300 6 Differential en Us 17183behnamatgBelum ada peringkat

- Pressure Indicator Gauge Series 300 2.75" Dial: Applications Special FeaturesDokumen2 halamanPressure Indicator Gauge Series 300 2.75" Dial: Applications Special FeaturesbehnamatgBelum ada peringkat

- 7132249A.01 Analyzer System Manual V1.0 (Kiln Inlet)Dokumen26 halaman7132249A.01 Analyzer System Manual V1.0 (Kiln Inlet)MinhThang SusumiBelum ada peringkat

- Astm G7 - G7M - 13Dokumen7 halamanAstm G7 - G7M - 13Sofia YuliBelum ada peringkat

- Service Rig DAS ManualDokumen76 halamanService Rig DAS Manualytd7524Belum ada peringkat

- Engineering Metrology and MeasurementDokumen27 halamanEngineering Metrology and MeasurementRandøm Talkìês100% (2)

- EC Service ManualDokumen56 halamanEC Service ManualnascalesBelum ada peringkat

- Manual 99MAH046B3 - enDokumen68 halamanManual 99MAH046B3 - enOkara666Belum ada peringkat

- Home WH7016C ThermostatDokumen8 halamanHome WH7016C ThermostatAntonio Carlos ZimmermannBelum ada peringkat

- 320, 320L Medicion de Presiones Bomba Hidraulica PDFDokumen181 halaman320, 320L Medicion de Presiones Bomba Hidraulica PDFrprim100% (2)

- WTW Tetra Con 925 - CE-GolderDokumen8 halamanWTW Tetra Con 925 - CE-GolderAlexander Alza ZamudioBelum ada peringkat

- Calibration Certificate Conductivity-कनवर्ट की हुईDokumen1 halamanCalibration Certificate Conductivity-कनवर्ट की हुईSatpal SharmaBelum ada peringkat

- Doc10-16 BHHRL Qual ManDokumen28 halamanDoc10-16 BHHRL Qual Manghadeer shaikhnaBelum ada peringkat

- ElectricalDokumen20 halamanElectricalmohanBelum ada peringkat

- 77 9005Dokumen27 halaman77 9005Sandro Muniz100% (1)

- Topcon X20 Monitor Instructions 2013Dokumen35 halamanTopcon X20 Monitor Instructions 2013Chan TkfcBelum ada peringkat

- What Is SAP PMDokumen47 halamanWhat Is SAP PMPrakash Sawant100% (1)

- Final - Schedule M IIIDokumen23 halamanFinal - Schedule M IIIdnalokeshBelum ada peringkat

- Dead WeightDokumen7 halamanDead WeightAmmar Al-AghbariBelum ada peringkat

- Weight Box (1 MG To 200g)Dokumen1 halamanWeight Box (1 MG To 200g)Amit KumarBelum ada peringkat

- 001.03 - UFP Cards, Configuration & ReplacementDokumen54 halaman001.03 - UFP Cards, Configuration & ReplacementAnas AhmedBelum ada peringkat

- Chapter 18 Quality ControlDokumen6 halamanChapter 18 Quality ControlEly0% (1)

- MELFA Smart Plus User 'S Manual: Mitsubishi Electric Industrial RobotDokumen148 halamanMELFA Smart Plus User 'S Manual: Mitsubishi Electric Industrial RobottmanBelum ada peringkat

- IS 15882-2009 Ballasts For Discharge LampsDokumen17 halamanIS 15882-2009 Ballasts For Discharge Lampsjagadees_eiBelum ada peringkat

- Larson Davis CAL200 Manual: AppendixDokumen15 halamanLarson Davis CAL200 Manual: AppendixINSTRUMENTACION INGENIEROSBelum ada peringkat

- Sertifikat Kalibrasi InfantometerDokumen2 halamanSertifikat Kalibrasi InfantometerYus MayaBelum ada peringkat

- ABL 800 ReferansemanualDokumen206 halamanABL 800 ReferansemanualYan PetrovBelum ada peringkat

- Manual AquaLab Series PreDokumen98 halamanManual AquaLab Series PrePaul Jasinto100% (1)

- SP Coating and Wrapping of Line PipeDokumen14 halamanSP Coating and Wrapping of Line PipeĐiệnBiênNhâm100% (1)

- Corector RometDokumen2 halamanCorector RometJose Manuel CastroBelum ada peringkat