Linde Air Heater

Diunggah oleh

jmsmechJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Linde Air Heater

Diunggah oleh

jmsmechHak Cipta:

Format Tersedia

Air-heated Vaporizers

Contents.

3 Introduction 4 General 5 Lead-VAP and Special-VAP 6 Lead-VAP

Standard design

8 Special-VAP

HQ-standard design (for higher quality uids) HD-standard design (for high pressure use) Clip-on standard design Pressure build-up standard design

16 Operational efciency

Conversion factor Correction factor, power factor, sample calculations

Subject to change without notice. Errors excepted. The reproduction, distribution and utilization of this prospectus as well as the communication of its contents to other with-out explicid authorization is prohibited. Offenders will be held liable for the payment of damages. All rights reserved in the event of the grant of a patent, utility model or design. Linde AG, April 2009

18 Know-how, quality, inspection, documentation 22 SHEQ - safety, health, environment and quality police 23 Service and guarantee 24 Contacts

Introduction.

Carl von Linde - gifted engineer, scientist, entrepreneur, companys founder and eponym of the Linde AG. With air liquefaction, Carl von Linde created the conditions needed to procedure pure gases using low-temperature processes. Air liquefaction was only the first step for Carl von Linde towards a commercial viable use for his invention. His goal was to separate the liquid air, while re-evaporating it, into its constituents, since only these held promising industrial potential. Carl von Linde created a new industry within just a few decades: refrigeration. His company was characterized from the very first beginning by innovativeness and close customer relations. This is what Linde stands for in the past, today, and in face of future challenges, world-wide. Linde as the world leader in adsorption technology has designed and supplied more than 400 PSA plants including the worlds largest units and units with highest availability.

General.

The recovery of large quantities of gases such as oxygen, nitrogen and argon is carried out through cryogenic decomposition of air. In the cryogenic (very cold) then condensed (liquid) states, these gases only take up around 1/800 of the volume they would require in the gaseous state which is the reason why storage for consumers is carried out as a fluid in thermallyinsulated tanks at temperatures down to minus 269C. If required, the liquid gas is vaporized in a downstream vaporizer. The technical principle is simple and fail-safe: The vaporizers work without external energy through exchange of heat with the surrounding air. This way, the liquefied gas is vaporized, warmed to almost the surrounding temperature, and finally led to the users in its gaseous state.

One thing we know: Optimal efficiency, great ease of maintenance, operating safety, environmental compatibility and quality, combined with long life, are the decisive factors in your satisfaction as a customer.

Lead-VAP The new generation.

Save energy costs and investments with the new generation of Lead-VAP for cryogenic gases. This generation of all aluminium vaporizers ensures maximum air circulation due to optimized fin and vaporizer geometrics. A full range of ambient air heated vaporizers in different versions and for different customer applications. Design According to PED 97/23/EC; CE-marked Max. allowable working pressure 40 bar Cleaned for oxygen service Wind-loads up to 160 km/h (100 mph) Seismic requirements acc. to uniform building code-zone 4 Low pressure drop Efficient fin tube design Optimised external and internal surfaces for optimum convection Benefit Maintenance-free aluminium design Low weight Corrosion and temperature resistant Easy to assemble - no welding or brazing required Screwed connections at in- and outlet for models up to 350 Nm/h Space-saving design, intensive convection Long lifetime

Special-VAP Qualitiy for special use.

For special requirements, use the well proven vaporizers from our Special-VAP series. For operating pressures up to 400 bar, you can select your high-pressure vaporizer from three standard sizes; for more stringent requirements on the purity of gases, we offer standard vaporizers in special High Quality design. Clip-on vaporizers and pressure build-up evaporators round off our product range. Design According to PED 97/23/EC; CE-marked Max. allowable working pressure 40 bar (for high pressure types 400 bar) Cleaned for oxygen service Low pressure drop Efficient fin tube design Benefits Low weight Corrosion and temperature resistant Easy to assemble Space-saving design, intensive convection Long lifetime

Standard design.

The vaporizers are suitable for a design overpressure = max. allowable working pressure (PS) of 40 bar and a allowable operating temperature range (TS) of +50/-269C. Design and testing was carried out in accordance with the directive 97/23/EC concerning pressure equipment, AD 2000-Merkbltter and DIN EN. The connecting flanges are DIN EN compliant. The Linde finned tubes and connecting flanges are made of aluminium alloy and the seals formed according to Linde standards. Variations defined by specific order instructions are possible. The stressing of the materials used, at low temperatures for example, was taken into account during their selection.

Explanation of type designation: L = air heated 40 = max. permissible working overpressure: 40 bar 8 F = number of Finned tubes: 8 3 = length of single finned tube: 3 m Partly the vaporizers have different foot standard of length, evident by an additional characteristic letter (-S; -L) of the type designation, for example L 40 - 30 F 6 - S. Explanation: S = short version = L = long version =

Flange - counter ange connection DN 40 / PN 40

600 mm footing a) 900 mm footing

Screwed connection M40 x 2 as well as pipe connection. To protect the operating staff when connecting the interventing pipelines, Linde evaporators are tted with edge protection.

vaporizer type dimensions approx. L 40 - 30 F 6 - L L 40 - 30 F 6 - S L 40 - 24 F 6 - L L 40 - 24 F 6 - S L 40 - 16 F 6 - L L 40 - 16 F 6 - S L 40 - 16 F 4 - L L 40 - 16 F 4 - S L 40 - 12 F 4 - L L 40 - 12 F 4 - S L 40 - 8 F 3 L 40 - 4 F 3 depth [m] widht [m] height[m] 1,84 1,84 1,84 1,84 1,24 1,24 1,24 1,24 1,24 1,24 0,72 0,72 1,54 1,54 1,24 1,24 1,24 1,24 1,24 1,24 0,94 0,94 1,12 0,52 7,14 6,84 7,14 6,84 7,14 6,84 5,14 4,84 5,14 4,84 3,86 3,84

weight empty nominal capacity*) [kg] N2 [Nm/h]

connections (inlet/outet) [mm]

Linde ident-no.

788 1000 778 644 flange/counter flange 800 DN 40 / PN 40 635 450 520 442 screwed: M40 x 2 3,27 pipe: DN 25 (33 x 2,4) 350 socket welding end: 28,3 320 259 260 screwed: M40 x 2 250 pipe: DN 15 (21,3 x 1,5) socket welding end: 18,2 111 130 58 62

M83562 M59970 M83563 M69789 M83564 M69785 M76127 M69784 N08413 M70106 M71496 M71591

*) The capacity is based on an ambient temperature of 20C, 70 % rel. humidity, 15C temperature difference between ambient and gas outlet temperature at a continuous 8-hours-operation a) Standard vaporizer design is the long version; price and delivery time for the short version available on special request

Range of Lead-VAP run production, beginning in front with type L 40 - 4 F 3

HQ-standard design.

The Special-VAP HQ-standard design is specially designed for higher quality fluids. The vaporizers are suitable for a design overpressure = max. allowable working pressure (PS) of 40 bar and a allowable operating temperature range (TS) of +50/-269C. Design and testing was carried out in accordance with the directive 97/23/EC concerning pressure equipment, AD 2000-Merkbltter and DIN EN. The material of the pipes, pipe bends and caps is corrosion-resistant austenitic CrNi-steel. In general air heated vaporizers consist of light metal tubes with longitudinal ribs (finned tubes with star-shaped cross-section). HQ-vaporizer are made in duplex-design, consisting of CrNisteel pipes inserted into aluminium finned tubes for increased transfer of heat. Factory-made, the inlet and outlet openings of the HQ-vaporizer are sealed gas-, dust- and moisture tight with shutter caps as well as in condition of low overpressure by protective gas.

Explanation of type designation: L = air heated 40 = max. permissible working overpressure: 40 bar 8 F = Number of Finned tubes: 8 3 = length of single finned tube: 3 m HQ = to be suitable for Higher Quality fluids

Remark: standard vaporizer design is the long leg version (L = 900mm) Left image shows the conventional construction of a nned tube with star-shape cross-section; right image shows the duplex-design consisting of an austenitic steel pipe inserted into a aluminium nned tube.

Inlet and outlet openings are sealed gas- and dust tight with caps, which must cut off prior installation. For highest purity and in order to avoid moisture tight in the course of carriage and stocking the HQ-vaporizers are delivered in condition of low overpressure by a protective gas.

vaporizer type dimensions approx. depth [m] widht [m] height[m] 1,84 1,84 1,24 1,24 1,24 1,12 0,52 1,54 1,24 1,24 1,24 0,94 0,72 0,52 6,976 6,976 6,976 5,106 5,106 3,826 3,836

nominal connections weight empty capacity*) (inlet/outlet) [kg] 960 796 550 399 312 139 72 N2 [Nm/h] [mm]

design [mm]

Linde ident-no.

L 40 - 30 F 5,8 - HQ L 40 - 24 F 5,8 - HQ L 40 - 16 F 5,8 - HQ L 40 - 16 F 4 - HQ L 40 - 12 F 4 - HQ L 40 - 8 F 3 - HQ L 40 - 4 F 3 - HQ

660 pipe: DN 40 (48,3 x 2) 530 material: stainless steel duplex 340 (CrNi-steel pipes inserted into 230 aluminium pipe: DN 15 finned tubes) 170 (21,3 x 2) material: 85 stainless steel 40

L06453 N23418 N47708 N47706 N53823 N47675 N43865

*) The capacity is based on an ambient temperature of 20C, 70 % rel. humidity, 15C temperature difference between ambient and gas outlet temperature at a continuous 8-hours-operation

Type L 40 - 30 F 5,8 - HQ still without connecting piping between the nned tubes. At all time during fabrication internal purity is guaranteed by protective covers.

10

HD-standard design.

The Special-VAP HD standard design is specially designed for high pressure use. The vaporizers are suitable for a design overpressure = max. allowable working pressure (PS) of 400 bar and a allowable operating temperature range (TS) of +50/-269C. Design and testing was carried out in accordance with the directive 97/23/EC concerning pressure equipment, AD 2000-Merkbltter and DIN EN. The material of the pipes, pipe bends and caps is corrosion-resistant austenitic CrNi-steel. HD-vaporizer are made in duplex-design, consisting of CrNi-steel pipes inserted into aluminium finned tubes for increased transfer of heat. Factory-made, the inlet and outlet openings of the HD-vaporizer are sealed gas-, dust- and moisture tight with shutter caps.

Explanation of type designation: L = air heated 400 = max. permissible working overpressure: 400 bar 8 F = number of Finned tubes: 8 3 = length of single finned tube: 3 m HD = to be suitable for high pressure use

Remark: standard vaporizer design is the long leg version (L = 900 mm)

For twenty years, we have offered vaporizer for high pressure use

Just like the HQ-types the openings of the HD-vaporizer are sealed gas-, dust- and moisture tight with covers, which must cut off prior installation.

vaporizer type dimensions approx. depth [m] widht [m] height[m] 1,84 1,24 1,12 1,54 1,24 0,72 6,976 6,976 3,826

nominal connections weight empty capacity*) (inlet/outlet) [kg] 957 536 139 N2 [Nm/h] [mm]

design [mm]

Linde ident-no.

L 400 - 30 F 5,8 - HD L 400 - 16 F 5,8 - HD L 400 - 8 F 3 - HD

660 pipe: DN 15 (21,3 x 2,9) 340 duplex material: stainless steel 85

Q76115 Q28666 Q76114

*) The capacity is based on an ambient temperature of 20C, 70% rel. humidity, 15 C temperature difference between ambient and gas outlet temperature at a continuous 8-hours-operation

11

12

Clip-on standard design.

The vaporizers are suitable for a design overpressure = max. allowable working pressure (PS) of 40 bar and a allowable operating temperature range (TS) of +50/-196C. Design and testing was carried out in accordance with the directive 97/23/EC concerning pressure equipment, AD 2000-Merkbltter and DIN EN. The Linde finned tubes and connecting flanges are made of alluminium alloy and the seals are formed according to Linde Standards. Clip-on standard design means the vaporizer without frame. As an option a mounting kit for installation on a cryo-tank is available on special request.

Explanation of type designation: L = air heated 40 = max. permissible working overpressure: 40 bar 8 F = number of Finned tubes: 8 2,5 = length of single finned tube: 2,5 m

Type L 40 - 2 F 2,5

Mounting kit

Type L 40 - 4 F 2,5

vaporizer type dimensions approx. depth [m] widht [m] height[m] 1,67 1,67 0,69 0,516 0,276 0,276 2,733 2,733 2,709

connections nominal weight empty (inlet/outlet) capacity*) [kg] 140 74 37 N2 [Nm/h] [mm]

Linde ident-no.

L 40 - 8 F 2,5 L 40 - 4 F 2,5 L 40 - 2 F 2,5

120 screwed: M40 x 2 pipe: DN 15 (21,3 x 1,5) 60 socket welding end: 18,2 material: stainless steel 30

J34895 I32740 I32631

*) The capacity is based on an ambient temperature of 20C, 70 % rel. humidity, 15C temperature difference between ambient and gas outlet temperature at a continuous 8-hours-operation

13

14

Pressure build-up.

The vaporizers are suitable for a design overpressure = max. allowable working pressure (PS) of 40 bar and a allowable operating temperature range (TS) of +50/-196C (HQ-type +50/-269C). Design and testing was carried out in accordance with the directive 97/23/EC concerning pressure equipment, AD 2000-Merkbltter and DIN EN. The Linde finned tubes and connecting flanges are made of alluminium alloy and the seals are formed according to Linde standards. The HQtype is made in duplex-design, consisting of CrNi-steel pipes inserted into aluminium finned tubes. Please take into consideration: The data on the performance - that is, the withdrawal quantity of the product gas - depend on the operating pressure, and must therefore be requested separately.

Explanation of type designation: LD = air heated - pressure build-up 40 = max. permissible working overpressure: 40 bar 5 F = number of Finned tubes: 5 4 = length of single finned tube: 4 m HQ = to be suitable for Higher Quality fluids

Horizontal evaporators ensure high circulation forces. The image shows the types LD 40 - 5 F 4 and LD 40 - 5 F 2.

vaporizer type dimensions approx. depth [m] widht [m] height [m] 4,174 2,171 1,25 2,171 4,174 1,153 0,655 0,655 0,5 0,74 0,74 0,5 0,58 0,58 2,085 0,58 0,58 2,034

external connections weight empty heat surface (inlet/outlet) [kg] 44 37 90 50,5 80 60 m2 [mm]

design [mm]

Linde ident-no.

LD 40 - 5 F 4 LD 40 - 5 F 2 LD 40 - 4 F 1,6 LD 40 - 5F 2 - HQ LD 40 - 5F 4 - HQ

8,8 pipe DN 25 (28 x 2) for connection to 4,4 Al-finned tubes reducing braze-on flange DN 40/25 13,3 PN 40 4,4 8,8 9,5 pipe DN 40 (48,3 x 2) pipe DN 40 (48,3 x 2) pipe: DN 40 (48,3 x 2) duplex duplex duplex

J46389 J46390 J46391 K47971 R56440 871321

LD 40 - 4 F 1,5 - HQ*)

*) Allowable operating temperature range (TS) for +50/-269C

15

16

Operational efficiency.

The nominal operational efficiency of the vaporizer is based on a reference ambient temperature of +20C for N2 (see tables of technical data). In this case, the difference in temperature between the ambient temperature and gas outlet is 15C. The operational efficiency is dependent on various boundary conditions such as ambient temperature, wind velocity, air humidity, air circulation, ingress of sunlight, period of operation and the medium used. The following diagrams show how the nominal output is affected by the medium used (Fig. 1: Conversion factor), the ambient temperature (Fig. 2: Correction factor) and the period of operation (Fig. 3: Power factor). Note: As the boundary conditions are subject to large fluctuations, the information provided should be regarded as average, approximate values. In Fig. 4, calculations are shown by way of example for determining the anticipated nominal efficiency taking the operating medium, ambient temperature and period of operation into account. Air heated vaporizers have a modular construction principle and can be connected together individually according to the required output. The specified nominal performance figures apply to eight-hour permanent operation; after that, the performance of the vaporizers may drop because of frosting. For longer periods of operation it is therefore advisable to arrange the vaporizer modules in parallel. While one vaporizer group is working, the other vaporizers can regenerate. This prevents non-productive intermissions gas withdrawal is assured at all times.

medium N2 Ar H2 O2 CH4 CO2 He

conversion factor 1 1,15 1,75 0,92 0,76 0,33 3,10

Fig. 1: Conversion factor for the nominal efciency of various media

Nominal output 1.2 1.0 0.8

Correction factor

0.6 0.4

-30

-20

-10

10 20 0 Ambient temperature [C]

30

40

50

Fig. 2: Correction factor - for the nominal operational efficiency as a function of ambient temperature

1.4 1.3 Power factor 1.2 1.1 1.0 0.9 Nominal output 0.8 8 10 6 Operational duration [h] 12 14 16

Fig. 3: Power factor - for the nominal operational efficiency as a function of operational duration

Examples for vaporizer type L40 - 8F 3; nominal output at +20C according to Fig. 1 = 130 Nm/h: Example 1: For N2 at +20C and 8 h duration of operation: Nominal output = 100 % x conversion factor 1 x correction factor 1 x power factor 1 = 100 % i.e. nominal output (N2) = 130 Nm/h actual output (N2) = 130 Nm/h x factor 1 = 130 Nm/h

Example 2: For O2 at -20C and 2 h duration of operation: Nominal output = 100 % x conversion factor 0,92 x correction factor 0,6 x power factor 1,25 = 69 % i.e. nominal output (N2) = 130 Nm/h actual output (O2) = 130 Nm/h x factor 0,69 = 90 Nm/h

Fig. 4: Sample calculations for determining nominal output

18

Know-how, quality, inspection, documentation.

Linde is commited to customers satisfaction: the only acceptable standard by which we can measure quality success. Our customers expect us to supply safe and reliable plants and components which operate both economically and in an environmentally friendly manner, reflecting the current state of technology. Since a period of almost half a century Linde designs and manufactures air-heated vaporizers for cryogenic applications. The new range of Lead- and Special-Vaporizer is a direct result of our ongoing product development. They conform to the latest technical standards, are proven, effective in performance and simple to use.

There is a permanent on-site-support by the notified body.

A view from above into the blades of a vaporizer shows the detailed sophistication of the technology. The new type of vaporizer is characterised by improved power, compared with the previous model.

19

Quality management is an indispensable part of our corporate strategy and therefore a managerial responsibility carried out at all levels of the company. Extensive testing ensures the highest welding quality and safety. The inspections will be carried out by applying the directives and operating instructions of the Linde quality managementsystem as well as supervised by the independent official notified body.

The cleanliness of our products, even oxygen applications, naturally conforms to the purity requirements of the EN 12300 standard. Because of the pressures that they will be subjected to in later operation, and the associated risks, units like vaporizers are subject to stringent manufacturing requirements. All named vaporizer types of these prospectus comply with the essential safety requirements defined in Annex I of directive 97/23/EC concerning pressure equipment. Each delivered CE vaporizer is unambiguously documented by the EC declaration of conformity, issued by Linde and related to the fabrication number. The associated operating instructions contain a type-relevant data sheet. Linde vaporizers for air-heated gas transformation safe, reliable supply made to measure.

Every vaporizer must meet the demands of the required proof test. The final inspection and pressure test are performed exclusively by trained and responsible qualified personnel and monitored by the Notified Body.

All measuring instruments are calibrate and checked periodically.

Each vaporizer can be identified by a name plate with its rating, CE seal, the identification number of the notified body responsible for monitoring/acceptance, and an individual fabrication number.

20

Documentation EC Declaration of Conformity; the associated operating instructions contain a type-relevant data sheet, which includes information among other things on attachment to foundations.

The Engineering Division, Schalchen Plant is certified of a Quality Management System according to ISO 9001.

21

COMPLIES PROVISIONS ACC. TO DIRECTIVE CONCERNING PRESSURE TREATMENT 97/23/EC

MONITORED OR FINAL ASSESSMENT BY NOTIFIED BODY

QUALITY MANAGEMENT SYSTEM ACC. TO EN ISO 9001

QUALITY

CLEANLINESS

LINDE KNOW-HOW

EN 12300 - O2

LINDE KNOW-HOW OF CRYOGENIC PRESSURE VESSELS

COMPLIES REQUIREMENTS OF CLEANLINESS FOR CRYOGENIC SERVICE; OXYGEN SERVICE

22

SHEQ - safety, health, environment and quality police.

At the Engineering Division, we do not want to harm people or the environment. We will comply with all applicable legal, regulatory, internal and industry requirements. We strive to be leading in SHEQ to meet safe, secure and healthy working conditions and supplying safe, compliant and environmentally responsible products and services for our customers. SHEQ is a key part of The Linde Groups overall strategy and we will also require our contractors and partners to manage in line with this policy.

To achieve this vision, SHEQ is 100 % of our behaviour, 100 % of the time.

23

Service and guarantee.

Welcome to the Engineering Division The Linde Schalchen Plant is located 90 km east of Munich, Germany. 700 engineers and skilled workers design and manufacture components and complete modules for the application in process plants. Backed up by more than 100 years of production know-how, highly developed plant modules are manufactured. Our innovative technologies and our competitiveness open the door to participation in prestigious plant projects worldwide. Linde provides complete services on field installation and operation. A specialized service crew is available for immediate and professional repair services. Linde AG Engineering Division Schalchen Plant Carl-von-Linde-Str. 15 83342 Tacherting/Germany Phone: +49.8621.85-0 (center) Fax: +49.8621.85-6628 E-Mail: plantcomponents@linde-le.com Internet: www.linde.de Production area of standardized equipment: Advice and sale Phone: +49.8621.85-6689 After sales service, guarantee Phone: +49.8621.85-6279 Office for the distribution of orders Phone: +49.8621.85-6432 Other products by production area of standardized equipment: Static vacuum insulated cryogenic vessels Spiral welded pipes

Do you need further and more detailed information? Just ask us we will be pleased to help you.

Designing Processes - Constructing Plants.

Lindes Engineering Division continuously develops extensive process engineering know-how in the planning, project management and construction of turnkey industrial plants.

The range of products comprises: Petrochemical plants LNG and natural gas processing plants Synthesis gas plants Hydrogen plants Gas processing plants Adsorption plants Air separation plants Cryogenic plants Biotechnological plants Furnaces for petrochemical plants and reneries

More than 3,800 plants worldwide document the leading position of the Engineering Division in international plant construction.

P/3.4.e/09

Product range.

Aluminium plate-n heat exchangers as single units or as manifolded assemblies Coldboxes with aluminium plate-n heat exchangers, columns and vessels Coil-wound heat exchangers and isothermal reactors for chemical and petro- chemical plants Columns and pressure vessels in aluminium for cryogenic plants Spiral-welded pipes in aluminium Storage tanks for liqueed gases Steam-heated waterbath vaporizers as well as air-heated vaporisers for liqueed gases

For further informations please contact: Linde AG Engineering Division, Schalchen Plant Carl-von-Linde-Str. 15, D-83342 Tacherting, Germany Phone +49.8621.85-6434 Fax +49.8621.85-6622 E-Mail: plantcomponents@linde-le.com Website: www.linde-plantcomponents.com

Anda mungkin juga menyukai

- GpcalcsDokumen7 halamanGpcalcsesakkiraj1590Belum ada peringkat

- Thermal Analysis of Exposed Pipeline Under Natural ConvectionDokumen6 halamanThermal Analysis of Exposed Pipeline Under Natural ConvectionSyahrizalYusoff100% (1)

- D2880 380331-1 PDFDokumen7 halamanD2880 380331-1 PDFVidyasenBelum ada peringkat

- Modeling Mineral Size Reduction in The Closed-Circuit Ball Mill at The Pine Point Mines Concentrator (1981)Dokumen18 halamanModeling Mineral Size Reduction in The Closed-Circuit Ball Mill at The Pine Point Mines Concentrator (1981)Ryan Cunningham100% (1)

- Excess FLow ValveDokumen9 halamanExcess FLow ValvechloeBelum ada peringkat

- Two-Phase Flow Discharge in Nozzles and Pipes - A Unified ApproachDokumen6 halamanTwo-Phase Flow Discharge in Nozzles and Pipes - A Unified ApproachAksheyBelum ada peringkat

- Evaporative Rates of A SpillDokumen3 halamanEvaporative Rates of A SpillkurtbkBelum ada peringkat

- Accelertion Head5 PDFDokumen1 halamanAccelertion Head5 PDFnirmal_subudhiBelum ada peringkat

- Acoustic Induced Vibration - Flare Systems PDFDokumen2 halamanAcoustic Induced Vibration - Flare Systems PDFsri9987Belum ada peringkat

- 2K Method PDFDokumen5 halaman2K Method PDFMiguel Antonio Francisco ReyesBelum ada peringkat

- Heat-Exchanger Bypass Control: William L. LuybenDokumen9 halamanHeat-Exchanger Bypass Control: William L. LuybenYu Hui100% (1)

- Effects of Approach Flow ConditionsDokumen6 halamanEffects of Approach Flow ConditionsBharath kumarBelum ada peringkat

- 12 Oil and Gas SeparatorsDokumen44 halaman12 Oil and Gas SeparatorsGadhoumiWalidBelum ada peringkat

- Structured Packing BrochureDokumen12 halamanStructured Packing BrochureMoad Bouzida100% (1)

- Understanding and Eliminating Pressure Fluctuations in 2010 Process SafetyDokumen6 halamanUnderstanding and Eliminating Pressure Fluctuations in 2010 Process SafetyandriBelum ada peringkat

- Controlling Ejector Performance: BY C. G. Blatchley Schutte & KoertingDokumen9 halamanControlling Ejector Performance: BY C. G. Blatchley Schutte & KoertingCan YıldırımBelum ada peringkat

- Tower Line Size Criteria PDFDokumen1 halamanTower Line Size Criteria PDFBurhanBelum ada peringkat

- Product-Data-Sheet-Catalog-12 - (Two Phase Control Valve Sizing Calculation Fisher)Dokumen41 halamanProduct-Data-Sheet-Catalog-12 - (Two Phase Control Valve Sizing Calculation Fisher)reninbabaski100% (1)

- Reciprocating CompressorsDokumen5 halamanReciprocating CompressorsthirumalaiBelum ada peringkat

- 05 V PattabathulaDokumen16 halaman05 V Pattabathulapcorreia_81Belum ada peringkat

- Multiple Pumps VFD OperationDokumen3 halamanMultiple Pumps VFD Operationbabuthomas23Belum ada peringkat

- Control Valve DPDokumen8 halamanControl Valve DPAmit SawantBelum ada peringkat

- E01 PDFDokumen28 halamanE01 PDFAnonymous HJZffHvTBelum ada peringkat

- LNG Centrifugal Compressors BrochureDokumen12 halamanLNG Centrifugal Compressors BrochurehacenescribdBelum ada peringkat

- Riso Ammonia Transport Safety ReportDokumen160 halamanRiso Ammonia Transport Safety ReportAlexandros GiannikosBelum ada peringkat

- The New 3rd Edition of The ALPEMA Plate-Fin Heat Exchanger StandardsDokumen3 halamanThe New 3rd Edition of The ALPEMA Plate-Fin Heat Exchanger StandardsvheshaghianBelum ada peringkat

- 14 Draw Off Nozzle Hydraulics PDFDokumen12 halaman14 Draw Off Nozzle Hydraulics PDFMohsin EhsanBelum ada peringkat

- 3443-SZ-RT-101 - 04 Attachment 15Dokumen8 halaman3443-SZ-RT-101 - 04 Attachment 15tak-1963Belum ada peringkat

- Minimum Submergence Required For Vortex Breaker - Industrial Professionals - Cheresources - Com CommunityDokumen7 halamanMinimum Submergence Required For Vortex Breaker - Industrial Professionals - Cheresources - Com CommunitySHIBelum ada peringkat

- IR HL Heatless DryerDokumen1 halamanIR HL Heatless DryerYing Kei ChanBelum ada peringkat

- Screening Reactor For Water HammerDokumen49 halamanScreening Reactor For Water HammerYu GanBelum ada peringkat

- NGV-Diverter Valve: New Sealing Concept ApplicationDokumen2 halamanNGV-Diverter Valve: New Sealing Concept Applicationshashikanth79Belum ada peringkat

- ClydeBergemannSootblowers PrinceGeorge06Dokumen36 halamanClydeBergemannSootblowers PrinceGeorge06Arun YogaBelum ada peringkat

- Design & Development of Air Release Valve/Anti Vacuum Valve For High PressureDokumen4 halamanDesign & Development of Air Release Valve/Anti Vacuum Valve For High PressureDheeraj ThakurBelum ada peringkat

- Piping Design 5 PDFDokumen9 halamanPiping Design 5 PDFSandra MArrugo100% (1)

- AP1000 Plant DescriptionDokumen31 halamanAP1000 Plant DescriptionAsier DCBelum ada peringkat

- Informacion Tecnica Bomba de Vacio DekkerDokumen1 halamanInformacion Tecnica Bomba de Vacio DekkerMiguelon AngelBelum ada peringkat

- Design Guidelines For Proplyene Splitters - Rev inDokumen10 halamanDesign Guidelines For Proplyene Splitters - Rev intotongopBelum ada peringkat

- High Integrity Protective SystemsDokumen9 halamanHigh Integrity Protective SystemsAbhiyan Anala ArvindBelum ada peringkat

- Article 5 Piping Design Part 5 Installation and CleaningDokumen9 halamanArticle 5 Piping Design Part 5 Installation and Cleaningharoon_siyech_engg100% (1)

- Engineeringpracticejan2016 PDFDokumen17 halamanEngineeringpracticejan2016 PDFChemkhiBelum ada peringkat

- 1 Chaker - Evaporative Cooling of Gas Turbine EnginesDokumen12 halaman1 Chaker - Evaporative Cooling of Gas Turbine Engineshermez19Belum ada peringkat

- Open Cooling Tower Design ConsiderationsDokumen5 halamanOpen Cooling Tower Design ConsiderationsvictorvikramBelum ada peringkat

- Sep Era Tors and FiltersDokumen15 halamanSep Era Tors and FiltersAndre BecBelum ada peringkat

- NPSHDokumen6 halamanNPSHAnsari SuhailBelum ada peringkat

- Calculating Relief Valves Under The New ASHRAEDokumen2 halamanCalculating Relief Valves Under The New ASHRAEchandrashekharsBelum ada peringkat

- Flow Special - Sizing Orifice Plates - ISADokumen4 halamanFlow Special - Sizing Orifice Plates - ISAamarnethaBelum ada peringkat

- StallDokumen16 halamanStallbhalchandrak1867100% (1)

- 2012-11-43 Anti-Surge Valves For Dynamic CompressorsDokumen5 halaman2012-11-43 Anti-Surge Valves For Dynamic Compressorssourcemenu100% (2)

- AIGA 083 - 13 Disposal of GasesDokumen82 halamanAIGA 083 - 13 Disposal of GasesIvonn OchoaBelum ada peringkat

- Alarm Trip Setting List 3Dokumen35 halamanAlarm Trip Setting List 3Vraja KisoriBelum ada peringkat

- Ethylene PipesDokumen8 halamanEthylene Pipesingbarragan87Belum ada peringkat

- EI Regulator Station Handbook TDC UKDokumen32 halamanEI Regulator Station Handbook TDC UKupesddn2010Belum ada peringkat

- Air Separation Plants History and Technological Progress 2019 Tcm19 457349Dokumen28 halamanAir Separation Plants History and Technological Progress 2019 Tcm19 457349Jambanlaya JasdBelum ada peringkat

- Discharge Coefficients Through Perforated Plates at Reynolds Numbers of 400 To 3,000Dokumen3 halamanDischarge Coefficients Through Perforated Plates at Reynolds Numbers of 400 To 3,000Anonymous knICaxBelum ada peringkat

- Is 1231.1974Dokumen22 halamanIs 1231.1974Jayam Harinatha GupthaBelum ada peringkat

- Chemical Process Retrofitting and Revamping: Techniques and ApplicationsDari EverandChemical Process Retrofitting and Revamping: Techniques and ApplicationsGade Pandu RangaiahBelum ada peringkat

- Plant Engineering and Design The Ultimate Step-By-Step GuideDari EverandPlant Engineering and Design The Ultimate Step-By-Step GuideBelum ada peringkat

- Modern Developments in the Mechanics of ContinuaDari EverandModern Developments in the Mechanics of ContinuaSalamon EskinaziBelum ada peringkat

- PUR SupportDokumen1 halamanPUR SupportjmsmechBelum ada peringkat

- Alex-Furadur Mortar Chemical Resistance ChartDokumen1 halamanAlex-Furadur Mortar Chemical Resistance ChartjmsmechBelum ada peringkat

- WOOD SupportDokumen1 halamanWOOD SupportjmsmechBelum ada peringkat

- Sika Waterbars PDFDokumen5 halamanSika Waterbars PDFjmsmechBelum ada peringkat

- Client: Method Statement For Construction of Civil WorksDokumen17 halamanClient: Method Statement For Construction of Civil WorksAzharudin ZoechnyBelum ada peringkat

- Selectarc B90: Inconel Type Electrode For Fabrication and RepairDokumen1 halamanSelectarc B90: Inconel Type Electrode For Fabrication and RepairjmsmechBelum ada peringkat

- Techno Gulf BrouchureDokumen20 halamanTechno Gulf BrouchurejmsmechBelum ada peringkat

- ISO 4034 Hexagon Nuts, Production Class C: Equivalent StandardsDokumen3 halamanISO 4034 Hexagon Nuts, Production Class C: Equivalent StandardsjmsmechBelum ada peringkat

- Boilers: Fireroom - The Fireroom Is A CompartmentDokumen16 halamanBoilers: Fireroom - The Fireroom Is A CompartmentRENGANATHAN PBelum ada peringkat

- Sail 3502 Steel Chequered Plate ColisDokumen1 halamanSail 3502 Steel Chequered Plate Colisतरकश के तीर50% (2)

- EN10060 HotRolledParts DimensionaandTolerancesDokumen12 halamanEN10060 HotRolledParts DimensionaandTolerancesEidrish ShaikhBelum ada peringkat

- HDPE Pipe Grade Safety Data SheetDokumen5 halamanHDPE Pipe Grade Safety Data SheetjmsmechBelum ada peringkat

- Conduit Technical Standard PDFDokumen13 halamanConduit Technical Standard PDFAykut BacakBelum ada peringkat

- Polyken 1027 PrimerDokumen1 halamanPolyken 1027 PrimerAdinugroho SunardiBelum ada peringkat

- Chequered Plate - Diamond and Tear Drop PatternDokumen1 halamanChequered Plate - Diamond and Tear Drop PatternjmsmechBelum ada peringkat

- Abdulrahman Hassan Ahmed: Technical Office EngineerDokumen3 halamanAbdulrahman Hassan Ahmed: Technical Office EngineerjmsmechBelum ada peringkat

- Ahmed Samy - Mechanical Site EngineerDokumen3 halamanAhmed Samy - Mechanical Site EngineerjmsmechBelum ada peringkat

- Safe - ErectioSafe Erection of Structural Steel For Buildingsns - Web PDFDokumen36 halamanSafe - ErectioSafe Erection of Structural Steel For Buildingsns - Web PDFFarid RezaeianBelum ada peringkat

- Pipe Purging BrochureDokumen19 halamanPipe Purging BrochurejmsmechBelum ada peringkat

- 33 Parking Handbook Singapore LTADokumen178 halaman33 Parking Handbook Singapore LTAA Post-Gaddafi FreedomBelum ada peringkat

- German CourseDokumen2 halamanGerman CoursejmsmechBelum ada peringkat

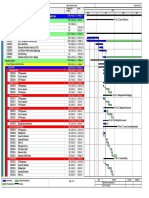

- 2 Weeks AheadDokumen12 halaman2 Weeks AheadjmsmechBelum ada peringkat

- BoilersDokumen69 halamanBoilersSantosh C0% (1)

- DP07J1 Fe11 P7000 TD106 SH01 02Dokumen1 halamanDP07J1 Fe11 P7000 TD106 SH01 02jmsmechBelum ada peringkat

- SUN Partnering For PerformanceDokumen24 halamanSUN Partnering For PerformancejmsmechBelum ada peringkat

- Detailed Engineering Design PhaseDokumen8 halamanDetailed Engineering Design Phaserenjithv_494% (18)

- Holidays and Observances in Saudi Arabia in 2016Dokumen1 halamanHolidays and Observances in Saudi Arabia in 2016jmsmechBelum ada peringkat

- Visio-Piping Organization ChartDokumen1 halamanVisio-Piping Organization ChartjmsmechBelum ada peringkat

- 1 Piping CostingDokumen33 halaman1 Piping Costingamoldhole97% (34)

- Handbook of Human Factors and Ergonomics Methods: Dr. George HavenithDokumen24 halamanHandbook of Human Factors and Ergonomics Methods: Dr. George HavenithRenzo Pajuelo CarrascoBelum ada peringkat

- Chapter 1 Weather and ClimateDokumen15 halamanChapter 1 Weather and ClimateZaza Red-eyedBelum ada peringkat

- Equipo Aire Acondicionado S3583 BARD 60 HZDokumen45 halamanEquipo Aire Acondicionado S3583 BARD 60 HZcmarinvzlaBelum ada peringkat

- SK-500II Syringe Pump Instruction Manual PDFDokumen29 halamanSK-500II Syringe Pump Instruction Manual PDFVinsmoke SanjiBelum ada peringkat

- Carbothane 133 HB PDS PDFDokumen5 halamanCarbothane 133 HB PDS PDFskBelum ada peringkat

- Project Proposal Template 1Dokumen10 halamanProject Proposal Template 1Catibog ClarisseBelum ada peringkat

- Refresher No.5 (Mesl)Dokumen4 halamanRefresher No.5 (Mesl)chyno.kang08Belum ada peringkat

- Kant Different RacesDokumen19 halamanKant Different RacesChris BlakleyBelum ada peringkat

- J.R.Manel Sashikala PDFDokumen27 halamanJ.R.Manel Sashikala PDFManel SashikalaBelum ada peringkat

- Moisture Management of TextilesDokumen8 halamanMoisture Management of TextilesMohammed Atiqul Hoque Chowdhury100% (1)

- 924BFEF68362Dokumen13 halaman924BFEF68362Maria MadanBelum ada peringkat

- UNO P.J. Plastic Shrinkage Cracking +evaporation Formulas ACI-1998 Vol95-M34Dokumen12 halamanUNO P.J. Plastic Shrinkage Cracking +evaporation Formulas ACI-1998 Vol95-M34Olesea NesterencoBelum ada peringkat

- Study of Macro and Micro ClimateDokumen7 halamanStudy of Macro and Micro ClimateAnshuman Samantaray0% (1)

- The Drying of Granular FertilizersDokumen16 halamanThe Drying of Granular FertilizersnataliamonteiroBelum ada peringkat

- Astm C 511-09 PDFDokumen3 halamanAstm C 511-09 PDFGanesh BhusariBelum ada peringkat

- Research On Expanded Polystyrene Product Manufacturing ProcessDokumen40 halamanResearch On Expanded Polystyrene Product Manufacturing Processsara rafieiBelum ada peringkat

- Labmed34 0304 PDFDokumen7 halamanLabmed34 0304 PDFHazim Azmi Al-QadryBelum ada peringkat

- Project: Techcalc-Projekt: Boundary ConditionsDokumen5 halamanProject: Techcalc-Projekt: Boundary ConditionsBogdan LucianBelum ada peringkat

- (Ex - Works) - PlanetsWater Full AWG Wholesale Factory Price List 2011 (PWG)Dokumen9 halaman(Ex - Works) - PlanetsWater Full AWG Wholesale Factory Price List 2011 (PWG)rianvenusBelum ada peringkat

- Aama 501.5-07Dokumen8 halamanAama 501.5-07zaheerahmed77Belum ada peringkat

- India Weather Data and Climate AnalysisDokumen39 halamanIndia Weather Data and Climate Analysislasrador0% (1)

- Questions 1 33Dokumen33 halamanQuestions 1 33dileepBelum ada peringkat

- DryerDokumen18 halamanDryer11751175Belum ada peringkat

- @suresh Academy Ccse IV - 2019 Test 10 QaDokumen17 halaman@suresh Academy Ccse IV - 2019 Test 10 QaKaniBelum ada peringkat

- Cdep Tropical Mock Board ExamsDokumen7 halamanCdep Tropical Mock Board Examsnakie08Belum ada peringkat

- Structural Report: Project Report On "Design of A Residential Building"Dokumen32 halamanStructural Report: Project Report On "Design of A Residential Building"swatantra boseBelum ada peringkat

- (Percdc) Multiple Choice Questions in General Engineering and Applied SciencesDokumen145 halaman(Percdc) Multiple Choice Questions in General Engineering and Applied SciencesMaria Dhanita David Alfaro100% (2)

- Is 4031-10 (1988) - Methods of Physical Tests For Hydraulic Cement, Part 10 - Determination of Drying ShrinkageDokumen3 halamanIs 4031-10 (1988) - Methods of Physical Tests For Hydraulic Cement, Part 10 - Determination of Drying ShrinkageApurv PatelBelum ada peringkat

- Duct SweatingDokumen6 halamanDuct SweatingNeal JohnsonBelum ada peringkat

- Operating Instructions: Digital Piezo/Pirani GaugeDokumen23 halamanOperating Instructions: Digital Piezo/Pirani GaugeHugo AguiarBelum ada peringkat