Magnetizing Current, Harmonic Content and Power Factor As The Indicators of Transformer Core Saturation

Diunggah oleh

vdaDeskripsi Asli:

Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Magnetizing Current, Harmonic Content and Power Factor As The Indicators of Transformer Core Saturation

Diunggah oleh

vdaHak Cipta:

Format Tersedia

AbstractThe paper proposes a measurement method for

obtaining the parameters needed to calculate a reliable

indicator of the state of transformer core saturation. The major

nonlinear effects in transformer core are saturation, eddy

current and hysteresis. Saturation is the predominant effect in

power transformers, followed by eddy current and hysteresis

effects. In saturation, a transformer core act as a source of

current generating harmonics, some of which will flow directly

toward the primary and secondary windings. The method is

based on magnetization current, harmonic content and power

factor evaluated of the transformer no-load current with high

magnetic flux density subjected. The investigation is done on

single phase model core type transformer. The transformer is

connected to variable voltage variable frequency (VVVF)

source and the investigation is done on various flux densities.

The results show that the magnetization current and harmonic

content increase significantly when high magnetic flux densities

are injected and vice versa with power factor that decrease

sharply. These phenomena can be used as the indication of

transformer core saturation.

Index TermsHarmonic content, no-load current, power

factor, saturation, transformer

I. NOMENCLATURES

B magnetic flux density

B

r

remanence magnetic flux density

B

s

saturation magnetic flux density

CRGO Cold-Rolled Grain Oriented

H magnetic field intensity

H

c

coercivity magnetic field intensity

H

pk

peak value of magnetic field intensity

H

s

saturation magnetic field intensity

IEC International Electrotechnical Commission

IEEE Institute of Electrical and Electronic Engineers

I

o

magnetizing current

I

rms

rms value of all the current harmonic component

I

1,rms

rms value of fundamental current

I

h,rms

rms value of current harmonic component of order h

M4 commercial name for grain oriented silicon steel sheets

grade

Manuscript received December 16, 2012; revised February 18, 2013.This

work was supported in part by Centre of Excellence for Renewable Energy

and School of Electrical Systems Engineering, Universiti Malaysia Perlis

(UniMAP) for the technical and financial support as well.

I. Daut is with Centre of Excellent for Renewable Energy, School of

Electrical Systems Engineering, Universiti Malaysia Perlis (e-mail:

ismail.daut@unimap.edu.my).

S. Hasan is with Centre of Excellent for Renewable Energy, School of

Electrical Systems Engineering, Universiti Malaysia Perlis and Fakultas

Teknik, Univ.Sumatera Utara (USU) Medan Indonesia (e-mail:

syafruddin@unimap.edu.my).

S. Taib is with the School of Electrical & Electronic Engineering,

Universiti Sains Malaysia (e-mail: soibtaib@eng.usm.my).

P power

PF total (true) power factor

PF

disp

displacement power factor

PF

dist

distribution power factor

THDi percent total current harmonic distortion

V

1rms

rms value of fundamental voltage

permeability of core material

II. INTRODUCTION

The magnetic circuit is one of the most important active

parts of transformer. It consists of laminated iron core and

carries flux linked to windings. Energy is transferred from

one electrical circuit to another through the magnetic field

carried by the core. The iron core provides a low reluctance

path to the magnetic flux thereby reducing magnetizing

current.

The performances of transformers are also constrained by

the magnetic flux limitations of the core. For ferromagnetic

core transformers, we must be mindful of the saturation limits

of the core. Remember that ferromagnetic materials cannot

support infinite magnetic flux densities: they tend to

"saturate" at a certain level (dictated by the material and core

dimensions), meaning that further increases in magnetic field

force (mmf) do not result in proportional increases in

magnetic field flux.

Choosing the right lamination material for a particular

application is an important power transformer design step,

since lamination properties have a direct link to the losses

power or efficiency of the transformer. Currently, important

lamination properties (core loss and permeability) to be used

for assessment are presented at 50 or 60 Hz, 1.0/1.5 T

sinusoidal. Electromagnetic designers have to decide on the

material based on this single operating point, although under

practical working conditions, some transformers operate at

flux density levels and frequencies beyond this point. It has

been shown that choosing the lamination material that based

on the lamination performance at one operating point only is

not enough [1]. Designers of transformers have, however,

never had data available on the specific iron losses of the

materials they use for alternating flux densities higher than of

the saturation value. The usual methods of measurement,

applied to specimens of the material, fail completely at higher

flux densities than because the power factor becomes very

small and the magnetizing current very high [2].The major

nonlinear effects in transformer iron core are saturation, eddy

current and hysteresis. Saturation is the predominant effect in

power transformers, followed by eddy current and hysteresis

effects [3]. The iron core of transformers and other

electromagnetic devices is laminated so that at 50 Hz or 60

Hz (or, in general, at power frequency) skin effect is

Magnetizing Current, Harmonic Content and Power Factor

as the Indicators of Transformer Core Saturation

Ismail Daut, Syafruddin Hasan, and Soib Taib

304 DOI: 10.7763/JOCET.2013.V1.69

Journal of Clean Energy Technologies, Vol. 1, No. 4, October 2013

insignificant. Due to saturation however, harmonics are

generated in either the flux or the magnetic field intensity or

in both, and for these the spatial distribution is not uniform.

In saturation, a transformer core act as a source of current

generating harmonics, some of which will flow directly

toward the primary and secondary windings. On the basis of

this observation, the paper proposes a measurement method

for obtaining the parameters needed to calculate a reliable

indictor of the state of saturation of transformers [4]. The

method is based on harmonic content evaluated of the

transformer no-load current with high magnetic flux density

subjected. The results show that the harmonic content

increase significantly when high magnetic flux density

injected.

Nowadays, loads of transformers are widely perturbed

with harmonics. Harmonic components cause the transformer

losses to increase and thus, transformer may fail to operate

[5]

III. HARMONIC PHENOMENA AND CORE SATURATION

A. Harmonic Phenomena

The non linear magnetic characteristics of a transformer

core are needed to predict distortion of its primary current.

One of the methods of estimating harmonic load content is

Percent Total Harmonic Distortion (%THD). The %THD can

be defined in two different ways, as a percentage of the

fundamental component (the IEEE definition of THD) or as a

percentage of the rms (used by the Canadian Standards

Association and the IEC) [7]. In this paper we use the later

one.

The percentage current total harmonic distortion is

2

,

2

100%

h rms

h

rms

I

THDi

I

=

=

(1)

where I

h,rms

is the amplitude of the harmonic component of

order h (i.e., the hth harmonic) and I

rms

is the rms values of all

the harmonics) that can be represented as

=

=

1

2

,

h

rms h rms

I I (2)

The total power factor,

PF =

P

v

1,rms

I

1,rms

_

1+[

1H

i

100%

,

2

(3)

The total power factor is sometime called the true power

factor. As shown in equation (3) the total power factor is the

product two components. The first component is called the

displacement power factor:

PF

dsp

=

P

v

1,rms

I

1,rms

(4)

The second component of the total power factor is called

distortion power factor and results from the harmonic

component of the current:

PF

dst

=

1

_1+[

THD

i

100%

(5)

If the voltage also has harmonic components, then the

distortion power factor would be the product of two terms

like the right side of equation (6), one for voltage and one for

current.

PF

dst

=

1

_1+[

THD

i

100%

1

_1+[

THD

100%

(6)

However, we normally expect the voltage distortion to be

very low compared to the current distortion.

B. Core Saturation

A typical hysteresis loop of a soft magnetic material is

shown in Fig.1. When a high magnetizing force is

encountered, a point is reached where further increase in, H,

does not cause useful increase in, B. This point is known as

the saturation point of that material. The saturation flux

density, B

s

and the required magnetizing force, H

s

, to saturate

the core are shown with dashed lines[8].

In Fig. 1, the hysteresis loop clearly shows the remanence

flux density, Br. The remanence flux is the polarized flux

remaining in the core after the excitation has been removed.

The magnetizing force, -H

c

, is called coercivity. It is the

amount of magnetizing force required to bring the remanence

flux density back to zero.

Fig. 1. Typical B-H curve of soft magnetic material.

C. Permeability

The permeability of a magnetic material is a measure of the

ease in magnetizing the material. Permeability, is the ratio

of the flux density, B, to the magnetizing force, H.

p =

B

H

(7)

The relationship between B and H is not linear, as shown in

the hysteresis loop in Fig.1. Then, it is evident that the ratio,

B/H, (permeability), also varies.

The variation of permeability with flux density, B, is

shown in Fig. 2. Also, it shows the flux density at which the

permeability is at a maximum.

Fig. 2. Variation in permeability with B and H.

305

Journal of Clean Energy Technologies, Vol. 1, No. 4, October 2013

Silicon steel was one of the first alloys to be used in

transformers and inductors. It has been greatly improved over

the years and is probably, pound for pound, the most, widely

used magnetic material. One of the drawbacks in using steel

in the early years was, as the material became older, the

losses would increase. With the addition of silicon to the steel,

the advantages were twofold: it increased the electrical

resistivity, therefore reducing the eddy current losses, and it

also improved the material's stability with age. Silicon steel

offers high saturation flux density, a relatively good

permeability at high flux density, and a moderate loss at

audio frequency. One of the important improvements made to

the silicon steel was in the process called cold-rolled,

grain-oriented,

By definition, saturation occurs when the peak exciting

current (B) is twice the average exciting current (A) as shown

in Fig. 3. Analytically, this means that [8]:

H

pk

= 2 H

s

(8)

Refer to Fig. 3, saturation occurs when B=2A

Fig. 3. Defining the excitation current

IV. MODEL OF EXPERIMENTAL SET-UP

The transformer test has the specification as single-phase

power transformer with primary winding of 220 turns and

secondary of 220 turns respectively. The dimension of the

core is 508 mm 306 mm with yoke and limb 100 mm width.

The core is assembled from 0.27 millimeter thickness

lamination of M4 grain-oriented silicon iron (CRGO) that

comprises of 17 layers and 5 mm corner overlap length

configuration (shown in Fig. 4).

306 mm

508 mm

5 mm

Fig. 4. Transformer core configuration

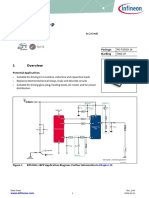

Fig. 5. Arrangement of experimental set-up

The arrangement of equipment set-up which used in this

research work is as shown in Fig. 5. The input current to

harmonic analyzer (PM 300) is connected to ac variable

voltage variable frequency supply and its voltage is come

from the secondary side of transformer test (transformer turn

ratio 1:1). The experiment was conducted with different flux

density by varying the input voltage and the frequency

maintain constant.

V. RESULT

The sample of current and voltage waveforms for 50 Hz of

frequency supply with magnetic flux density of 1.5 Tesla and

1.9 Tesla are shown in Fig. 6 (a) and Fig. 6 (b).

(a) B = 1.5 Tesla

(b) B = 1.9 Tesla

Fig. 6. Current and voltage waveforms

The harmonic phenomena in term of current total

harmonic distortion and magnetization current (Io) of

single-phase transformer at various magnetic flux densities

for frequency 50 Hz is displayed in Table.

TABLE I: MAGNETIZING CURRENT, %THDI AND PF MEASURED

AT VARIOUS MAGNETIC FLUX DENSITIES

B [T]

Io [A] THD [%] PF

1.0 0.146 16.92 0.621

1.1 0.172 21.23 0.587

1.2 0.211 25.15 0.525

1.3 0.258 28.58 0.457

1.4 0.317 31.62 0.395

1.5 0.388 33.44 0.342

1.6 0.475 37.33 0.274

1.7 0.594 44.48 0.174

1.8 0.827 56.38 0.108

1.9 1.385 64.83 0.092

2.0 2.486 75.66 0.054

The related magnetization current and percent total

harmonic distortion of magnetization current (%THDi) and

the respective magnetic flux densities for frequency 50 Hz

are depicted as shown in Fig. 7 and Fig. 8. Meanwhile, the

curve of power factor versus magnetic flux densities is

displayed in Fig. 9.

306

Journal of Clean Energy Technologies, Vol. 1, No. 4, October 2013

Fig. 7. Magnetization current versus magnetic flux density

Fig. 8. %THD versus magnetic flux density

Fig. 9. Power Factor versus magnetic flux density

VI. DISCUSSION

Fig. 6(a) and (b) show the waveforms of supply voltage

and current with different magnetic flux density, i.e, 1.5 T

and 1.9 T. Although the applied voltage is sinusoidal, the

current waveform is not sinusoidal. It is clear from Fig.7(a)

and (b) that the non-sinusoidal current is still symmetrical

around zero crossing of voltage waveform.

The magnetizing current (Io) and harmonics phenomena

which are evaluated in terms of percent total harmonic

distortion of current (THDi) and power factor are shown in

Table 1. The excitation (magnetizing) current, Io at magnetic

flux density B = 1.8 T (i.e., Io = 0.827 A) is more than

doubled compare to at 1.4 or 1.5 T (Io = 0.317 A or 0.388).

Meanwhile, the %THDi increased when the transformer is

subjected with higher magnetic flux density. The increasing

of %THD is very significant when the magnetic flux densities

are changed from 1.7 to 2.0 T. It could be signified that the

lamination cores of transformer lead to saturate. Fig. 7 and

Fig.8 also show that the pattern of Io and %THDi versus

magnetic flux density nearly the same as B-H curve of a

magnetic material.

As mention in Equation (3), the power factors are inverse

proportional to %THDi. These phenomenon are displayed in

Table I or Fig. 9. It is obvious that the power factors are

decreasing significantly when the magnetic flux densities are

changed from 1.7 T to 2.0 T. It could be also as indication that

the lamination cores of transformer have been lead to

saturate.

VII. CONCLUSION

Test data obtained for to no-load measurement of

single-phase transformer was reproduced in the Centre of

Excellence for Renewable Energy (CERE), UniMAP.

This paper presented a practical method for the estimation

of nonlinear core saturation in term of magnetization current,

its harmonics content and power factor. Analysis of the test

data indicate the high magnetic flux density contribute more

magnetization current, high harmonic content and low power

factor rather than at normal magnetic flux density of actual

transformer operation (1.4 or 1.5 Tesla).

The pattern of magnetizing current and percentage current

total harmonic distortion versus magnetic flux densities are

nearly the same as B-H curve of a magnetic material.

Therefore, these phenomenon can be used as indicator to

show that at 1.8 Tesla the material of transformer core has

been lead to saturation.

REFERENCES

[1] K. Karsai, D. Kerenyi, and L. Kiss, Large power transformers, Elsevier

Publication, Amsterdam, 1987, pp. 41.

[2] E. So, R. Arseneau, and E. Hanique, No-Load loss Measurements of

Power Transformers under Distorted Supply Voltage waveform

Conditions, IEEE Transaction on Instrumentation and Measurement,

vol. 52, no. 2, April 2003, pp. 429-432.

[3] R. Arseneau, E. So, and E. Hanique, Measurements and Correction of

No-Load Losses of Power Transformers, IEEE Transaction on

Instrumentation and Measurement, vol. 54, no. 2, pp. 503-506.

[4] A. H. A. Haj and I. E. Amin, Factors that Influence Transformer

No-Load Current Harmonics, IEEE Transaction on Power Delivery,

vol. 15, no. 1, January 2000, pp. 163-166.

[5] M. Mirzaie, M. Y. Asrami, S. B. Sadati, and A. S. Akmal, Impacts of

Non-Sinusoidal Load Currents on Distribution Transformer

Losses-Part II: Standard Aspects and Experimental Measurement,

International Review of Electrical Engineering (IREE) Journal, vol. 6.

no. 5, October 2011, pp. 2215-2220.

[6] V. S. Kulkarni and A. S. Khaparde, Transformer Engineering Design

and Practice (Marcel Dekker, Inc., New York, 2004)

[7] International Electrotechnical Commission Standards, IEC 76, part

one, Power Transformers, 2

nd

ed., 1993.

[8] S. L.Timothy and D. W. E. William, Electric Power and Controls,

Pearson-Prentice Hall, New Jersey, United States of America, 2004.

[9] C. W. T. McLyman, Transformer and Inductor Design Handbook, 3

rd

Edition, Revised and Expanded, Marcel Dekker. Inc., New York, 2004.

Ismail Daut received his B. Elect.Eng. (Hons) from

University of Science Malaysia in 1980 and MSc in

Electrical and Electromagnetic Engineering from

University of Wales, College of Cardiff, United

Kingdom in 1991 and PhD in Energy Conservation

and Power Engineering from University of Wales,

College of Cardiff, United Kingdom in 1994. His

research interest includes energy conversion, electrical

machine design and high voltage. He has authored

and co-authored more than 200 technical papers in the

national, international journal and conferences.

Syafruddin Hasan was born in July 1, 1959 in Pidie,

Aceh-Indonesia. He received his BSc from

Universitas Sumatera Utara (USU) Medan in 1985

and MSc from Institut Teknologi Bandung (ITB)

Bandung-Indonesia, 1993 all in Electrical

Engineering. He is a lecture in UniMAP and USU. He

is currently PhD student in Universiti Malaysia Perlis

(UniMAP). His field of interest includes

Electromagnetic Theory, Electrical Machines, Power

Electronic Drives and Power Quality.

307

Journal of Clean Energy Technologies, Vol. 1, No. 4, October 2013

Anda mungkin juga menyukai

- Modern Electrical Installation for Craft StudentsDari EverandModern Electrical Installation for Craft StudentsPenilaian: 4.5 dari 5 bintang4.5/5 (4)

- ESB-Earthing and Lightning ProtectionDokumen13 halamanESB-Earthing and Lightning Protectiondinesh_kp7647Belum ada peringkat

- Power Measurements Under Nonsinusoidal Conditions : A Thesis in Electrical EngineeringDari EverandPower Measurements Under Nonsinusoidal Conditions : A Thesis in Electrical EngineeringBelum ada peringkat

- TransistorDokumen18 halamanTransistorTsamarul HizbiBelum ada peringkat

- Fourier Analysis For Harmonic Signals in Electrical Power Systems (170) ADDokumen37 halamanFourier Analysis For Harmonic Signals in Electrical Power Systems (170) ADRASHU PATELBelum ada peringkat

- 30 Years of Radionics (Kelly) PDFDokumen6 halaman30 Years of Radionics (Kelly) PDFevandrojsilvaBelum ada peringkat

- Solenoid Actuators: Theory and Computational MethodsDari EverandSolenoid Actuators: Theory and Computational MethodsPenilaian: 3 dari 5 bintang3/5 (1)

- Magnetic CircuitsDokumen52 halamanMagnetic Circuitsgopi_905100% (1)

- Electrical Installation Condition ReportDokumen9 halamanElectrical Installation Condition ReportAlrx BennettBelum ada peringkat

- E86060 k8220 A101 A8 7600Dokumen320 halamanE86060 k8220 A101 A8 7600Alexis ArayBelum ada peringkat

- Introduction of HTLS ConductorsDokumen37 halamanIntroduction of HTLS ConductorsAshish MaheshwariBelum ada peringkat

- Harmonics: Theory, Sources, & Mitigation: Harmonics and Power Quality Conference September 14-15, 2006Dokumen18 halamanHarmonics: Theory, Sources, & Mitigation: Harmonics and Power Quality Conference September 14-15, 2006KiranVedanteBelum ada peringkat

- Girish Narayana HaefelyDokumen5 halamanGirish Narayana HaefelydragishablBelum ada peringkat

- Transfomer No Load Current HarmonicsDokumen6 halamanTransfomer No Load Current HarmonicsДејан ПејовскиBelum ada peringkat

- Transformer Inrush Transients Using Jiles-Atherton Model in PSCAD EMTDCDokumen5 halamanTransformer Inrush Transients Using Jiles-Atherton Model in PSCAD EMTDCANKAN CHANDRABelum ada peringkat

- Dist Panchayat Officers KarnatakaDokumen2 halamanDist Panchayat Officers KarnatakavdaBelum ada peringkat

- Investigations On A Standing Wave Thermoacoustic RefrigeratorDokumen8 halamanInvestigations On A Standing Wave Thermoacoustic RefrigeratorAli AHBelum ada peringkat

- Harmonic IndicesDokumen2 halamanHarmonic IndicesJustin Collins100% (3)

- Harmonic Survey of Typical Non-Linear Loads PDFDokumen5 halamanHarmonic Survey of Typical Non-Linear Loads PDFgtgreatBelum ada peringkat

- Bs Students Handbook Black WhiteDokumen93 halamanBs Students Handbook Black Whitevda0% (1)

- Flare TroubleshootingDokumen6 halamanFlare Troubleshootingrvkumar61100% (1)

- Powin Enclosures Product Manual Rev B01Dokumen51 halamanPowin Enclosures Product Manual Rev B01melihguneriBelum ada peringkat

- Influence of Static VAR Compensator Application FoDokumen9 halamanInfluence of Static VAR Compensator Application Fouthman nuhaBelum ada peringkat

- Distortion and Power Factor of Nonlinear LoadsDokumen8 halamanDistortion and Power Factor of Nonlinear LoadsNahivy MandujanoBelum ada peringkat

- Computation of Transient Electromagnetic Force On Power Transformer Windings by Inrush CurrentDokumen8 halamanComputation of Transient Electromagnetic Force On Power Transformer Windings by Inrush CurrentDavid LopesBelum ada peringkat

- Single Phase Transformer B-H LoopDokumen9 halamanSingle Phase Transformer B-H LoopSiddharth KumarBelum ada peringkat

- Chapter 2Dokumen11 halamanChapter 2Ishwar KBelum ada peringkat

- Comparision PDFDokumen5 halamanComparision PDFWESTAREAOPERATIONBelum ada peringkat

- Curenti de ScurtDokumen12 halamanCurenti de ScurtCornel ArageaBelum ada peringkat

- Energy Efficient TRansformersDokumen19 halamanEnergy Efficient TRansformersMahidhar TalapaneniBelum ada peringkat

- Transient Harmonic Analysis of TransformerDokumen70 halamanTransient Harmonic Analysis of TransformerAchmad SetiawanBelum ada peringkat

- Harmonic Comparison Between Fluorescent and WOLED (White Organic LED) LampsDokumen6 halamanHarmonic Comparison Between Fluorescent and WOLED (White Organic LED) LampsHari MaghfirohBelum ada peringkat

- 07 TT 02 ElectromagneticDokumen4 halaman07 TT 02 ElectromagneticAzad RahmanBelum ada peringkat

- Unit Iv Harmonics (9) : A A DFDokumen15 halamanUnit Iv Harmonics (9) : A A DFkavyaBelum ada peringkat

- Hall EffectDokumen14 halamanHall EffectAvinash Kumar GuptaBelum ada peringkat

- CT - Residual CT - Effect of HarmonicDokumen4 halamanCT - Residual CT - Effect of HarmonicSandeep PartiBelum ada peringkat

- (Metrology and Measurement Systems) Power System Frequency Estimation Algorithm For Electric Energy Metering of Nonlinear LoadsDokumen14 halaman(Metrology and Measurement Systems) Power System Frequency Estimation Algorithm For Electric Energy Metering of Nonlinear LoadsABMOHEBelum ada peringkat

- Study O - F The Harmonics On Measljrments of The Energy MetersDokumen4 halamanStudy O - F The Harmonics On Measljrments of The Energy Metersdheny3007Belum ada peringkat

- V14i1 14Dokumen10 halamanV14i1 14alimaghamiBelum ada peringkat

- Glossary: W W (M JM ) (Ohm)Dokumen1 halamanGlossary: W W (M JM ) (Ohm)Jarmar38Belum ada peringkat

- 2 - BP Machine 3Dokumen113 halaman2 - BP Machine 3DGAFBelum ada peringkat

- Transformer Differential ProtectionDokumen21 halamanTransformer Differential ProtectionMian QadeerBelum ada peringkat

- Acoustic Streaming in A Microchannel Cross SectionDokumen10 halamanAcoustic Streaming in A Microchannel Cross SectionNilanjan ChandraBelum ada peringkat

- Three Phase Shunt Hybrid Filters For The Current Harmonics Suppression and The Reactive Power CompensationDokumen11 halamanThree Phase Shunt Hybrid Filters For The Current Harmonics Suppression and The Reactive Power CompensationHemanth Kumar RajendakumarBelum ada peringkat

- Fourier Analysis For Harmonic Signals in Electrica-1Dokumen29 halamanFourier Analysis For Harmonic Signals in Electrica-1القاهر RBelum ada peringkat

- Harmonics in Power System - Electrical India Magazine On Power & Electrical Products, Renewable Energy, Transformers, Switchgear & CablesDokumen9 halamanHarmonics in Power System - Electrical India Magazine On Power & Electrical Products, Renewable Energy, Transformers, Switchgear & CablesMohammad HamamdBelum ada peringkat

- Paper ISEEE 2013 NepublicatDokumen6 halamanPaper ISEEE 2013 NepublicatCornel ArageaBelum ada peringkat

- Review of Distinguishing Schemes For Pow PDFDokumen8 halamanReview of Distinguishing Schemes For Pow PDFDante FilhoBelum ada peringkat

- Optimum Magnetic DesignDokumen30 halamanOptimum Magnetic DesignGuru Prasad ReddyBelum ada peringkat

- CH1Dokumen37 halamanCH1ffffff100% (6)

- Derating of Distribution Transformers For Non-Sinusoidal Load Currents Using Finite Element MethodDokumen9 halamanDerating of Distribution Transformers For Non-Sinusoidal Load Currents Using Finite Element MethodGheorghiu_Cristian_KBelum ada peringkat

- 3 - 2a Transformer Energization - TheoryDokumen5 halaman3 - 2a Transformer Energization - TheoryistenicBelum ada peringkat

- Energy Conversion Lab 1Dokumen3 halamanEnergy Conversion Lab 1Mohammad HossainBelum ada peringkat

- Total Harmonic Distortion (THD) Analysis inDokumen10 halamanTotal Harmonic Distortion (THD) Analysis inAditya VijayBelum ada peringkat

- The Effect of Amplitude Modulation Index and FrequDokumen7 halamanThe Effect of Amplitude Modulation Index and FrequsilpaBelum ada peringkat

- EE-101 (Unit-3)Dokumen83 halamanEE-101 (Unit-3)Chauhan AyushmaanBelum ada peringkat

- General Application Note DDLM014 Rev ADokumen18 halamanGeneral Application Note DDLM014 Rev ALammie Sing Yew LamBelum ada peringkat

- Harmonic Rovisp 2021Dokumen6 halamanHarmonic Rovisp 2021AmalinaAbdullahBelum ada peringkat

- Energy Conversion I: EET1016 (2010) Chapter-1: Mechanical Energy Electrical Energy Motor Generaotr Electrical EnergyDokumen14 halamanEnergy Conversion I: EET1016 (2010) Chapter-1: Mechanical Energy Electrical Energy Motor Generaotr Electrical EnergybitshitassBelum ada peringkat

- Keshav AryanDokumen11 halamanKeshav AryanKeshav AryanBelum ada peringkat

- E3sconf Issat2024 01007Dokumen9 halamanE3sconf Issat2024 01007Defrianto PratamaBelum ada peringkat

- Power Sytem Quality and ReliabilityDokumen7 halamanPower Sytem Quality and ReliabilityKGBelum ada peringkat

- Calculation of Power Transformer Losses by Finite Element MethodDokumen4 halamanCalculation of Power Transformer Losses by Finite Element MethodVictor Julián Fernández CarrazanaBelum ada peringkat

- 4 - Verification Methode Calcul K Factor 50kva Reference Exemple CalculDokumen9 halaman4 - Verification Methode Calcul K Factor 50kva Reference Exemple CalculMoulay m'hammed LOUKILIBelum ada peringkat

- Total Harmonic Distortion and Effects in Electrical Power SystemsDokumen5 halamanTotal Harmonic Distortion and Effects in Electrical Power Systemsshiv ranaBelum ada peringkat

- PQ Unit-Iv PDFDokumen15 halamanPQ Unit-Iv PDFramyadspBelum ada peringkat

- Project 1Dokumen7 halamanProject 1Sanjay YadavBelum ada peringkat

- 201asdfsdavvdfsdfs BDokumen12 halaman201asdfsdavvdfsdfs BSreedhar ThiruvalliBelum ada peringkat

- Archive of SID: Derating of Distribution Transformers For Non-Sinusoidal Load Currents Using Finite Element MethodDokumen8 halamanArchive of SID: Derating of Distribution Transformers For Non-Sinusoidal Load Currents Using Finite Element MethodMoulay m'hammed LOUKILIBelum ada peringkat

- Chapter 1 MACHINESDokumen30 halamanChapter 1 MACHINESalia khanBelum ada peringkat

- Eidlitz Unknown IndiaDokumen108 halamanEidlitz Unknown IndiavdaBelum ada peringkat

- The Nectar of Instruction Text ONEDokumen2 halamanThe Nectar of Instruction Text ONEvdaBelum ada peringkat

- ApplicationNote UsingThe50a 3phForRelayTestingDokumen7 halamanApplicationNote UsingThe50a 3phForRelayTestingManish SonowaneBelum ada peringkat

- BBG Train (Helium Carrier) : Typical Settings (Individual Analyzers May Vary)Dokumen4 halamanBBG Train (Helium Carrier) : Typical Settings (Individual Analyzers May Vary)vdaBelum ada peringkat

- BCJ/BCP Train (Nitrogen Carrier) : BCJ Train Typical Settings (Individual Analyzers May Vary)Dokumen2 halamanBCJ/BCP Train (Nitrogen Carrier) : BCJ Train Typical Settings (Individual Analyzers May Vary)vdaBelum ada peringkat

- BCF Train (Hydrogen Carrier) : N2 C1 C3+ VentDokumen2 halamanBCF Train (Hydrogen Carrier) : N2 C1 C3+ VentvdaBelum ada peringkat

- BCT (C6+) One Minute Train (Helium Carrier) : Typical Settings (Individual Analyzers May Vary)Dokumen2 halamanBCT (C6+) One Minute Train (Helium Carrier) : Typical Settings (Individual Analyzers May Vary)vdaBelum ada peringkat

- Ds Tbx5-En eDokumen24 halamanDs Tbx5-En evdaBelum ada peringkat

- M NacDokumen34 halamanM NacvdaBelum ada peringkat

- Welltell Wireless Io Start-Up Guide: Measurement & Control SystemsDokumen20 halamanWelltell Wireless Io Start-Up Guide: Measurement & Control SystemsvdaBelum ada peringkat

- Iff Pac 2011Dokumen13 halamanIff Pac 2011vdaBelum ada peringkat

- Project Oxhydroelectric Effect Procedure and Apparatus To Extract Electric Energy From WaterDokumen11 halamanProject Oxhydroelectric Effect Procedure and Apparatus To Extract Electric Energy From WaterFrancesco Paolo TuccinardiBelum ada peringkat

- NOM 003 SCFI 2014 Electrical Products Safety RequirementsDokumen6 halamanNOM 003 SCFI 2014 Electrical Products Safety Requirements2357131270Belum ada peringkat

- 02 - Utilizing Possibilities of IEC 61850 and GOOSEDokumen4 halaman02 - Utilizing Possibilities of IEC 61850 and GOOSEChristian Arias VegaBelum ada peringkat

- HC SR04 Ultrasonic Sensor: Elijah J. Morgan Nov. 16 2014Dokumen6 halamanHC SR04 Ultrasonic Sensor: Elijah J. Morgan Nov. 16 2014Kishalay DharBelum ada peringkat

- PFC Boost DesignDokumen13 halamanPFC Boost DesignAnonymous 4intki5Belum ada peringkat

- Speed Control of DC Motor Using PID Algorithm (STM32F4) : InstructablesDokumen10 halamanSpeed Control of DC Motor Using PID Algorithm (STM32F4) : InstructablespedroBelum ada peringkat

- 74LS83 PDFDokumen5 halaman74LS83 PDFKeertanaBelum ada peringkat

- Audio Opamps, Fact, No Myths and THD Measurement ResultsDokumen19 halamanAudio Opamps, Fact, No Myths and THD Measurement ResultsRogerio FerreiraBelum ada peringkat

- Intellimod™ Module PS21765: Powerex, Inc., 173 Pavilion Lane, Youngwood, Pennsylvania 15697 (724) 925-7272Dokumen9 halamanIntellimod™ Module PS21765: Powerex, Inc., 173 Pavilion Lane, Youngwood, Pennsylvania 15697 (724) 925-7272FebriBelum ada peringkat

- Assembly and Parts Album: KDE12EA/EA3Dokumen1 halamanAssembly and Parts Album: KDE12EA/EA3Duvan Garridt MillanBelum ada peringkat

- Technical Guidelines On Charging Facilities For Electric VehiclesDokumen12 halamanTechnical Guidelines On Charging Facilities For Electric VehiclesdavidwongBelum ada peringkat

- DF005S - DF10S: 1.0A Surface Mount Glass Passivated Bridge Rectifier FeaturesDokumen2 halamanDF005S - DF10S: 1.0A Surface Mount Glass Passivated Bridge Rectifier FeaturesClaudiney BricksBelum ada peringkat

- 146Dokumen6 halaman146Božidar Filipović-GrčićBelum ada peringkat

- Ca3280, Ca3280A: Dual, 9Mhz, Operational Transconductance Amplifier (Ota) FeaturesDokumen10 halamanCa3280, Ca3280A: Dual, 9Mhz, Operational Transconductance Amplifier (Ota) FeaturesDinh Thang LeBelum ada peringkat

- DKG 171 UserDokumen2 halamanDKG 171 UserHernan JavierBelum ada peringkat

- Schams Solar Flyer MPPT-EnDokumen2 halamanSchams Solar Flyer MPPT-Enkrissn7100% (1)

- Mateable Transfer Wiring-System: For Connectors To DIN 41 612 and VG 95 324Dokumen32 halamanMateable Transfer Wiring-System: For Connectors To DIN 41 612 and VG 95 324Pușcă MartinBelum ada peringkat

- Assembly Kits For 3VA Molded Case Circuit Breakers SIVACON S4 201612151418084694Dokumen28 halamanAssembly Kits For 3VA Molded Case Circuit Breakers SIVACON S4 201612151418084694cc_bauBelum ada peringkat

- Infineon BTS7002 1EPP DataSheet v01 - 04 ENDokumen55 halamanInfineon BTS7002 1EPP DataSheet v01 - 04 ENRoger Ruben Capristan CastilloBelum ada peringkat

- 200712614185721391Dokumen25 halaman200712614185721391Vu van VuBelum ada peringkat

- Electrical - SafetyDokumen13 halamanElectrical - Safetymark darrelBelum ada peringkat

- Training Report On Thermal Power Plant (Kota Super Thermal Power Plant)Dokumen10 halamanTraining Report On Thermal Power Plant (Kota Super Thermal Power Plant)Abhishek DaveBelum ada peringkat