Pma

Diunggah oleh

karanvk0 penilaian0% menganggap dokumen ini bermanfaat (0 suara)

69 tayangan4 halamanThe appraisal forms in this PDF file are part of a Knowledge summary entitled Particular material appraisal (PMA) and the pressure equipment regulations (PER) Three forms are provided to help those faced with the task of producing a PMA: form referring to the relevant 'essential safety requirement' clauses of the PER example completed form blank form Please note that the blank form is only a suggestion and may be tailored to suit any manufacturer's system.

Deskripsi Asli:

Hak Cipta

© Attribution Non-Commercial (BY-NC)

Format Tersedia

PDF, TXT atau baca online dari Scribd

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniThe appraisal forms in this PDF file are part of a Knowledge summary entitled Particular material appraisal (PMA) and the pressure equipment regulations (PER) Three forms are provided to help those faced with the task of producing a PMA: form referring to the relevant 'essential safety requirement' clauses of the PER example completed form blank form Please note that the blank form is only a suggestion and may be tailored to suit any manufacturer's system.

Hak Cipta:

Attribution Non-Commercial (BY-NC)

Format Tersedia

Unduh sebagai PDF, TXT atau baca online dari Scribd

0 penilaian0% menganggap dokumen ini bermanfaat (0 suara)

69 tayangan4 halamanPma

Diunggah oleh

karanvkThe appraisal forms in this PDF file are part of a Knowledge summary entitled Particular material appraisal (PMA) and the pressure equipment regulations (PER) Three forms are provided to help those faced with the task of producing a PMA: form referring to the relevant 'essential safety requirement' clauses of the PER example completed form blank form Please note that the blank form is only a suggestion and may be tailored to suit any manufacturer's system.

Hak Cipta:

Attribution Non-Commercial (BY-NC)

Format Tersedia

Unduh sebagai PDF, TXT atau baca online dari Scribd

Anda di halaman 1dari 4

The appraisal forms in this PDF file

are part of a Knowledge summary entitled

Particular material appraisal (PMA) and the

pressure equipment regulations (PER)

If you wish, you can view the Knowledge summary now

___________________________________

Three forms are provided to help those faced with the task of producing a PMA:

form referring to the relevant 'essential safety requirement' clauses of the PER

example completed form

blank form

Please note that the blank form is only a suggestion and may be tailored to suit any

manufacturers system. For example, by the addition of contract numbers, noting the

documents within the QA system that may need to be referred to, etc.

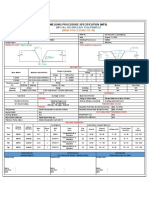

PARTICULAR MATERIAL APPRAISAL FORM

Essential Safety Requirements and Relevant Clause Numbers

Material Specification Supply Condition

Application

Equipment Type Equipment Description Fluid Service Category

Article 1 cl. 2.1.1, 2.1.2, 2.1.3, 2.1.4, 2.1.5 Article 9 cl 2.1

and 2.2

Annex II cl 1,2,3,4. And

Tables 1 to 9 inclusive.

Service

Conditions

Max Allowable Pressure Allowable Temperature

Range

Corrosion Control Formability

Annex 1 cl. 2.2.1 Annex 1 cl 2.2.1 Annex 1 cl 4.1(b) Annex 1 cl 3.1.1 and cl

4.1(d)

Weldability Heat Treatment Ageing Sensitivity

Annex 1 cl 4.1(d) Annex 1 cl 3.1.4

and cl 4.1(d)

Annex 1 cl 4.1( c )

Properties

Material Specification Reqts. Application Requirements Comments

Yield/ProofStrength Re Ambient Annex 1 cl 4.1(a) and cl

7.1.1

Tensile Strength Rm Ambient Annex 1 cl 4.1(a) and cl

7.1.1

Yield/ProofStrength Re Design Temp Annex 1 cl 4.1(a) and cl

7.1.2

Tensile Strength Rm Design Temperature Annex 1 cl 4.1(a) and cl

7.1.2

Ductility Annex 1 cl 4.1(a)and cl 7.5

Toughness Impact Tests Annex 1 cl 4.1(a) and cl

7.5

Toughness Fracture Toughness Tests Annex 1 cl 4.1(a)

Joint Properties Annex 1 cl 4 para 2

Proof of

Conformity

Annex 1 cl 4.3

Manufacturers

Representative

Date Notified Body

Representative

Date

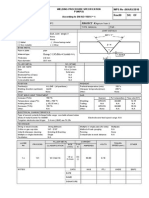

PARTICULAR MATERIAL APPRAISAL FORM

Example Completed Form

Material

Specification

BS EN 10028-3 P355NH Supply Condition NORMALISED

Application

Equipment Type Equipment Description Fluid Service Category

PRESSURE VESSEL TWI TYPE 343/12 HEAT

EXCHANGER

GAS Gp1 IV

Service

Conditions

Max Allowable Pressure Allowable Temperature

Range

Corrosion Control Formability

75 barg -40/350deg C 3mm allowance acceptable

Weldability Heat Treatment Ageing Sensitivity

weldable PWHT at 580-620

deg C

not sensitive

Properties

Material Specification Reqts. Application Requirements Comments

Yield/ProofStrengt

h Re Ambient

325 N/mm

2

min as material spec

Tensile Strength

Rm Ambient

490 N/mm

2

min as material spec

Yield/ProofStrengt

h Re Design Temp

196 N/mm

2

min as material spec

Tensile Strength Rm Design Temperature not applicable

Ductility 22% min carbon steel 14% min

Toughness Impact

Tests

34J @ '-40deg C min 27J @'-40 deg C min from BS PD 5500 Annex D

Toughness Fracture Toughness Tests not applicable

Joint Properties as parent material as parent material

Proof of

Conformity

TWI Purchase Order ABC/1234 and BSES Material Test Certificate

JKL/4567

Manufacturers

Representative

Date Notified Body

Representative

Date

PARTICULAR MATERIAL APPRAISAL FORM

Material Specification Supply Condition

Application

Equipment Type Equipment Description Fluid Service Category

Service

Conditions

Max Allowable Pressure Allowable Temperature

Range

Corrosion Control Formability

Weldability Heat Treatment Ageing Sensitivity

Properties

Material Specification Reqts. Application Requirements Comments

Yield/Proof Strength Re Ambient

Tensile Strength Rm Ambient

Yield/Proof Strength Re Design Temp

Tensile Strength Rm Design Temperature

Ductility

Toughness Impact Tests

Toughness Fracture Toughness Tests

Joint Properties

Proof of

Conformity

Manufacturers

Representative

Date Notified Body

Representative

Date

Anda mungkin juga menyukai

- Ped Eam-0526-24-1-2006-03Dokumen6 halamanPed Eam-0526-24-1-2006-03nathachaiBelum ada peringkat

- Particular Material Appraisal (PMA) FormDokumen2 halamanParticular Material Appraisal (PMA) FormEsapermana Riyan75% (4)

- CSNT, Not Impact Tested: Particular Material AppraisalDokumen1 halamanCSNT, Not Impact Tested: Particular Material AppraisaldgardelBelum ada peringkat

- Sample Welding Procedure Specification (WPS) : Joints (See 4.13.1)Dokumen2 halamanSample Welding Procedure Specification (WPS) : Joints (See 4.13.1)muadzBelum ada peringkat

- GTL WPSDokumen6 halamanGTL WPSYoucef ChorfaBelum ada peringkat

- Particular Material Appraisal (PMA) Doc #001: Property Requirement ComplianceDokumen1 halamanParticular Material Appraisal (PMA) Doc #001: Property Requirement ComplianceIzzet BozkurtBelum ada peringkat

- NoticeDokumen1 halamanNoticeAnirban Sen SharmaBelum ada peringkat

- Agoco Welding Procedure Specification: Gtaw/Smaw Manual JOINTS (QW-402)Dokumen3 halamanAgoco Welding Procedure Specification: Gtaw/Smaw Manual JOINTS (QW-402)Anonymous 7vljJzHBelum ada peringkat

- List of Questions EN 13445 - 2014 PDFDokumen14 halamanList of Questions EN 13445 - 2014 PDFwindsurferke007Belum ada peringkat

- BPVC Ix QW-482Dokumen2 halamanBPVC Ix QW-482ganesh82Belum ada peringkat

- Comparaison en 10253-4 Et DinDokumen32 halamanComparaison en 10253-4 Et Dinodaue100% (2)

- En 13445 WPS PQR WPQDokumen5 halamanEn 13445 WPS PQR WPQmuhammad hadiBelum ada peringkat

- En 764-4-2002Dokumen44 halamanEn 764-4-2002Marija IvanovskaBelum ada peringkat

- Form Qw-482 Suggested Format For Welding Procedure Specifications (WPS) (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)Dokumen2 halamanForm Qw-482 Suggested Format For Welding Procedure Specifications (WPS) (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)mohammadBelum ada peringkat

- P91 MaterialDokumen15 halamanP91 MaterialelrajilBelum ada peringkat

- Wps MainlineDokumen5 halamanWps MainlineAlfian FebriansyahBelum ada peringkat

- QCF312 WPQRDokumen2 halamanQCF312 WPQRminhnnBelum ada peringkat

- WPS Indosol 001 (ASME) RDokumen2 halamanWPS Indosol 001 (ASME) RDoni HardiBelum ada peringkat

- Multi Process Welding Procedures QW200.4 (ASME IX)Dokumen1 halamanMulti Process Welding Procedures QW200.4 (ASME IX)HoangBelum ada peringkat

- Ami-001 WPSDokumen2 halamanAmi-001 WPSPramod Athiyarathu100% (1)

- TDC-10A Rev 3 Upgradation by Welding of C12A Steel CastingsDokumen3 halamanTDC-10A Rev 3 Upgradation by Welding of C12A Steel CastingsGohilakrishnan ThiagarajanBelum ada peringkat

- QW-483 BlankDokumen2 halamanQW-483 BlankCraftyBob100% (1)

- Wps For Aluminium WeldingDokumen8 halamanWps For Aluminium WeldingMohammed MusaBelum ada peringkat

- Pressure Test in Accordance With The Standard Din en 13445: Inspecta GroupDokumen14 halamanPressure Test in Accordance With The Standard Din en 13445: Inspecta GroupNanang PhBelum ada peringkat

- Pwps 06Dokumen1 halamanPwps 06eldobie3Belum ada peringkat

- ITP-format For VesselsDokumen5 halamanITP-format For VesselsHanuman RaoBelum ada peringkat

- Name:Murat First Name (S) : WPQ N°: TUR-18-A-931: Essential Variables (QW - 350) Actual Values Qualified Ranges QWDokumen2 halamanName:Murat First Name (S) : WPQ N°: TUR-18-A-931: Essential Variables (QW - 350) Actual Values Qualified Ranges QWSabit CirdiBelum ada peringkat

- TDC 1150Dokumen3 halamanTDC 1150shazanBelum ada peringkat

- Wps Sp14 Reva PDFDokumen9 halamanWps Sp14 Reva PDFravi00098Belum ada peringkat

- List of Questions EN 13445 - 2014Dokumen11 halamanList of Questions EN 13445 - 2014kamal615Belum ada peringkat

- Guide On PMA Per PED PDFDokumen6 halamanGuide On PMA Per PED PDFJean-Noël LerouxBelum ada peringkat

- QW 483Dokumen2 halamanQW 483delta lab sangliBelum ada peringkat

- Piping Module - 3, ASME B31.3Dokumen2 halamanPiping Module - 3, ASME B31.3RAGHVENDRA PRATAP SINGHBelum ada peringkat

- PED - 2014-68-EU - Guidelines - EN - v6.0 Part 2Dokumen124 halamanPED - 2014-68-EU - Guidelines - EN - v6.0 Part 2KailasBelum ada peringkat

- Tube-To-Tube Sheet Joint RequirementsDokumen2 halamanTube-To-Tube Sheet Joint RequirementsWaqas WaqasBelum ada peringkat

- QW-482 WPS FormatDokumen2 halamanQW-482 WPS FormatMardeOpamen100% (1)

- WPQ WeldCanada PDFDokumen1 halamanWPQ WeldCanada PDFAhmad DanielBelum ada peringkat

- Qw-482 Suggested Format For Welding Procedure Specifications (WPS) (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)Dokumen8 halamanQw-482 Suggested Format For Welding Procedure Specifications (WPS) (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)Muhammad HannanBelum ada peringkat

- PQRDokumen3 halamanPQRnazirulhakimBelum ada peringkat

- Pressure Vessel Inspection ReportDokumen34 halamanPressure Vessel Inspection ReportJinlong SuBelum ada peringkat

- 1035 03Dokumen2 halaman1035 03Anuj ShahiBelum ada peringkat

- Wps GT 9b Cvn90 Rev 1 PDFDokumen6 halamanWps GT 9b Cvn90 Rev 1 PDFM. Zaki RahmaniBelum ada peringkat

- List of en Standards: SR No Code/Standard DescriptionDokumen4 halamanList of en Standards: SR No Code/Standard DescriptionAnilBelum ada peringkat

- En 10025-2-2004 BS HotRolledProductDokumen7 halamanEn 10025-2-2004 BS HotRolledProductChrill DsilvaBelum ada peringkat

- 2019-5 TechPresentation BeachDokumen141 halaman2019-5 TechPresentation Beachaneeshta100% (1)

- WPS & PQR (E Co Cr-E)Dokumen3 halamanWPS & PQR (E Co Cr-E)HossamSAshourBelum ada peringkat

- Definition of Buttering From ASME Section IXDokumen2 halamanDefinition of Buttering From ASME Section IXsanket100% (3)

- MDR Form A-1Dokumen2 halamanMDR Form A-1Yuvraj ThoratBelum ada peringkat

- N0200003 - NEW-F201-0 - Inspection & Test PlanDokumen3 halamanN0200003 - NEW-F201-0 - Inspection & Test PlanAfiq RamliBelum ada peringkat

- Welder List: 18 Juni 2017Dokumen4 halamanWelder List: 18 Juni 2017Ijo QueenBelum ada peringkat

- Spectacle Blind FlangeDokumen3 halamanSpectacle Blind Flangel kishoreBelum ada peringkat

- Technics Offshore Engineering Pte LTD: Material & Weld Traceability RecordDokumen17 halamanTechnics Offshore Engineering Pte LTD: Material & Weld Traceability RecordHanuman RaoBelum ada peringkat

- Clad PQRDokumen5 halamanClad PQRRinshadBelum ada peringkat

- Pe 03 28 Guiding Principles For The Content of Pma - en PDFDokumen5 halamanPe 03 28 Guiding Principles For The Content of Pma - en PDFGentelmanOnlyBelum ada peringkat

- Guide Ped AssemblyDokumen4 halamanGuide Ped AssemblyEduardo DepiattiBelum ada peringkat

- Responsibilities For Assessment of Materials: Unit 11Dokumen6 halamanResponsibilities For Assessment of Materials: Unit 11JorgeBelum ada peringkat

- PE-03-28-Rev.5 Guiding Principles For The Contents of PMADokumen5 halamanPE-03-28-Rev.5 Guiding Principles For The Contents of PMAbartolomeperezBelum ada peringkat

- Code & Standard For ASME U & Stamp.Dokumen21 halamanCode & Standard For ASME U & Stamp.Md Anamul HoqueBelum ada peringkat

- Passivation Criteria For NadCAPDokumen49 halamanPassivation Criteria For NadCAPSounak BanerjeeBelum ada peringkat

- Flow Measurement StandardDokumen26 halamanFlow Measurement StandardDeborah MalanumBelum ada peringkat