Hydrodynamic slug modeling

Diunggah oleh

fanziskusJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Hydrodynamic slug modeling

Diunggah oleh

fanziskusHak Cipta:

Format Tersedia

Lagrangian slug ow modeling and sensitivity on hydrodynamic slug initiation

methods in a severe slugging case

T.K. Kjeldby

a,

, R.A.W.M. Henkes

b

, O.J. Nydal

a

a

Norwegian University of Science and Technology, Department of Energy and Process Engineering, Kolbjrn Hejes vei 1B, 7491 Trondheim, Norway

b

Delft University of Technology, Laboratory for Aero and Hydrodynamics, Leeghwaterstraat 21, 2628 CA Delft, The Netherlands

a r t i c l e i n f o

Article history:

Received 12 July 2012

Received in revised form 11 January 2013

Accepted 15 January 2013

Available online 8 February 2013

Keywords:

Two-phase ow

Severe slugging

Slug tracking

Two-uid model

Slug capturing

Slug ow

a b s t r a c t

Severe slugging is a dynamic two-phase ow phenomenon with regular liquid accumulation and blow-

out in ow-line riser geometries. This paper discusses the applicability of a slug tracking model on a case

where hydrodynamic slug initiation in a horizontal part of the pipeline upstream the riser base affects the

severe slugging cycle period. The given experimental case is from the Shell laboratories in Amsterdam:

airwater ow in a 100 m long pipe (65 m horizontal and 35 m 2.54 downwards) followed by a

15 m long vertical riser.

A Lagrangian slug and bubble tracking model is described. A two-uid model is applied in the bubble

region and the slug region is treated as incompressible ow, with an integral momentum equation. Slug

initiation from unstable stratied ow can be captured directly by solving the two-uid model on a ne

grid (a hybrid capturing and tracking scheme). Alternatively, slug initiation can be made from sub grid

models, allowing for larger grid sizes. The sub grid models are based on the two established ow regime

transition criteria derived from the stability of stratied ow and from the limiting solution of the unit

cell slug ow model.

Sensitivity studies on hydrodynamic slug initiation models on the severe slugging characteristics are

presented. No hydrodynamic slug initiation (e.g. large grid size in the capturing scheme) overestimates

the severe slug period compared with the experiments. Slug capturing and sub grid initiation models

both give good predictions for small grid sizes (provided the detailed inlet conguration is included in

the capturing case). Good predictions are also shown for larger grid sizes (factor of 50) and sub grid ini-

tiation models.

The numerical tests show that correct prediction of the severe slugging cycle is sensitive to the initia-

tion of upstream hydrodynamic slugs, but less sensitive to the local structure of the slug ow (frequencies

and lengths) in the upstream region.

2013 Elsevier Ltd. All rights reserved.

1. Introduction

The slug ow regime occurs in a wide range of industrial mul-

tiphase pipe ow applications. Slug ow represents a particular

challenge in the oil and gas industry where large scale ow insta-

bilities may occur in pipeline-riser systems.

The modeling of slug ow may be approached on different time

and length scales. A common procedure is to solve the two-uid

equations (mass and momentum conservation equations for each

phase) on an Eulerian grid. This is a procedure typically used by

nuclear safety codes like CATHARE and RELAP (Bestion, 1990;

Umminger et al., 2002), as well as by oil and gas pipeline simula-

tors like OLGA (Bendiksen et al., 1991).

Small scale slug ow is then treated as an averaged ow

whereas the large scale severe slug ow phenomenon is captured

by the two-uid model. This gives a computationally efcient

model, but requires implementation of averaged hydrodynamic

slug ow models and criteria for ow regime transitions from

stratied ow.

Some studies have demonstrated the capability of the two-uid

model to also resolve small scale slug ow, without the need for

transition models (Issa and Kempf, 2003; Bonizzi et al., 2009).

These slug capturing methods rely on a ne grid spacing to resolve

the sharp discontinuities in holdup at bubble noses and slug fronts.

One way of reducing the need for a ne grid spacing when a sta-

tionary grid is utilized is to apply higher order mass-and momen-

tum ux functions (see Fltten, 2003; Wangensteen, 2010; Loilier

et al., 2005).

Another approach is to formulate a Lagrangian model. This al-

lows for tracking of fronts with a moving grid and elimination of

0301-9322/$ - see front matter 2013 Elsevier Ltd. All rights reserved.

http://dx.doi.org/10.1016/j.ijmultiphaseow.2013.01.002

Corresponding author. Tel.: +47 98646395.

E-mail address: tor.kjeldby@ntnu.no (T.K. Kjeldby).

International Journal of Multiphase Flow 53 (2013) 2939

Contents lists available at SciVerse ScienceDirect

International Journal of Multiphase Flow

j our nal homepage: www. el sevi er . com/ l ocat e/ i j mul ow

numerical diffusion at discontinuities. Such concepts have been

tested with different discretization and solution procedures (Nydal

and Banerjee, 1996; Leebeeck and Nydal, 2010; Renault, 2007;

Kjls, 2007).

The slug tracking model version by Kjls (2007) is extended

here, and applied as a computational framework to investigate

the coupling of the initiation of hydrodynamic slugs and severe

slugging cycles as observed experimentally.

2. The model

The discretization of the governing conservation equations is

implemented in terms of a hybrid two-uid and slug tracking mod-

el formulation. The object oriented design is illustrated in Fig. 1,

where the computational objects are referred to as borders, sec-

tions and units. A section can either be a bubble or a slug, while

a unit consists of a list of sections of equal type. Two sections are

always separated by a border, which can either be stationary or

moving. The computational grid is shown in Fig. 2.

In bubble sections the full two-uid model is solved. A slug unit

is assumed to be incompressible, which allows for the application

of a single momentum balance over each slug unit.

The mass balance for phase k is obtained by integration over the

section control volume:

d

dt

_

V

k;J

q

k

dV

_

L

J

@q

k

u

k

u

b

@x

A

k

dx

_

M

s

k;J

1

Here, q denotes density, u velocity, A cross section area and V vol-

ume. The term

_

M

s

k

is a possible mass source. The border velocity

is denoted as u

b

. Mass balances are solved for all sections in the

pipe. The mass balances are discretized by the upwind donor cell

principle and they are integrated implicitly in time.

The pressure equation is written as:

@p

J

@t

k

@q

k;J

@p

V

k;J

q

k;J

_ _

@V

J

@t

k

1

q

k;J

_

L

J

@q

k

u

k

u

b

@x

A

k

dx

_ _

k

_

M

s

k;J

q

k;J

_ _

2

This equation is obtained by adding the mass conservation equa-

tions for each phase and by expanding the time derivative term

by the product rule together with the introduction of an equation

of state for the gas. The pressure equation is solved for all bubble

sections. The pressure in a slug section is not a computational var-

iable, but it follows from the computed frictional and gravitational

contributions along the slug unit.

The momentum equation for phase k is obtained by integration

of the momentum balance over the momentum control volume j:

d

dt

_

V

k;j

q

k

u

k

dV

_

L

j

@q

k

u

k

u

k

u

b

@x

A

k

dx

_

V

k;j

@p

@x

dV

_

V

k;j

q

k

g cos h

@h

k

@x

dV

_

V

k;j

s

k

S

k

A

k

dV

_

V

k;j

s

i

S

i

A

k

dV

_

V

k;j

q

k

g sinhdV 3

The pipe inclination is given by h and the height of the liquid lm is

given by h

l

. The gravitational acceleration is denoted by g. This

momentum control volume is staggered relative to the mass bal-

ance and pressure control volume J.

The shear stress between phase k and the pipe wall is denoted

as s

k

while the interface shear stress is denoted as s

i

. The friction

factor between the wall and phase k is obtained from the Blasius

model:

k

k

0:316Re

0:25

k

4

Here, Re

k

is the Reynolds number of phase k. There are numerous

empirical expressions for the interface friction in the literature.

For test purposes, we determine k

i

as the product of an Interface

Friction Multiplier (IFM) and the gas friction factor, as shown in

Eq. (5). IFM = 1 often leads to acceptable holdup predictions for

smooth stratied ows:

k

i

IFM k

g

5

The momentum equations are solved at bubblebubble borders and

in slug units. The single momentum balance applied for each slug

unit in combination with zero gas fraction in slugs implies that

the liquid phase velocity u

l

is the same within all sections in a slug

unit, given that the pipe diameter is constant.

An important closure model is the one for the bubble nose

velocity u

b

:

u

b;j

C

0;j

u

l;j

U

0;j

6

Fig. 1. Units, sections and borders.

Fig. 2. Computational grid.

30 T.K. Kjeldby et al. / International Journal of Multiphase Flow 53 (2013) 2939

Several experimental investigations have been made to establish

empirical correlations for the distribution coefcient C

0

and for

the drift velocity U

0

, where Dumitrescu (1943) and Davies and Tay-

lor (1950) were some of the earlier ones. The coefcients by Bendik-

sen (1984) apply for all pipe angles:

C

01

1:05 0:15sin

2

h

C

02

1:2

U

0v

0:35

gD

_

sinh

U

0h

0:54

gD

_

cos h

7

C

0

C

01

U

0

U

0v

U

0h

if ju

m

j 6 u

lim

C

0

C

02

U

0

U

0v

if ju

m

j > u

lim

8

u

lim

U

0h

C

02

C

01

9

A transition to laminar ow needs to be included for more viscous

systems. To allow the model to decide whether a bubbleslug dis-

continuity is a slug front or a bubble nose, a bubble turning criterion

is needed. The criterion used in the model is that a bubble nose al-

ways travel in the direction of lower pressure. A gradual transition

relation has also been included in the model to avoid discontinuities

at the point of bubble turning.

If a slugbubble border is not a bubble nose, it is treated as a

slug front. The velocity of the slug front border is determined from

a liquid mass balance across the front as given by Eq. (10). The spa-

tial indexes are dened in Fig. 3. From the mass balance Eq. (10) a

corresponding set of slug front velocity coefcients is obtained

similar to the bubble nose coefcients given by Eq. (8):

u

b;j

A

l;J1

u

l;j1

A

l;J

u

l;J

A

l;J1

A

l;J

10

3. Experiments and simulation setup

Four experimental cases from a severe slugging experimental

facility described in Seim et al. (2011), have been compared with

simulations. The combinations of gas and liquid mass ow rates

and the corresponding supercial velocities are given in Table 1.

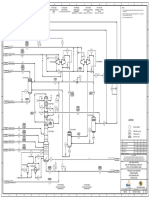

The pipeline geometry is shown in Fig. 5 which is a screenshot

from the dynamic animation of the simulation results. Thebdimen-

sions of the setup are given in Table 2. The simulation geometry

closely resembles the experimental geometry. The large diameter

pipe in the leftmost part of the conguration has been included

to simulate a 250 l air buffer tank at the inlet. This tank provides

the upstream compressibility which is needed for the severe slug-

ging cycle to occur.

The option to dene a curved pipe geometry with a bend has

been implemented in the model. This enables a continuous change

in the gravity term as slugs and bubbles pass the bend. This has

proved to be particularly useful for a numerically well behaved

bubble turning process. The curved pipe geometrical denitions

used in Table 2 are illustrated in Fig. 4.

A closed inlet and an open outlet at xed atmospheric pressure

is applied. A fully open valve is connected to the end of the riser

(PIPE 10 in Table 2). Air is supplied to the system by a gas mass

source at the inlet, while liquid enters from a liquid mass source

slightly downstream from the inlet (PIPE 2 in Table 2).

The experimental time series shown in Fig. 6a and b are the

pressure at the riser base for Case 1 and 3, respectively. Case 1

shows large variations in the pressure. There is a well dened per-

iod of severe slugging, with liquid accumulation in the riser. Case 3

shows only very small pressure variations which represent stable

ow.

The experimental pipeline is constructed from steel, which

makes visual inspection of the ow difcult. The shape of the time

series shown in Fig. 6a, however, and in particular the quick pres-

sure recovery at the location denoted (4), indicates the generation

of hydrodynamic slugs upstream of the riser base during the blow-

out. Liquid is accumulating in the horizontal part of the pipeline

(PIPE 4 in Table 2) during the severe slug build-up (1) and this li-

quid is transported to the bend during the blowout (3).

A fairly close agreement between experiment and simulation

was obtained without inclusion of the valve for Case 1. For the sta-

ble Case 3 inclusion of the valve in the model was needed in order

to obtain stable ow. Both a stratied and a mixed ow valve for-

mulation were tested.

The stratied valve model was implemented by using equiva-

lent friction factors for both phases based on a provided valve coef-

cient of C

v

= 12 [gal min

1

psi

1/2

]. This was observed to give a too

low friction for the gas phase in the two uid region, resulting in

too high gas ow through the valve and severe slugging behavior

in Case 3 where stable ow was expected.

Fig. 3. Slug front.

Table 1

Experimental cases.

Case U

sl

(m/s) U

sg

(m/s) _ m

l

kg=s _ mg kg=s Type

1 0.20 1.80 0.399225 0.004438 Severe slugging

2 0.11 0.90 0.218253 0.002216 Severe slugging

3 0.40 3.60 0.806991 0.008881 Stable ow

4 0.24 0.90 0.483247 0.002216 Severe slugging

Table 2

Simulation geometry with pipes numbered from 1 at the inlet to 10 at the outlet.

Pipe L (m) D (m) h () h

in

() h

out

() R(m)

1 7.958 0.2000 45.00

2 2.100 0.0508 45.00

3 0.157 0.0508 45.00 0.00 0.2

4 65.000 0.0508 0.00

5 35.000 0.0508 2.54

6 0.323 0.0508 2.54 90.00 0.2

7 2.500 0.0508 90.00

8 13.000 0.0450 90.00

9 0.314 0.0450 90.00 0.00 0.2

10 6.000 0.0450 0.00

Fig. 4. Curved pipe geometrical denitions.

T.K. Kjeldby et al. / International Journal of Multiphase Flow 53 (2013) 2939 31

A mixed ow valve model based on no slip with the provided

valve C

v

was observed to perform better, i.e. giving a reduced

amplitude in the pressure oscillations. Tuning of the valve coef-

cient, however, was found necessary to obtain stable ow as in

the experiments. A valve model based on the non-dimensional

pressure loss coefcient K for mixture ow assumption has been

applied. The pressure drop across the valve is then written as:

Dp

m

Kq

m

u

2

m

2

11

where q

m

and u

m

are dened as:

q

m

q

l

a

l

q

g

a

g

12

u

m

u

l

a

l

u

g

a

g

13

Fig. 5. Simulation geometry. Diameter to length ratio is exaggerated.

800 850 900 950 1000

1

1.5

2

2.5

3

x 10

5

1

2

3

4

(a) Pressure recordings for severe slugging - Case 1

800 850 900 950 1000

1

1.5

2

2.5

3

x 10

5

(b) Pressure recordings for stable ow - Case 3

Fig. 6. Experimental pressure time series at the riser base from Seim et al. (2011).

(a) 1 - Liquid column in riser is growing and pressure at riser base increases

(b) 2 - Liquid column accelerates up the riser. This gives a sudden upstream pressure drop and an increase in gas velocity

(c) 3 - The increase in gas velocity gives hydrodynamic slug initiation in the upstream horizontal pipe

(d) 4 - Rapid pressure recovery at riser base due to arrival of hydrodynamic slugs which increase hydrostatic pressure as

they propagate into the vertical riser

Fig. 7. Severe slugging inducing hydrodynamic slug initiation. Diameter to length ratio is exaggerated.

32 T.K. Kjeldby et al. / International Journal of Multiphase Flow 53 (2013) 2939

The volume fraction of phase k is here given as a

k

. This pressure

drop is set equal to the pressure drop of each phase k in the two-

uid model:

Dp

k

q

k

k

k

u

2

k

S

k

8A

k

Dx 14

Here, A

k

is the cross section area and S

k

the wetted perimeter of

phase k. Eqs. (11) and (14) then gives the friction factor for a pipe

section of length Dx to which the valve is connected:

k

k

q

m

u

2

m

4A

k

K

q

k

u

2

k

S

k

Dx

15

To approach no-slip conditions in a pipe segment with a valve, the

interface friction factor is set to a high value:

k

i

1000 k

g

16

A pressure loss coefcient K = 136 was found to give good results for

both Case 1 and Case 3, see Fig. 9 and Fig. 13. Fig. 7 contains a set of

screenshots from the Case 1 simulation showing the different stages

of the severe slugging cycle. The numbers given in the gure cap-

tions are comparable with the numbers shown in Fig. 6a.

4. Slug initiation models

The capability of slug capturing models to initiate hydrody-

namic slugs directly from the two-uid model has been demon-

strated by Issa and Kempf (2003) and Bonizzi et al. (2009) as

well as by others. This approach requires the application of a very

ne grid. If a coarse grid is applied, these small scale ow dynamics

are not resolved and sub-grid slug initiation models must be ap-

plied. Two such slug initiation models are tested in this study:

One is based on the instability of stratied ow and the other on

the existence of slug ow.

The initial length of a slug created by one of the models is de-

noted as L

init

, while the minimum slug length needed to survive

during a simulation is set to 1D. Slugs shorter than this length

are removed and their liquid is redistributed across neighboring

bubble sections.

4.1. Hydrodynamic slug initiation at the stratied ow stability limit

The Stratied Stability criterion, from now on indicated as SS, is

derived from a stability analysis of the two-uid model (see among

others Barnea and Taitel (1993)), and it is given by Eq. (17):

q

l

q

g

g cos h

A

l

q

l

@A

l

@h

l

A

g

q

g

@Ag

@hg

_

_

_

_

u

g

u

l

2

> 0 17

Utilizing

@Ag

@hg

@A

l

@h

l

;

@A

l

@a

l

A and

@h

l

@a

l

@h

l

@b

l

@b

l

@a

l

together with a relation for

wetted angle b

l

derived by Biberg (2005)

b

l

pa

l

3p

2

_ _

1=3

1 2a

l

a

1=3

l

a

1=3

g

_ _

18

and the denition of stratied liquid height h

l

h

l

D

2

1 cos b

l

19

gives the slug initiation criterion depending on the wetted angle.

q

l

q

g

g cos h

a

l

q

l

a

g

q

g

_ _

@h

l

@b

l

@b

l

@a

l

> u

g

u

l

2

20

A hydrodynamic slug is created when this relation is satised. The

geometrical relations are shown in Fig. 8.

4.2. Hydrodynamic slug initiation at the slug existence limit

Another model used to predict the transition from stratied to

hydrodynamic slug ow is the Slug Existence criterion, from now

on termed SE. This criterion was derived by Bendiksen and Espedal

(1992) and is equivalent to the limiting solution of the unit-cell

slug ow model, when the slug fraction is zero. In our case of no

gas entrainment into the liquid slug, a hydrodynamic slug is cre-

ated when the following is satised:

u

g

> u

b

21

Here, u

m

is the local mixture velocity, u

b

is the slug bubble velocity

and u

g

the stratied ow gas velocity.

u

b

C

o

u

m

U

o

22

5. Selected time series

Experimental and simulated time series for Case 1, 2, 3 and 4

are presented in Figs. 913. The base case simulation parameters

are:

Hydrodynamic slug initiation from SE (Slug Existence criterion)

activated in the horizontal part of the pipeline (PIPE 4 in

Table 2), L

init

= 2D.

Interface friction multiplier, IFM = 3.

Valve coefcient, K = 136.

Inclination of inlet region (PIPE 2 in Table 2), h

2

= 45.

Inclination of horizontal part of the pipeline (PIPE 4 in Table 2),

h

4

= 0.

Comparison between the Dx = 21D and 81D time series from

Case 1 reveals small differences in shape as well as in the slugging

period. The amplitude of the local oscillations at the instant of the

pressure recovery, corresponding to (4) in Fig. 6a, however, is

slightly higher when a coarse grid is applied.

A good agreement between experiments and simulations for

the slugging cycle period, minimum pressure and maximum pres-

sure is found for both Case 1 and 2. Some larger deviation for the

slugging cycle period is observed in Case 4.

A close agreement between experiment and simulation for Case

3 was obtained by tuning of the valve coefcient K. The animation

in Fig. 14 shows the presence of short hydrodynamic slugs in the

horizontal part of the pipeline which die as they propagate into

the declining part of the pipeline.

Fig. 8. Stratied ow geometry.

T.K. Kjeldby et al. / International Journal of Multiphase Flow 53 (2013) 2939 33

6. Sensitivity analysis for Case 1 and Case 3

Sensitivity simulations were carried out to assess the effects of

slug initiation methods, interface friction, pipe angles and grid

spacing.

Some of the simulations for Case 1 give time series with a non-

constant oscillation period as shown in Fig. 15, while other simula-

tions develop into stable ow as shown in Fig. 6b. Simulations

where these characteristics are observed have been used to dene

the outer limits of the range over which the sensitivity to a variable

0 100 200 300 400 500

1

1.5

2

2.5

3

x 10

5

Fig. 9. Pressure at the riser base for Case 1, Dx = 21D.

0 100 200 300 400 500

1

1.5

2

2.5

3

x 10

5

Fig. 13. Pressure at the riser base for Case 3, Dx = 21D.

0 100 200 300 400 500

1

1.5

2

2.5

3

x 10

5

Fig. 10. Pressure at the riser base for Case 1, Dx = 81D.

0 100 200 300 400 500

1

1.5

2

2.5

3

x 10

5

Fig. 11. Pressure at the riser base for Case 2, Dx = 21D.

0 100 200 300 400 500

1

1.5

2

2.5

3

x 10

5

Fig. 12. Pressure at the riser base for Case 4, Dx = 21D.

34 T.K. Kjeldby et al. / International Journal of Multiphase Flow 53 (2013) 2939

is checked. Consequently, only simulations with constant ampli-

tude as shown in Fig. 16 have been presented in Figs. 18 and 20.

The standard simulation settings listed in Section 5 are applied.

The parameter to which sensitivity is checked is stated explicitly

in each sub-section.

The ow regime within PIPE 2 is not known from the experi-

ments. Only stratied ow has been found in PIPE 2 in the captur-

ing simulations.

6.1. Sensitivity to slug initiation model and bubble section grid spacing

Case 1

Hydrodynamic slugs can be formed in the horizontal pipe dur-

ing blowout of a severe slug. When a slug accelerates up into the

vertical riser, then the gas velocity increases, and hydrodynamic

slugs can be generated upstream. When a hydrodynamic slug is

formed it accelerates downstream and ushes liquid towards the

riser base. The location and time of slug initiation might thus inu-

ence on how much liquid is removed from the horizontal pipe dur-

ing each slugging cycle. This inuences the slugging cycle period.

Fig. 17 shows liquid holdup proles for the hydrodynamic slug

generation for Dx = 4.5, 21 and 161D. Each sequence of pictures

shows a staged process where the liquid level close to the inlet

of the horizontal part of the pipeline grows from low to high. Ulti-

mately a hydrodynamic slug is formed. For small Dx a distinct

hydraulic jump can be seen prior to slug initiation. At Dx = 4.5D

slug initiation is obtained directly from the two-uid model. At

Dx = 21 and 161D the grid is too large for slug capturing and slugs

are generated based on predictions made by the SS initiation

criterion.

The slug lengths grow when the grid spacing of the bubble sec-

tion is increased. This effect is due to the fact that only one slug can

be initiated in a bubble section at the time. Consequently, when a

ne grid spacing is utilized, hydrodynamic slug initiation can be

predicted by the slug initiation model in a high number of bubble

sections in the horizontal region at the same time. A similar mass

and momentum transfer in the horizontal part of the system can

however be obtained by a lower number of longer slugs. This is

why the resulting period of the severe slugging cycle, however,

hardly depends on the bubble section grid spacing, even if the

hydrodynamic slug frequency will be grid dependent.

The results presented in Fig. 18 show severe slugging cycle peri-

ods resulting from simulations where hydrodynamic slug initiation

from the SE criterion, from the SS criterion and from the two-uid

model (by slug capturing) have been compared. Hydrodynamic

slug generation directly from the two-uid model (by slug captur-

ing) is captured for a grid size Dx < = 8.5D when holdup waves

bridge the pipe. The predicted slugging period approaches the

experimental value when the grid spacing is reduced. For a grid

spacing above Dx = 8.5D hydrodynamic slug initiation is not cap-

tured by the two-uid model and the period becomes approxi-

mately 50% higher.

The two slug initiation criteria SS and SE give quite similar re-

sults for the slugging period. Both show only a minor grid depen-

dency. Based on the results given in Fig. 18, the SE model has

been chosen as the standard simulation setting.

6.2. Sensitivity to inclination of the inlet Case 1

A picture of the experimental inlet conguration is shown in

Fig. 19. Air arrives at the mixing point through a large diameter

pipe which is connected to the buffer tank, whereas water enters

via a smaller diameter pipe at an angle to the air pipe. When water

is pumped into the system at an angle it carries momentum. In the

Fig. 14. Case 3 animation. Diameter to length ratio is exaggerated.

500 600 700 800 900 1000 1100 1200 1300 1400 1500

1

1.5

2

2.5

3

x 10

5

Fig. 15. Case 1 with non-constant period during sensitivity tests.

500 600 700 800 900 1000 1100 1200 1300 1400 1500

1

1.5

2

2.5

3

x 10

5

Fig. 16. Case 1 with constant period during sensitivity tests.

T.K. Kjeldby et al. / International Journal of Multiphase Flow 53 (2013) 2939 35

simulations, momentum contributions from the sources have not

been included.

The inuence of gravity and of gas drag on the water accelerates

the water to enter the horizontal part of the pipeline with a posi-

tive velocity. Simulations show that this gives a hydraulic jump

at the inlet of the horizontal pipe, as can be seen in Fig. 17. The

velocity at which water enters the horizontal pipe inuences the

precise location where the hydraulic jump occurs. Fig. 20a shows

a sensitivity analysis of how the angle of the inlet, denoted as h

2

,

inuences the slugging period.

Simulations performed at Dx = 161D appear to be more sensi-

tive to h

2

. At this grid spacing stable ow is found when h > 25.

For simulations with the slug capturing approach it turned out

the liquid source had to be included in the declining inlet (PIPE 2 in

Table 2). An attempt was made to position the liquid source at the

inlet of the horizontal pipe (PIPE 4 in Table 2), but this resulted in

rapid lling of the nearby short sections, slug formation and severe

slugging simulations with non-constant period as shown in Fig. 15.

Fig. 17. Examples of slug initiation sequences in the horizontal part of the pipeline (PIPE 4 in Table 2). Diameter to length ratio is exaggerated.

Fig. 18. Case 1 grid dependency of the slugging period.

Fig. 19. Experimental inlet conguration from Seim et al. (2011).

36 T.K. Kjeldby et al. / International Journal of Multiphase Flow 53 (2013) 2939

Fig. 20. Case 1 sensitivity analysis results. SE denotes slug initiation from the slug existence model while SS denotes initiation at the stratied stability limit.

T.K. Kjeldby et al. / International Journal of Multiphase Flow 53 (2013) 2939 37

This illustrates the dependency of the slug capturing approach on

an accurate simulation setup.

6.3. Sensitivity to inclination of the pipe downstream of the inlet

Case 1

A sensitivity analysis of the angle of the pipe downstream of the

inlet (the horizontal PIPE 4 in Table 2), denoted as h

4

, has been per-

formed to investigate the effect on the hydrodynamic slug genera-

tion and on the overall slugging cycle period. The results are

presented in Fig. 20b. For small negative angles hydrodynamic

slugs are generated, similarly to how they are generated when

the pipe is horizontal. When the angle is decreased further, hydro-

dynamic slugs are no longer formed, and liquid ows as a stratied

layer towards the riser base, where severe slugging without hydro-

dynamic slug initiation is obtained for D x = 21D. In the absence of

hydrodynamic slugs, the slugging period of the severe slugging cy-

cle has doubled. However, for a too coarse grid spacing with

Dx = 161D stable ow is found.

At small positive angles hydrodynamic slugs are formed similar

to the conguration with the horizontal pipe. When the angle is in-

creased further, liquid fallback contributes to the formation of

hydrodynamic slugs. Now such slugs are no longer generated

exclusively by the hydrodynamic mechanism and irregular slug-

ging cycle periods are obtained. This trend is observed for both

Dx = 21D and D x = 161D.

6.4. Sensitivity on L

init

Case 1

Slugs that are created based on one of the hydrodynamic initi-

ation criteria are set up with an initial length L

init

. The results from

the sensitivity analysis of this variable obtained with the SE

and the SS slug initiation models are shown in Fig. 20c and in

20d, respectively. The severe slugging frequencies are similar for

L

init

< 6D.

6.5. Sensitivity on interface friction factor Case 1

The sensitivity on the interface friction is checked through var-

iation of the variable IFM (Interface Friction Multiplier). The results

are presented in Fig. 20e. A relatively small inuence on the results

is observed for both Dx = 21D and Dx = 161D.

6.6. Sensitivity to hydrodynamic slug initiation model and bubble

section grid spacing Case 3

The sensitivity on the grid spacing of the bubble section and on

the hydrodynamic slug initiation model is checked for Case 3 and

presented in Fig. 21. The three methods give similar results for

small grid sizes. Capturing and the SS initiation methods fail for

larger grid sizes.

The results obtained with the SS model show the characteristic

large pressure oscillations similarly to what is observed in the se-

vere slugging Case 1. SE provides an earlier hydrodynamic slug ini-

tiation than SS and slug ow upstream the riser base stabilizes the

severe slugging.

7. Conclusion

Pipeline-riser ow loop experiments for severe slugging dem-

onstrate the coupling between hydrodynamic slug initiation and

the severe slugging frequency. Liquid accumulation in a horizontal

pipe segment upstream the riser base is propagated towards the

bend during the severe slug blowout, and affects the initiation of

the next severe slug at the riser base. The case has been computa-

tionally explored with a dynamic slug tracking model with three

slug initiation methods: slug initiation from a two uid model

(slug capturing on a ne grid), from a stratied ow stability crite-

rion and from a slug existence criterion (sub grid initiation mod-

els). The different initiation models give good correspondence

with the experimental results for small grid sizes. The slug captur-

ing method naturally has to fail for increasing grid sizes whereas

the sub grid initiation models give quite similar results also at lar-

ger grid sizes. Sensitivity tests on pipe inclinations shows that for

the capturing simulations it is also important to include a detailed

representation of the inlet geometries at the point of the mixing

section.

Acknowledgements

Thanks to O. Novak (NTNU), who has made improvements to

the animation tool that helped the interpretation of the predictions

by the slugging models.

Appendix A. Supplementary data

Supplementary data associated with this article can be found, in

the online version, at http://dx.doi.org/10.1016/j.ijmultiphaseow.

2013.01.002.

References

Barnea, D., Taitel, Y., 1993. Kelvin-helmholtz stability criteria for stratied ow:

viscous versus non-viscous (inviscid) approaches. Int. J. Multiphase Flow 19 (4),

639649.

Bendiksen, K., 1984. An experimental investigation of the motion of long bubbles in

inclined tubes. Int. J. Multiphase Flow 10 (4), 467483.

Bendiksen, K., Espedal, M., 1992. Onset of slugging in horizontal gasliquid pipe

ow. Int. J. Multiphase Flow 18 (2), 237247.

Bendiksen, K., Malnes, D., Moe, R., Nuland, S., 1991. The dynamic two-uid model

OLGA: theory and application. SPE Prod. Eng., 171180.

Bestion, D., 1990. The physical closure laws in the CATHARE code. Nucl. Eng. Des.

124, 229245.

Biberg, D., 2005. Mathematical Models for Two-Phase Stratied Pipe Flow. Ph.D.

Thesis. University of Oslo.

Bonizzi, M., Andreussi, P., Banerjee, S., 2009. Flow regime independent, high

resolution multi-eld modelling of near-horizontal gasliquid ows in

pipelines. Int. J. Multiphase Flow 35 (1), 3446. Fig. 21. Case 3 grid dependency.

38 T.K. Kjeldby et al. / International Journal of Multiphase Flow 53 (2013) 2939

Davies, R.M., Taylor, G., 1950. The mechanics of large bubbles rising through

extended liquids and through liquids in tubes. Roy. Soc. Ser. A, Math. Phys. Sci.

200 (1062), 375390.

Dumitrescu, D.T., 1943. Strmung an einer luftblase im senkrechten rohr. Z. Angew.

Math. Mech 23 (3), 139149.

Fltten, T., 2003. Hybrid Flux Splitting Schemes for Numerical Resolution of Two-

Phase Flows. Ph.D. Thesis. Norwegian University of Science and Technology.

Issa, R., Kempf, M., 2003. Simulation of slug ow in horizontal and nearly

horizontal pipes with the two-uid model. Int. J. Multiphase Flow 29, 69

95.

Kjls, J., 2007. Plug Propagation in Multiphase Pipelines: Modeling and Small Scale

Experiments. Ph.D. Thesis. Norwegian University of Sceince and Technology.

Leebeeck, A.D., Nydal, O., 2010. Simulation of large amplitude waves in a slug

tracking scheme compared to roll wave experiments at high pressure. Int. J.

Multiphase Flow 36 (1), 4050.

Nydal, O., Banerjee, S., 1996. Dynamic slug tracking simulations for gasliquid ow

in pipelines. Chem. Eng. Commun., 1339.

Loilier, P., Omgba-Essama, C., Thompson, C., 2005. Numerical experiments of two-

phase ow in pipelines with a two-uid compressible model. In: 12th

International Conference on Multiphase Production Technology, Barcelona.

Renault, F., 2007. A Lagrangian Slug Capturing Scheme for GasLiquid Flows in

Pipes. Ph.D. Thesis. Norwegian University of Science and Technology.

Seim, J., van Beusekom, V., Henkes, R., Nydal, O., 2011. Experiments and modelling

for the control of riser instabilities with gas lift. In: 15th International

Conference on Multiphase Production Technology, Cannes, France.

Umminger, K., Mandl, R., Wegner, R., 2002. Restart of natural circulation in a PWR

PKL test results and s-relap5 calculations. Nucl. Eng. Des. 215 (12), 3950.

Wangensteen, T., 2010. Mixture-Slip Flux Splitting for the Numerical Computation

of 1d Two Phase Flow. Ph.D. Thesis. Norwegian University of Science and

Technology.

T.K. Kjeldby et al. / International Journal of Multiphase Flow 53 (2013) 2939 39

Anda mungkin juga menyukai

- A Comprehensive Mechanistic Model For Upward Two-Phase Flow in WellboresDokumen10 halamanA Comprehensive Mechanistic Model For Upward Two-Phase Flow in Wellboresfanziskus100% (1)

- TB KeyPerformanceEvaluation PDFDokumen2 halamanTB KeyPerformanceEvaluation PDFvcharles100% (1)

- CO2 Storage Projects in Europe Map 120919Dokumen10 halamanCO2 Storage Projects in Europe Map 120919av1986362Belum ada peringkat

- Flare Line Failure Case, What We Have LearnedDokumen20 halamanFlare Line Failure Case, What We Have LearnedNABEEL VMBelum ada peringkat

- Design of One Way SlabDokumen13 halamanDesign of One Way SlabAhmad PooladiBelum ada peringkat

- G SF 240 PDFDokumen29 halamanG SF 240 PDFAmirhosein605334Belum ada peringkat

- Piping Stress Analysis Using CAESAR II PDFDokumen37 halamanPiping Stress Analysis Using CAESAR II PDFPer Bagus HandokoBelum ada peringkat

- Gas-Liquid Flow in Slightly Inclined PipesDokumen11 halamanGas-Liquid Flow in Slightly Inclined PipesBrenda DavisBelum ada peringkat

- Evaluate Heat-Exchanger Tube Rupture Scenarios Using Dynamic Simulation PDFDokumen6 halamanEvaluate Heat-Exchanger Tube Rupture Scenarios Using Dynamic Simulation PDFZhen Kai OngBelum ada peringkat

- Dynamic Simulation LNG ProcessesDokumen4 halamanDynamic Simulation LNG ProcessessppramBelum ada peringkat

- SOP CalculationDokumen8 halamanSOP Calculationmatteo2009Belum ada peringkat

- AGA 2011 PPT Comparison of Dewpoint Methods Natural GasDokumen36 halamanAGA 2011 PPT Comparison of Dewpoint Methods Natural Gasalbert_ben13Belum ada peringkat

- Pig OlgaDokumen24 halamanPig OlgaCitlalli QuetzalcoatlBelum ada peringkat

- QuarksDokumen243 halamanQuarksManfred Manfrito100% (1)

- HP Surge ValveDokumen4 halamanHP Surge ValveVee Balaji100% (1)

- 110-Ee-420 110-VV-434 110-VV-420 110-VV-435 110-VV-430 110-Ep-425 110-CC-420Dokumen1 halaman110-Ee-420 110-VV-434 110-VV-420 110-VV-435 110-VV-430 110-Ep-425 110-CC-420DIPANKAR LALABelum ada peringkat

- SPE-171415-MS Increasing Sales Gas Output From Glycol Dehydration PlantsDokumen7 halamanSPE-171415-MS Increasing Sales Gas Output From Glycol Dehydration Plantsnguyenphuoc258Belum ada peringkat

- Sense'' Testing Combined Cycle Plants Competitive: Performance FOR IN IndustryDokumen11 halamanSense'' Testing Combined Cycle Plants Competitive: Performance FOR IN IndustryharkiranrandhawaBelum ada peringkat

- Crude Oil Pipeline Calculation PDFDokumen104 halamanCrude Oil Pipeline Calculation PDFYaserBelum ada peringkat

- Polarisation of LightDokumen8 halamanPolarisation of LightVenu Gopal100% (1)

- NewLecture8 Centrifugal CompressorsDokumen126 halamanNewLecture8 Centrifugal CompressorsKhalid Mahmood100% (1)

- Site Performance Review - Gas TurbineDokumen10 halamanSite Performance Review - Gas TurbinemishraenggBelum ada peringkat

- Beam DesignDokumen33 halamanBeam DesignstructuresBelum ada peringkat

- Norsok ST 2001Dokumen131 halamanNorsok ST 2001mamounsdBelum ada peringkat

- Api 931 Chapter 6 Dispersion of Gases PDFDokumen40 halamanApi 931 Chapter 6 Dispersion of Gases PDFArcangelo Di TanoBelum ada peringkat

- Modeling of Buried Natural Gas Pipeline Decompression: X. L. Zhou G. G. KingDokumen8 halamanModeling of Buried Natural Gas Pipeline Decompression: X. L. Zhou G. G. Kingmatrix69Belum ada peringkat

- Process Simulation of Dehydration Unit For The Comparative Analysis of Natural Gas Processing and Carbon Capture ApplicationDokumen40 halamanProcess Simulation of Dehydration Unit For The Comparative Analysis of Natural Gas Processing and Carbon Capture ApplicationeduryuBelum ada peringkat

- Matching ASC Valve Performance With Integrated Turbomachinery Control System PDFDokumen4 halamanMatching ASC Valve Performance With Integrated Turbomachinery Control System PDFfri_13th100% (1)

- An Overview of Model Predictive ControlDokumen18 halamanAn Overview of Model Predictive ControlguillermocochaBelum ada peringkat

- High-Pressure Fluid Phase Equilibria: Phenomenology and ComputationDari EverandHigh-Pressure Fluid Phase Equilibria: Phenomenology and ComputationBelum ada peringkat

- Synergi Pipeline Simulator Brochure - tcm8 59286 PDFDokumen4 halamanSynergi Pipeline Simulator Brochure - tcm8 59286 PDFAlexanderBelum ada peringkat

- Chemical Process Retrofitting and Revamping: Techniques and ApplicationsDari EverandChemical Process Retrofitting and Revamping: Techniques and ApplicationsGade Pandu RangaiahBelum ada peringkat

- Blowdown of Vessels and Pipelines: S.M. Richardson & G. SavilleDokumen15 halamanBlowdown of Vessels and Pipelines: S.M. Richardson & G. SavillefaisalmuradBelum ada peringkat

- A New Approach For Finger Storage Slug CatcherDokumen8 halamanA New Approach For Finger Storage Slug CatcherfanziskusBelum ada peringkat

- Waha3 ManualDokumen186 halamanWaha3 ManualsaifoaBelum ada peringkat

- SPE-175877-MS EOS Tuning - Comparison Between Several Valid Approaches and New RecommendationsDokumen17 halamanSPE-175877-MS EOS Tuning - Comparison Between Several Valid Approaches and New RecommendationsCamilo Benítez100% (1)

- STATOIL-Slug ControlDokumen28 halamanSTATOIL-Slug Controlviswalng100% (1)

- Brochure LNG 2019Dokumen6 halamanBrochure LNG 2019ddBelum ada peringkat

- Dynamic Depressuring PDFDokumen16 halamanDynamic Depressuring PDFAsimBelum ada peringkat

- Slug Catcher Conceptual DesignDokumen8 halamanSlug Catcher Conceptual Designfanziskus100% (1)

- Validation of OLGA HD BHR-2015-G4Dokumen17 halamanValidation of OLGA HD BHR-2015-G4kwonilBelum ada peringkat

- Spe 194597 MS PDFDokumen17 halamanSpe 194597 MS PDFMANISH GUPTABelum ada peringkat

- The Physical Behaviour of Crude Oil Influencing Its Carriage by Sea (CRUCOGSA) The Final Report Upon A Research ProgrammeDokumen2 halamanThe Physical Behaviour of Crude Oil Influencing Its Carriage by Sea (CRUCOGSA) The Final Report Upon A Research ProgrammelostnfndBelum ada peringkat

- Orbit Article Molecular Sieve Dehydration Switching ValvesDokumen12 halamanOrbit Article Molecular Sieve Dehydration Switching ValvesPasquale Sessa0% (1)

- PH Measurement in Tail Gas Clean-Up: Petroleum Refining IndustryDokumen2 halamanPH Measurement in Tail Gas Clean-Up: Petroleum Refining IndustryachillesntroyBelum ada peringkat

- Joule Thomson ExpansionDokumen2 halamanJoule Thomson ExpansiondndudcBelum ada peringkat

- Aspentech Course Catalog Fy18Dokumen27 halamanAspentech Course Catalog Fy18Waseem AkramBelum ada peringkat

- Beggs and Brill Correlation for Liquid Holdup and Friction FactorDokumen6 halamanBeggs and Brill Correlation for Liquid Holdup and Friction FactorAli Al AkbarBelum ada peringkat

- Analysis of Hydrodynamic Slugging in Offshore Oil PipelinesDokumen16 halamanAnalysis of Hydrodynamic Slugging in Offshore Oil Pipelineswiwiz2000Belum ada peringkat

- Centrifugal Compressor Surge Control AnalysisDokumen3 halamanCentrifugal Compressor Surge Control AnalysisEdward JulianBelum ada peringkat

- Thermal BowingDokumen8 halamanThermal BowingA. VenugopalBelum ada peringkat

- Asd Global at HXGN Live 2015Dokumen2 halamanAsd Global at HXGN Live 2015vb_pol@yahooBelum ada peringkat

- FM PDFDokumen28 halamanFM PDFJuan ZamoraBelum ada peringkat

- I.std - Procedure For Preparation of 3D Cad ModelsDokumen17 halamanI.std - Procedure For Preparation of 3D Cad ModelsMatteoBelum ada peringkat

- Transient OperationsDokumen44 halamanTransient OperationsAKOGU J. AKPOCHI J.Belum ada peringkat

- Optimization Method of Plunger Gas Lift Process Based On Olga SoftwareDokumen9 halamanOptimization Method of Plunger Gas Lift Process Based On Olga Softwaresureyya.yusifovaBelum ada peringkat

- Reduce Flare System Failure with Vibration AnalysisDokumen2 halamanReduce Flare System Failure with Vibration Analysissri9987Belum ada peringkat

- IGC Document 154 09 EDokumen47 halamanIGC Document 154 09 Elutfirashid87Belum ada peringkat

- What Are The Types of HRSGDokumen2 halamanWhat Are The Types of HRSGThiruvengadamBelum ada peringkat

- Hazen Williams Friction Loss Hydraulic TablesDokumen78 halamanHazen Williams Friction Loss Hydraulic TablesMisama NedianBelum ada peringkat

- H-I SUPER-DEHYDRATION WITH GLYCOLSDokumen15 halamanH-I SUPER-DEHYDRATION WITH GLYCOLSDiego1980bBelum ada peringkat

- Pinch and Approach Point On HRSGDokumen12 halamanPinch and Approach Point On HRSGluaguBelum ada peringkat

- Predicting Phase Behavior of Condensate/Crude-Oil Systems Using Methane Interaction CoefficientsDokumen7 halamanPredicting Phase Behavior of Condensate/Crude-Oil Systems Using Methane Interaction Coefficientskmilo04Belum ada peringkat

- Considerations in Designing Multiphase Flow Lines - Pipeline & Gas JournalDokumen9 halamanConsiderations in Designing Multiphase Flow Lines - Pipeline & Gas Journalt_rajith1179Belum ada peringkat

- Olga5 UsermanualDokumen453 halamanOlga5 Usermanualdavidrrg100% (1)

- HP New Analysis For FlaresDokumen0 halamanHP New Analysis For Flareskataria200784Belum ada peringkat

- (SLB-SIS) 04. April 2020 NewsletterDokumen7 halaman(SLB-SIS) 04. April 2020 Newslettergalih13002010Belum ada peringkat

- ch3 PDFDokumen96 halamanch3 PDFJuan Zamora100% (1)

- Industrial & Engineering Chemistry Volume 28 Issue 12 1936 (Doi 10.1021/ie50324a027) Sieder, E. N. Tate, G. E. - Heat Transfer and Pressure Drop of Liquids in TubesDokumen7 halamanIndustrial & Engineering Chemistry Volume 28 Issue 12 1936 (Doi 10.1021/ie50324a027) Sieder, E. N. Tate, G. E. - Heat Transfer and Pressure Drop of Liquids in Tubesrahulsaini855Belum ada peringkat

- Pilot-Operated Safety Relief Valves A Simple, Effective Plant Upgrade - HP - Nov 2011 PDFDokumen5 halamanPilot-Operated Safety Relief Valves A Simple, Effective Plant Upgrade - HP - Nov 2011 PDFonizuka-t2263Belum ada peringkat

- Hint An Educational Software For Heat Exchanger NetworkDokumen9 halamanHint An Educational Software For Heat Exchanger NetworkJ Andres Sanchez100% (1)

- Mathematical Modeling of Horizontal Two-Phase Flow Through Fully Eccentric AnnuliDokumen124 halamanMathematical Modeling of Horizontal Two-Phase Flow Through Fully Eccentric AnnuliIlham NugrohoBelum ada peringkat

- Evaluation of Two Phase Flow Correalations For Pipelines and Inclines Upward FlwoDokumen10 halamanEvaluation of Two Phase Flow Correalations For Pipelines and Inclines Upward FlwofanziskusBelum ada peringkat

- Taitel Stability of Severe SluggingDokumen15 halamanTaitel Stability of Severe SluggingfanziskusBelum ada peringkat

- Numerical Simulation of Gas-Liquid Slug Flow Along Vertical Pipes Using The Slug Tracking ModelDokumen9 halamanNumerical Simulation of Gas-Liquid Slug Flow Along Vertical Pipes Using The Slug Tracking ModelfanziskusBelum ada peringkat

- An Evaluation of Recent Mechanistic Models of Multiphase Flow For Predicting Pressure Drops in Oil and Gas WellsDokumen11 halamanAn Evaluation of Recent Mechanistic Models of Multiphase Flow For Predicting Pressure Drops in Oil and Gas WellsfanziskusBelum ada peringkat

- A Conceptual Study of Finger-Type Slug Catcher For Heavy-Oil FieldsDokumen8 halamanA Conceptual Study of Finger-Type Slug Catcher For Heavy-Oil FieldsfanziskusBelum ada peringkat

- Fundamentals of Multiphase FlowDokumen410 halamanFundamentals of Multiphase FlowF.L.YBelum ada peringkat

- Fundamentals of Multiphase FlowDokumen410 halamanFundamentals of Multiphase FlowF.L.YBelum ada peringkat

- Investigation of Transition From Annular To Intermittent Flow in PipesDokumen7 halamanInvestigation of Transition From Annular To Intermittent Flow in PipesfanziskusBelum ada peringkat

- Quasi-3d Modelling of Two-Phase Slug Flow in PipesDokumen7 halamanQuasi-3d Modelling of Two-Phase Slug Flow in PipesfanziskusBelum ada peringkat

- Feesa LTD Case Study - Hydrodynamic Slug Size in Multiphase FlowlinesDokumen3 halamanFeesa LTD Case Study - Hydrodynamic Slug Size in Multiphase FlowlinesJorge David Flores DionisioBelum ada peringkat

- Modeling of Two-Phase Flows in Horizontal TubesDokumen127 halamanModeling of Two-Phase Flows in Horizontal TubesfanziskusBelum ada peringkat

- Damping Hibrid Stepper MotorDokumen8 halamanDamping Hibrid Stepper MotorMake_PicBelum ada peringkat

- Perancangan Dan Analisis Belt Conveyor Kapasitas 150 Ton/Jam Berdasarkan Standar CEMA Dan DIN 22101Dokumen9 halamanPerancangan Dan Analisis Belt Conveyor Kapasitas 150 Ton/Jam Berdasarkan Standar CEMA Dan DIN 22101eko nurmawanBelum ada peringkat

- Pressure Surges: Resulting FromDokumen7 halamanPressure Surges: Resulting Fromshan07011984Belum ada peringkat

- Chapter 1 Notes: Physical Quantities, Units & MeasurementDokumen8 halamanChapter 1 Notes: Physical Quantities, Units & MeasurementterrygohBelum ada peringkat

- Seismic Retrofitting of Unreinforced Masonry Walls by FRP StripsDokumen8 halamanSeismic Retrofitting of Unreinforced Masonry Walls by FRP StripsIbrahim DanishBelum ada peringkat

- 3 Rotational Spectroscopy1Dokumen19 halaman3 Rotational Spectroscopy1Omprakash LatiyalBelum ada peringkat

- Experimental Study of SS304L Cylindrical Shell WitDokumen10 halamanExperimental Study of SS304L Cylindrical Shell WitVPN NetworkBelum ada peringkat

- Ijsetr Vol 4 Issue 6 2293 2302Dokumen10 halamanIjsetr Vol 4 Issue 6 2293 2302HOMERBelum ada peringkat

- Science Class AssignmentsDokumen7 halamanScience Class Assignmentssushil rathiBelum ada peringkat

- 1ST Quarterly Examination in Science 8 (2023-2024)Dokumen11 halaman1ST Quarterly Examination in Science 8 (2023-2024)Jonalyn ViernesBelum ada peringkat

- Charged Particle Motion in Time-Varying Electromagnetic FieldsDokumen2 halamanCharged Particle Motion in Time-Varying Electromagnetic FieldsMridusmita BoruahBelum ada peringkat

- Obt751 - Analytical Methods and Instrumentation Lecture - 2Dokumen28 halamanObt751 - Analytical Methods and Instrumentation Lecture - 2Jayashree Sathiyanarayanan100% (1)

- Design and Construction of Bernoulli Blower ExhibitDokumen5 halamanDesign and Construction of Bernoulli Blower ExhibitainvvyBelum ada peringkat

- rc1 2015 16 Chapter Two Example On Analysis of Double Reinforced Beam SectionsDokumen8 halamanrc1 2015 16 Chapter Two Example On Analysis of Double Reinforced Beam SectionsABAMELABelum ada peringkat

- Earth Science TQDokumen2 halamanEarth Science TQmharlit cagaananBelum ada peringkat

- Numerical and Experimental Approach For Roll Grinding ProcessDokumen7 halamanNumerical and Experimental Approach For Roll Grinding ProcessGinanjar Surya RamadhanBelum ada peringkat

- Rich Mathematical Problems in AstronomyDokumen26 halamanRich Mathematical Problems in AstronomyasljdkfBelum ada peringkat

- Year 10 Physics Revision Lesson PlanDokumen2 halamanYear 10 Physics Revision Lesson PlanHannah Newmann100% (1)

- Model Question: Third Semester M.Sc. (Physics)Dokumen1 halamanModel Question: Third Semester M.Sc. (Physics)Sagar RawalBelum ada peringkat

- Molecular Orbital Theory ExplainedDokumen80 halamanMolecular Orbital Theory ExplainedMridul Bhaskar0% (1)

- Fluid MechanicsDokumen4 halamanFluid MechanicsihllhmBelum ada peringkat

- Tutorial - 4 and Solution Feb 2 2017 FinalDokumen2 halamanTutorial - 4 and Solution Feb 2 2017 FinalRounak MajumdarBelum ada peringkat

- Chapter 1 - Mece5104 - Mechanical VibrationDokumen22 halamanChapter 1 - Mece5104 - Mechanical VibrationCedricBelum ada peringkat

- Radial Conduction Experiment Technical InstituteDokumen5 halamanRadial Conduction Experiment Technical InstituteWalid AdnanBelum ada peringkat