Concast WPS - REV-01

Diunggah oleh

meena34Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Concast WPS - REV-01

Diunggah oleh

meena34Hak Cipta:

Format Tersedia

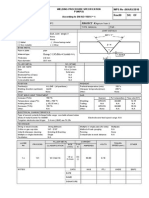

Samay Project Services P Ltd.

Doc.No.: SPL/CSPL/AGECL/QA-002, Rev-01 DATE : 20.01.12 SUPPORTING PQR REF. No.: SPL/CSPL/AGECL/QA-001-01

Title :

Welding Procedure specification for all material specification

Page 1 of 28

WELDING PROCEDURE TYPE

: :

SMAW MANUAL

SYSTEM 1

TANKS

DETAILS OF EQUIPMENT COVERED 1. 2. 3. 300 Cu.m, DM water storage tank 300 Cu.m, make up water storage tank 60 Cu.m Over Head Surge tank

JOINTS (QW-402) : : Single 'V' Butt Nil

Joint Design Backing Material (type) 2 BASE METALS (QW-403)

Specification Type and Grade Thickness Range Base Metal

: : :

IS -2062, IS-1367, A-234 Gr.WPB, 4 mm to 10 mm Groove Single 'V' Fillet: All thickness Fillet: All Size

Client: M/s. CONCAST STEEL & POWER LTD., .

Consultant : Avant Garde Engineers and Consultants (P) ltd., PROJECT: 1 X 30 MW CAPTIVE POWER PLANT & 1 X 40 MW CPP

Samay Project Services P Ltd.,

Doc.No.: SPL/CSPL/AGECL/QA-002, Rev-01 DATE : 20.01.12 SUPPORTING PQR REF. No.: SPL/CSPL/AGECL/QA-001-01

Title :

Welding Procedure specification for all material specification

Page 2 of 28

FILLER METALS (QW-404) : : : : : 5.1, E-6013 2 1 2.5mm Dia., 3.15 mm Dia

Specification No. (SFA) AWS NO. (Class) F-No. A-No. Size of the Filler Metals 4

WELD METAL THICKNESS RANGE : : : : 9.6mm Max / 2 times thk qualified All thk Rutile Electrode Shall be used confirming to E-6013 and Standard mfrs like ESAB, ADVANI and D & H.

Groove Fillet Electrode Flux Class Other

POSITION (QW-405) : : : NA Up-Hill All

Position of the Groove Welding Progression Position (s) of Fillet 6 PREHEAT (QW-406)

Preheat Temp. Min Interpass Temp Max Preheat maintenance 7

: : :

10 Deg. C 150 Deg. C to 250 Deg. C NA

POST WELD HEAT TREATMENT (QW- 407) : : NA NA

Temp Range Time Range 8 GAS (QW-408)

Shielding Trailing Backing

Client: M/s. CONCAST STEEL & POWER LTD., .

: : :

Percentage of Composition Gas Mixture Flow Rate NA NA NA NA NA NA NA NA NA

Consultant : Avant Garde Engineers and Consultants (P) ltd., PROJECT: 1 X 30 MW CAPTIVE POWER PLANT & 1 X 40 MW CPP

Samay Project Services P Ltd.,

Doc.No.: SPL/CSPL/AGECL/QA-002, Rev-01 DATE : 20.01.12 SUPPORTING PQR REF. No.: SPL/CSPL/AGECL/QA-001-01

Title :

Welding Procedure specification for all material specification

Page 3 of 28

ELECTRICAL CHARACTERS (QW-409) : : : : : : : DC 70-150 A 18-30 V Reverse NA NA NA

Current AC or DC Current Range Voltage Range Polarity Tungsten Electrode Size Mode of Metal Transfer for GTAW Electrode Wire Feed Speed Range

10

TECHNIQUE (QW-410) : : : : : : :

Process Filler Metal Class Dia 2.5mm 2.5mm 3.15mm

String or Weave Bead Initial Interpass and Cleaning Method of Back Gouging Multipass or Single pass per side Multiple or Single Electrode Travel Speed (Range) Other

Weld Layer (s)

String & Weave Both By Wire Brushing and Chipping Not applicable Multipass Single 65 to 75 mm per Minute N.A.

Current Type Polar Reverse Reverse Reverse Amp. Range 70-90 A 70-90 A 100-110 A Volt Range 18-30 V 18-30 V 18-30 V Travel Speed Range 50-65 mm 65-75 mm 65-75 mm

Root Filler Final (Basis on thick.)

SMAW SMAW SMAW

E6013 E6013 E6013

Client: M/s. CONCAST STEEL & POWER LTD., .

Consultant : Avant Garde Engineers and Consultants (P) ltd., PROJECT: 1 X 30 MW CAPTIVE POWER PLANT & 1 X 40 MW CPP

Samay Project Services P Ltd.,

Doc.No.: SPL/CSPL/AGECL/QA-002, Rev-01 DATE : 20.01.12 SUPPORTING PQR REF. No.: SPL/CSPL/AGECL/QA-001-01

Title :

Welding Procedure specification for all material specification

Page 4 of 28

WELDING PROCEDURE TYPE

: :

GTAW & SMAW MANUAL

SYSTEM 2

VESSELS

DETAILS OF EQUIPMENT COVERED ATM Flash tank

JOINTS (QW-402) : : Single 'V' Butt Nil

Joint Design Backing Material (type) 2 BASE METALS (QW-403)

Specification Type and Grade Thickness Range Base Metal

: : :

IS -2002 Gr.2 4 mm to 10 mm Groove Single 'V' Fillet: All thickness Fillet: All Size

FILLER METALS (QW-404) : : 5.18,5.1 ER70 S2 & E7018

Specification No. (SFA) AWS NO. (Class)

Client: M/s. CONCAST STEEL & POWER LTD., .

Consultant : Avant Garde Engineers and Consultants (P) ltd., PROJECT: 1 X 30 MW CAPTIVE POWER PLANT & 1 X 40 MW CPP

Samay Project Services P Ltd.,

Doc.No.: SPL/CSPL/AGECL/QA-002, Rev-01 DATE : 20.01.12 SUPPORTING PQR REF. No.: SPL/CSPL/AGECL/QA-001-01

Title :

Welding Procedure specification for all material specification

Page 5 of 28

F-No. A-No. Size of the Filler Metals 4 : : : 6,4 1 2.5mm Dia., 3.15 mm Dia. & 2.4mm Dia

WELD METAL THICKNESS RANGE : : : : 9.6mm Max / 2 times thk qualified All thk Rutile Electrode Shall be used confirming to ER70S2, E7018 and Standard mfrs like ESAB, ADVANI & D & H

Groove Fillet Electrode Flux Class Other

POSITION (QW-405) : : : 6G Up-Hill All

Position of the Groove Welding Progression Position (s) of Fillet 6 PREHEAT (QW-406)

Preheat Temp. Min Interpass Temp Max Preheat maintenance 7

: : :

10 Deg. C 150 Deg. C to 250 Deg. C NA

POST WELD HEAT TREATMENT (QW- 407) : : NA NA

Temp Range Time Range

GAS (QW-408) Percentage of Composition

Shielding Trailing Backing 9

: : :

Gas Argon NA NA

Mixture NA NA NA

Flow Rate 20cuft/hr NA NA

ELECTRICAL CHARACTERS (QW-409) : DC

Current AC or DC

Client: M/s. CONCAST STEEL & POWER LTD., .

Consultant : Avant Garde Engineers and Consultants (P) ltd., PROJECT: 1 X 30 MW CAPTIVE POWER PLANT & 1 X 40 MW CPP

Samay Project Services P Ltd.,

Doc.No.: SPL/CSPL/AGECL/QA-002, Rev-01 DATE : 20.01.12 SUPPORTING PQR REF. No.: SPL/CSPL/AGECL/QA-001-01

Title :

Welding Procedure specification for all material specification

Page 6 of 28

Current Range Voltage Range Polarity Tungsten Electrode Size Tungsten type Electrode Wire Feed Speed Range : : : : : : 90-100 A GTAW, 110-125 A SMAW 18-30 V Straight GTAW, Reverse - SMAW 2.4mm SFA5.12 EWTh-2 NA

10

TECHNIQUE (QW-410) : String & Weave Both(Less than three times of filler wire thickness)

String or Weave Bead

Initial Interpass and Cleaning Method of Back Gouging Multipass or Single pass per side Multiple or Single Electrode Travel Speed (Range) Other Weld Layer (s) Precess

: : : : : : Filler Metal Class Dia

By Wire Brushing and Chipping Not applicable Multipass Single 65 to 75 mm per Minute N.A. Type Polar Current Amp. Range 100-125 A 90-100 A 90-100 A Volt Range Travel Speed Range inch/min 2 3.5 5-6 5-6

Root Filler Final (Basis on thick.)

GTAW SMAW SMAW

ER70S2 E7018 E7018

2.4mm 2.5mm 3.15m m

Straight Reverse Reverse

18-30 V 18-30 V 18-30 V

Client: M/s. CONCAST STEEL & POWER LTD., .

Consultant : Avant Garde Engineers and Consultants (P) ltd., PROJECT: 1 X 30 MW CAPTIVE POWER PLANT & 1 X 40 MW CPP

Samay Project Services P Ltd.,

Doc.No.: SPL/CSPL/AGECL/QA-002, Rev-01 DATE : 20.01.12 SUPPORTING PQR REF. No.: SPL/CSPL/AGECL/QA-001-01

Title :

Welding Procedure specification for all material specification

Page 7 of 28

SYSTEM : 3. 1. Critical piping carbon steel material 2. Critical piping stainless steel material 3. Critical piping low alloy steel material GR.P11, GR.P12 4. Critical piping low alloy steel material GR.P22 5. Non critical piping carbon steel material 6. Piping less than 6mm wall thick carbon steel material 7. Piping less than 6mm wall thick stainless steel material 1. Critical piping system carbon steel material

WELDING PROCEDURE TYPE

: :

GTAW & SMAW MANUAL

JOINTS (QW-402) : : Single 'V' Butt Nil

Joint Design Backing Material (type)

Client: M/s. CONCAST STEEL & POWER LTD., .

Consultant : Avant Garde Engineers and Consultants (P) ltd., PROJECT: 1 X 30 MW CAPTIVE POWER PLANT & 1 X 40 MW CPP

Samay Project Services P Ltd.,

Doc.No.: SPL/CSPL/AGECL/QA-002, Rev-01 DATE : 20.01.12 SUPPORTING PQR REF. No.: SPL/CSPL/AGECL/QA-001-01

Title :

Welding Procedure specification for all material specification

Page 8 of 28

BASE METALS (QW-403) : : SA 106 Gr.B 8mm and above

Specification Type and Grade Thickness Range

Base Metal

Groove Single 'V' Socket weld (fittings less than 50NB) Fillet: All Thickness Fillet: All Size

Pipe Dia Range

15NB to 1200 NB

FILLER METALS (QW-404) : : : : : 5.18,5.1 ER70S2, E7018 6, 4 1 2.5mm Dia., 3.15 mm Dia. & 2.4mm Dia.

Specification No. (SFA) AWS NO. (Class) F-No. A-No. Size of the Filler Metals 4

WELD METAL THICKNESS RANGE : : : : 9.6mm Max / 2 times thk qualified All thk Rutile Electrode Shall be used confirming to ER70S2, E7018 and Standard mfrs like ESAB, ADVANI & D & H.

Groove Fillet Electrode Flux Class Other

POSITION (QW-405) : : : 6G Up-Hill All

Position of the Groove Welding Progression Position (s) of Fillet 6 PREHEAT (QW-406)

Preheat Temp. Min Interpose Temp Max

Client: M/s. CONCAST STEEL & POWER LTD., .

: :

Min 10 Deg. C 150 Deg. C to 250 Deg. C

Consultant : Avant Garde Engineers and Consultants (P) ltd., PROJECT: 1 X 30 MW CAPTIVE POWER PLANT & 1 X 40 MW CPP

Samay Project Services P Ltd.,

Doc.No.: SPL/CSPL/AGECL/QA-002, Rev-01 DATE : 20.01.12 SUPPORTING PQR REF. No.: SPL/CSPL/AGECL/QA-001-01

Title :

Welding Procedure specification for all material specification

Page 9 of 28

Preheat maintenance 7 : NA

POST WELD HEAT TREATMENT (QW--407) : : NA NA

Temp Range Time Range

GAS (QW-408) Percentage of Composition

Shielding Trailing Backing 9

: : :

Gas Argon NA NA

Mixture NA NA NA

Flow Rate 20cuft/hr NA NA

ELECTRICAL CHARACTERS (QW-409) : : : : : : : DC 90-100 A GTAW, 110-125 A SMAW 18-30 V Straight GTAW, Reverse - SMAW 2.4mm SFA5.12 EWTh-2 NA

Current AC or DC Current Range Voltage Range Polarity Tungsten Electrode Size Tungsten type Electrode Wire Feed Speed Range

10

TECHNIQUE (QW-410) : String & Weave Both(Less than three times of filler wire thickness)

String or Weave Bead

Initial Interpass and Cleaning Method of Back Gouging Multipass or Single pass per side Multiple or Single Electrode Travel Speed (Range) Other

: : : : : :

By Wire Brushing and Chipping Not applicable Multipass Single 65 to 75 mm per Minute N.A.

Client: M/s. CONCAST STEEL & POWER LTD., .

Consultant : Avant Garde Engineers and Consultants (P) ltd., PROJECT: 1 X 30 MW CAPTIVE POWER PLANT & 1 X 40 MW CPP

Samay Project Services P Ltd.,

Doc.No.: SPL/CSPL/AGECL/QA-002, Rev-01 DATE : 20.01.12 SUPPORTING PQR REF. No.: SPL/CSPL/AGECL/QA-001-01

Title :

Welding Procedure specification for all material specification

Page 10 of 28

Weld Layer (s)

Precess

Filler Metal Class Dia

Type Polar

Current Amp. Range 100-125 A 90-100 A 90-100 A

Volt Range

Root Filler Final (Basis on thick.)

GTAW SMAW SMAW

ER70S2 E7018 E7018

2.4mm 2.5mm 3.15m m

Straight Reverse Reverse

18-30 V 18-30 V 18-30 V

Travel Speed Range inch/min 2 3.5 5-6 5-6

Client: M/s. CONCAST STEEL & POWER LTD., .

Consultant : Avant Garde Engineers and Consultants (P) ltd., PROJECT: 1 X 30 MW CAPTIVE POWER PLANT & 1 X 40 MW CPP

Samay Project Services P Ltd.,

Doc.No.: SPL/CSPL/AGECL/QA-002, Rev-01 DATE : 20.01.12 SUPPORTING PQR REF. No.: SPL/CSPL/AGECL/QA-001-01

Title :

Welding Procedure specification for all material specification

Page 11 of 28

2. Critical piping system stainless steel material

WELDING PROCEDURE TYPE : : GTAW & SMAW MANUAL

JOINTS (QW-402) : : Single 'V' Butt Nil

Joint Design Backing Material (type) 2 BASE METALS (QW-403)

Specification Type and Grade Thickness Range Base Metal

: : :

SA 312 TP 304 7.11mm and above Groove Single 'V' Socket weld (fittings less than 50NB) Fillet: All Thickness Fillet: All Size

Pipe Dia Range

15NB to 1200 NB

Client: M/s. CONCAST STEEL & POWER LTD., .

Consultant : Avant Garde Engineers and Consultants (P) ltd., PROJECT: 1 X 30 MW CAPTIVE POWER PLANT & 1 X 40 MW CPP

Samay Project Services P Ltd.,

Doc.No.: SPL/CSPL/AGECL/QA-002, Rev-01 DATE : 20.01.12 SUPPORTING PQR REF. No.: SPL/CSPL/AGECL/QA-001-01

Title :

Welding Procedure specification for all material specification

Page 12 of 28

3 FILLER METALS (QW-404) : : : : : 5.4 & 5.9 ER347, E347 5&6 8 2.5mm Dia., 3.15 mm Dia & 2.4 mm Dia.

Specification No. (SFA) AWS NO. (Class) F-No. A-No. Size of the Filler Metals 4

WELD METAL THICKNESS RANGE : : : : 9.6mm Max / 2 times thk qualified All thk Rutile Electrode Shall be used confirming to ER347, E347 and Standard mfrs like ESAB, ADVANI & D & H.

Groove Fillet Electrode Flux Class Other

POSITION (QW-405) : : : 6G Up-Hill All

Position of the Groove Welding Progression Position (s) of Fillet 6 PREHEAT (QW-406)

Preheat Temp. Min Interpose Temp Max Preheat maintenance 7

: : :

Min 10 Deg. C 150 Deg. C to 250 Deg. C NA

POST WELD HEAT TREATMENT (QW--407) : : NA NA

Temp Range Time Range

GAS (QW-408) Percentage of Composition

Shielding Trailing Backing

Client: M/s. CONCAST STEEL & POWER LTD., .

: : :

Gas Argon NA Argon

Mixture NA NA NA

Flow Rate 20cuft/hr NA 10 to 12 LPM

Consultant : Avant Garde Engineers and Consultants (P) ltd., PROJECT: 1 X 30 MW CAPTIVE POWER PLANT & 1 X 40 MW CPP

Samay Project Services P Ltd.,

Doc.No.: SPL/CSPL/AGECL/QA-002, Rev-01 DATE : 20.01.12 SUPPORTING PQR REF. No.: SPL/CSPL/AGECL/QA-001-01

Title :

Welding Procedure specification for all material specification

Page 13 of 28

ELECTRICAL CHARACTERS (QW-409) : : : : : : : DC 90-100 A GTAW, 110-125 A SMAW 18-30 V Straight GTAW, Reverse - SMAW 2.4mm SFA5.12 EWTh-2 NA

Current AC or DC Current Range Voltage Range Polarity Tungsten Electrode Size Tungsten type Electrode Wire Feed Speed Range

10

TECHNIQUE (QW-410) : String & Weave Both(Less than three times of filler wire thickness)

String or Weave Bead

Initial Interpass and Cleaning Method of Back Gouging Multipass or Single pass per side Multiple or Single Electrode Travel Speed (Range) Other Weld Layer (s) Precess

: : : : : : Filler Metal Class Dia

By Wire Brushing and Chipping Not applicable Multipass Single 65 to 75 mm per Minute N.A. Type Polar Current Amp. Range 100-125 A 90-100 A 90-100 A Volt Range Travel Speed Range inch/min 2 3.5 5-6 5-6

Root Filler Final (Basis on thick.)

GTAW SMAW SMAW

ER347 E347 E347

2.4mm 2.5mm 3.15mm

Straight Reverse Reverse

18-30 V 18-30 V 18-30 V

Client: M/s. CONCAST STEEL & POWER LTD., .

Consultant : Avant Garde Engineers and Consultants (P) ltd., PROJECT: 1 X 30 MW CAPTIVE POWER PLANT & 1 X 40 MW CPP

Samay Project Services P Ltd.,

Doc.No.: SPL/CSPL/AGECL/QA-002, Rev-01 DATE : 20.01.12 SUPPORTING PQR REF. No.: SPL/CSPL/AGECL/QA-001-01

Title :

Welding Procedure specification for all material specification

Page 14 of 28 3. Critical piping low alloy steel material GR.P11, GR.P12

WELDING PROCEDURE TYPE : : GTAW & SMAW MANUAL

JOINTS (QW-402) : : Single 'V' Butt Nil

Joint Design Backing Material (type) 2 BASE METALS (QW-403)

Specification Type and Grade Thickness Range

: : 8mm and above

Base Metal

Groove Single 'V' Socket weld (fittings less than 50NB) Fillet: All Thickness Fillet: All Size

Pipe Dia Range

15NB to 1200 NB

FILLER METALS (QW-404)

Consultant : Avant Garde Engineers and Consultants (P) ltd., PROJECT: 1 X 30 MW CAPTIVE POWER PLANT & 1 X 40 MW CPP

Client: M/s. CONCAST STEEL & POWER LTD., .

Samay Project Services P Ltd.,

Doc.No.: SPL/CSPL/AGECL/QA-002, Rev-01 DATE : 20.01.12 SUPPORTING PQR REF. No.: SPL/CSPL/AGECL/QA-001-01

Title :

Welding Procedure specification for all material specification

Page 15 of 28

Specification No. (SFA) AWS NO. (Class) F-No. A-No. Size of the Filler Metals 4

: : : : :

5.28, 5.5 ER 80S B2, E8018B2 6, 4 3 2.5mm Dia., 3.15 mm Dia. & 2.4mm Dia.

WELD METAL THICKNESS RANGE : : : : 14.22mm Max / 2 times thk qualified All thk Rutile Electrode Shall be used confirming to ER80SB2, E8018B2 and Standard mfrs like ESAB, ADVANI & D & H.

Groove Fillet Electrode Flux Class Other

POSITION (QW-405) : : : 6G Up-Hill All

Position of the Groove Welding Progression Position (s) of Fillet 6 PREHEAT (QW-406)

Preheat Temp. Min Interpose Temp Max Preheat maintenance 7

: : :

Min 120 Deg. C 150 Deg. C to 250 Deg. C NA

POST WELD HEAT TREATMENT (QW--407) : : NA NA

Temp Range Time Range

GAS (QW-408) Percentage of Composition

Shielding Trailing Backing 9

: : :

Gas Argon NA NA

Mixture NA NA NA

Flow Rate 20cuft/hr NA NA

ELECTRICAL CHARACTERS (QW-409)

Consultant : Avant Garde Engineers and Consultants (P) ltd., PROJECT: 1 X 30 MW CAPTIVE POWER PLANT & 1 X 40 MW CPP

Client: M/s. CONCAST STEEL & POWER LTD., .

Samay Project Services P Ltd.,

Doc.No.: SPL/CSPL/AGECL/QA-002, Rev-01 DATE : 20.01.12 SUPPORTING PQR REF. No.: SPL/CSPL/AGECL/QA-001-01

Title :

Welding Procedure specification for all material specification

Page 16 of 28

Current AC or DC Current Range Voltage Range Polarity Tungsten Electrode Size Tungsten type Electrode Wire Feed Speed Range

: : : : : : :

DC 90-100 A GTAW, 110-125 A SMAW 18-30 V Straight GTAW, Reverse - SMAW 2.4mm SFA5.12 EWTh-2 NA

10

TECHNIQUE (QW-410) : String & Weave Both(Less than three times of filler wire thickness)

String or Weave Bead

Initial Interpass and Cleaning Method of Back Gouging Multipass or Single pass per side Multiple or Single Electrode Travel Speed (Range) Other Weld Layer (s) Process

: : : : : : Filler Metal Class Dia

By Wire Brushing and Chipping Not applicable Multipass Single 65 to 75 mm per Minute N.A. Type Polar Current Amp. Range 75-100 A 90-100 A 100-140 A Volt Range Travel Speed Range inch/min 2 3.5 5-6 5-6

Root Filler Final (Basis on thick.)

GTAW SMAW SMAW

ER 80SB2 E8018B2 E8018B2

2.4mm 2.5mm 3.15m m

Straight Reverse Reverse

18-30 V 18-30 V 18-30 V

Client: M/s. CONCAST STEEL & POWER LTD., .

Consultant : Avant Garde Engineers and Consultants (P) ltd., PROJECT: 1 X 30 MW CAPTIVE POWER PLANT & 1 X 40 MW CPP

Samay Project Services P Ltd.,

Doc.No.: SPL/CSPL/AGECL/QA-002, Rev-01 DATE : 20.01.12 SUPPORTING PQR REF. No.: SPL/CSPL/AGECL/QA-001-01

Title :

Welding Procedure specification for all material specification

Page 17 of 28 4. Critical piping low alloy steel material GR.P22

WELDING PROCEDURE TYPE : : GTAW & SMAW MANUAL

JOINTS (QW-402) : : Single 'V' Butt Nil

Joint Design Backing Material (type) 2 BASE METALS (QW-403)

Specification Type and Grade Thickness Range

: : 8mm and above

Base Metal

Groove Single 'V' Socket weld (fittings less than 50NB) Fillet: All Thickness Fillet: All Size

Pipe Dia Range

15NB to 1200 NB

FILLER METALS (QW-404) : : 5.28, 5.5 ER 90S B3, E9018B3

Specification No. (SFA) AWS NO. (Class)

Client: M/s. CONCAST STEEL & POWER LTD., .

Consultant : Avant Garde Engineers and Consultants (P) ltd., PROJECT: 1 X 30 MW CAPTIVE POWER PLANT & 1 X 40 MW CPP

Samay Project Services P Ltd.,

Doc.No.: SPL/CSPL/AGECL/QA-002, Rev-01 DATE : 20.01.12 SUPPORTING PQR REF. No.: SPL/CSPL/AGECL/QA-001-01

Title :

Welding Procedure specification for all material specification

Page 18 of 28

F-No. A-No. Size of the Filler Metals 4 : : : 6, 4 4 2.5mm Dia., 3.15 mm Dia. & 5 mm Dia.

WELD METAL THICKNESS RANGE : : : : 56 mm Max / 2 times thk qualified All thk Rutile Electrode Shall be used confirming to ER90SB3, E9018B3 and Standard mfrs like ESAB, ADVANI & D & H.

Groove Fillet Electrode Flux Class Other

POSITION (QW-405) : : : 6G Up-Hill All

Position of the Groove Welding Progression Position (s) of Fillet 6 PREHEAT (QW-406)

Preheat Temp. Min Interpose Temp Max Preheat maintenance 7

: : :

Min 200 Deg. C 150 Deg. C to 250 Deg. C NA

POST WELD HEAT TREATMENT (QW--407) : : NA NA

Temp Range Time Range

GAS (QW-408) Percentage of Composition

Shielding Trailing Backing 9

: : :

Gas Argon NA NA

Mixture NA NA NA

Flow Rate 20cuft/hr NA NA

ELECTRICAL CHARACTERS (QW-409) : : DC 90-100 A GTAW, 125-135 A SMAW

Current AC or DC Current Range

Client: M/s. CONCAST STEEL & POWER LTD., .

Consultant : Avant Garde Engineers and Consultants (P) ltd., PROJECT: 1 X 30 MW CAPTIVE POWER PLANT & 1 X 40 MW CPP

Samay Project Services P Ltd.,

Doc.No.: SPL/CSPL/AGECL/QA-002, Rev-01 DATE : 20.01.12 SUPPORTING PQR REF. No.: SPL/CSPL/AGECL/QA-001-01

Title :

Welding Procedure specification for all material specification

Page 19 of 28

Voltage Range Polarity Tungsten Electrode Size Tungsten type Electrode Wire Feed Speed Range : : : : : 18-30 V Straight GTAW, Reverse - SMAW 2.4mm SFA5.12 EWTh-2 NA

10

TECHNIQUE (QW-410) : String & Weave Both(Less than three times of filler wire thickness)

String or Weave Bead

Initial Interpass and Cleaning Method of Back Gouging Multipass or Single pass per side Multiple or Single Electrode Travel Speed (Range) Other Weld Layer (s) Process

: : : : : : Filler Metal Class Dia

By Wire Brushing and Chipping Not applicable Multipass Single 65 to 75 mm per Minute N.A. Type Polar Current Amp. Range 75-100A 90-100 A 100-140 A 100-140 A Volt Range Travel Speed Range inch/min 2 3.5 5-6 5-6 5-6

Root Filler Filler Final (Basis on thick.)

GTAW SMAW SMAW SMAW

ER 90SB3 E9018B3 E9018B3 E9018B3

2.4mm 2.5mm 3.15m m 3.15 mm

Straight Reverse Reverse Reverse

18-30 V 18-30 V 18-30 V 18-30 V

Client: M/s. CONCAST STEEL & POWER LTD., .

Consultant : Avant Garde Engineers and Consultants (P) ltd., PROJECT: 1 X 30 MW CAPTIVE POWER PLANT & 1 X 40 MW CPP

Samay Project Services P Ltd.,

Doc.No.: SPL/CSPL/AGECL/QA-002, Rev-01 DATE : 20.01.12 SUPPORTING PQR REF. No.: SPL/CSPL/AGECL/QA-001-01

Title :

Welding Procedure specification for all material specification

Page 20 of 28

5. Non Critical piping system carbon steel material

WELDING PROCEDURE TYPE : : SMAW MANUAL

JOINTS (QW-402) : : Single 'V' Butt Nil

Joint Design Backing Material (type) 2 BASE METALS (QW-403)

Specification Type and Grade Thickness Range Base Metal

: : :

IS1239 Pt. I & II, IS2062, IS3589 8mm and above Groove Single 'V' Socket weld (fittings less than 50NB) Fillet: All Thickness Fillet: All Size

Pipe Dia Range

Client: M/s. CONCAST STEEL & POWER LTD., .

15NB to 1200 NB

Consultant : Avant Garde Engineers and Consultants (P) ltd., PROJECT: 1 X 30 MW CAPTIVE POWER PLANT & 1 X 40 MW CPP

Samay Project Services P Ltd.,

Doc.No.: SPL/CSPL/AGECL/QA-002, Rev-01 DATE : 20.01.12 SUPPORTING PQR REF. No.: SPL/CSPL/AGECL/QA-001-01

Title :

Welding Procedure specification for all material specification

Page 21 of 28

FILLER METALS (QW-404) : : : : : 5.1 E6013 2 1 2.5mm Dia., 3.15 mm Dia

Specification No. (SFA) AWS NO. (Class) F-No. A-No. Size of the Filler Metals 4

WELD METAL THICKNESS RANGE : : : : 9.6mm Max / 2 times thk qualified All thk Rutile Electrode Shall be used confirming to E6013, and Standard mfrs like ESAB, ADVANI & D & H.

Groove Fillet Electrode Flux Class Other

POSITION (QW-405) : : : 6G Up-Hill All

Position of the Groove Welding Progression Position (s) of Fillet 6 PREHEAT (QW-406)

Preheat Temp. Min Interpose Temp Max Preheat maintenance 7

: : :

Min 10 Deg. C 150 Deg. C to 250 Deg. C NA

POST WELD HEAT TREATMENT (QW--407) : : NA NA

Temp Range Time Range

GAS (QW-408) Percentage of Composition

Shielding Trailing Backing

Client: M/s. CONCAST STEEL & POWER LTD., .

: : :

Gas NA NA NA

Mixture NA NA NA

Flow Rate NA NA NA

Consultant : Avant Garde Engineers and Consultants (P) ltd., PROJECT: 1 X 30 MW CAPTIVE POWER PLANT & 1 X 40 MW CPP

Samay Project Services P Ltd.,

Doc.No.: SPL/CSPL/AGECL/QA-002, Rev-01 DATE : 20.01.12 SUPPORTING PQR REF. No.: SPL/CSPL/AGECL/QA-001-01

Title :

Welding Procedure specification for all material specification

Page 22 of 28

ELECTRICAL CHARACTERS (QW-409) : : : : : : : DC 110-125 A 18-30 V Reverse NA NA NA

Current AC or DC Current Range Voltage Range Polarity Tungsten Electrode Size Mode of Metal Transfer for GTAW Electrode Wire Feed Speed Range

10

TECHNIQUE (QW-410) : : : : : : : Precess Filler Metal Class Dia String & Weave Both By Wire Brushing and Chipping Not applicable Multipass Single 65 to 75 mm per Minute N.A. Type Polar Current Amp. Range 100-125 A 100-125 A 100-125 A Volt Range Travel Speed Range inch/min 2 3.5 5-6 5-6

String or Weave Bead Initial Interpass and Cleaning Method of Back Gouging Multipass or Single pass per side Multiple or Single Electrode Travel Speed (Range) Other Weld Layer (s)

Root Filler Final (Basis on thick.)

SMAW SMAW SMAW

E6013 E6013 E6013

2.5mm 2.5mm 3.15mm

Reverse Reverse Reverse

18-30 V 18-30 V 18-30 V

Client: M/s. CONCAST STEEL & POWER LTD., .

Consultant : Avant Garde Engineers and Consultants (P) ltd., PROJECT: 1 X 30 MW CAPTIVE POWER PLANT & 1 X 40 MW CPP

Samay Project Services P Ltd.,

Doc.No.: SPL/CSPL/AGECL/QA-002, Rev-01 DATE : 20.01.12 SUPPORTING PQR REF. No.: SPL/CSPL/AGECL/QA-001-01

Title :

Welding Procedure specification for all material specification

Page 23 of 28

6. Piping less than 6mm wall thickness carbon steel piping

WELDING PROCEDURE TYPE : : GTAW MANUAL

JOINTS (QW-402) : : Single 'V' Butt Nil

Joint Design Backing Material (type) 2 BASE METALS (QW-403)

Specification Type and Grade Thickness Range

: :

IS1239 Pt. I & II, IS2062, IS3589, SA 106 Gr.B 3.68mm and above

Base Metal

Groove Single 'V' Socket weld (fittings less than 50NB) Fillet: All Thickness Fillet: All Size

Client: M/s. CONCAST STEEL & POWER LTD., .

Consultant : Avant Garde Engineers and Consultants (P) ltd., PROJECT: 1 X 30 MW CAPTIVE POWER PLANT & 1 X 40 MW CPP

Samay Project Services P Ltd.,

Doc.No.: SPL/CSPL/AGECL/QA-002, Rev-01 DATE : 20.01.12 SUPPORTING PQR REF. No.: SPL/CSPL/AGECL/QA-001-01

Title :

Welding Procedure specification for all material specification

Page 24 of 28

Pipe Dia Range : 15NB to 1200 NB

FILLER METALS (QW-404) : : : : : 5.18 ER70S2 6 1 2.4mm dia.

Specification No. (SFA) AWS NO. (Class) F-No. A-No. Size of the Filler Metals 4

WELD METAL THICKNESS RANGE : : : : 9.6mm Max / 2 times thk qualified All thk Rutile Electrode Shall be used confirming to ER70S2, and Standard mfrs like ESAB, ADVANI & D & H.

Groove Fillet Electrode Flux Class Other

POSITION (QW-405) : : : 6G Up-Hill All

Position of the Groove Welding Progression Position (s) of Fillet 6 PREHEAT (QW-406)

Preheat Temp. Min Interpose Temp Max Preheat maintenance 7

: : :

Min 10 Deg. C 150 Deg. C to 250 Deg. C NA

POST WELD HEAT TREATMENT (QW--407) : : NA NA

Temp Range Time Range

GAS (QW-408) Percentage of Composition Gas Mixture Flow Rate

Client: M/s. CONCAST STEEL & POWER LTD., .

Consultant : Avant Garde Engineers and Consultants (P) ltd., PROJECT: 1 X 30 MW CAPTIVE POWER PLANT & 1 X 40 MW CPP

Samay Project Services P Ltd.,

Doc.No.: SPL/CSPL/AGECL/QA-002, Rev-01 DATE : 20.01.12 SUPPORTING PQR REF. No.: SPL/CSPL/AGECL/QA-001-01

Title :

Welding Procedure specification for all material specification

Page 25 of 28

Shielding Trailing Backing 9 : : : Argon NA NA NA NA NA 20cuft/hr NA NA

ELECTRICAL CHARACTERS (QW-409) : : : : : : : DC 90-100 A 18-30 V Straight 2.4mm SFA5.12 EWTh-2 NA

Current AC or DC Current Range Voltage Range Polarity Tungsten Electrode Size Tungsten Type Electrode Wire Feed Speed Range

10

TECHNIQUE (QW-410) : String & Weave Both(Less than four times of filler wire thickness)

String or Weave Bead

Initial Interpass and Cleaning Method of Back Gouging Multipass or Single pass per side Multiple or Single Electrode Travel Speed (Range) Other Weld Layer (s) Precess

: : : : : : Filler Metal Class Dia

By Wire Brushing and Chipping Not applicable Multipass Single 65 to 75 mm per Minute N.A. Type Polar Current Amp. Range 90-100 A 90-100 A 90-100 A Volt Range Travel Speed Range inch/min 2 3.5 5-6 5-6

Root Filler Final (Basis on thick.)

GTAW GTAW GTAW

ER70S2 ER70S2 ER70S2

2.4mm 2.4mm 2.4mm

Straight Straight Straight

18-30 V 18-30 V 18-30 V

Client: M/s. CONCAST STEEL & POWER LTD., .

Consultant : Avant Garde Engineers and Consultants (P) ltd., PROJECT: 1 X 30 MW CAPTIVE POWER PLANT & 1 X 40 MW CPP

Samay Project Services P Ltd.,

Doc.No.: SPL/CSPL/AGECL/QA-002, Rev-01 DATE : 20.01.12 SUPPORTING PQR REF. No.: SPL/CSPL/AGECL/QA-001-01

Title :

Welding Procedure specification for all material specification

Page 26 of 28

7. Piping less than 6mm wall thickness stainless steel piping

WELDING PROCEDURE TYPE : : GTAW MANUAL

JOINTS (QW-402) : : Single 'V' Butt Nil

Joint Design Backing Material (type) 2 BASE METALS (QW-403)

Specification Type and Grade Thickness Range

: :

SA 312 TP 304 3.05mm and above

Base Metal

Groove Single 'V' Socket weld (fittings less than 50NB) Fillet: All Thickness Fillet: All Size

Client: M/s. CONCAST STEEL & POWER LTD., .

Consultant : Avant Garde Engineers and Consultants (P) ltd., PROJECT: 1 X 30 MW CAPTIVE POWER PLANT & 1 X 40 MW CPP

Samay Project Services P Ltd.,

Doc.No.: SPL/CSPL/AGECL/QA-002, Rev-01 DATE : 20.01.12 SUPPORTING PQR REF. No.: SPL/CSPL/AGECL/QA-001-01

Title :

Welding Procedure specification for all material specification

Page 27 of 28

Pipe Dia Range : 15NB to 1200 NB

FILLER METALS (QW-404) : : : : : 5.9 ER347 6 8 2.4mm Dia.

Specification No. (SFA) AWS NO. (Class) F-No. A-No. Size of the Filler Metals 4

WELD METAL THICKNESS RANGE : : : : 9.6mm Max / 2 times thk qualified All thk Rutile Electrode Shall be used confirming to ER347, and Standard mfrs like ESAB, ADVANI & D & H.

Groove Fillet Electrode Flux Class Other

POSITION (QW-405) : : : 6G Up-Hill All

Position of the Groove Welding Progression Position (s) of Fillet 6 PREHEAT (QW-406)

Preheat Temp. Min Interpose Temp Max Preheat maintenance 7

: : :

Min 10 Deg. C 150 Deg. C to 250 Deg. C NA

POST WELD HEAT TREATMENT (QW--407) : : NA NA

Temp Range Time Range

GAS (QW-408) Percentage of Composition

Shielding

Client: M/s. CONCAST STEEL & POWER LTD., .

Gas Argon

Mixture NA

Flow Rate 20cuft/hr

Consultant : Avant Garde Engineers and Consultants (P) ltd., PROJECT: 1 X 30 MW CAPTIVE POWER PLANT & 1 X 40 MW CPP

Samay Project Services P Ltd.,

Doc.No.: SPL/CSPL/AGECL/QA-002, Rev-01 DATE : 20.01.12 SUPPORTING PQR REF. No.: SPL/CSPL/AGECL/QA-001-01

Title :

Welding Procedure specification for all material specification

Page 28 of 28

Trailing Backing 9 : : NA Argon NA NA NA 10 to 12 LPM

ELECTRICAL CHARACTERS (QW-409) : : : : : : : DC 90-100 A 18-30 V Straight 2.4mm SFA5.12 EWTh-2 NA

Current AC or DC Current Range Voltage Range Polarity Tungsten Electrode Size Tungsten Type Electrode Wire Feed Speed Range

10

TECHNIQUE (QW-410) : String & Weave Both(Less than three times of filler wire thickness)

String or Weave Bead

Initial Interpass and Cleaning Method of Back Gouging Multipass or Single pass per side Multiple or Single Electrode Travel Speed (Range) Other Weld Layer (s) Precess

: : : : : : Filler Metal Class Dia

By Wire Brushing and Chipping Not applicable Multipass Single 65 to 75 mm per Minute N.A. Type Polar Current Amp. Range 90-100 A 90-100 A 90-100 A Volt Range Travel Speed Range inch/min 2 3.5 5-6 5-6

Root Filler Final (Basis on thick.)

GTAW GTAW GTAW

ER347 ER347 ER347

2.4mm 2.4mm 2.4mm

Straight Straight Straight

18-30 V 18-30 V 18-30 V

Client: M/s. CONCAST STEEL & POWER LTD., .

Consultant : Avant Garde Engineers and Consultants (P) ltd., PROJECT: 1 X 30 MW CAPTIVE POWER PLANT & 1 X 40 MW CPP

Anda mungkin juga menyukai

- Wps p91 - BhelDokumen2 halamanWps p91 - BhelAshish Gupta100% (4)

- wps63 PDFDokumen4 halamanwps63 PDFErick HoganBelum ada peringkat

- WPS Pipe 08'' SHD 40 SMAW REV02Dokumen2 halamanWPS Pipe 08'' SHD 40 SMAW REV02Amine MaalejBelum ada peringkat

- Welding Procedure Specification For Storage Tank & Piping SystemDokumen3 halamanWelding Procedure Specification For Storage Tank & Piping SystemAhmad MohammadBelum ada peringkat

- WPS 03 GtawDokumen3 halamanWPS 03 GtawBiswajit DeyBelum ada peringkat

- Wps GT 9b Cvn90 Rev 1 PDFDokumen6 halamanWps GT 9b Cvn90 Rev 1 PDFM. Zaki RahmaniBelum ada peringkat

- NPCIL Tube Fitting SpecificationsDokumen22 halamanNPCIL Tube Fitting Specificationssumant.c.singh1694100% (1)

- Welding Report For Tank 1Dokumen1 halamanWelding Report For Tank 1Rifki HasyaBelum ada peringkat

- Quality Assurance PlanDokumen3 halamanQuality Assurance PlanVicky Gautam100% (1)

- WPS for FCAW Welding of SteelDokumen2 halamanWPS for FCAW Welding of SteelHamid MansouriBelum ada peringkat

- Madina Trading WPS No. 017Dokumen12 halamanMadina Trading WPS No. 017MAT-LIONBelum ada peringkat

- Company Name Key Information Questions Answers File Reference Test Conducted On Reviews & ApprovalsDokumen11 halamanCompany Name Key Information Questions Answers File Reference Test Conducted On Reviews & ApprovalsMAT-LIONBelum ada peringkat

- Procedure Qualification Record (PQR) : Jl. Brigjend Katamso KM 5.6 Tanjung Uncang - Batam IndonesiaDokumen2 halamanProcedure Qualification Record (PQR) : Jl. Brigjend Katamso KM 5.6 Tanjung Uncang - Batam IndonesiaMulPXBelum ada peringkat

- Fcaw 16 THKDokumen5 halamanFcaw 16 THKparesh2387Belum ada peringkat

- WPS E6013+e7018Dokumen2 halamanWPS E6013+e7018Anvesh Vaddi100% (1)

- WPS-Shell To Tubesheet (CS-SS)Dokumen1 halamanWPS-Shell To Tubesheet (CS-SS)suria qaqcBelum ada peringkat

- WPS FGPDokumen1 halamanWPS FGPShabbir HussainBelum ada peringkat

- 5092 P8 P1 SM 01Dokumen5 halaman5092 P8 P1 SM 01Danem HalasBelum ada peringkat

- PT Kuwera Karya Me: PanduDokumen2 halamanPT Kuwera Karya Me: PanduGalang Pratama PutraBelum ada peringkat

- Wps For Smaw06-001 (Pipe 6g CS)Dokumen10 halamanWps For Smaw06-001 (Pipe 6g CS)walitedisonBelum ada peringkat

- WPSDokumen42 halamanWPSjoehodoh100% (1)

- QW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)Dokumen1 halamanQW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)rohitbhat2345Belum ada peringkat

- PQR & WPQ Standard Testing Parameter WorksheetDokumen4 halamanPQR & WPQ Standard Testing Parameter WorksheetcosmicbunnyBelum ada peringkat

- Title: WQ 482 Welding Procedure Specification (WPS) : SupersedesDokumen1 halamanTitle: WQ 482 Welding Procedure Specification (WPS) : SupersedesdethamrnBelum ada peringkat

- WPQP 6g Smaw API 5lx52 Od10inch 15.9mmDokumen1 halamanWPQP 6g Smaw API 5lx52 Od10inch 15.9mmufomskiBelum ada peringkat

- WPQ Format - SMAWDokumen3 halamanWPQ Format - SMAWBalkishan DyavanapellyBelum ada peringkat

- Fcaw Wps-001a PDFDokumen3 halamanFcaw Wps-001a PDFirfan bari100% (1)

- QW-483 BlankDokumen2 halamanQW-483 BlankCraftyBob100% (1)

- WPQDokumen10 halamanWPQayoki100% (3)

- Qap 8000ce Reactor - Repat - 1Dokumen2 halamanQap 8000ce Reactor - Repat - 1AliasgarBelum ada peringkat

- Assure Solutions: Hydro Test ReportDokumen1 halamanAssure Solutions: Hydro Test ReportKailas NimbalkarBelum ada peringkat

- Welding Procedure Specification for Vertical Storage TanksDokumen6 halamanWelding Procedure Specification for Vertical Storage TanksYASH BARDHAN SinghBelum ada peringkat

- PWPS - GTSM-73 Rev-ADokumen5 halamanPWPS - GTSM-73 Rev-AVimin PrakashBelum ada peringkat

- Pttep Painitng of Offshore FacilitiesDokumen66 halamanPttep Painitng of Offshore FacilitiesSufianBelum ada peringkat

- PQR 01 PDFDokumen2 halamanPQR 01 PDFVijay BhaleraoBelum ada peringkat

- Pwps 06Dokumen1 halamanPwps 06eldobie3Belum ada peringkat

- Welding Procedure Specification: ST NDDokumen1 halamanWelding Procedure Specification: ST NDMaung SleeperBelum ada peringkat

- ASME Code Section IX - QW-360: Weldingoperator - Performance - QualificationDokumen2 halamanASME Code Section IX - QW-360: Weldingoperator - Performance - QualificationAmit SharmaBelum ada peringkat

- QC FORMDokumen3 halamanQC FORMRicardo LourençoBelum ada peringkat

- Dep 30.10.60.32 - Welding of Metals, Based On Iso StandardsDokumen76 halamanDep 30.10.60.32 - Welding of Metals, Based On Iso StandardsPablo PazBelum ada peringkat

- ITP For Piping SystemsDokumen6 halamanITP For Piping SystemsGia Minh Tieu TuBelum ada peringkat

- WPS PQR FormatsDokumen22 halamanWPS PQR Formatsmdharmaraj28Belum ada peringkat

- Wps - Asme Ix - Gtaw - Plat SteDokumen6 halamanWps - Asme Ix - Gtaw - Plat SteMuhammad Fitransyah Syamsuar PutraBelum ada peringkat

- Er 100 S 1Dokumen1 halamanEr 100 S 1Oliver Quezada Inostroza100% (1)

- Radiographic Testing: Inspection ReportDokumen2 halamanRadiographic Testing: Inspection Reportsuria qaqcBelum ada peringkat

- (Section IX, ASME Boiler and Pressure Vessel Code) : Welding Procedure Specification (WPS)Dokumen2 halaman(Section IX, ASME Boiler and Pressure Vessel Code) : Welding Procedure Specification (WPS)Quality LaveenaBelum ada peringkat

- Sabari Engineering PQRDokumen3 halamanSabari Engineering PQRAdvanced Quality Centre AQC100% (1)

- PQR / WPQ Witness Report: Weld Layer (S) Welding Process Electrode Current Voltag e Travel Speed Dia. Class Polarity AmpDokumen1 halamanPQR / WPQ Witness Report: Weld Layer (S) Welding Process Electrode Current Voltag e Travel Speed Dia. Class Polarity AmpSatish KeskarBelum ada peringkat

- WPQ-1083 3G PDFDokumen2 halamanWPQ-1083 3G PDFduendex360100% (1)

- Duplex Ss Welding PDF FreeDokumen8 halamanDuplex Ss Welding PDF Freeel_sharkawy2011Belum ada peringkat

- Welding Procedure SpecificationDokumen3 halamanWelding Procedure SpecificationAhmed saber100% (1)

- KBR Inspection Test Plan For Anchor Bolts: Level 1 Level 2 Level 3Dokumen4 halamanKBR Inspection Test Plan For Anchor Bolts: Level 1 Level 2 Level 3kamlBelum ada peringkat

- GTAW Welding Procedure for TP-304 PipingDokumen2 halamanGTAW Welding Procedure for TP-304 PipingproxywarBelum ada peringkat

- Welding Procedure Specification NO. 1-7-1: National Certified Pipe Welding BureauDokumen5 halamanWelding Procedure Specification NO. 1-7-1: National Certified Pipe Welding BureauTharakeshBelum ada peringkat

- Indcon Projects Electrode Qualification Procedure IOCL Gas PipelineDokumen11 halamanIndcon Projects Electrode Qualification Procedure IOCL Gas PipelineAkhilesh Kumar67% (3)

- WPS 316 LDokumen4 halamanWPS 316 Llaz_k100% (2)

- WPS 204 NewDokumen6 halamanWPS 204 Newarockiyathass100% (1)

- WPSDokumen2 halamanWPSBalu SukumarBelum ada peringkat

- Essar Constructions Ltd. Hazira.: List of FormatsDokumen68 halamanEssar Constructions Ltd. Hazira.: List of Formatsravi00098Belum ada peringkat

- WPS-PQR For Split TeeDokumen9 halamanWPS-PQR For Split TeemaheshmalaichamyBelum ada peringkat

- BGR ApplicationFormDokumen4 halamanBGR ApplicationFormsudheerBelum ada peringkat

- Motion Gate Inergen System Room List: Bank # Room Description Floor LDokumen6 halamanMotion Gate Inergen System Room List: Bank # Room Description Floor Lmeena34Belum ada peringkat

- UAE - Sprinkler Pipe ScheduleDokumen1 halamanUAE - Sprinkler Pipe Schedulemeena34Belum ada peringkat

- Hydraulic Calculation For Dry & Wet RiserDokumen51 halamanHydraulic Calculation For Dry & Wet RiserAzeem BashaBelum ada peringkat

- FM200 DiffrenceDokumen13 halamanFM200 Diffrencemeena34Belum ada peringkat

- Client: Orange Power Plant New Delhi Project: 1X10Mw Biomass Power PlantDokumen1 halamanClient: Orange Power Plant New Delhi Project: 1X10Mw Biomass Power Plantmeena34Belum ada peringkat

- Fire Protection Hydraulic CalculationsDokumen25 halamanFire Protection Hydraulic Calculationsmeena34100% (1)

- Motion Gate Inergen System Room List: Bank # Room Description Floor LDokumen6 halamanMotion Gate Inergen System Room List: Bank # Room Description Floor Lmeena34Belum ada peringkat

- Hydraulic Calculation For Dry & Wet RiserDokumen51 halamanHydraulic Calculation For Dry & Wet RiserAzeem BashaBelum ada peringkat

- List of CompaniesDokumen16 halamanList of Companiesmeena34100% (2)

- Motion Gate Inergen System Room List: Bank # Room Description Floor LDokumen6 halamanMotion Gate Inergen System Room List: Bank # Room Description Floor Lmeena34Belum ada peringkat

- Nfpa 13Dokumen23 halamanNfpa 13meena340% (1)

- Customer: M/S. Ultratech Cement Limited, Tadipatri Project: 2 X 25 MW Thermal Power PlantDokumen1 halamanCustomer: M/S. Ultratech Cement Limited, Tadipatri Project: 2 X 25 MW Thermal Power Plantmeena34Belum ada peringkat

- Dharwad Pump House BoqDokumen9 halamanDharwad Pump House Boqmeena34Belum ada peringkat

- Office AddressDokumen2 halamanOffice Addressmeena34Belum ada peringkat

- 10th April 2013Dokumen2 halaman10th April 2013meena34Belum ada peringkat

- Sila KalamDokumen1 halamanSila Kalammeena34Belum ada peringkat

- Page - 48 Rawlbolt Shield and Loose BoltDokumen1 halamanPage - 48 Rawlbolt Shield and Loose Boltmeena34Belum ada peringkat

- Technical Specification 58Dokumen1 halamanTechnical Specification 58meena34Belum ada peringkat

- 05.station Transformer. - GA & Sectional Drg.Dokumen1 halaman05.station Transformer. - GA & Sectional Drg.meena34Belum ada peringkat

- MonitorsDokumen21 halamanMonitorsmeena34Belum ada peringkat

- Samay Project Services leave application formDokumen1 halamanSamay Project Services leave application formmeena34Belum ada peringkat

- Ball ValveDokumen2 halamanBall Valvemeena34Belum ada peringkat

- RanjitDokumen2 halamanRanjitmeena34Belum ada peringkat

- Holidays 2014Dokumen1 halamanHolidays 2014meena34Belum ada peringkat

- Deluge - Unknown AuthorDokumen11 halamanDeluge - Unknown Authormeena34Belum ada peringkat

- Manis Foundries PVT Ltd-Dindigul: Department Location Request For Changes SignatureDokumen4 halamanManis Foundries PVT Ltd-Dindigul: Department Location Request For Changes Signaturemeena34Belum ada peringkat

- Holidays 2014Dokumen1 halamanHolidays 2014meena34Belum ada peringkat

- AptitudeDokumen25 halamanAptitudeRegan100% (2)