ISO Standards For The Fermentation & Isolation of Medicinal Products

Diunggah oleh

pharmasynthJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

ISO Standards For The Fermentation & Isolation of Medicinal Products

Diunggah oleh

pharmasynthHak Cipta:

Format Tersedia

ISO Standards for the Fermentation & Isolation of Medicinal Products

PharmaSynths 1200m facility is located in the suburb of Darra south of the Brisbane's central business district (CBD). This facility is comprised of a series of modular clean room laboratories with ISO 8 fermentation suites and support areas. Purification and final product isolation suites are ISO 7 cleanrooms.

2

Our ISO Class 8 manufacturing room for microbial fermentation performed under cGMP conditions features:

Fermenters from 5L development reactors to 500L production vessels Continuous tubular bowl centrifuges Millipore ultrafiltration housings and associated equipment Stokes stoppering shelf Lyophiliser (50L condenser capacity) Stainless steel process tankage to 600L Bioprocess chromatography system Chromatography columns to 200L 150L temperature and pressure synthesis reactor Biohazard hoods USP grade purified water system Clean steam system Clean steam Autoclave Compressed air Vacuum Chilled glycol loop

PharmaSynth's ISO Class 7 purification room performed under cGMP conditions features:

Fermentation (batch, fed batch and continuous) Continuous centrifugation Ultrafiltration Membrane filtration Reverse osmosis Chromatography Homogenisation Lyophilisation Hydrolysis Synthetic reactions

The fermentation and isolation suites described above are also supported by a ISO 8 storage areas ranging from -80C to controlled ambient temperatures for raw material, in process material, and finished product.

Meaning of the above ISO classifications:

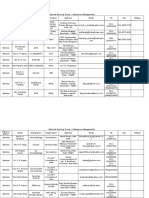

The classification of air cleanliness is very simple as the class equates to the number of particles of a particular size (e.g., 0.5, 1 or 5 m particles) per cubic micrometer of air. An ISO Class 8 clean room is the eight classification type of the ISO 14644-1 and the environment within the room is about 100,000 times cleaner than natural air. Measuring the concentration of airborne particles, ISO 8 requires less than 29,300 particles sized larger than 5 micrometers per cubic meter of air, no more than 832,000 particles sized less than 1 micrometer per cubic meter of air and fewer than 3.52 million particles sized less than 0.5 micrometer per cubic meter of air. Class 8 clean rooms dont regulate particles smaller than 0.5 micrometers. Each ISO class represents a ten-fold difference in cleanliness. For example, an ISO 3 room will be ten times cleaner than an ISO 4 room . See table below:

What does the above ISO designations mean for our clients?

PharmaSynth's use of ISO health standards provides tools to assess and evaluate conformity and ensures consistency for our clients. ISO standards safeguard consumer interests by ensuring good quality care and safe and reliable products and services. Regulators can rely on these trusted internationally harmonized solutions, which are continually reviewed and improved to provide a technical basis for market-friendly regulations that meet citizens expectations. In addition, ISO standards are strategic tools whereby we give our clients the ability to gain a competitive advantage through products and services that are safe, reliable and trustworthy.

Contact Us

Email: enquiries@pharmasynth.com.au Website: http://www.pharmasynth.com.au/

Anda mungkin juga menyukai

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5795)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (895)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (121)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (74)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- Environmental SustainabilityDokumen3 halamanEnvironmental SustainabilityJoseph Michael Perez100% (1)

- JUNOS Cheat SheetDokumen2 halamanJUNOS Cheat SheetJaeson VelascoBelum ada peringkat

- Pioneer PDP-501MX Plasma DisplayDokumen96 halamanPioneer PDP-501MX Plasma DisplayJavier RodriguezBelum ada peringkat

- Diagram of Vitamix Blade Blade Assembly: InstructionsDokumen5 halamanDiagram of Vitamix Blade Blade Assembly: InstructionsRenato PurcinoBelum ada peringkat

- Bolted Tank Specifications Final 11-5-15Dokumen6 halamanBolted Tank Specifications Final 11-5-15Rodrigo ZapataBelum ada peringkat

- Guideline G6 Certification Process v2 0Dokumen18 halamanGuideline G6 Certification Process v2 0Wong Wong WLBelum ada peringkat

- Sch40 80 ASTM A53 - Brochure - 042512Dokumen2 halamanSch40 80 ASTM A53 - Brochure - 042512Fallo SusiloBelum ada peringkat

- Lecture 3. Growth of Functions Asymptotic NotationDokumen9 halamanLecture 3. Growth of Functions Asymptotic NotationJasdeep Singh Pardeep SinghBelum ada peringkat

- 720U2301 Rev 07 - Minimate Pro Operator ManualDokumen126 halaman720U2301 Rev 07 - Minimate Pro Operator ManualCristobalKlingerBelum ada peringkat

- Thrust StandDokumen43 halamanThrust StandABHIMANYU KHADGABelum ada peringkat

- CL21C650MLMXZD PDFDokumen45 halamanCL21C650MLMXZD PDFJone Ferreira Dos SantosBelum ada peringkat

- Computer Science Ram PresentationDokumen11 halamanComputer Science Ram Presentationapi-268896185100% (3)

- Topic 10 - Advanced Approvals in Salesforce CPQDokumen18 halamanTopic 10 - Advanced Approvals in Salesforce CPQRamkumar Poovalai100% (1)

- Bubble Point Temperature - Ideal Gas - Ideal Liquid: TrialDokumen4 halamanBubble Point Temperature - Ideal Gas - Ideal Liquid: TrialNur Dewi PusporiniBelum ada peringkat

- STP Tender Document For 08.05.2018Dokumen32 halamanSTP Tender Document For 08.05.2018Arunprasad DurairajBelum ada peringkat

- BDM DriverDokumen16 halamanBDM DrivervolvodiagBelum ada peringkat

- Chapter 2 GTAWDokumen72 halamanChapter 2 GTAWDevrath Bangalore Bangalore100% (1)

- C9 Game Guide For VIPsDokumen62 halamanC9 Game Guide For VIPsChrystyanoBelum ada peringkat

- Pads Hyperlynx DDR WizardDokumen3 halamanPads Hyperlynx DDR Wizardkrishna_p_n_44510456Belum ada peringkat

- Chapter 8 Designing and Developing Effective HRD ProgramsDokumen37 halamanChapter 8 Designing and Developing Effective HRD ProgramsVincent Raj KumarBelum ada peringkat

- Rotork: Product TrainingDokumen4 halamanRotork: Product TraininghieuBelum ada peringkat

- Lecture 5 Acetic AcidDokumen6 halamanLecture 5 Acetic AcidYan LaksanaBelum ada peringkat

- Waste To Wealth Green Potential From Palm Biomass in MalaysiaDokumen9 halamanWaste To Wealth Green Potential From Palm Biomass in MalaysiaLai Mei EeBelum ada peringkat

- 12556/gorakhdham Exp Third Ac (3A)Dokumen2 halaman12556/gorakhdham Exp Third Ac (3A)Lovkesh GoyalBelum ada peringkat

- All C PG and CPP Service ManualDokumen60 halamanAll C PG and CPP Service Manualhurantia100% (1)

- A White Paper On IExpense Features in R12Dokumen17 halamanA White Paper On IExpense Features in R12Balaji ShindeBelum ada peringkat

- Position PaperDokumen7 halamanPosition PaperClem CollantesBelum ada peringkat

- Contact List For All NWGDokumen22 halamanContact List For All NWGKarthickBelum ada peringkat

- The Organization & Structure of Banks & Their IndustryDokumen19 halamanThe Organization & Structure of Banks & Their Industryrachim04Belum ada peringkat

- Heinzmann ControlsDokumen4 halamanHeinzmann ControlsShahzad AhmadBelum ada peringkat