MEC481 Ip

Diunggah oleh

Sunil SharmaJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

MEC481 Ip

Diunggah oleh

Sunil SharmaHak Cipta:

Format Tersedia

Lovely Professional University, Punjab

Course Code MEC481 Course Category Course Title WELDING TECHNOLOGY Courses with conceptual focus Course Planner 16727::Sunil Sharma Lectures 2.0 Tutorials Practicals Credits 0.0 0.0 2.0

TextBooks Sr No T-1 Title Welding Process and Technology Reference Books Sr No R-1 R-2 R-3 Other Reading Sr No OR-1 OR-2 Journals articles as Compulsary reading (specific articles, complete reference) Welding and Cutting , Indian welding journal , Title Welding Technology Modern Arc Welding Technology Welding and Welding Technology Author O.P.Khanna Nadkarni Richard Little Edition 1st 1st 1st 2005 2001 Year Publisher Name Dhanpat Rai Oxford and IBH Publishing Co. Pvt. Ltd New Delhi Tata McGraw Hill Author Dr. R.S. Parmar Edition 3rd Year 2011 Publisher Name khanna publisher.

Relevant Websites Sr No RW-1 RW-2 RW-3 RW-4 RW-5 (Web address) (only if relevant to the course) http://ocw.mit.edu/courses/materials-science-and-engineering/3-37-welding-andjoining-processes-fall-2002/ http://www.efunda.com/processes/metal_processing/welding.cfm Salient Features MIT OCW on welding Types of welding

http://www.iiwelding.org/Publications/FreeStuffs/Pages/IIWfreedocumentswelcome.asp Recent developments in welding x www.airgas.com/ http://www.weldingtipsandtricks.com/types-of-welding.html Welding equipment manufacturer TIG and MIG welding

LTP week distribution: (LTP Weeks) Weeks before MTE Weeks After MTE Spill Over 7 7 2

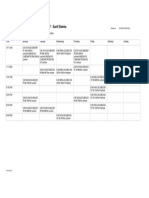

Detailed Plan For Lectures

Week Number Lecture Number Broad Topic(Sub Topic) Chapters/Sections of Text/reference books Other Readings, Lecture Description Relevant Websites, Audio Visual Aids, software and Virtual Labs RW-1 Introduction to welding Learning Outcomes Pedagogical Tool Demonstration/ Case Study / Images / animation / ppt etc. Planned

Week 1

Lecture 1

Introduction(Welding as a production process) Introduction(Advantages)

T-1:Chapter 1/1.4 R-1:Chapter 1/1.1 R-1:Chapter 1/1.5

Introduction to welding Discussion

Advantages of welding

Learning about advantages and limitations of welding Learning about Advantages and limitations of welding

Discussion

Introduction(Limitations)

R-1:Chapter 1/1.6

Limitations of welding

Discussion

Lecture 2

Introduction(Gas welding process) T-1:Chapter 16/16.116.2 R-1:Chapter 3/3.2 Introduction(Types of fuels) T-1:Chapter 16/16.2 R-1:Chapter 3/3.7 T-1:Chapter 16/16.3 R-1:Chapter 3/3.3 T-1:Chapter 3/3.1 R-1:Chapter 4/4.0 T-1:Chapter 4/4.104.11 R-1:Chapter 4/4.14 T-1:Chapter 2/2.2.1.8 R-1:Chapter 7/7.2 T-1:Chapter 2/2.2.1.8 R-1:Chapter 7/7.2 T-1:Chapter 2/2.2.5 R-1:Chapter 7/7.1 T-1:Chapter 17/17.1 R-1:Chapter 12/12.3 T-1:Chapter 17/17.2 R-1:Chapter 11/11.5

RW-1 RW-2

Classification of welding Learning about Different types of welding process Different types of fuels

Figure of gas welding

RW-1 RW-2 RW-2

Learning about Discussion Different types of fuels Learning about Equipment of gas welding Figure of gas welding equipment

Introduction(Gas welding equipment) Week 2 Lecture 3 Introduction(Electric arc welding)

Equipment of gas welding Electric arc welding

RW-1

Learning about Electric Figure of electric arc arc welding welding Learning about accessories and power supplies Learning about atomic hydrogen welding Learning about atomic hydrogen welding Figure of power supplies

Introduction(Power supplies and accessories)

RW-4

Accessories and power supplies

Introduction(Atomic hydrogen welding) Lecture 4 Introduction(Atomic hydrogen welding) Introduction(Thermit welding)

RW-1

Details of Atomic hydrogen welding Details of Atomic hydrogen welding Details of Thermit welding Details of Soldering

Figure of atomic hydrogen weding Figure of atomic hydrogen weding

RW-1

RW-1

Learning about thermit Figure of thermit welding welding Learning about soldering Figure of soldering

Introduction(Soldering)

RW-1

Introduction(Brazing)

RW-1

Details of Brazing

Learning about brazing Figure of brazing process

Week 3

Lecture 5

Introduction(Braze welding)

T-1:Chapter 17/17.2.8.1 R-1:Chapter 10/10.1 T-1:Chapter 9/9.2 R-1:Chapter 4/4.5.3 T-1:Chapter 9/9.2 R-1:Chapter 4/4.5.3

RW-1

Details of Braze welding Learning about braze welding

Figure of braze welding

Special welding process(Power sources) Special welding process (Equipment and accessories)

Power sources used in special welding process RW-4 Equipment and accessories in special welding process Applications of special welding process Limitations of special welding process RW-5 Details of TIG welding

Learning about power Discussion sources used in special welding process Learning about equipment and accessories in special welding process Learning about applications Learning about limitations of special welding process Learning about TIG welding Learning about MIG welding Figure of equipments

Lecture 6

Special welding process (Applications) Special welding process (Limitations) Special welding process(of Gas tungsten arc (TIG) welding)

T-1:Chapter 9/9.6 R-1:Chapter 4/4.5.8 R-1:Chapter 4/4.5.7

Discussion

Discussion

T-1:Chapter 2/2.2.1.4 R-1:Chapter 4/4.5

Figure of TIG welding process Figure of MIG welding process

Week 4

Lecture 7

Special welding process(Gas metal T-1:Chapter 10/10.1arc (MIG) welding) 10.2-10.7 R-1:Chapter 4/4.5 Special welding process (Submerged arc welding) T-1:Chapter 8/8.18.2-8.10 R-1:Chapter 4/4.4

RW-5

Details of MIG welding

Details of Submerged arc Learning about electro welding slag welding

Figure of SAW process

Lecture 8 Week 5 Lecture 10 Special welding process(Principle of Resistance welding) T-1:Chapter 12/12.112.2 R-1:Chapter 5/5.2 T-1:Chapter 12/12.5 R-1:Chapter 5/5.2 T-1:Chapter 12/12.312.8 R-1:Chapter 5/5.7 T-1:Chapter 12/12.15 R-1:Chapter 5/5.8 RW-2 OR-1 OR-2

Test 1 Details of Resistance welding Learning about resistance welding Figure of resistance welding process

Special welding process (Accessories) Special welding process(Spot Resistance welding)

Accessories in resistance Learning about welding accessories in resistance welding Types of resistance welding

Discussion

Learning about types of Figure of spot resistance welding resistance welding process Learning about types of Figure of seam resistance welding resistance welding Learning about types of Figure of projection resistance welding welding process

Special welding process(Seam Resistance welding)

Types of resistance welding Types of resistance welding

Special welding process(Projection T-1:Chapter 12/12.16 welding) R-1:Chapter 5/5.9

Week 5

Lecture 9

Special welding process(Electro slag welding)

T-1:Chapter 11/11.111.2-11.9 R-1:Chapter 4/4.9 T-1:Chapter 2/2.2.2.6 R-1:Chapter 5/5.12 T-1:Chapter 2/2.2.2.5 R-1:Chapter 5/5.11 R-1:Chapter 5/5.11

Details of Electro slag welding

Learning about

Figure of electro slag welding

Week 6

Lecture 11

Special welding process (Percussion welding) Special welding process(Flash welding) Special welding process (Equipment)

Details of Percussion welding

Learning about percussion welding

Figure of percussion welding process Figure of flash welding process

Details of Flash welding Learning about flash welding

Equipment used in flash Learning about Discussion welding equipment used in flash welding RW-1 Details of Electron beam Learning about electron Figure of electron welding beam welding beam welding

Lecture 12

Modern welding processes (Electron beam welding)

T-1:Chapter 14/14.114.2-14.8 R-1:Chapter 8/8.1 T-1:Chapter 14/14.10 R-1:Chapter 8/8.2

Modern welding processes(Laser beam welding)

RW-2

Details of Laser beam welding Details of Plasma arc welding Introduction to friction welding

Learning about laser beam welding

Figure of laser beam welding

Modern welding processes(Plasma T-1:Chapter 2/2.2.1.6 arc welding) R-1:Chapter 4/4.11 Modern welding processes(Friction T-1:Chapter 13/13.1 welding) R-1:Chapter 6/6.5

Learning about plasma Figure of plasma arc arc welding welding Learning about the principle and applications of friction welding Learning about the principle and applications of friction welding Learning about explosive welding Learning about ultrasonic welding Learning about stud welding Learning about under water welding Learning about diffusion bonding Figure and discussion

Week 7

Lecture 13

Modern welding processes(Friction T-1:Chapter 13/13.1 welding) R-1:Chapter 6/6.5

Introduction to friction welding

Figure and discussion

Modern welding processes (Explosive welding) Modern welding processes (Ultrasonic welding) Modern welding processes(Stud welding) Modern welding processes(Under water welding) Lecture 14 Modern welding processes (Diffusion bonding)

T-1:Chapter 13/13.2 R-1:Chapter 6/6.4 T-1:Chapter 2/2.2.3.3 R-1:Chapter 6/6.3 T-1:Chapter 2/2.2.1.9 R-1:Chapter 4/4.13 T-1:Chapter 22/22.5 R-1:Chapter 9/9.3 T-1:Chapter 2/2.2.3.7 R-1:Chapter 6/6.2 RW-1

Details of Explosive welding Details of Ultrasonic welding Details of Stud welding

Figure of explosive welding process Figure of ultrasonic welding process Figure of stud welding process Figure of under water welding process Figure of diffusion welding

Details of Under water welding Details of Diffusion bonding

Week 7

Lecture 14

Modern welding processes(Cold welding) Modern welding processes (Welding of dissimilar metals)

T-1:Chapter 15/15.2 R-1:Chapter 6/6.1 R-1:Chapter 24/24.2

RW-1

Details of Cold welding

Learning about cold welding

Figure of cold welding process

Welding of dissimilar metals

Learning about welding Discussion of dissimilar metals

MID-TERM

Week 8 Lecture 15 Weldment Testing(Defects in welding in various processes) Weldment Testing(Causes and remedies) Weldment Testing(Destructive testing of weldments) Lecture 16 Weldment Testing(Strength) Weldment Testing(Hardness) Weldment Testing(Ductility) Weldment Testing(Fatigue) Weldment Testing(Creep properties etc) Week 9 Lecture 17 Weldment Testing(Nondestructive testing of weldments) Weldment Testing(Ultrasonic dye penetrant) Lecture 18 Weldment Testing(Magnetic particle inspection) Weldment Testing(X ray testing procedure) Weldment Testing(Identification of defects) Weldment Testing(Weld thermal cycle) Lecture 20 T-1:Chapter 9/9.3 R-1:Chapter 30/30.11 R-1:Chapter 38/38.3 Defects in welding Causes and solutions Learning about defects Figure of various in welding defects Learning about causes and remedies Learning about destructive testing of weldments Discussion

Details of Destructive testing of weldments Test of Strength Test of hardness Test of ductility Test of fatigue Test of creep

Discussion

R-1:Chapter 38/38.4 R-1:Chapter 38/38.8 R-1:Chapter 38/38.5 R-1:Chapter 38/38.7 R-1:Chapter 38/38.9 R-1:Chapter 38/38.10 R-1:Chapter 38/38.18 R-1:Chapter 38/38.15 R-1:Chapter 38/38.14 R-1:Chapter 38/38.20 R-1:Chapter 29/29.4 OR-1 OR-2

Learning about strength Discussion test Learning about hardness test Discussion

Learning about ductility Discussion test Learning about fatigue test Learning about creep behavior Discussion Discussion Figure of non destructive testing

Nondestructive testing of Learning about weldments nondestructive testing of weldments

Details of Ultrasonic dye Learning about Discussion penetrant ultrasonic dye penetrant Details of Magnetic particle inspection Details of X ray testing procedure Introduction about defects and their identification Details of Weld thermal cycle Test 2 Learning about magnetic particle inspection Learning about X ray testing procedure Discussion

Week 10

Lecture 19

Discussion

Learning about Discussion identification of defects Learning about weld thermal cycle Discussion

Week 11

Lecture 21

Weldment Testing(Residual R-1:Chapter 31/31.6 stressed distortion in welding stress relieving techniques) Weldability and automation (Definition) Weldability and automation (Temperature distribution in welding heat affected zone) R-1:Chapter 14/14.1 R-1:Chapter 29/29.9

OR-1 OR-2

Residual stressed distortion in welding stress relieving techniques Definitions of weldability

Learning about stesses and their removal

Discussion

RW-2 OR-1 OR-2 RW-2

Learning about weldability definition

Discussion Figure of temperature distribution Discussion

Temperature distribution Learning about heat in heat affected zone affected zone Details of Weldability of Learning about steel weldability of steel

Lecture 22

Weldability and automation (Weldability of steel) Weldability and automation(Cast iron) Weldability and automation (Aluminum)

R-1:Chapter 17/17.217.3-17.4-17.5 R-1:Chapter 16/16.2 R-1:Chapter 21/21.3

RW-2 RW-2

Details of Weldability of Learning about Discussion cast iron weldability of cast iron Weldability of aluminum Learning about weldability of aluminum Details of Pre heating and post heating of weldments Estimate transition temperature Different types of automation in welding Test 3 Automated welding by Seam tracking vision Automated welding by Arc sensing welding robots Different Welding symbols positions of welding joint Design of groove in weldments Design of groove in weldments Learning about Pre heating and post heating of weldments Discussion

Week 12

Lecture 23

Weldability and automation(Pre heating and post heating of weldments) Weldability and automation (Estimation of transition temperature) Weldability and automation (Automation in welding)

R-1:Chapter 32/32.3

RW-1

Discussion

R-1:Chapter 29/29.2

RW-1

Learning about Figure of transition estimation of transition temperature temperature Learning about automated welding Learning about seam tracking vision Learning about arc sensing welding robot Discussion

R-1:Chapter 46/46.2

RW-3

Lecture 24 Week 13 Lecture 25 Weldability and automation(Seam tracking vision) Weldability and automation(Arc sensing welding robots) Lecture 26 R-1:Chapter 41/41.12 T-1:Chapter 21/21.2.8 RW-3

Discussion on seam tracking Figure of arc sensing welding robots

RW-3

Design of weldments(Welding R-1:Chapter 41/41.4 symbols positions of welding joint) Design of weldments(Groove design) R-1:Chapter 41/41.3 R-1:Chapter 41/41.3 R-1:Chapter 41/41.5/41.6

Learning about welding Figure of various symbols welding symbols and positions Learning about groove design Learning about groove design Figure of groove design Figure of groove design Problems on stress calculation

Week 14

Lecture 27

Design of weldments(Groove design) Design of weldments(Weld stress calculations)

Calculations of Weld Learning about weld stress and design of weld stress and weld size size design Spill Over

Lecture 28

Design of weldments(Design of weld size)

SPILL OVER

Week 15 Lecture 29 Spill Over

Week 15

Lecture 30

Spill Over

Scheme for CA:

Component Test Frequency 2 Total :Out Of 3 Each Marks Total Marks 10 10 20 20

Details of Academic Task(s)

AT No. Objective Topic of the Academic Task Nature of Academic Task (group/individuals/field work Evaluation Mode Allottment / submission Week 3/4

Test 1

To assess the knowledge of student regarding covered topics

Welding as a production process, Advantages, Limitations, Gas Individual welding process, Types of fuels, Gas welding equipment, Electric arc welding, Power supplies and accessories, Atomic hydrogen welding, Thermit welding, Soldering, Brazing, Braze welding, Power sources, Equipment and accessories, Applications, Limitations, of Gas tungsten arc (TIG) welding, Gas metal arc (MIG) welding, Submerged arc welding Defects in welding in various processes, Causes and remedies, Destructive testing of weldments, Strength, Hardness, Ductility, Fatigue, Creep properties etc, Nondestructive testing of weldments, Ultrasonic dye penetrant, Magnetic particle inspection, X ray testing procedure, Identification of defects, Weld thermal cycle, Individual

Evaluation of test

Test 2

To assess the knowledge of students regarding covered topics

Evaluation

9 / 10

Test 3

To assess the knowledge of students regarding covered topics

Residual stressed distortion in welding stress relieving techniques, Individual Weldability and automation : Definition, Temperature distribution in welding heat affected zone, Weldability of steel, Cast iron, Aluminum, Pre heating and post heating of weldments, Estimation of transition temperature, Automation in welding

Evaluation

11 / 12

Anda mungkin juga menyukai

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (121)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (400)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2259)

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (895)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- 6th Central Pay Commission Salary CalculatorDokumen15 halaman6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (74)

- Iron Man Helmet Papercraft Template PDFDokumen4 halamanIron Man Helmet Papercraft Template PDFNishant Khandekar25% (8)

- Learner's Book Answers: Unit 1 CellsDokumen31 halamanLearner's Book Answers: Unit 1 CellsLyaz Antony91% (91)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- Basic - Concepts - in - Pharmaceutical - Care CLINICAL PHARMACYDokumen17 halamanBasic - Concepts - in - Pharmaceutical - Care CLINICAL PHARMACYPrincess RonsableBelum ada peringkat

- Biomimicry: Exploring Research, Challenges, Gaps and Tools (Paper ID 102)Dokumen15 halamanBiomimicry: Exploring Research, Challenges, Gaps and Tools (Paper ID 102)Sunil SharmaBelum ada peringkat

- Stulz C7000R 01 PDFDokumen198 halamanStulz C7000R 01 PDFNarciso Torres0% (1)

- 027 03 Dec13 CseDokumen647 halaman027 03 Dec13 CseParth NagarBelum ada peringkat

- Milling APT ProgramDokumen5 halamanMilling APT ProgramSunil SharmaBelum ada peringkat

- Training Calendar For The M/o May 2014 Topic/Area Programme Code Trainer/Resource Person Time Date of Training Name Designation Division/School Sr. No Target Audience (As Per List Attached)Dokumen18 halamanTraining Calendar For The M/o May 2014 Topic/Area Programme Code Trainer/Resource Person Time Date of Training Name Designation Division/School Sr. No Target Audience (As Per List Attached)Sunil SharmaBelum ada peringkat

- Book Proposal FormDokumen3 halamanBook Proposal FormSiva Bala KrishnanBelum ada peringkat

- Time Table For Registration Number: 11601081 Home SectionDokumen2 halamanTime Table For Registration Number: 11601081 Home SectionSunil SharmaBelum ada peringkat

- Test Unit 3, Next Wednesday, Include Chezy Formula DerivationDokumen1 halamanTest Unit 3, Next Wednesday, Include Chezy Formula DerivationSunil SharmaBelum ada peringkat

- Research JournalsDokumen1 halamanResearch JournalsSunil SharmaBelum ada peringkat

- PopularScience of NoblePhysics2016 PDFDokumen5 halamanPopularScience of NoblePhysics2016 PDFSunil SharmaBelum ada peringkat

- MTE ANALYSIS-Student Feedback Form: S.No Student Name Regd - NO MM 40 Reason For Low Performance SignatureDokumen1 halamanMTE ANALYSIS-Student Feedback Form: S.No Student Name Regd - NO MM 40 Reason For Low Performance SignatureSunil SharmaBelum ada peringkat

- Civ339:Hydraulics and Hydraulic Machinery Laboratory: Course OutcomesDokumen1 halamanCiv339:Hydraulics and Hydraulic Machinery Laboratory: Course OutcomesSunil SharmaBelum ada peringkat

- IR Basics PDFDokumen40 halamanIR Basics PDFSunil SharmaBelum ada peringkat

- Sop 2Dokumen2 halamanSop 2Sunil SharmaBelum ada peringkat

- Research JournalsDokumen1 halamanResearch JournalsSunil SharmaBelum ada peringkat

- Uniform Distribution - Definition & Examples - MathCaptain PDFDokumen1 halamanUniform Distribution - Definition & Examples - MathCaptain PDFSunil SharmaBelum ada peringkat

- C15 4Dokumen16 halamanC15 4Sunil SharmaBelum ada peringkat

- Uniform Distribution - Definition & Examples - MathCaptainDokumen1 halamanUniform Distribution - Definition & Examples - MathCaptainSunil SharmaBelum ada peringkat

- Solidworks SimulationDokumen1 halamanSolidworks SimulationSunil SharmaBelum ada peringkat

- LS Srinath Four Chapters CompleteDokumen137 halamanLS Srinath Four Chapters CompleteSunil SharmaBelum ada peringkat

- Tensor ReviewDokumen34 halamanTensor ReviewShiva HarshBelum ada peringkat

- RPDokumen1 halamanRPSunil SharmaBelum ada peringkat

- Arbitrary Axis RotationDokumen6 halamanArbitrary Axis RotationSunil SharmaBelum ada peringkat

- Faculty's Time Table: Sunil Sharma 16727Dokumen1 halamanFaculty's Time Table: Sunil Sharma 16727Sunil SharmaBelum ada peringkat

- PUNSUP Advt.Dokumen18 halamanPUNSUP Advt.Saket BehlBelum ada peringkat

- PCC AC NewDokumen1 halamanPCC AC NewSunil SharmaBelum ada peringkat

- Faculty's Time Table: Sumeet Nagar 11588Dokumen1 halamanFaculty's Time Table: Sumeet Nagar 11588Sunil SharmaBelum ada peringkat

- MobileBill 1029371686Dokumen4 halamanMobileBill 1029371686Sunil SharmaBelum ada peringkat

- Manager (IT)Dokumen13 halamanManager (IT)dfadadsasBelum ada peringkat

- NotificationDokumen6 halamanNotificationSunil SharmaBelum ada peringkat

- MC68 HC05 B4 UDokumen253 halamanMC68 HC05 B4 Uflo724Belum ada peringkat

- STRUCTUREDokumen26 halamanSTRUCTUREJulia RatihBelum ada peringkat

- Eurotuner February 2010 PDFDokumen1 halamanEurotuner February 2010 PDFJenniferBelum ada peringkat

- Third Space Learning Ratio GCSE WorksheetDokumen11 halamanThird Space Learning Ratio GCSE WorksheetDrichy Obi-EmelonyeBelum ada peringkat

- 4 Chacon Et Al 2004Dokumen7 halaman4 Chacon Et Al 2004Luis Serrano CortezBelum ada peringkat

- SQAAU SM Assignment BriefDokumen10 halamanSQAAU SM Assignment BriefJamil NassarBelum ada peringkat

- Probability spaces and σ-algebras: Scott SheffieldDokumen12 halamanProbability spaces and σ-algebras: Scott SheffieldRikta DasBelum ada peringkat

- Samsung 932GW PDFDokumen72 halamanSamsung 932GW PDFSaidfa FaBelum ada peringkat

- Boolean Operators Literature ReviewDokumen8 halamanBoolean Operators Literature Reviewc5qz47sm100% (1)

- Fret Position CalculatorDokumen1 halamanFret Position CalculatorRay RamirezBelum ada peringkat

- Uc3842b 3843BDokumen10 halamanUc3842b 3843Bbob75Belum ada peringkat

- Competitive Analysis: Features: Smart IrrigationDokumen2 halamanCompetitive Analysis: Features: Smart IrrigationRoseanne RamonBelum ada peringkat

- Comparing Registers: MIPS vs. ARM AssemblyDokumen12 halamanComparing Registers: MIPS vs. ARM Assemblyshruti chouhanBelum ada peringkat

- Intro Ducci OnDokumen38 halamanIntro Ducci OnCARLOS EDUARDO AGUIRRE LEONBelum ada peringkat

- Reviewer in Contact Center Services NC IIDokumen12 halamanReviewer in Contact Center Services NC IIRonalei TañedoBelum ada peringkat

- Survey 2 Module 2Dokumen76 halamanSurvey 2 Module 2veereshBelum ada peringkat

- Title of The Training Program Regional Training of Grades 4-8 Reading Teachers On Care For Non-Readers (CNR) Program Module No., Day & Session NoDokumen18 halamanTitle of The Training Program Regional Training of Grades 4-8 Reading Teachers On Care For Non-Readers (CNR) Program Module No., Day & Session Nomarvin susminaBelum ada peringkat

- 20-12-11 Ericsson V, Samsung EDTX ComplaintDokumen22 halaman20-12-11 Ericsson V, Samsung EDTX ComplaintFlorian MuellerBelum ada peringkat

- 1xEV RF Optimization Guidelines R24Dokumen83 halaman1xEV RF Optimization Guidelines R24lady_sBelum ada peringkat

- Wilson's TheoremDokumen7 halamanWilson's TheoremJonik KalalBelum ada peringkat

- Practicality and Efficiency: Presented By: Grace EscabasDokumen11 halamanPracticality and Efficiency: Presented By: Grace EscabasMiaeBelum ada peringkat

- Werling Optimal Trajectory Generationfor Dynamic Street Scenariosina Frenet FrameDokumen8 halamanWerling Optimal Trajectory Generationfor Dynamic Street Scenariosina Frenet FramehugoBelum ada peringkat

- Activity On The Layers of The Earth 1Dokumen1 halamanActivity On The Layers of The Earth 1Ian MarianoBelum ada peringkat

- 14.ergonomic Workstation Design For Science Laboratory (Norhafizah Rosman) PP 93-102Dokumen10 halaman14.ergonomic Workstation Design For Science Laboratory (Norhafizah Rosman) PP 93-102upenapahangBelum ada peringkat

- 1 Conformity Asch StudyDokumen31 halaman1 Conformity Asch StudyjasbruBelum ada peringkat