Prcess Description of REFINER1

Diunggah oleh

Ade Y SaputraDeskripsi Asli:

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Prcess Description of REFINER1

Diunggah oleh

Ade Y SaputraHak Cipta:

Format Tersedia

1 1.

REFINING AND STOCK PROPORTIONING Short Fibre Pulp Refining See Process Flow Diagram Stock Preparation

1.1.1

Proce

De cription

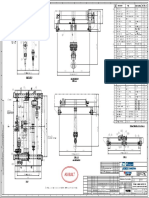

The pumping consistency from the LBKP dump tower is controlled by Q !""#$ Dilution water to the tower bottom is controlled by flow ratio controller FF !""#% of stock flow F&!""#'( The pumping consistency is !"! )( From LBKP dump tower LBKP is pumped to LBKP pulp refiner feed chest "' *+ ,-, by pump "' *+ %,* at the consistency of %.%)( Le/el of the tank is controlled by L ! "",$( The consistency is controlled by Q !""#$( The /olume of LBKP pulp refiner feed chest "' *+ ,-, is *,, m" and it is e0uipped with agitator "' ** ',-( The short fibre pulp is pumped from the chest to refining by pump "' ** %+, and pump "' ** %,1 at the consistency of %., )( The consistency is controlled by Q !""1, and Q !""1+( &t is possible to control p2 in the LBKP refiner feed lines by adding sodium bicarbonate. 3a2 4". to LBKP refiner feed chest( The sodium bicarbonate proportioning is controlled by F !'#+, in ratio to total LBKP pulp flow( The short fibre pulp refining system consists of two e0ual lines which are both e0uipped with two refiners coupled in series5 %+ *+ ,"# and %+ *+ ,"- Line + %+ *+ ,"$ and %+ *+ ,"% Line * 6efiners are double disc refiners. type Beloit 7ones ",,, series( 8ach refiner can be by!passed by opening by!pass /al/es and closing line on!off /al/es accordingly( #hen refiner i electe$ to GS%% &Stoc' Proportioning( group t)rt" the refiner control )re ch)nge$ to A*TO )n$ +hen refiner t)rt ,)l,e )re in on-line po ition. 1/KP pulp refiner 1 1/KP pulp refiner 6 1/KP pulp refiner 4 1/KP pulp refiner 5 %+ *+ ,"# %+ *+ ,"%+ *+ ,"$ %+ *+ ,"% Inlet 234-45!4 234-4554 234-4544 234-4564 Open Outlet 236-45!4 236-4554 236-4544 236-4564 Open /0p) 231-45!4 231-4554 231-4544 231-4564 Clo e

8ach refiner can be bypassed by opening the bypass /al/e( 9fter the bypass /al/e is opened. inlet and outlet /al/es close(

Orig. Rev. A 19.08.08/YB Date/Author Date/Checked Date/Approved Date/ ssued Original issue !otes

YO"A!#$ BA%BA!& '

The pressures in the refining lines are kept constant by P !""-- and P !""#-. which gi/e set points to fre0uency controllers of the pumps( For the start!up of the refining lines and also for a situation when the pulp need in a refining line is small. the refining lines are e0uipped with recirculation lines( The recirculation flows are controlled by F& !"'++, and F& !"'+,-. which measure the flow in the main line but control the recirculation of the stock back to the LBKP pulp refiner feed chest( The set points of these flow controllers shall be set to a small flow :about %" l;s<. so that the recirculation is on at the start!up and the refiners can be loaded. but normally. when stock proportioning is started. the recirculation /al/e closes( 9fter the refining. short fibre pulp is proportioned to the LBKP pulp chest. "' ** $,$( The total flow to the chest is ad=usted by le/el controller L& !"'+,+( The proportioning of the short fibre pulp from separate refining lines are controlled by flow ratio controllers FF& !"'+,$ and FF& !"'+,"( Pre!dilution water to LBKP pulp chest is controlled by FF& !"'+,*( Flow controller gets its set point from LBKP pulp chest le/el control L& !"'+,+ The /olume of the LBKP pulp chest. "' ** $,$ is %, m " and it is e0uipped with agitator "' ** ',$( The short fibre pulp is pumped from the chest by pump "' ** %,# to proportioning at the consistency of "(* )( The consistency is controlled by Q ! "",-( 9ll short fibre refining lines are e0uipped with on!line beating degree measurements after refiners. 9& !"'+,# line + and 9& !"'+,% line *. type /TG. 6efining is controlled by the process control system( The following control strategies may be used5 7)nu)l control" in +hich c) e g)p bet+een filling i 'ept con t)nt 8controller i in 9 7o$e: refining power is controlled. in which case the refining power of each refiner is kept constant 8controller i in A 7o$e: specific energy consumption :S8 < of indi/idual refiners or refining lines is controlled. in which case the system calculates the refining power re0uired taking into consideration the flow through each line :controller i in R 7o$e:. Thi i nor7)ll0 the control 7o$e to be u e$. SEC i et b0 the oper)tor )n$ the proce control 0 te7 count refining po+er th)t )re nee$e$ for cert)in SEC. Proce control 0 te7 t)'e into )ccount ,)ri)tion in the pulp flo+ )n$ con i tencie )n$ 'eep the SEC con t)nt. Refiner h),e the )7e refining po+er in the beginning of the refining. SEC i c)lcul)te$ for e)ch refiner b0 the follo+ing 7)nner.

S8 = :P6 P, <k>h + :Flow onsistency< k

SEC PR

; ;

Specific energ0 con u7ption" '#h<t Refining po+er" '#

YO"A!#$ BA%BA!& (

P= Flo+

; ;

I$ling po+er +ith +)ter" '# > !== '# l< ? =.=4@ 8unit c)ling f)ctor:

Con i tenc0 ; ' ;

The po+er $i tribution r)tio of refiner in e)ch line c)n be )$Au te$ in c) e of $ifferent $i c con$ition etc. 6efiners are controlled by5 Position Line + %+ *+ ,"# %+ *+ ,"Line * %+ *+ ,"$ %+ *+ ,"% 1.1.6 LBKP pulp refiner " LBKP pulp refiner ' 86!"'+' 86!"'+" LBKP pulp refiner + LBKP pulp refiner * 86!"'+$ 86!"'+% 3ame Power ontrol

Control of Refiner St)rt-up of Refiner The refiner can be started up from the control system /ideo display( The start!up can be made if interlocking and start!up conditions are fulfilled( &nterlocking conditions of the refiner )re follo+ing 8po ition nu7ber )re ho+n onl0 for 1/KP refiner 1" !1 61 =4B:. stock inlet pressure PI-41@ is lower than ma? limit :$,, kPa< $el)0 4= stock outlet pressure PI-41C is lower than ma? limit :$,, kPa< $el)0 4= emergency stop circuit %%%%%% is 4K sealing water pressure PI-%%%% is o/er the low limit :",, kPa< ! $el)0 sealing water pressure difference :sealing water pressure @ stock discharge pressure< is o/er the low limit :+,, kPa< 1 $el)0 the main motor winding temperature TI-45=!@ is below the high limit( refiner selection /al/e 2S-45!4 is in operating position )n$ the refiner drain /al/e 23-45!! is in open position the AA :7otor control centre< of the main motor is ready to start Start!up condition of the refiner5 the plates are open 8E3-%%% OPEN: 68A4T8 is selected from local control bo? %%%%%% at least one minute has elapsed from the stopping of the main motor 6unning conditions of the refiner5

YO"A!#$ BA%BA!& )

interlocking conditions are fulfilled the stock flow is abo/e the low limit. delay " min &f any of the interlocking conditions is not fulfilled. the main motor of the refiner stops and the plates are opened with 0uick mo/ement( The stock flow is not allowed to be below the low limit for more than " minutes( :The plates are. howe/er. opened immediately when the low limit of stock flow has been passed<( Stopping the Refiner The refiner can be stopped from process control system according( Stopping the refiner line Broup stop stops refining( Flushing starts when refiner stops( During flashing inlet and outlet /al/e of refiner close. flashing water and drain /al/e of refiner open( 1o)$ing the Refiner The refiner is ready to be loaded when the following conditions are fulfilled5 stock flow FIC-4511= o/er the low limit :%* l;s< stock inlet pressure PI-41@ i o/er the low limit 8C= 'P): 1 $el)0 stock inlet pressure PI-41C is below the high limit 8@== 'P): 1= $el)0 stock outlet pressure PI-41C is below the high limit 8@== 'P): 1= $el)0 the main motor of the refiner 451@.A is running selection /al/e 2S-45!4 are in on!line position the refiner drain /al/e 23-45!! is closed the refiner flush /al/es 23-45!5 )re closed main motorCs power measurement ER-451@ circuit is 4K and below high limit stock pump 45 66 !1= is running the loading motor 86!"'+$(B current is below high limit fre0uency con/erter is ready for operation stock consistency DC-44E= is higher than low limit :*.*% )< 9ir pressure of spring is , bar :8D!EEEE lose< 9 further condition for control from the remote control place :automatic control< is that the remote operation mode is selected( &f ser/ice is selected. only local control is possible :maintenance etc<( 4pening and closing of the refiner plates during ser/ice operations is possible if operation mode is set to ser/ice( &n this case the following interlocks are o/erruled5 stock pressure below the low limit stock pressure abo/e the high limit stock flow below low limit the main motor of the refiner stopped

YO"A!#$ BA%BA!& *

stock pump stopped /al/e selection consistency too low Pl)te Control" Duic' 9o,e7ent Open The plates open automatically with fast mo/ement in the following cases5 refiner power abo/e PA9F limit refiner power abo/e PL4> limit when ser/ice operation mode is selected by the switch QG& K A4D8A83T 4P83 of the local control desk. irrespecti/e of the selected control position by the control QG& K A4D8A83T 4P83 of the remote control site. irrespecti/e of the selected control position if the position measurement HL&A,% and process disturbance signal is acti/e if )n0 of the refiner re)$ine con$ition )re not fulfille$ 8 ee lo)$ing the refiner : The plates cannot be dri/en open if the plates are in the open limit( The control IQuick Ao/ement 4penI by!passes all other plate controls( Power limit PA9F must always work regardless of the selected operating mode :3ormal;Ser/ice<( Pl)te Control" Duic' 9o,e7ent Clo e The loading motor can be dri/en to closed position from local control positions. if the following conditions are /alid5 ser/ice operation mode is selected power measurement is below PL4> limit open control is not /alid the position measurement is JL&A ,% limit main motor is not running

&n the ser/ice operation mode the Kmain motor runningL signal o/errides the L&A ,% limit. enabling the plates to be dri/en towards the closed position at slow speed far enough that they touch( It i not po ible to control the filling b0 f) t 7o,e7ent clo e fro7 the control roo7. Pl)te Control" Duic' 9o,e7ent Clo e The loading motor can be dri/en to closed position from the remote control positions. if the following conditions are /alid5 position measurement is in order :no analogue errors< power measurement is below PL4> limit rotor position is JL&A+, limit or the refiner is ready for loading 0uick open control is off operation mode is set to remote

YO"A!#$ BA%BA!& +

power control is in manual mode Pl)te Control" 1o)$ing 9o,e7ent Open The loading motor can be dri/en to open position in manual control both from the remote and local control positions. using the main motorCs power reading. if the following conditions are /alid5 IQuick Ao/ement 4penI is not on the plates are not in the open limit Pl)te Control" 1o)$ing 9o,e7ent Clo e The loading motor can be dri/en to closed position in manual control both from the remote and local control positions. using the main motorCs power reading. if the following conditions are /alid5 IQuick Ao/ement 4penI is not on ILoading Ao/ement 4penI is not on power measurement is below P2&B2 limit refiner is ready for loading

Auto7)tic Control ontrol can be set to automatic mode if the following conditions are met5 6emote operation mode is selected refiner is ready for loading >hen control is set to automatic mode. the plates are first dri/en close by 0uick mo/ement( The 0uick mo/ement must stop at Plow power limit. from which closing continues at /ariable speed that depends on the difference /alue between setpoint and measured /alue( &f any of the following conditions abo/e becomes in/alid. control must switch to manual mode( local fast open is on local mode selected remote 0uick open control open command from stop seguence touch point /ibration J22

Po+er 1i7it Plow limit :A<M Ppulse limit :9<M Phigh limit Pma? limit M M P, N ,(* ? :3ominal power @ P,< P, N ,(* ? :Pset ! P,< :4nly in 9GT4 mode< Dimensioned refining power :fi?ed<+*% k> +(,% ? dimensioned refining power +"+* k>

YO"A!#$ BA%BA!& ,

P, Pset

M M

&dling power in water run :fi?ed< Power setpoint

Pre ure 1i7it Stock pressure

low high ma?

M M M

,(- bar %(, bar $(, bar

Sealing water :Sealing water @ stock discharge< Flo+ 1i7it Stock flow Sealing water Con i tenc0 1i7it low M high M

low ma? low

M M M

,(" bar +(, bar ,(+% bar

low low

M M

%" l;s ,(," l;s

*(* ) @.= )

1ength of Control Pul e )n$ De)$ Fone of Control &n automatic control the loading mo/ement must be continuous up to the limit P low. when using 0uick mo/ement and up to Ppulse when using slow mo/ement( 9fter this the pulse controller is released to reach the desired set point( The durations of the control pulses shorten as follows5 ,(- ! *(, seconds :O+, k>< The k>!/alue after the seconds indicates the dead Pone of the control( Time between se0uential pulses must be appro?imately %!+, seconds(

Anda mungkin juga menyukai

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (587)

- Cable Sizing CalculationDokumen6 halamanCable Sizing CalculationAde Y SaputraBelum ada peringkat

- Harga ArresterDokumen2 halamanHarga ArresterAde Y SaputraBelum ada peringkat

- SEMA MH Hook Block Assly. Sheet 1 3Dokumen1 halamanSEMA MH Hook Block Assly. Sheet 1 3Ade Y SaputraBelum ada peringkat

- SEMA AH Hook Block Assly. Sheet 2 3Dokumen1 halamanSEMA AH Hook Block Assly. Sheet 2 3Ade Y SaputraBelum ada peringkat

- 100W Son-T High OutputDokumen2 halaman100W Son-T High OutputAde Y SaputraBelum ada peringkat

- Jual Besi Pipa Galvanis Medium - Harga Distributor - TokoBesiBajaDokumen5 halamanJual Besi Pipa Galvanis Medium - Harga Distributor - TokoBesiBajaAde Y SaputraBelum ada peringkat

- 3147 Hoist r3Dokumen1 halaman3147 Hoist r3Ade Y SaputraBelum ada peringkat

- Section:A-A': Typical Power JointDokumen1 halamanSection:A-A': Typical Power JointAde Y SaputraBelum ada peringkat

- 2MLD09-0100-01664365 B: ClientDokumen1 halaman2MLD09-0100-01664365 B: ClientAde Y SaputraBelum ada peringkat

- Besi U PDFDokumen1 halamanBesi U PDFAde Y SaputraBelum ada peringkat

- Fuse Modular Terminal Block - DT 6/2,5-DREHSILED 24 (5X20) - 3034251Dokumen18 halamanFuse Modular Terminal Block - DT 6/2,5-DREHSILED 24 (5X20) - 3034251Ade Y SaputraBelum ada peringkat

- 50 AMP WELDER ReceptacleDokumen2 halaman50 AMP WELDER ReceptacleAde Y SaputraBelum ada peringkat

- Paper Title (Use Style - Paper Title)Dokumen6 halamanPaper Title (Use Style - Paper Title)Ade Y SaputraBelum ada peringkat

- SAP PM T - CodesDokumen4 halamanSAP PM T - CodesBujjibabu Katta0% (1)

- Star - DeltaDokumen4 halamanStar - DeltaAde Y SaputraBelum ada peringkat

- Jual Besi Pipa Galvanis Medium - Harga Distributor - TokoBesiBajaDokumen5 halamanJual Besi Pipa Galvanis Medium - Harga Distributor - TokoBesiBajaAde Y SaputraBelum ada peringkat

- ACSR BS215 Part 2Dokumen1 halamanACSR BS215 Part 2Ade Y SaputraBelum ada peringkat

- Heavy Duty Power Cable for Distribution and TransmissionDokumen5 halamanHeavy Duty Power Cable for Distribution and TransmissionSemar AngBelum ada peringkat

- Variable Frequency DriveDokumen40 halamanVariable Frequency DriveAde Y Saputra100% (1)

- Acsr - Astm b232Dokumen3 halamanAcsr - Astm b232Ade Y SaputraBelum ada peringkat

- Acsr SPLN 41-7 PDFDokumen2 halamanAcsr SPLN 41-7 PDFAde Y Saputra100% (1)

- Acsr SPLN 41-7 PDFDokumen2 halamanAcsr SPLN 41-7 PDFAde Y Saputra100% (1)

- Acsr Din en 50182Dokumen1 halamanAcsr Din en 50182Ade Y SaputraBelum ada peringkat

- Tipe NGRDokumen4 halamanTipe NGRAde Y SaputraBelum ada peringkat

- NGR GarutRev1Dokumen1 halamanNGR GarutRev1Ade Y SaputraBelum ada peringkat

- MHPPDokumen8 halamanMHPPAde Y Saputra100% (1)

- Engineering Note: PT - Indah Kiat Pulp & Paper TBKDokumen8 halamanEngineering Note: PT - Indah Kiat Pulp & Paper TBKAde Y SaputraBelum ada peringkat

- Piping Instalation (11aug09)Dokumen10 halamanPiping Instalation (11aug09)Ade Y SaputraBelum ada peringkat

- Engineering Note: PT - Indah Kiat Pulp & Paper TBKDokumen8 halamanEngineering Note: PT - Indah Kiat Pulp & Paper TBKAde Y SaputraBelum ada peringkat

- LBKP Feed PumpDokumen1 halamanLBKP Feed PumpAde Y SaputraBelum ada peringkat

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (399)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (73)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (265)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (119)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- Business Mathematics: Quarter 1 - Module 3: Kinds of ProportionDokumen25 halamanBusiness Mathematics: Quarter 1 - Module 3: Kinds of ProportionZia Belle Bedro - LuardoBelum ada peringkat

- Kotval Mullin Fiscal ImpactDokumen44 halamanKotval Mullin Fiscal ImpactMarkWeberBelum ada peringkat

- Exercise of Soil MechainicsDokumen72 halamanExercise of Soil MechainicschamsBelum ada peringkat

- Combine ResultDokumen12 halamanCombine Resultpreeti.2405Belum ada peringkat

- Module 1: Introduction To Numerical Analysis QuestionsDokumen2 halamanModule 1: Introduction To Numerical Analysis QuestionsNinoMay Suazo RobleBelum ada peringkat

- 15 Atom HidrogenDokumen42 halaman15 Atom HidrogenRahajengBelum ada peringkat

- Signal DegradationDokumen57 halamanSignal DegradationSathiyanBelum ada peringkat

- Fire Resistance of CFTDokumen24 halamanFire Resistance of CFTsjh1016Belum ada peringkat

- UT Dallas Syllabus For Math1326.502.07s Taught by Raj Seekri (Seekri)Dokumen5 halamanUT Dallas Syllabus For Math1326.502.07s Taught by Raj Seekri (Seekri)UT Dallas Provost's Technology GroupBelum ada peringkat

- Table of Spicification Mathematics 5 First Periodical Test: Objectives R U Ap An E CDokumen9 halamanTable of Spicification Mathematics 5 First Periodical Test: Objectives R U Ap An E CApril Jean CahoyBelum ada peringkat

- Physics Set A H.Y 14-15Dokumen4 halamanPhysics Set A H.Y 14-15Raja KumarBelum ada peringkat

- Seepage Pressure PDFDokumen8 halamanSeepage Pressure PDFVenance MasanjaBelum ada peringkat

- Trig2 Tutorial VDokumen2 halamanTrig2 Tutorial VSabrina LinuxBelum ada peringkat

- M3 PPT 1 1 Phase Ac CircuitDokumen67 halamanM3 PPT 1 1 Phase Ac CircuitUDhayBelum ada peringkat

- Algorithmic Differentiation in Finance Explained-Henrard, Marc, Palgrave Macmillan (2017) PDFDokumen112 halamanAlgorithmic Differentiation in Finance Explained-Henrard, Marc, Palgrave Macmillan (2017) PDFdata100% (3)

- Causal Inference For Data Science (MEAP) - de VillaDokumen163 halamanCausal Inference For Data Science (MEAP) - de VillaJuan RodriguezBelum ada peringkat

- Loan EMI Calculator: Download Free App From Play Store atDokumen9 halamanLoan EMI Calculator: Download Free App From Play Store atkantilal rathodBelum ada peringkat

- LQGDokumen64 halamanLQGstephenBelum ada peringkat

- DLL Q4 G5 Math Week 1Dokumen6 halamanDLL Q4 G5 Math Week 1Virgie Anne ConcepcionBelum ada peringkat

- Visit TutorialDokumen83 halamanVisit Tutorialfab1991Belum ada peringkat

- Everyday Math Unit 7 ReviewDokumen3 halamanEveryday Math Unit 7 ReviewReekhaBelum ada peringkat

- Magical Student Character Creation GuideDokumen20 halamanMagical Student Character Creation Guidekeglon002Belum ada peringkat

- Maximum Efficiency and Output of Class-F Power AmplifiersDokumen5 halamanMaximum Efficiency and Output of Class-F Power AmplifierscemshitBelum ada peringkat

- Problem 12-53: A T A V TDokumen57 halamanProblem 12-53: A T A V Tadam johnsonBelum ada peringkat

- Conversion of Dates and Amount To Arabic Numerals in SSRS AX ReportsDokumen5 halamanConversion of Dates and Amount To Arabic Numerals in SSRS AX ReportsDynamic Netsoft TechnologiesBelum ada peringkat

- Ship Stability and SubdivionDokumen16 halamanShip Stability and SubdivionAnmol AgarwalBelum ada peringkat

- Algebra 1Dokumen38 halamanAlgebra 1Elias RezaBelum ada peringkat

- Improving Proficiency in The Four Fundamental Operations in Mathematics in Grade Two SPED FL/GT Pupils LF Don Emilio Salumbides Elementary School Through The Implementation of Vedic Math TechniquesDokumen5 halamanImproving Proficiency in The Four Fundamental Operations in Mathematics in Grade Two SPED FL/GT Pupils LF Don Emilio Salumbides Elementary School Through The Implementation of Vedic Math TechniquesPsychology and Education: A Multidisciplinary JournalBelum ada peringkat

- Martin Caidin - The God MachineDokumen134 halamanMartin Caidin - The God MachineLogan BlackstoneBelum ada peringkat

- Bahan Univariate Linear RegressionDokumen64 halamanBahan Univariate Linear RegressionDwi AstitiBelum ada peringkat