50 FMC

Diunggah oleh

Tran Tuan KietDeskripsi Asli:

Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

50 FMC

Diunggah oleh

Tran Tuan KietHak Cipta:

Format Tersedia

50-FMC Draft Recommendation

D e t e r m i n a t i o n of t h e f r a c t u r e e n e r g y of m o r t a r and c o n c r e t e by m e a n s of t h r e e - p o i n t bend tests on n o t c h e d b e a m s

CONTENTS 1. Scope. 2. Specimens. 3. Conditions of storage. 4. Apparatus. 5. Procedure. 6. Test results. 7. Test report.

Horizontal ,~urfaceat castinq

l~notch depth L Fig. 1

1. S C O P E This Recommendation specifies a method for the determination of the fracture energy (GF) of mortar and concrete by means of stable three-point bend tests on notched beams. The fracture energy is defined as the amount of energy necessary to create one unit area of a crack. The area of a crack is defined as the projected area on a plane parallel to the main crack direction. This test method is not recommended for fibre-reinforced concrete.

recommended to make the insert in the mould wedgeshaped with an angle of 10-15 ~ in order to make it possible to loosen the mould w i t h o u t damaging the beam. If the notch is cast the beam must be handled very carefully during demoulding. The notch width at the tip should be less than 10 mm. If the fracture energy of concrete of an existing structure has to be determined, it is suggested that suitable specimens are cut from drilled cores. A notch has to be sawn and metal or concrete arms have to be glued to the specimen, so that the total specimen fulfils the geometrical conditions given in table I. The diameter of the core has to be adjusted to the maximum aggregate size.

2. S P E C I M E N S

The specimens shall be beams with a central notch according to figure 1. The depth of the beam as tested shall be horizontal during casting. The size of the beam shall depend on the maximum size of the aggregate, Dmax, according to table I. If the maximum aggregate size exceeds 64 mm the depth and width shall be increased proportional to this size and the length and span increased proportional to the square root of this size. The notch shall always have a depth which is equal to half the beam depth -I- 5 mm. It is recommended that it is sawn under wet conditions at least one day before the test. It may also be cast but this is only recommended if a suitable saw is not available. If the notch is cast it is

3. C O N D I T I O N S OF S T O R A G E During the period of curing the ambient temperature shall be 20 ___ 2~ The specimen shall remain in the mould, protected from shock, vibrations and drying, for at least 16 hours. After removal from the mould, the specimen shall be stored in lime-saturated water until less than 30 minutes before testing.

4. A P P A R A T U S

4.1. T e s t i n g m a c h i n e

The testing machine has to be stiff enough or furnished with a closed-loop serve control in order to make it possible to perform stable tests. A test can be regarded as stable in the load and the deformation change slowly during the w h o l e test, i.e. w i t h o u t any sudden jump. Unless the complete load-time curve is recorded the check of stability must be made visually during the test, as the load-deformation curve does not always reveal an instability. If the testing machine has no closed-loop serve control the required stiffness is about 10 kN/mm for the smallest standard beam. The corresponding stiffnesses of the larger

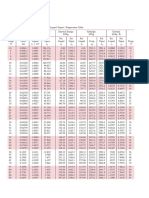

TABLE I SIZES OF SPECIMENS.

~)max __ (mm)

l 9I

Depth d (mm) 100 200 300 400 5 5 5 5

Width b (mm) 100 100 150 200 5 5 5 5

Length L (mm) 840 1,190 1,450 1,640 10 10 10 10

Span / (mm)

800 1,130 1,385 1,600 + -t+ -t5 5 5 5

I 1-16 . I 16.1-32 I :32.11-48

1-64

287

Vol. 18 - N~ 106 - Mat~riaux et Constructions Les rigidit~s correspondant aux plus grandes des poutres-type sont respectivement de I'ordre de 25,70 et 1 50 kN/mm. Ces nombres n'indiquent que I'ordre de grandeur des rigidit~s requises, d'importantes variations pouvant se produire selon les propri~t6s des b~tons ~tudi~s. Chaque fois qu'on rencontrera des difficult~s dans I'obtention de la stabilit6 de I'essai, il faudra utiliser le d~placement d'ouverture des I~vres de la fissure comme valeur de contr61e du taux de d(~formation. 4 . 2 . A p p u i s et d i s p o s i t i f de raise en c h a r g e Les appuis et le dispositif de mise en charge doivent ~tre tels que le syst~me m~canique soit isostatique, conform6ment ~ la figure 2. 4 . 3 . M e s u r e des d e f o r m a t i o n s La fl~che au centre de la poutre sera d6termin~e par rapport ~ une ligne d6finie par deux points de la poutre situ6s au-dessus des appuis. Le deplacement du point d'application de la charge peut ~galement ~tre mesur~ par rapport & la ligne d'appui si le dispositif d'application de la charge et les appuis sont con?us de telle sorte qu'en ces points les d~formations non 61astiques restent inf~rieures ~ 0,01 mm. Les d6placements seront mesur~s avec une precision de 0,01 mm au moins. avec : Wo=aire limit6e par la courbe (F, 6), cf, figure 3 (Nm); m = ml +2 m2 (kg) ; rnt=masse propre de la poutre entre appuis, calcul6e comme la masse totale multipli6e par le rapport IlL; m2=masse de la partie du dispositif de chargement non solidaire de la machine d'essais, mais suivant la poutre dans sa d6formation jusqu'~ la rupture; g=acc~l(~ration de la pesanteur, 9,81 m/s2; 5o=fl~che Iors de la rupture totale de la poutre (m); Aiig=aire du ligament, d~finie plus haut (m2). L'(~nergie de rupture sera d~duite de I'(~quation :

GF=(Wo+mgSo)/Aiig [N/m (Jim2)],

Articulation sp~riclue

4'

Fig, 2

5. P R O C E D U R E E X P E R I M E N T A L E L'essai est effectu~ & une vitesse de d6formation approximativement constante, choisie de telle sorte que le maximum de charge soit atteint 30 ,~ 60 secondes environ apr~s le d~but de I'essai. La fl~che au centre de la poutre et la valeur correspondante de la charge sont enregistr~es jusqu'~ ce que la poutre soit compl~tement partag~e en deux. Dans le cas oe la d~formation n'est pas mesur~e directement sur I'~chantillon, il est recommand~ qu'avant I'enregistrement de la courbe effort-d~formation, la charge soit cycl~e trois fois entre 5 et 25% de la charge maximale escompt~e. La charge devra ~tre mesur~e avec une precision d'au moins 2% de la valeur maximale enregistr~e en cours d'essai. Dans le cadre de I'essai, le poids de la poutre, d'une part, et, d'autre part, celui du dispositif d'application de la charge non solidaire de la machine d'essai, seront d~termin@s. L'aire du ligament, Alig, sera 6galement mesur~e. Cette aire est d6finie comme la projection de la zone de rupture sur un plan perpendiculaire ~ la ligne moyenne de la poutre. La Iongueur L de la poutre, tout comme sa port~e/, seront mesur~es avec une pr6cision de 1 mm au moins.

7. C O M P T E R E N D U D ' E S S A I

t~matiquement

7 . 1 . I n f o r m a t i o n s i n d i s p e n s a b l e s & m e n t i o n n e r sysd a n s le c o r n p t e r e n d u d ' e s s a i --

num6ro d'identification de I'@chantillon; dimensions de 1'6chantillon : b, d, L, /, Alig; m~thode de fabrication de I'encoche; poids de I'~chantillon; masse m l ; masse m2;

W0; 50;

- Fmax=charge maximale appliqu~e, m2 non comprise; - precision de la mesure des d~placements; - moyen de contrble de la stabilit~ de I'essai; F(char~e)

6. R ESU LTATS La courbe effort-d6formation sera corrig~e des ~ventuelles non lin(}arit6s aux faibles charges, comme le montre la figure 3 (trac(~ en tirets). L'~nergie W0, repr6sent6e par I'aire limit~e par la courbe F-6, ainsi que la valeur ultime de la fl~che 60 lots de la rupture complete, seront mesur6es.

288

~(fl~che) Fig. 3

50-FMC Draft Recommendation standard beams are about 25, 70, and 150 kN/mm respectively. These figures only indicate the order of magnitude of the required stiffnesses, and large variations may occur depending on the properties of the tested concrete. Whenever there are problems in running the test in a stable way, crack mouth opening displacement shall be used as the control value for deformation rate.

BaJ_/_l

4.2. S u p p o r t s a n d l o a d i n g a r r a n g e m e n t The supports and loading arrangements shall be such that the forces acting on the beam are statically determinate, e. g. according to figure 2. where:

4.3. Deformation measurement

Fig. 2

The deformation of the center of the beam shall be determined with regard to a line between two points on the beam above the supports. Alternatively the deformation of the load-point with respect to the support may be measured if the load-application and supports are arranged in such a way that nonelastic deformations at these points are less than 0.01 ram. The deformation shall be measured with an accuracy of at least 0.01 mm.

Wo = area according to figure 3 (N/m); m = ml + 2m2 (kg); ml weight of the beam between the supports, calculated as the beam weight multiplied by//L;

----

m2 weight of the part of the loading arrangement which is not attached to the machine, but follows the beam until failure;

=

g = acceleration due to gravity, 9.81 m/s2; = deformation at the final failure of the beam (m); Allg = area of the ligament as defined above (m2).

5. PROCEDURE The test is performed with an approximately constant rate of deformation, which is chosen so that the maximum load is reached within about 30-60 seconds after the start of the test. The deformation of the center of the beam and the corresponding load are registered until the beam is completely separated into two halves. In case the deformation is not measured directly on the specimen it is recommended that before measuring the load-deformation curve the load is cycled 3 times between 5% and 25% of the expected maximum load. The load shall be measured with an accuracy of at least 2% of the maximum value in the test. In connection with the test, the weight of the beam and the weight of the part of the loading arrangement which is not attached to the testing machine shall be determined. The area of the ligament, AJig, shall be measured. It is defined as the projection of the fracture zone on a plane perpendicular to the beam axis. The length L of the beam as well as the span / during the test shall be measured with an accuracy of at least 1 mm.

7. TEST REPORT 7.1. Basic i n f o r m a t i o n , a l w a y s t o be m e n t i o n e d

the report

in

-identification number of specimen; - dimensions of the specimen: b, d, L,/, Azig; - m e t h o d of making the notch; - w e i g h t of the specimen; - weight /771; - weight m2;

- Wo;

-

8o;

--Fmax = maximum applied load, excluding m2; -accuracy of deformation measurements; - how the stability has been checked;

F(toad)

6. TEST RESULTS The load-deformation curve is corrected for eventual non-linearities at low loads, see dashed line in figure 3. The energy Wo, represented by the area under the curve, is measured as well as the deformation 8o at final fracture. The fracture energy is calculated from the equation: GF = (Wo + mgSo)/Alig [N/m (J/m2)], Fig. 3

6(def]

~o

289

V01. 18 - N~ 106 - Mat6riaux et Constructions -

observations sur la stabilit~ de I'essai;

FG.

- o b s e r v e d indications of instability;

GF.

7.2.

Informations

additionnelles

7.2. A d d i t i o n a l -type

information

- Nature du b~ton; - Nature des granulats; - Quantit6 de ciment et c o m p o s i t i o n du b6ton; - Age du bdton au jour de I'essai; - R~sistance ~ la compression, avec indication de la m~thode d'(~valuation de cette r6sistance; - R 6 s i s t a n c e ~ la traction, avec indication m~thode d'~valuation de cette r~sistance; de la

of concrete;

-type of cement; -type of aggregate;

-

- c e m e n t content and mix p r o p o r t i o n s of concrete; age at testing;

- compressive strength, i n c l u d i n g m e t h o d of determination; - t e n s i l e strength, including m e t h o d of determination; - e l a s t i c modulus, including m e t h o d of determination; - density; -any unusual features or interesting observations.

- M o d u l e d'~lasticit6 Iongitudinale, avec indication de la m6thode d'~valuation; - Densit6; - Toute caract~ristique particuli~re ou observation int6ressante.

290

Anda mungkin juga menyukai

- Astm C78Dokumen3 halamanAstm C78avrajan100% (3)

- Flexural Strength ConcreteDokumen3 halamanFlexural Strength ConcreteShantanu DuttaBelum ada peringkat

- Water Energy Generator US20060180473A1Dokumen26 halamanWater Energy Generator US20060180473A1JohnBelum ada peringkat

- John Titor TIME MACHINEDokumen21 halamanJohn Titor TIME MACHINEKevin Carey100% (1)

- Design of Plumbing Systems For Multi-Storey Buildings PDFDokumen14 halamanDesign of Plumbing Systems For Multi-Storey Buildings PDFpequenita34100% (4)

- Pressure Losses in PipesDokumen18 halamanPressure Losses in PipesElSobrinodeRoshiBelum ada peringkat

- Electrical Engineering Interview QuestionDokumen9 halamanElectrical Engineering Interview QuestionRohan BoseBelum ada peringkat

- Mechanical Science for Technicians: Volume 1Dari EverandMechanical Science for Technicians: Volume 1Penilaian: 5 dari 5 bintang5/5 (1)

- Ductulator - Air Duct CalculatorDokumen1 halamanDuctulator - Air Duct CalculatorCarlos R. SantiagoBelum ada peringkat

- D 1331 - 89 R01 - RdezmzeDokumen3 halamanD 1331 - 89 R01 - Rdezmzejamaljamal20Belum ada peringkat

- BS 1377 Part 9 Plate Bearing Test GuideDokumen9 halamanBS 1377 Part 9 Plate Bearing Test GuidedamithBelum ada peringkat

- Pile Load TestDokumen8 halamanPile Load TestNgoc Ba NguyenBelum ada peringkat

- Quality Control of Construction Testing of Concrete CubesDokumen7 halamanQuality Control of Construction Testing of Concrete CubesHemanth KumarBelum ada peringkat

- BS 1881-Part 209-90Dokumen8 halamanBS 1881-Part 209-90NidDouBelum ada peringkat

- Strength of Materials and Structures: An Introduction to the Mechanics of Solids and StructuresDari EverandStrength of Materials and Structures: An Introduction to the Mechanics of Solids and StructuresPenilaian: 4 dari 5 bintang4/5 (1)

- Example 2 - Pile Cap, STM's MethodDokumen15 halamanExample 2 - Pile Cap, STM's MethodMarkoGlamuzina100% (2)

- A Quantum Model About Coherence To Understand Non Ionizing Radiation, Geesink, June 2013Dokumen146 halamanA Quantum Model About Coherence To Understand Non Ionizing Radiation, Geesink, June 2013marcelogiovaneBelum ada peringkat

- Astm C 393Dokumen4 halamanAstm C 393Arash Aghagol0% (1)

- Torsion Test1Dokumen6 halamanTorsion Test1musher95100% (1)

- Report Full Direct Shear Test Edit (Repaired)Dokumen15 halamanReport Full Direct Shear Test Edit (Repaired)Asyraf Malik100% (15)

- Applied Functional Analysis Applications To Mathematical PhysicsDokumen503 halamanApplied Functional Analysis Applications To Mathematical PhysicsDietethique100% (7)

- Astm C131Dokumen8 halamanAstm C131chatransito10% (1)

- Aci 544.1R-96Dokumen66 halamanAci 544.1R-96Tran Tuan KietBelum ada peringkat

- Calibration of Metal TapesDokumen16 halamanCalibration of Metal Tapesarabcal100% (1)

- Eaching High-Rise Plumbing DesignDokumen19 halamanEaching High-Rise Plumbing Designm_salah20202000Belum ada peringkat

- RILEM TC 162-TDF Test and Design Methods For Steel Fibre Reinforced ConcreteDokumen3 halamanRILEM TC 162-TDF Test and Design Methods For Steel Fibre Reinforced ConcreteAbdul GhaffarBelum ada peringkat

- En1170-5 1997Dokumen4 halamanEn1170-5 1997Abdullah Talha TuranBelum ada peringkat

- Som ExperimentsDokumen17 halamanSom ExperimentsAnudeex ShettyBelum ada peringkat

- CRD-C90 - Test For Transverse Shear StrengthDokumen3 halamanCRD-C90 - Test For Transverse Shear StrengthWeff JingBelum ada peringkat

- Method For Determining The Unconfined Compressive Strength of Intact Rock Core Specimens SCT39Dokumen4 halamanMethod For Determining The Unconfined Compressive Strength of Intact Rock Core Specimens SCT39Deepak Kumar MallickBelum ada peringkat

- Astm C 393 - 00Dokumen4 halamanAstm C 393 - 00AlexandreBelum ada peringkat

- SM 4 ExperimentsDokumen19 halamanSM 4 ExperimentsSarath TejaBelum ada peringkat

- Test 08Dokumen6 halamanTest 08Kauther KautherBelum ada peringkat

- Ramkrishna Mahato Government Engineering College: S0Lid Mechanics LaboratoryDokumen34 halamanRamkrishna Mahato Government Engineering College: S0Lid Mechanics LaboratoryMaynak DeyBelum ada peringkat

- sct39 PDFDokumen4 halamansct39 PDFGkou DojkuBelum ada peringkat

- Lecture (7)Dokumen10 halamanLecture (7)DDelGGulBelum ada peringkat

- SM Lab ManualsDokumen27 halamanSM Lab ManualspraveenampilliBelum ada peringkat

- C 78 - 94 QZC4LTK0Dokumen3 halamanC 78 - 94 QZC4LTK0Rufo CascoBelum ada peringkat

- Geotechnical Parameters ofDokumen25 halamanGeotechnical Parameters ofChelvam sBelum ada peringkat

- Bending Test: Final RecommendationDokumen4 halamanBending Test: Final RecommendationfarhanfiksiBelum ada peringkat

- C170 90 (Reapproved1999) PDFDokumen3 halamanC170 90 (Reapproved1999) PDFGie Mak100% (1)

- Strut BucklingDokumen9 halamanStrut BucklingEvonYong100% (1)

- NACA TN 1125: Effect of Ratio of Rivet Pitch to Diameter on Fatigue StrengthDokumen18 halamanNACA TN 1125: Effect of Ratio of Rivet Pitch to Diameter on Fatigue StrengthBaljinder SinghBelum ada peringkat

- Steel Torsion TestDokumen9 halamanSteel Torsion TestPattarawat NakkumBelum ada peringkat

- Unconfined Compression TestDokumen10 halamanUnconfined Compression Testsajjad.ghazai2001Belum ada peringkat

- 50-FMC Draft Recommendation on Determining Fracture Energy of Mortar and ConcreteDokumen4 halaman50-FMC Draft Recommendation on Determining Fracture Energy of Mortar and ConcreteEbi RahmaniBelum ada peringkat

- BF 02472745Dokumen8 halamanBF 02472745oumaymafstBelum ada peringkat

- CRD - c89 (1) Longitudenal Shear StrengthDokumen2 halamanCRD - c89 (1) Longitudenal Shear StrengthKothiyal MukeshBelum ada peringkat

- Residual Stresses in Iron: CastingsDokumen37 halamanResidual Stresses in Iron: CastingsAdityaBelum ada peringkat

- Reaffirmed 2006Dokumen13 halamanReaffirmed 2006harikri3113Belum ada peringkat

- IS516-1959 Compressive Strength TestDokumen1 halamanIS516-1959 Compressive Strength Testanandhan boobalanBelum ada peringkat

- Flexural Modulus of Elasticity of Dimension Stone: Standard Test Method ForDokumen3 halamanFlexural Modulus of Elasticity of Dimension Stone: Standard Test Method ForRufo CascoBelum ada peringkat

- C 651Dokumen4 halamanC 651Asep TheaBelum ada peringkat

- Compressive Strength of Concrete: 1. ObjectiveDokumen6 halamanCompressive Strength of Concrete: 1. ObjectivedavyordersBelum ada peringkat

- Direct Shear TestDokumen4 halamanDirect Shear TestBuğra -Belum ada peringkat

- Bending Stiffness of FiberboardDokumen6 halamanBending Stiffness of FiberboardBobKatBelum ada peringkat

- Determination of Strain in A Steel Bar PDFDokumen8 halamanDetermination of Strain in A Steel Bar PDFEarl AradoBelum ada peringkat

- Bending StiffnessDokumen6 halamanBending StiffnessMark Samsel RohanBelum ada peringkat

- Aggeragate Crushing Value TestDokumen2 halamanAggeragate Crushing Value TestSanjeev KumarBelum ada peringkat

- CV301 Lab 4 Flexural Strength of Concrete 09-08-20Dokumen5 halamanCV301 Lab 4 Flexural Strength of Concrete 09-08-20Muhammad Ali HafeezBelum ada peringkat

- 1 Tension Test of Steel BarsDokumen3 halaman1 Tension Test of Steel BarsrashaBelum ada peringkat

- Structural Analysis With Strain Gage Measurements: Experiment 1Dokumen7 halamanStructural Analysis With Strain Gage Measurements: Experiment 1Yılmaz GürpınarBelum ada peringkat

- Cylindrical Compression Helix Springs For Suspension SystemsDari EverandCylindrical Compression Helix Springs For Suspension SystemsBelum ada peringkat

- L22 SummaryDokumen2 halamanL22 SummaryAndrei AevoaieBelum ada peringkat

- Springer Transactions in Civil and Environmental EngineeringDokumen10 halamanSpringer Transactions in Civil and Environmental EngineeringTran Tuan KietBelum ada peringkat

- Bao - Trung My Au Ket Cau Thep Thiet Ke So SanhDokumen1 halamanBao - Trung My Au Ket Cau Thep Thiet Ke So SanhTran Tuan KietBelum ada peringkat

- Esdep Lecture Note (Wg1a) .1Dokumen13 halamanEsdep Lecture Note (Wg1a) .1Tran Tuan KietBelum ada peringkat

- l03 React Tank 1Dokumen17 halamanl03 React Tank 1MuhammadUsmanBelum ada peringkat

- RPUB00003Dokumen40 halamanRPUB00003Ko PaukBelum ada peringkat

- PubDokumen8 halamanPubTran Tuan KietBelum ada peringkat

- l15 Reac Kine 2 PDFDokumen7 halamanl15 Reac Kine 2 PDFTran Tuan KietBelum ada peringkat

- 1 PDFDokumen23 halaman1 PDFAsad Jalil100% (1)

- CE 465 Water Supply and Sewage System DesignDokumen3 halamanCE 465 Water Supply and Sewage System Designkiet20002000Belum ada peringkat

- E2 20b 02 01Dokumen6 halamanE2 20b 02 01Tran Tuan KietBelum ada peringkat

- Baigiang Avcn A4 3616Dokumen2 halamanBaigiang Avcn A4 3616Tran Tuan KietBelum ada peringkat

- TableDokumen7 halamanTableTran Tuan KietBelum ada peringkat

- Land evaluation process and methodologyDokumen53 halamanLand evaluation process and methodologyTran Tuan KietBelum ada peringkat

- A Micro - Macro Impact Test at Controlled Energy For ErosionDokumen10 halamanA Micro - Macro Impact Test at Controlled Energy For ErosionTran Tuan KietBelum ada peringkat

- ReviewDokumen3 halamanReviewTran Tuan KietBelum ada peringkat

- ACI - Measurement of Properties of Fiber Reinforced ConcreteDokumen12 halamanACI - Measurement of Properties of Fiber Reinforced ConcreteTran Tuan Kiet100% (1)

- Chapter 7: Solving Structural Dynamic Problems Using Dcalc: Designcalcs, Inc. (Http://Dcalc - Us)Dokumen23 halamanChapter 7: Solving Structural Dynamic Problems Using Dcalc: Designcalcs, Inc. (Http://Dcalc - Us)سكان المعادى جراند سيتىBelum ada peringkat

- ContentsDokumen9 halamanContentsTran Tuan KietBelum ada peringkat

- How To Reply To Peer Review Comments When Submitting Papers For Publication PDFDokumen15 halamanHow To Reply To Peer Review Comments When Submitting Papers For Publication PDFAbhay KumarBelum ada peringkat

- Durability of Strain-Hardening Cement Composites (SHCC) - An OverviewDokumen8 halamanDurability of Strain-Hardening Cement Composites (SHCC) - An OverviewTran Tuan KietBelum ada peringkat

- Acosta 2007Dokumen2 halamanAcosta 2007Tran Tuan KietBelum ada peringkat

- Brandt 2008Dokumen7 halamanBrandt 2008Tran Tuan KietBelum ada peringkat

- Notch Sensitivity Review of Stress-Rupture TestsDokumen31 halamanNotch Sensitivity Review of Stress-Rupture TestsTran Tuan KietBelum ada peringkat

- 2 3Dokumen18 halaman2 3Tran Tuan KietBelum ada peringkat

- Micromechanics of Crack Bridging in Fibre-Reinforced ConcreteDokumen9 halamanMicromechanics of Crack Bridging in Fibre-Reinforced ConcreteTran Tuan KietBelum ada peringkat

- Moran Introduction To Thermal Systems Engineering Thermodynamics Fluid Mechanics and Heat Transfer 2002 09Dokumen5 halamanMoran Introduction To Thermal Systems Engineering Thermodynamics Fluid Mechanics and Heat Transfer 2002 09Marco GassaniBelum ada peringkat

- Triboelectric Nanogenerator Built Inside Shoe Insole For Harvesting Walking EnergyDokumen7 halamanTriboelectric Nanogenerator Built Inside Shoe Insole For Harvesting Walking EnergyQuốc TínBelum ada peringkat

- ESPs Two Phase FlowDokumen26 halamanESPs Two Phase FlowScott YoungBelum ada peringkat

- Thermodynamics 1 Basic Principles, Concepts and DefinitionDokumen8 halamanThermodynamics 1 Basic Principles, Concepts and DefinitionHENRICK IGLEBelum ada peringkat

- Remote Sensing Session 2 Modern Surveying - 20Ce32P: Study MaterialDokumen14 halamanRemote Sensing Session 2 Modern Surveying - 20Ce32P: Study Materialshashi kumarBelum ada peringkat

- High Voltage Engineering: DR Suhail KhokharDokumen8 halamanHigh Voltage Engineering: DR Suhail KhokharSuhail KhokharBelum ada peringkat

- Rumus CCI 4737Dokumen5 halamanRumus CCI 4737Eko NbsBelum ada peringkat

- Homework 07 Solutions: Math 21a Spring, 2014Dokumen6 halamanHomework 07 Solutions: Math 21a Spring, 2014TARANNAUM JAHAN SULTANBelum ada peringkat

- NEET Vectors Important QuestionsDokumen22 halamanNEET Vectors Important QuestionsShivkumar baithaBelum ada peringkat

- Techno-Economic Analysis of Air Humidification DesalinationDokumen5 halamanTechno-Economic Analysis of Air Humidification DesalinationIbrahim Al-MutazBelum ada peringkat

- DPP FluidDokumen23 halamanDPP FluidAditya SinhaBelum ada peringkat

- Experimental Comparison of Single and Multistage Air Compressor EfficienciesDokumen11 halamanExperimental Comparison of Single and Multistage Air Compressor EfficienciesJohn barry CorpuzBelum ada peringkat

- CLASS 11 Vacation Assignment CHEMISTRY PDFDokumen12 halamanCLASS 11 Vacation Assignment CHEMISTRY PDFGowri ShankarBelum ada peringkat

- Publications: Journal of Advances in Modeling Earth SystemsDokumen24 halamanPublications: Journal of Advances in Modeling Earth SystemsBetoBelum ada peringkat

- Chapter 1 Physical WorldDokumen24 halamanChapter 1 Physical WorldPankaj ChhabraBelum ada peringkat

- Foundation Science For EngineersDokumen7 halamanFoundation Science For EngineersZaid HadiBelum ada peringkat

- Bowex enDokumen32 halamanBowex enTimon2005Belum ada peringkat

- IB Chemistry - SL Topic 2 Questions 1. Species Number of Protons Number of Neutrons Number of ElectronsDokumen19 halamanIB Chemistry - SL Topic 2 Questions 1. Species Number of Protons Number of Neutrons Number of Electronsyasmine hooeyBelum ada peringkat

- Effect of Casting Speed On Continuous Casting of Steel Slab: January 2014Dokumen12 halamanEffect of Casting Speed On Continuous Casting of Steel Slab: January 2014Prakash SarangiBelum ada peringkat

- EN200 Naval Engineering Chapter 1 PDFDokumen33 halamanEN200 Naval Engineering Chapter 1 PDFanusha_wiproBelum ada peringkat

- Berryman. 2003. On Principles, Laws and Theory in Population Ecology. OikosDokumen7 halamanBerryman. 2003. On Principles, Laws and Theory in Population Ecology. OikosValentina¬Belum ada peringkat

- Neeraj Books CatalogueDokumen22 halamanNeeraj Books Cataloguenazina shaikBelum ada peringkat

- MomentumenergyandcollisionslabDokumen9 halamanMomentumenergyandcollisionslabapi-244640341100% (1)