Fluke Power Scope

Diunggah oleh

100003Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Fluke Power Scope

Diunggah oleh

100003Hak Cipta:

Format Tersedia

Measuring power with a Fluke ScopeMeter 190 Series

Application Note

Although many electrical test tools are available to measure voltage, few can measure current, and even fewer are equipped to measure electrical power directly. Moreover, there is always the question of how to measure power in electronic systems that are not operating at mains frequencies. The Fluke ScopeMeter 190 Series has the answer.

Power measurements

The prime parameter specified for any electrical system is operating voltage. But that voltage in itself has little meaning if, once applied, it doesnt result in power to, for example, exert a force, drive a machine or run a lighting system. Accurate measurement of electrical power is therefore crucial for understanding a systems behaviour. Suppose we have an electrical circuit consisting of a voltage source U1, a switch Sw and a load resistor RL (see figure 1). By closing the switch, the supply voltage U1 is connected to the load RL and a current I will flow as a result. Once this current is flowing, the load will heat as a result of the power applied to it according to: P = U1 * I (1)

This elementary power measurement, using a DC-source for U1 and a resistive load RL requires little more than a multimeter, which will usually be a digital multimeter (DMM). The DMM is used first to measure the voltage U1 and then to measure the current supplied to the load RL, from which power supplied to the load is calculated from formula (1). Once the switch is closed, all values in this DC-system are static and therefore the two measurements can be made successively using a single instrument if so desired. If the source is a low-frequency AC source, the same rules basically apply. We can measure the RMS value of the applied voltage and that of the current, and multiply these to get the power handled by the load. As long as were working at mains frequencies, most DMMs can do the job.

If the load isnt purely resistive but also includes inductive or capacitive elements, a phase difference between the applied voltage and the current will result that needs to be taken into account to determine the power. The relation now is: P = U1 * I * cos (2)

where j is the phase-angle in degrees between voltage and current. Multimeters are generally not equipped to make measurements on more than one input and therefore cannot measure phase angle. For these measurements, a more specialized instrument is needed, for instance a phase meter or an oscilloscope.

Figure 1. Basic circuit loop in which voltage and current are measured.

From the Fluke Digital Library @ www.fluke.com/library

If power measurements are made more frequently, a power meter like the Fluke 43B Power Quality Analyzer would be the most appropriate test tool. This instrument measures both voltage and current simultaneously and automatically takes the phase angle into account. For the occasional user, however, this may be an expensive option and a more generic tool like the ScopeMeter would be preferred.

(instantaneous) power can be read off, at every point in time, for instance using the cursors of the Fluke 190 Series.

Example of a light dimmer

As an example, weve applied the mains voltage to a so-called light dimmer. This is a thyristor-based power control device in which current is allowed to flow only during a selected part of the mains cycle. The effective output voltage to the load (the lights) can be controlled by changing the phase angle. The measured voltage (see figure 2, trace A) shows that the output is active during approximately twothirds of the time, or about 120 degrees during each half-cycle. During one-third of the time, the dimmer is off and no output voltage is supplied to the lights. If we change this phase angle, the lights will brighten or dim.

Use of the Fluke ScopeMeter

All Fluke ScopeMeters have two input channels and can measure voltage and current at the same time, whilst also measuring and displaying the phase angle between them. See also the section practical set-up hints near the end of this publication for further details. If the voltage is non-sinusoidal or if the load isnt purely resistive, power measurements become too complex to be performed on a DMM. The best way to determine power under these conditions is to take a large number of current and voltage measurements over each cycle of the supply voltage. The measurements need to be made simultaneously on both signals. Each set of simultaneous measurements can then be multiplied to produce a corresponding set of data points from which a curve can be constructed of the power handling at successive moments in time. The Fluke 190 Series ScopeMeter is capable of performing this specific function for you! Included in the functionality of the Fluke ScopeMeter 190 Series is the ability to multiply individual curves (waveforms) to create a resultant curve. With this function, sets of samples from channels A and B are multiplied to create a resultant curve labeled M. In other words, every time a sample for channel A and a sample for channel B is taken and written on screen, these are also multiplied and displayed to create the resultant waveform M on screen. From this waveform, the

Figure 3. Menu tree for setting up the waveform multiplication.

scaling can be modified. After pressing softkey F3 we can also change the vertical position of the resultant trace M.

Figure 4. Voltage, Current and Power curves on the Fluke 190 Series ScopeMeter. Figure 2. Output voltage and current of a dimmer driving a string of lights.

In figure 2 we can also see the resulting current through the light-bulbs (channel B, blue curve). We can now set up the ScopeMeter to calculate the power applied to the lights (see figures 3 and 4). To do this select: SCOPE, then F4 (= Waveform Options), next Mathematics, and Enter, then A * B, and Enter. Next we select a scaling that we expect will keep the power curve on screen; this may also be changed later. The two input waveforms and the resultant (M) will now be visible. If the resultant is too small or too large, the

Figure 4 shows the voltage (waveform A, in red), the current (B, in blue) and the multiplied curve (M, in green), representing the power supplied to the lights. On the Fluke ScopeMeter 190 Series, the cursors can be used to measure the power at any point in time, as shown in figure 5.

Figure 5. The ScopeMeters cursor is used for power measurement at a specific point in time.

2 Fluke Corporation

Measuring power with a Fluke ScopeMeter 190 Series

Here, the cursor is set at about the maximum peak of the power curve, and the reading tells us that the lights are handling a peak of approximately 1.7 kW at that instant in time.

Power measurement in a switched-mode power supply (SMPS)

In electronic systems, the frequencies of the signals are often much higher and the waveforms much more diverse than those in above example. As an example, consider some waveforms from a switchedmode power supply (figure 6). In this system, the mains voltage is rectified and filtered, resulting in a DC voltage of about 350 V. This is then applied to a switching transistor that drives a stepdown transformer.

Figure 7. Voltage and current waveforms are used to create the power-curve.

From the curves in figure 6, we calculate the power that the transistor is handling by multiplying the two graphs, as in figure 7. Here also the timebase-setting has been changed to see the part of the waveform that is of particular interest in more detail. On these curves, we can use the cursors of the Fluke 190 Series to measure the peak in power handling, as is done in figure 8.

Figure 6. Voltage and current handled by the switcher component in a SMPS.

In figure 6 we can see the voltage across the switching transistor (curve A, in red) and the current through the transistor (curve B, in blue). The voltage reaches peak values of over 400 V (see the 4 divisions of amplitude at 100 V/div) and the current has a peak-value of over 200 mA. A single cycle of this converters signal takes approximately 26 s, which means the operating frequency is around 36 kHz. Note, however, that for a given SMPS, the frequency may vary with changes in the line voltage and loading.

Figure 8. Cursor used to measure the peak of the power, handled by the transistor.

From this we see that the switching transistor is handling a peak power of 123 W. During design of the SMPS, one has to be aware that such power peaks may occur and the components need to be selected with this in mind.

all input signals (and which is connected to the mains safety ground). In contrast, the ScopeMeter 190 Series has independently floating inputs. This allows for voltage measurements at voltage test-points as well as across current-sensing resistors, which may be at different voltage levels. See the ScopeMeters technical specification for full details. When used with current clamps or with current sensing resistors in the network, the ScopeMeter inputs can be set-up to read amplitudes in amps directly. To do so, select the input channel key (e.g.: B) and then softkey F3 (Probe channel B). A selection can then be made if the input signal represents a voltage or a current, or even a temperature. Whats more, the sensitivity of the current clamp or the circuits sensing resistor can be selected from a selection table, indicated in mV/mA (equivalent to V/A or simply ). If we have connected a 1 current sensing resistor in our network and want to measure the voltage across it, the current sensitivity would be set at 1 V/A. If we include a 0.1 resistor in our network to sense the current, then the sensitivity would be set at 100 mV/A. If the voltage across that resistor is measured using the standard (10:1) voltage probe, the overall sensitivity would be 10 mV/A. By selecting this sensitivity from the menu, the current that we read on the ScopeMeter screen directly indicates the true value.

Total energy

The total energy handled over time can be calculated by multiplying the continuous power and the time the system is active: W=P*t (3)

Instrument set-up

The ScopeMeter is unique in that its inputs are fully insulated from one another, allowing direct connection to electrical wiring, even if this is at mains potential. Most standard oscilloscopes have a common ground connection on the inputs which has to be used as a common reference point for

The result is expressed in watt-seconds (Ws), also known as joules (J). The value in joules can be rescaled into kWh, whereby 1 kWh = 1000 Wh = 1000 * 3600 Ws = 3.6 * 106 Ws

3 Fluke Corporation

Measuring power with a Fluke ScopeMeter 190 Series

Some ScopeMeter models also contain a function for calculating the total power accumulated over a period of time, which is then selected using the cursors. Power over time equals energy, and we can read this on the ScopeMeter as watt-seconds directly.

Practical set-up hints

The best way to measure a current in a circuit loop is with a current clamp. These are commercially available for AC and for DC+AC measurements, and for various current ranges. The Fluke 80i-100s, for instance, measures DC and AC currents from 0.1 to 100A; the Fluke i1010 can even be used up to1000A AC and/or DC. These clamps eliminate the need to open up the circuit loop when making measurements and provide good isolation between any live wiring and the test instrument. When working on power circuits, this is definitely the safest way to measure the current. If a current clamp is used for measuring small currents and the sensitivity of the clamp in insufficient, the effective sensitivity can be increased by feeding multiple turns of the wire through the clamp. The actual current is now the measured current divided by the number of turns. Sometimes, however, its not so simple to cut the wiring of an existing circuit loop in order to include a current meter, for example when all wiring is part of a printed circuit board. A possible way to bring the current meter into the loop of a lowpower circuit would then be to set up the DMM for current measurement and select the highest current-range provided. Now connect the meter over the contacts of the on/off-switch. If the switch is left open, the meter will close the loop and read the current, while no wiring needs to be interrupted or modified.

Figure 9. Power curve and energy measurement.

If no switch is provided, or if the DMM has no current-measuring capability, we may also add a current sensing resistor of a known value Rs to the circuit, which needs to be small in value compared with the load-resistance RL (see figure 10). We can now measure the voltage across this sensing resistor and calculate the current from Ohms law. Adding the resistor is a one-time modification, which is more convenient than repeatedly opening up the circuit loop. If Rs is more than 10 times smaller in value than the load RL, less than a percent of the energy will be handled by the series resistance, and thus the error in the power measurement that results from adding the resistor will be less than 1%.

Looking at figure 9, we can see that between the two cursors, i.e. within a single cycle of the mains voltage, an energy of 10.09 Ws is delivered to the lights. A cycle of the mains in this case takes 20 ms. Per second this leads to a power consumption of: 10.09 Ws / 20ms = 10.09 * 50 W*s/s = 505 W And over a time-span of one hour, this equals a total energy consumption of: 505 W * 1 h = 505 Wh = 0.505 kWh = 1.8 MWs

Conclusion

Power measurements on low-frequency linear systems can be performed using a DMM. The measurement of power in electronic systems where waveforms are more complex and frequencies often much higher than the mains frequency requires more sophisticated tools. The Fluke 190 Series of ScopeMeters are well equipped to make these measurements, and can even make fast peak-power measurements to determine the power handling of fast electronic components, for instance in switched-mode power supplies.

Fluke. Keeping your world up and running.

Fluke Corporation PO Box 9090, Everett, WA USA 98206 Fluke Europe B.V. PO Box 1186, 5602 BD Eindhoven, The Netherlands For more information call: In the U.S.A. (800) 443-5853 or Fax (425) 446-5116 In Europe/M-East/Africa (31 40) 2 675 200 or Fax (31 40) 2 675 222 In Canada (800) 36-FLUKE or Fax (905) 890-6866 From other countries +1 (425) 446-5500 or Fax +1 (425) 446-5116 Web access: http://www.fluke.com

2004 Fluke Corporation. All rights reserved. Printed in U.S.A. 3/2004 2140127 A-ENG-N Rev A

Figure 10. Adding a current sensing resistor to the circuitry to allow current measurement.

4 Fluke Corporation

Measuring power with a Fluke ScopeMeter 190 Series

Anda mungkin juga menyukai

- 2015-2016 First Half Power Gen ScheduleDokumen1 halaman2015-2016 First Half Power Gen Schedule100003Belum ada peringkat

- Dok TD Mrg3e CDokumen97 halamanDok TD Mrg3e C100003Belum ada peringkat

- KEB-Harmonic Filter-Manual 00U0HU0-K081 Rev 3A 2015 M01Dokumen24 halamanKEB-Harmonic Filter-Manual 00U0HU0-K081 Rev 3A 2015 M01100003Belum ada peringkat

- DDokumen24 halamanD100003100% (2)

- Basic Techniques For Management of The Infant and Toddler Dental PatientDokumen1 halamanBasic Techniques For Management of The Infant and Toddler Dental Patient100003Belum ada peringkat

- Woodward Technical Training Calendar 2016Dokumen1 halamanWoodward Technical Training Calendar 2016100003Belum ada peringkat

- 4K Service Manual 4th Gen SM4014EN 200510Dokumen174 halaman4K Service Manual 4th Gen SM4014EN 20051010000388% (25)

- Ig Mint Mint+iom 6.2Dokumen135 halamanIg Mint Mint+iom 6.2100003Belum ada peringkat

- HT 700 Hydr Service Manual SM1270 199904Dokumen328 halamanHT 700 Hydr Service Manual SM1270 199904100003100% (36)

- 3K Service Manual 4th Gen SM4013EN 200906Dokumen308 halaman3K Service Manual 4th Gen SM4013EN 200906100003100% (53)

- IG-6.2-IS-3.4-ApplicationGuide Intelilite PDFDokumen61 halamanIG-6.2-IS-3.4-ApplicationGuide Intelilite PDFRoberto MerizaldeBelum ada peringkat

- MT 600 Service Manual SM1317 199907Dokumen277 halamanMT 600 Service Manual SM1317 19990710000395% (37)

- 8000 Service Manual SM1228 200611Dokumen390 halaman8000 Service Manual SM1228 200611100003100% (11)

- 5&6000 Service Manual SM1866EN 199904Dokumen326 halaman5&6000 Service Manual SM1866EN 199904100003100% (28)

- Ppe 2Dokumen47 halamanPpe 2Hetsa KhoaliteBelum ada peringkat

- Users Manual: Wireless MultimeterDokumen50 halamanUsers Manual: Wireless Multimeter100003Belum ada peringkat

- IG - Operator Guide PDFDokumen19 halamanIG - Operator Guide PDFm_najmanBelum ada peringkat

- 8 Cyl Cat 3408 PartsDokumen869 halaman8 Cyl Cat 3408 Parts100003100% (6)

- Ford Coolant ChartDokumen3 halamanFord Coolant Chart100003Belum ada peringkat

- O & M Manual For The Fixed and Drawout Magum Transfer Switches - Instruction Booklet - IB01602011E - EATON® PDFDokumen44 halamanO & M Manual For The Fixed and Drawout Magum Transfer Switches - Instruction Booklet - IB01602011E - EATON® PDFpevareBelum ada peringkat

- DSE generator overcurrent protection settingsDokumen2 halamanDSE generator overcurrent protection settingsAndersonBelum ada peringkat

- NWTC Ski ManualDokumen28 halamanNWTC Ski Manual100003Belum ada peringkat

- BLEACH CLEANING GUIDE AFTER EMERGENCIESDokumen3 halamanBLEACH CLEANING GUIDE AFTER EMERGENCIESbdavid2012Belum ada peringkat

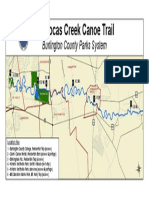

- Rancocas Canoe Trail Map 201403260812388398Dokumen1 halamanRancocas Canoe Trail Map 201403260812388398100003Belum ada peringkat

- Solutions For Un ConvDokumen16 halamanSolutions For Un Convravinder2318949Belum ada peringkat

- Cold Weather Smart Card Mar 2013Dokumen20 halamanCold Weather Smart Card Mar 2013100003Belum ada peringkat

- Using CTs with DSE ProductsDokumen2 halamanUsing CTs with DSE ProductsJoaquin Chavez ArquiñigoBelum ada peringkat

- 056-024 GSM ModemDokumen3 halaman056-024 GSM Modem100003Belum ada peringkat

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (344)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (587)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (73)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (265)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (119)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- Select Base Unit: Micrologix 1500 System Expansion WorksheetDokumen11 halamanSelect Base Unit: Micrologix 1500 System Expansion WorksheetimyourscinBelum ada peringkat

- Operating Instructions: Coring Stripping ToolDokumen2 halamanOperating Instructions: Coring Stripping ToolCarlos CastilloBelum ada peringkat

- IEC 60870-5-103 Communication Protocol User Guide: Page: 1 of 13 NA011 IEC 870-5-103Dokumen13 halamanIEC 60870-5-103 Communication Protocol User Guide: Page: 1 of 13 NA011 IEC 870-5-103Utkan BALABANBelum ada peringkat

- 68hc705j1 Microcontrolador MotorolaDokumen163 halaman68hc705j1 Microcontrolador MotorolaNefi Martinez TorresBelum ada peringkat

- EOBDII Fault Code Reader: With CAN Protocol. For Petrol Engines From 2001 Onwards and From 2004 For Diesel EnginesDokumen78 halamanEOBDII Fault Code Reader: With CAN Protocol. For Petrol Engines From 2001 Onwards and From 2004 For Diesel EnginesJuan ContrerasBelum ada peringkat

- AirWatch Device Features Summary v8 - 1Dokumen3 halamanAirWatch Device Features Summary v8 - 1Razvan CristeaBelum ada peringkat

- 5.regultion of A Three Phase Alternator (MMF Method)Dokumen7 halaman5.regultion of A Three Phase Alternator (MMF Method)mandadi_saileshBelum ada peringkat

- Inertial Navigation Sensors-2010Dokumen24 halamanInertial Navigation Sensors-2010Hyun-Suk JangBelum ada peringkat

- Relay Testing ProcedureDokumen50 halamanRelay Testing Procedureunnikrish05Belum ada peringkat

- DCR Power Controllers For Ionpure Cedi ModulesDokumen2 halamanDCR Power Controllers For Ionpure Cedi ModulesArvind LodhiBelum ada peringkat

- Design a Cellphone-based ECG MonitorDokumen22 halamanDesign a Cellphone-based ECG MonitorMona NaiduBelum ada peringkat

- The Main Circuit Board of A MicrocomputerDokumen16 halamanThe Main Circuit Board of A Microcomputeramandeep123Belum ada peringkat

- Transmission Line ParametersDokumen16 halamanTransmission Line ParametersMohd Taufiq Ishak100% (1)

- Cpe 242 Computer Architecture and Engineering Instruction Level ParallelismDokumen46 halamanCpe 242 Computer Architecture and Engineering Instruction Level ParallelismSagar ManeBelum ada peringkat

- JVC KD-LX100J Manual de Servicio PDFDokumen38 halamanJVC KD-LX100J Manual de Servicio PDFMIGUELBelum ada peringkat

- Cillian RuddyDokumen7 halamanCillian RuddyAnish PaiBelum ada peringkat

- RRU3959 Description (2100 MHZ)Dokumen13 halamanRRU3959 Description (2100 MHZ)ShahzaibAshraf100% (2)

- Model 229 Leakage Current Tester ManualDokumen6 halamanModel 229 Leakage Current Tester ManualJosue Briseño AndradeBelum ada peringkat

- Sds Operation M Ver6Dokumen106 halamanSds Operation M Ver6Roberto Vertel RomeroBelum ada peringkat

- AKNM - 3049 - AKNMGptcDokumen53 halamanAKNM - 3049 - AKNMGptchod eceBelum ada peringkat

- Lec3 Single StageDokumen24 halamanLec3 Single Stagerajeevjain09Belum ada peringkat

- MBI5026Dokumen16 halamanMBI5026Racer RacerBelum ada peringkat

- Manual UDA 2182Dokumen258 halamanManual UDA 2182Elias CelisBelum ada peringkat

- Safety Manual: Mitsubishi Electric Industrial RobotDokumen36 halamanSafety Manual: Mitsubishi Electric Industrial Robotemil100% (1)

- ARC Master Controller User ManualDokumen16 halamanARC Master Controller User ManualDinesh MehtaBelum ada peringkat

- Software Requirements Specification: NetflixDokumen28 halamanSoftware Requirements Specification: NetflixAeron OriolaBelum ada peringkat

- DC Motor Speed Control Methods Using MATLAB - Simulink and Their Integration Into Undergraduate Electric Machinery CoursesDokumen9 halamanDC Motor Speed Control Methods Using MATLAB - Simulink and Their Integration Into Undergraduate Electric Machinery CoursesWen ZJBelum ada peringkat

- Marine Diesel Engine S60 Dimensions and SpecsDokumen2 halamanMarine Diesel Engine S60 Dimensions and SpecsRomie HarieBelum ada peringkat

- Auto Rescue Device For Elevator ARDDokumen1 halamanAuto Rescue Device For Elevator ARDcarryon66Belum ada peringkat

- Chem6-Ammeter Ionic and Covalent CompoundDokumen3 halamanChem6-Ammeter Ionic and Covalent CompoundNor Ashikin IsmailBelum ada peringkat