Crack Width Check

Diunggah oleh

krishna kumarJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Crack Width Check

Diunggah oleh

krishna kumarHak Cipta:

Format Tersedia

36

CHAPTER 2

SERVICEABLITY

2.1 INTRODUCTION

Service load deflections under full load may be excessively large, or long-

term deflections due to sustained loads may cause damage. Tension cracks in

beams may be wide enough to be visually disturbing, or may even permit serious

corrosion of reinforcing bars. These and other questions, such as vibration or

fatigue, require consideration.

Serviceability studies are carried out based on elastic theory, with stresses

in both concrete and steel assumed to be proportional to strain. The concrete on

the tension side of the neutral axis may be assumed uncracked, partially cracked,

or fully cracked, depending on the loads and material strengths.

The current approach is to investigate service load cracking and deflections

specifically, after proportioning members based on strength requirements. ACI

Code provisions reflect this change in thinking.

2.2 CRACKING IN FLEXURAL MEMBERS

Prior to the formation of flexural cracks, the steel stress is no more than

n times the stress in the adjacent concrete, where n is the modular ratio, E

s

/ E

c

.

In a well-designed beam, flexural cracks are fine, so-called hairline

cracks, almost invisible to the casual observer, and they permit little if any

corrosion of the reinforcement. As loads are gradually increased above the

cracking load, both the number and width of cracks increase, and at service load

level a maximum width of crack of about 0.01 in. is typical. If loads are further

increased, crack widths increase further, although the number of cracks is more or

less stable.

a. Variables Affecting Width of Cracks

Studies by Gergely and Lutz and others have confirmed that crack width

is proportional to f

s

n

, where f

s

is the steel stress and n is an exponent that varies

in the range from about 1.0 to 1.4. For steel stresses in the range of practical

interest, say from 20 to 36 ksi, n may be taken equal to 1.0. The steel stress is

easily computed based on elastic cracked-section analysis. Alternatively, f

s

may be

taken equal to 0.60f

y

according to ACI Code 10.6.4.

37

Experiments by Broms and others have showed that both crack spacing

and crack width are related to the concrete cover distance d

c

, measured from the

center of the bar to the face of the concrete. Generally, to control cracking, it is

better to use a larger number of smaller-diameter bars to provide the required A

s

than to use the minimum number of larger bars, and the bars should be well

distributed over the tensile zone of the concrete.

b. The Gergely-Lutz Equation for Crack Width

Based on their research at Cornell University, which involved the statistical

analysis of a large amount of experimental data, Gergely and Lutz proposed the

following equation for predicting the maximum width of crack at the tension face

of a beam:

w = 0.076 f

s

3

c

A d (2.1)

in which w is the maximum width of crack, in thousandth inches, and f

s

is the

steel stress at the load for which the crack width is to be determined, measured

in ksi. The geometric parameters are shown in Fig.2.1 and are as follows:

FIGURE 2.1

Geometric basic of crack width calculations.

where d

c

= thickness of concrete cover measured from tension face to center

of bar closest to that face, in.

= ratio of distances from tension face and from steel centroid to

neutral axis, equal to h

2

/ h

1

A = concrete area surrounding one bar, equal to total effective tension

area of concrete surrounding reinforcement and having same

centroid, divided by number of bars, in

2

Equation (2.1), which applies only to beams in which deformed bars are used,

includes all the factors just named as having an important influence on the width

38

of cracks: steel stress, concrete cover, and the distribution of the reinforcement in

the concrete tensile zone. In addition, the factor is added, to account for the

increase in crack width with distance from the neutral axis (see Fig.2.l b).

c. Permissible Crack Widths

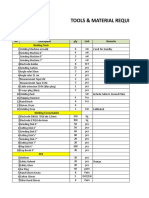

The recommendations of ACI Committee 224 are summarized in Table 2.1.

However, good engineering judgment must be used in setting limiting values in

particular cases. It should be recognized that, because of the random nature of

cracking, individual cracks significantly wider than predicted by Eq. (2.1) are

likely. The designer should also keep in mind, however, that Eq. (2.1) predicts the

crack width at the surface of the member, whereas the width of crack is known

to be less at the steel- concrete interface. Increasing the concrete cover, even

though it increases the surface crack width, may be beneficial in avoiding

corrosion.

Table 2.1

Tolerable crack widths for reinforced concrete

d. Cyclic and Sustained Load Effects

Both cyclic and sustained loading account for increasing crack width.

While there is a large amount of scatter in test data, results of fatigue tests and

sustained loading tests indicate that a doubling of crack width can be expected

with time. Under most conditions the spacing of cracks does not change with time

at constant levels of sustained stress or cyclic stress range.

2.3 ACI CODE PROVISIONS FOR CRACK CONTROL

Accordingly, Eq. (2.1) can be simplified for typical beams by adopting a

representative value of = 1.2. Then a parameter z may be defined as follows:

39

z = f

s

3

3

c

A d

z =

1.2 0.076

w

=

091 0.

w

Control of the maximum crack width can be thus obtained by setting an upper

limit on the parameter z. ACI Code 10.6.4 specifies that z shall not exceed 175

for interior exposure and 145 for exterior exposure. These limits correspond to

maximum crack widths of 0.016 and 0.013 in, respectively. In addition, ACI Code

10.6.3 specifies that tension reinforcement shall be well distributed in the zone of

maximum concrete tension. ACI Code 9.4 states that designs shall not be based

on a yield strength f

y

in excess of 80,000 psi.

When bars having different diameters are used together, as is often

advantageous in practice, the concrete tension area per bar should be computed

using an equivalent number of bars, found by dividing the total area of reinforce-

ment by the area of the 4 largest bar used, according to the ACI Code. When

bundled bars are used, Lutz has recommended that each bundle be counted as the

equivalent of 1.4 bars in computing A, recognizing that the bundled bars have an

increased bond perimeter compared to a single bar having the same area as the

bundle.

Equations (2.1) and (2.2) can also be used for one-way slabs. For typical

slabs, however, where effective depth is less than for beams and concrete cover

below the bars may be about 1 in., a representative value of is about 1.35 rather

than 1.2 as for beams. For a given limiting crack width, therefore, limiting z

values should be multiplied by the ratio 1.2 / 1.35. Thus, for slabs z should not

exceed 155 for interior exposure and 130 for exterior exposure, corresponding to

crack widths of 0.016 in. and 0.013 in. respectively.

When concrete T-beam flanges are in tension, as in the negative-moment

region of continuous T beams, concentration of the reinforcement over the web

may result in excessive crack width in the overhanging slab, even though cracks

directly over the web are fine and well distributed. To prevent this, the tensile

reinforcement should be distributed over the width of the flange, rather than

concentrated. However, because of shear lag, the outer bars in such a distribution

would be considerably less highly stressed than those directly over the web,

producing an uneconomical design.As a reasonable compromise, ACI Code 10.6.6

requires that the tension reinforcement in such cases be distributed over the

40

effective flange width or a width equal to onetenth the span, whichever is smaller.

If the effective flange width exceeds one-tenth the span, some longitudinal

reinforcement must be provided in the outer portions of the flange. The amount

of such additional reinforcement is left to the discretion of the designer; it should

at least be the equivalent of temperature reinforcement for the slab and is often

taken as twice that amount.

For beams with relatively deep webs, some reinforcement should be placed

near the vertical faces of the web to control the width of cracks in the concrete

tension zone above the level of the main rebars. Without such steel, crack widths

in the web wider than those at the level of the main bars have been observed.

According to ACI Code 10.6.7, if the depth of the web exceeds 36 in., longitu-

dinal skin reinforcement must be uniformly distributed along both side faces of

the member for a distance d/2 nearest the fiexural tension steel. The area of skin

reinforcement, Ask, per foot of height on each side face, must not be less than

0.012(d 30) in

2

per ft. The maximum spacing must not exceed d/6 or 12 in. The

total area of longitudinal skin reinforcement in both faces need not exceed one-

half the area of the required flexural tensile reinforcement. The contribution of the

skin steel to flexural strength is usually disregarded, although it may be included

in the strength calculations if a strain compatibility analysis is used to establish

the stress in the skin steel at the flexural failure load.

FIGURE 2.2

Minimum number of bars in beam stem.

For beams with main flexural reinforcement in one layer in the web, a

convenient design aid can be developed, based on Eq. (2.2), that permits tabula-

tion of the minimum number of bars that will satisfy ACI Code requirements for

crack control. With reference to Fig. 2.2, the total tensile area of concrete is equal

to 2d

c

b

w

. Thus the tensile area per bar is

A =

m

b d 2

w c

(a)

41

where m is the number of bars in the single layer of reinforcement. Then from

Eq. (2.2)

3

z

|

|

.

|

\

|

s

f

=

m

b d 2

w

2

c

(b)

from which

m =

3

s

w

2

c

) (z/f

b d 2

(c)

For the typical Grade 60 bars, f

s

may be taken as 0.6 0.6 = 36 ksi, and for bars

of diameter d

b

with 1.5 in. cover below the stirrups, which generally are Nos. 3

or 4 bars.

d

c

= 2.0 + 0.5d

b

(d)

That value is then substituted in Eq. (c) to obtain

m = 3

w b

) (z/

b d

36

) 0.5 2(2.0 +

(2.3)

giving the minimum number of bars that can be used to satisfy crack control

requirements, in terms of bar diameter d

b

and beam width b

w

for the imposed

limit on z. Table A.9 of App. A gives values of m, the minium number of bars

that will staisfy ACI Code requirements for crack control for both interior and

exterior exposure.

Example 2.1. Check for satisfactory crack widths. The T beam of Fig. 2.3

carries a service load moment of 5850 in-kips. Estimate the maximum width of

crack to be expected at the bottom surface of the member at full service load and

determine if reinforcing details, with respect to cracking, are satisfactory for

exterior exposure according to the ACI Code.

FIGURE 2.3

T beam for crack width

determination in example 2.1.

Solution. The total tensile steel area provided by the six No. 10 bars is 7.59 in

2

.

The steel stress at service load can be estimated closely by taking the internal

lever arm equal to the distance dt / 2:

42

f

s

=

2) / ( t d A

M

s

s

=

23 59 7

5850

.

= 33.6 ksi

(Alternatively, the ACI Code permits using f

s

= 0.60f

y

giving 36.0 ksi). The

distance from the steel centroid to the tensile face of the beam is 4 in.; hence, the

total effective concrete area for purposes of cracking calculations is 4 2 10 = 80

in and

A =

6

80

= 13.30 in

2

Then, by Eq. (2.1), with d

c

= 2

4

3

in.,

w = 0.076 1.2 33.6

3

30 13 75 2 . .

= 10 thousandth in. = 0.010 in.

Alternatively, by Eq. (2.2),

z = 33.6

3

30 13 75 2 . . = 112 < 145

(ACI Code exterior use)

2.4 CONTROL OF DEFLECTIONS

The first is indirect and consists in setting suitable upper limits on the

span-depth ratio. This is simple, and it is satisfactory in many cases where spans,

loads and load distributions, and member sizes and proportions fall in the usual

ranges. Otherwise, it is essential to calculate deflections and to compare those

predicted values with specific limitations that may be imposed by codes or by

special requirements.

The deflections of concern are generally those that occur during the normal

service life of the member. In service, a member sustains the full dead load, plus

some fraction or all of the specified service live load. Safety provisions of the

ACI Code and similar design specifications ensure that, under loads up to the full

service load, stresses in both steel and concrete remain within the elastic ranges.

Consequently, deflections that occur at once upon application of load, the so-called

immediate defiections, can be calculated based on the properties either of the

uncracked elastic member, the cracked elastic member, or some combination of

these.

In addition to concrete deformations that occur immediately when load is

applied, there are other deformations that take place gradually over an extended

period of time. These time-dependent deformations are chiefly due to concrete

43

creep and shrinkage. As a result of these influences, reinforced concrete members

continue to deflect with the passage of time. Long-term deflections continue over

a period of several years, and may eventually be two or more times the initial

elastic deflections. Clearly, methods for predicting both instantaneous and time-

dependent deflections are essential.

2.5 IMMEDIATE DEFLECTIONS

Elastic deflections can be expressed in the general form

=

EI

f supports) spans, (loads,

where EI is the flexural rigidity and f(loads, spans, supports) is a function of the

particular load, span, and support arrangement.

If the maximum moment in a flexural member is so small that the tension

stress in the concrete does not exceed the modulus of rupture f

r

, no flexural

tension cracks will occur. The full, uncracked section is then available for resisting

stress and providing rigidity. In agreement with this analysis, the effective moment

of inertia for this low range of loads is that of the uncracked, transformed section

l

ut

, and E is the modulus of concrete E

c

. Correspondingly, for this load range,

iu

=

ut c

I E

f

(a)

At higher loads, flexural tension cracks are formed. In addition, if shear stresses

exceed v

cr

and web reinforcement is employed to resist them, diagonal cracks can

exist at service loads. In the region of flexural cracks the position of the neutral

axis varies: directly at each crack it is located at the level calculated for the

cracked, transformed section midway between cracks it dips to a location closer

to that calculated for the uncracked transformed section. Correspondingly, flexural-

tension cracking causes the effective moment of inertia to be that of the cracked

transformed section in the immediate neighborhood of flexural-tension cracks, and

closer to that of the uncracked transformed section midway between cracks, with

a gradual transition between these extremes.

It is seen that the value of the local moment of inertia varies in those

portions of the beam in which the bending moment exceeds the cracking moment

of the section

M

cr

=

t

ut r

I f

y

(2.4)

where y

t

is the distance from the neutral axis to the tension face and f

r

is the

44

modulus of rupture. The exact variation of I depends on the shape of the moment

diagram and on the crack pattern, and is difficult to determine. This makes an

exact deflection calculation impossible.

However, extensively documented studies have shown that deflections

ic

occurring in a beam after the maximum moment M

cr

has reached and exceeded

the cracking moment M

cr

can be calculated by using an effective moment of

inertia I

e

, that is,

ic

=

c c

I E

f

(b)

where

I

c

=

3

a

cr

M

M

|

|

.

|

\

|

I

ut

+

(

(

|

.

|

\

|

3

a

cr

M

M

1

I

cr

and I

ut

(2.5)

where I

cr

is the moment of inertia of the cracked transformed section.

FIGURE 2.4

Variation of I

e

with moment ratio

In Fig. 2.4, the effective moment of inertia, given by Eq. (2.5), is plotted

as a function of the ratio M

a

/M

cr

(the reciprocal of the moment ratio used in the

equation). It is seen that, for values of maximum moment M

a

less than the

cracking moment M

cr

that is, M

a

/ M

cr

less than 1.0, I

e

= I

ut

. With increasing

values of M

a

, I

e

approaches I

cr

, and for values of M

a

/ M

cr

of 3 or more, I

e

is

almost the same as I

cr

Typical values of M

a

/ M

cr

at full service load range from

about 1.5 to 3.

45

FIGURE 2.5

Deflection of a

reinforced

concrete beam

Figure 2.5 shows the growth of deflections with increasing moment for a

simple-span beam, and illustrates the use of Eq. (2.5). For moments no larger than

M

cr

deflections are practically proportional to moments and the deflection at which

cracking begins is obtained from Eq.(a) with M= M

cr

. At larger moments, the

effective moment of inertia I

e

becomes progressively smaller, according to Eq.

(2.5), and deflections are found by Eq.(b) for the load level of interest. The

moment M

2

might correspond to the full service load, for example, while the

moment M

1

would represent the dead load moment for a typical case. A moment-

deflection curve corresponding to the line E

c

/C

r

represents an upper bound for

deflections, consistent with Fig.2.4, except that at loads somewhat beyond the

service load, the nonlinear response of steel or concrete or both causes a further

nonlinear increase in deflections.

Note that to calculate the increment of deflection due to live load, causing

a moment increase M

2

M

1

, a two step computation is required: the first for

deflection

2

due to live and dead load, and the second for deflection

1

due to

dead load alone, each with the appropriate value of I

e

.Then the deflection

increment due to live load is found, equal to

2

1

.

2.6 DEFLECTIONS DUE TO LONG-TERM LOADS

The creep deformations of concrete are directly proportional to the com-

pressive stress up to and beyond the usual service load range. They increase

asymptotically with time and, for the same stress, are larger for low-strength than

46

for high-strength concretes. The ratio of additional time-dependent strain to initial

elastic strain is given by the creep coefficient C

cu

.

FIGURE 2.6

Effect of concrete creep on curvature: (a) beam cross section;

(b) strains: (c) stress and forces.

For a reinforced concrete beam, the long-term deformation is much more

complicated than for an axially loaded cylinder, because while the concrete creeps

under sustained load, the steel does not. The situation in a reinforced concrete

beam is illustrated by Fig. 2.6. Under sustained load, the initial strain

i

at the

top face of the beam increases, due to creep, by the amount

t

, while the strain

s

in the steel is essentially unchanged. Because the rotation of the strain

distribution diagram is therefore about a point at the level of the steel, rather than

about the cracked elastic neutral axis, the neutral axis moves down as a result of

creep, and

i

t

<

i

t

(a)

demonstrating that the usual creep coefficients could not be applied to initial

curvatures to obtain creep curvatures (hence deflections).

The situation is further complicated. Due to the lowering of the neutral

axis associated with creep (see Fig. 2.6b) and the resulting increase in compression

area, the compressive stress required to produce a given resultant C to equilibrate

T = A

s

f

s

is less than before, in contrast to the situation in a creep test of a

compressed cylinder, because the beam creep occurs at a gradually diminishing

stress. On the other hand, with the new lower neutral axis, the internal lever arm

between compressive and tensile resultant forces is less, calling for an increase in

47

both resultants for a constant moment. This, in turn, will require a small increase

in stress, and hence strain, in the steel; thus

s

is not constant as assumed

originally.

Because of such complexities, it is necessary in practice to calculate

additional, time-dependent deflections of beams due to creep (and shrinkage) using

a simplified, empirical approach by which the initial elastic deflections are

multiplied by a factor A to obtain the additional long-time deflections. Values of

for use in design are based on long-term deflection data for reinforced concrete

beams.

Thus

t

=

i

(2.6)

where

t

is the additional long-term deflection due to the combined effect of

creep and shrinkage, and

i

, is the initial elastic deflection.

The coefficient depends on the duration of the sustained load. It also

depends on whether the beam has only reinforcement A

s

on the tension side, or

whether additional longitudinal reinforcement A

s

is provided on the compression

side.

If a beam carries a certain sustained load W (e.g., the dead load plus the

average traffic load on a bridge) and is subject to a short-term heavy live load P

(e.g., the weight of an unusually heavy vehicle), the maximum total deflection

under this combined loading is obtained as follows:

1. Calculate the instantaneous deflection

iw

caused by the sustained load W

by methods given in Sec. 2.5.

2. Calculate the additional long-term deflection caused by W; i.e.,

tw

=

iw

3. Then the total deflection caused by the sustained part of the load is

w

=

iw

+

tw

4. In calculating the additional instantaneous deflection caused by the short-

term load P, account must be taken of the fact that the load-deflection

relation after cracking is nonlinear, as illustrated by Fig. 2.5. Hence

ip

=

i(w+p)

iw

where

i(w + p)

is the total instantaneous deflection that would be obtained

if W and P were applied simultaneously, calculated by using le determined

for the moment caused by W + P.

5. Then the total deflection under the sustained load plus heavy short-term

48

load is

=

w

+

ip

I

e

for the maximum load reached should be used to recalculate the

sustained load deflection before calculating long-term effects.

FIGURE 2.7

Effect of load history on deflection of a building girder.

This will be illustrated referring to Fig. 2.7, showing the load-deflection

plot for a building girder that is designed to carry a specified dead and live load.

Assume first that the dead and live loads increase monotonically. As the full dead

load W

d

is applied, the load deflection curve follows the path 0-1, and the dead

load deflection,

d

, is found using I

e1

calculated from Eq. (2.5), with M

a

= M

d

.

The time-dependent effect of the dead load would be

d

. As live load is then

applied, path 1-2 would be followed. Live load deflection, A

1

, would be found in

two steps, as described in Sec.2.5, first finding

d + l

based on I

e2

, with M

0

in

Eq. (2.5) equal to

d + 1

, then subtracting dead load deflection

d

.

If, on the other hand, short-term construction loads were applied, then

removed, the deflection path 1-2-3 would be followed. Then, under dead load

only, the resulting deflection would then be

d

. Note that this deflection can be

found in one step using W

d

, but with I

e2

corresponding to the maximum load

reached. The long-term deflection now would be

d

, significantly larger than

before.

On the other hand, should the full design live load then be applied, the

deflection would follow path 3-4, and the live load deflection would be less than

for the first case. It, too, can be calculated by a simple one-step calculation using

W

1

alone, in this case, and with moment of inertia equal to I

e2

.

2.7 ACI CODE PROVISIONS FOR CONTROL OF DEFLECTIONS

a. Minimum Depth-Span Ratios

According to ACI Code 9.5.2, the minimum depths of Table 2.2 apply to

one-way construction not supporting or attached to partitions or other construction

likely to be damaged by large deflections, unless computation of deflections

indicates a lesser depth can be used without adverse effects. Values given in Table

6.2 are to be used directly for normal weight concrete with w

c

= 145 pcf and

reinforcement with f

y

= 60,000 psi. For members using lightweight concrete with

density in the range from 90 to 120 pcf, the values of Table 2.2 should be

multiplied by (1.65 0.005w

c

) 1.09. For yield strengths other than 60,000 psi,

the values should be multiplied by (0.4 + f

y

/ 100,000).

Table 2.2 Minimum depth of nonprestressed beams or one-way slabs unless

deflections are computed.

b. Calculation of Immediate Defiections

When there is need to use member depths shallower than are permitted by

Table, or when members support construction that is likely to be damaged by large

deflections, or for prestressed members, deflections must be calculated and com-

pared with limiting values. For design purposes, the moment of the Uncracked

transformed section, I

ut

,can be replaced by that of the gross concrete section, I

g

neglecting reinforcement, without serious error. With this simplification, Eqs. (2.4)

and (2.5) are replaced by the following:

49

Anda mungkin juga menyukai

- ISOLATED FOUNDATION DESIGNDokumen74 halamanISOLATED FOUNDATION DESIGNkrishna kumarBelum ada peringkat

- Static Analysis Load DefinitionsDokumen2 halamanStatic Analysis Load DefinitionsPraveen SreedharanBelum ada peringkat

- Instagram Photo by Ekaum Channel • Nov 29, 2021 AtDokumen3 halamanInstagram Photo by Ekaum Channel • Nov 29, 2021 Atkrishna kumarBelum ada peringkat

- Shallow FoundationsDokumen13 halamanShallow Foundationskrishna kumarBelum ada peringkat

- CORROSION LOSSE - LiteratureDokumen3 halamanCORROSION LOSSE - Literaturekrishna kumarBelum ada peringkat

- Centroids of common shapesDokumen4 halamanCentroids of common shapesharilal9285100% (1)

- Machine Foundations (List of Books)Dokumen4 halamanMachine Foundations (List of Books)krishna kumarBelum ada peringkat

- LOAD_CAL_1OF2Dokumen1 halamanLOAD_CAL_1OF2krishna kumarBelum ada peringkat

- Diff BWT Is 800 101Dokumen96 halamanDiff BWT Is 800 101tops123Belum ada peringkat

- Connections Bracing 1Dokumen34 halamanConnections Bracing 1Julio Rafael Terrones VásquezBelum ada peringkat

- Comparative studies of transmission line tower codesDokumen6 halamanComparative studies of transmission line tower codeskrishna kumarBelum ada peringkat

- 32.5 - CCT-Pile Support ReactionDokumen19 halaman32.5 - CCT-Pile Support Reactionkrishna kumarBelum ada peringkat

- COMMON MISTAKES IN STRUCTURAL ENGG-8_7_09Dokumen21 halamanCOMMON MISTAKES IN STRUCTURAL ENGG-8_7_09krishna kumarBelum ada peringkat

- Metal Floor Support SolutionDokumen3 halamanMetal Floor Support Solutionkrishna kumarBelum ada peringkat

- Learn Structural Design of Foundations with STAAD Pro InterfaceDokumen2 halamanLearn Structural Design of Foundations with STAAD Pro Interfacekrishna kumarBelum ada peringkat

- Helical Anchor Inc Engineering Manual Rev 02 PDFDokumen55 halamanHelical Anchor Inc Engineering Manual Rev 02 PDFismael.lorandi623Belum ada peringkat

- Roof Top Aluminium rail structural analysis and designDokumen2 halamanRoof Top Aluminium rail structural analysis and designkrishna kumarBelum ada peringkat

- Pile Design - 15m Length: Calculation of Stiffness FactorsDokumen3 halamanPile Design - 15m Length: Calculation of Stiffness Factorskrishna kumarBelum ada peringkat

- Heavy Hex Nuts Dimensions Weight Imperial - MetricDokumen2 halamanHeavy Hex Nuts Dimensions Weight Imperial - MetricAkshay PoddarBelum ada peringkat

- 10.0 Base Plate & Anchor BoltDokumen16 halaman10.0 Base Plate & Anchor Boltkrishna kumar100% (1)

- (Allan, R.N., & J.W. Fisher.,1967) - Behavior of Bolted Joints With Oversize or Slotted Holes PDFDokumen64 halaman(Allan, R.N., & J.W. Fisher.,1967) - Behavior of Bolted Joints With Oversize or Slotted Holes PDFchristos032100% (2)

- Araymond Fastener-Mechanical Test - 247767 - PowAR SlotDokumen7 halamanAraymond Fastener-Mechanical Test - 247767 - PowAR Slotkrishna kumarBelum ada peringkat

- B.V. Patel Umarakh.: Guided BY: Shaunak DesaiDokumen28 halamanB.V. Patel Umarakh.: Guided BY: Shaunak DesaiKristian Marlowe OleBelum ada peringkat

- SYMBOL Characters and For MS Office (Word & Excel)Dokumen6 halamanSYMBOL Characters and For MS Office (Word & Excel)krishna kumarBelum ada peringkat

- Dubai Wind Code GuideDokumen25 halamanDubai Wind Code GuideEdin LissicaBelum ada peringkat

- Is 14593 1998Dokumen15 halamanIs 14593 1998rbs_75Belum ada peringkat

- Introduction To Structural Dynamics & Aeroelasticity PDFDokumen176 halamanIntroduction To Structural Dynamics & Aeroelasticity PDFRicardo GómezBelum ada peringkat

- Complete RCC Design Very ImportantDokumen41 halamanComplete RCC Design Very ImportantAmal PremachandranBelum ada peringkat

- Is 1363 Black Hexagon Bolts, Nuts, Lock Nuts and Hexagon ScrewsDokumen16 halamanIs 1363 Black Hexagon Bolts, Nuts, Lock Nuts and Hexagon ScrewsprashantlingayatBelum ada peringkat

- Is 5624 1993 Foundation Bolts PDFDokumen8 halamanIs 5624 1993 Foundation Bolts PDFBijaya RaulaBelum ada peringkat

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5782)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (587)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (72)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (344)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (119)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- Sur - Erection BOQ - Electr Equipm - RevADokumen11 halamanSur - Erection BOQ - Electr Equipm - RevAshaikhsajid242100% (1)

- Design of Square Footing F2Dokumen18 halamanDesign of Square Footing F2Mohammed Sumer100% (1)

- 8 4078a PDFDokumen5 halaman8 4078a PDFarasBelum ada peringkat

- Material & Consumables RequirementsDokumen6 halamanMaterial & Consumables RequirementsDoc TorBelum ada peringkat

- Wet BenchDokumen29 halamanWet BenchAnurag KiroriwalBelum ada peringkat

- Polycoat Rbe PDFDokumen2 halamanPolycoat Rbe PDFAmer GonzalesBelum ada peringkat

- Brochure - 2023 - Keihanna CityDokumen32 halamanBrochure - 2023 - Keihanna Cityperencanaan emonev3Belum ada peringkat

- Experiment No. 04 (Chemical Kinetics and Chemical Equilibria)Dokumen1 halamanExperiment No. 04 (Chemical Kinetics and Chemical Equilibria)crrobinBelum ada peringkat

- HPB Series Photoelectric Controls Specifications and Features GuideDokumen9 halamanHPB Series Photoelectric Controls Specifications and Features GuideRusdian Hasbi RidhoBelum ada peringkat

- Bissell Premier User Guide Owners Manual 47A2 80R4 17N4 36Z9 SeriesDokumen20 halamanBissell Premier User Guide Owners Manual 47A2 80R4 17N4 36Z9 SeriesGreg Johnson50% (2)

- Courses ENCE355 Lectures Part2 Chapter8cDokumen21 halamanCourses ENCE355 Lectures Part2 Chapter8cvanamgouthamBelum ada peringkat

- 2 - DupaDokumen96 halaman2 - DupaRoge CaractaBelum ada peringkat

- Grosvenor Full Product Range & Technical Nformation CatalogueDokumen87 halamanGrosvenor Full Product Range & Technical Nformation CatalogueDylan LopezBelum ada peringkat

- La Sportiva Catalogo Mountain Running 2013Dokumen39 halamanLa Sportiva Catalogo Mountain Running 2013Mayayo: Carrerasdemontana.comBelum ada peringkat

- Types of Adhesives: Structural Adhesives Refer To Relatively Strong Adhesives That Are Normally Used WellDokumen2 halamanTypes of Adhesives: Structural Adhesives Refer To Relatively Strong Adhesives That Are Normally Used WellmedanonakamaBelum ada peringkat

- Introduction to CNC: History, Elements, and Machine ToolsDokumen13 halamanIntroduction to CNC: History, Elements, and Machine ToolsDEVARAJU VBelum ada peringkat

- Introduction To Drylab A: Stephan Sylvest Keller, Dtu NanolabDokumen6 halamanIntroduction To Drylab A: Stephan Sylvest Keller, Dtu NanolabAlberto GallottiniBelum ada peringkat

- Group CHM258 AssignmentDokumen5 halamanGroup CHM258 Assignmentshark eyeBelum ada peringkat

- 07 - Tfmua We 0431Dokumen122 halaman07 - Tfmua We 0431jrrodrigueza2100% (1)

- PQ Formulary PDFDokumen16 halamanPQ Formulary PDFjcriveroBelum ada peringkat

- Effective Thermal Design of Cooling TowersDokumen6 halamanEffective Thermal Design of Cooling TowersandrshoBelum ada peringkat

- Catalog CanDokumen416 halamanCatalog CanOCangaceiroBelum ada peringkat

- GTT CS1Dokumen4 halamanGTT CS1iuliiulianBelum ada peringkat

- Maxlyzer Service Manual PDFDokumen37 halamanMaxlyzer Service Manual PDFFidaa JaafrahBelum ada peringkat

- Cable Tray ManualDokumen59 halamanCable Tray Manualamer_arauf100% (5)

- Act. 2Dokumen8 halamanAct. 2olpotBelum ada peringkat

- (EVT 474) LECTURE 3 - Urban Air PollutionDokumen66 halaman(EVT 474) LECTURE 3 - Urban Air PollutionSitinurliyana DarimiBelum ada peringkat

- Volant HydroFORM Centralizer Case Study - Steerable Drilling LinersDokumen1 halamanVolant HydroFORM Centralizer Case Study - Steerable Drilling LinersSudish BhatBelum ada peringkat

- VFPE Geomembrane Installation For Landfill Capping Applications EngineeringDokumen3 halamanVFPE Geomembrane Installation For Landfill Capping Applications EngineeringDAVE MARK EMBODOBelum ada peringkat

- E5CC E5EC Users Manual PDFDokumen336 halamanE5CC E5EC Users Manual PDFJorgeErnestoCartagenaBelum ada peringkat