Tank coil design thermal calculations

Diunggah oleh

Elton SitumeangJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Tank coil design thermal calculations

Diunggah oleh

Elton SitumeangHak Cipta:

Format Tersedia

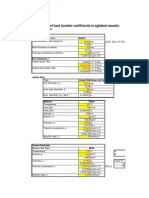

PROCESS CALCULATION SHEET

Job ID: Title: Tank coil design calculation 1 2 3 4 5 6 7 8 9 10 Minimum ambient temp deg C 11 Temperature of Insulation surface 12 Product temperature deg C 13 Steam inlet temperature deg C 14 15 18 22.89468104 65 158 64.4 149 316.4 F F F 73.210426 F Roof surface area m2 = Roof surface area ft2 Shell Surface area m2 = Shell Surface area ft2 4680.97 50385.57 4359.16 46921.57 Tank dia m Tank height m Client : Item No: 74.5 20

Document No:

Rev.

Surface temperature Calculation:

1.43371 0.15 x

16 Heat transfer coefficient in surrounding h 17 Thickness of insulation(mineral wool)

Thermal conductivity of insulation (x/k)*h 20 Surface temperature deg C

18 19 21 22 Steam pressure kg/cm2g 23 Steam pressure kg/cm2A 24 Steam saturation temperature

0.025 8.60226 22.89468104 4.8 5.833 315.00 1183.80 1183.80 284.80 899.00 5.28541 0.01760

BTU/hr(ft)^2.F ft BTU/hr(ft).F 73.21043 F

82.964661 psia Deg F BTU/lb BTU/lb BTU/lb BTU/lb ft3/lb ft3/lb waspwin software waspwin software waspwin software waspwin software waspwin software

25 Enthalpy of superheated steam at supply conditions = 26 Enthalpy of saturated steam at supply pressure = 27 Enthalpy of saturated condensate at supply pressure = 28 Heat available per lb of steam = 29 Specific volume of superheated steam = 30 Specific volume of condensate = 31 32 33 CRUDE specific gravity 34 35 Heat loss from shell 36 hc = 0.3 Dt^0.25 37 delta t F 38 hc 39 Calculation of radiation coeff - hr

0.9

8.810425879 0.516857092 BTU/hr(ft)^2.F

40 hr = 0.173 e [( T1abs/100)^4 - ( T2abs/100)^4]/(T1abs-T2abs) 41 42 43 44 45 46 47 48 Heat loss from roof 49 hc = 0.38 delta t^0.25 50 51 52 53 54 55 57 59

Date Date Sht 1 of 3

T1abs = T2abs = e= hr = hc + hr = Shell Heat Loss Q = (hc+hr)ADt =

533.2104259 524.4 0.8 0.818678533 1.335535625 592868.7985

Rankine Rankine BTU/hr(ft)^2.F BTU/hr(ft)^2.F BTU/hr

0.65468565 hr (remains same) = hc+hr = 0.818678533 1.473364183 609087.2542

BTU/hr(ft)^2.F BTU/hr(ft)^2.F BTU/hr(ft)^2.F BTU/hr

Roof Heat Loss Q = (hc+hr)ADt = Combined heat loss from shell and roof Qc = and to take care of wind effects.

1201956.053

BTU/hr

56 Add 20% for combined losses from appurtenences and tank bottom 58 Total Heat Loss = 1442347.263 BTU/hr

Description Made by / Revised by Checked by Approved by

Page 1

PROCESS CALCULATION SHEET

Job ID: Title: Tank coil design calculation 1 2 3 4 5 6 7 8 9 11 12 Thermal calculations 13 14 Crude side convection coefficient 15 16 Neglecting metal tube resistance and neglecting steam superheat 17 Hot surface temperature Th = 18 Cold liquid temperature Tc = 19 Temperature Difference Dt = 20 Film temperature tf = 21 Pipe OD do = 22 For a 2" pipe area per ft length 23 24 VGO Properties at film temperature 25 26 Thermal Conductivity of VGO k = 27 VGO Density r = 28 acceleration of gravity g = 29 VGO Specific heat c = 30 Coeff. of thermal expansion b = approx 31 Viscosity m =( 12 centistokes x 0.84 ) = 32 33 hc= 116 (( k^3 r^2 c b / m) ( Dt/do))^0.25 = 34 35 Steam side heat transfer coefficient 36 37 38 No of pipes per tank Nt = 39 Assume each pipe length L = 40 Total condensate load W = 41 Condensate Loading G = W/(0.5 L Nt ) = 42 43 44 Condensate properties at condensing temperature 45 Viscosity m = 46 thermal conductivity k = 47 density r = 48 acceleration of gravity g = 49 50 51 52 Condensing film coeff 53 Pipe OD 54 Pipe ID 55 56

Date

Document No:

Rev.

Client : Item No: 1604.390727 727.7402576 8479.86642 357.3771185 2 178.6885593 0.053 0.002206183 22.49845139 m3/hr m m2 m/s lb/hr kg/hr ft3/hr m3/hr 0

Steam flow rate Steam required for maintaning tank temp Steam required for maitening tank temp Steam volume flow rate ( at inlets) Steam volume flow rate ( at inlets) Number of inlets Flow per pipe Pipe ID Pipe c/s area

10 Steam velocity at inlets

315.00 149 166.00 232.00 2.4 0.62832

F F F F inches ft2/ft

0.067 55.62 416687846 0.52 0.004310345 27 31.361

BTU/hr(ft)2(F/ft) lb/ft3 ft / hr^2 btu/lb/deg F 1/F Centipoises BTU/hr(ft)2F

h(m^2/(k^3 r^2 g))^(1/3) = 1.51 ( 4 G / m)^ ( -1/3) 2 100 1604.390727 16.04390727

12.40 pp 265, 269 12.45

ft lb/hr lb/hr/ft

0.463 0.3973 57.619 416687846 1.51 ( 4 G / m ) ^ (-1/3) = ( m^2/(k^3 r^2 g) )^(1/3) = h= 0.291774432 0.000135193 2158.204 2.4 2.09 hio = h ( ID / OD ) 1879.43627

lb/ft/hr Btu/hr/ft2/(F/ft) lb/ft3 ft / hr^2

waspwin software waspwin software waspwin software

Btu/hr/ft2/F inches inches Btu/hr/ft2/F

Date Sht 2 of 3

Description Made by / Revised by Checked by Approved by

Page 2

PROCESS CALCULATION SHEET

Job ID: Title: Tank coil design calculation 1 2 3 4 5 6 7 8 9 11 12 Length of each pipe 13 No of pipes per tank 14 Total pipe length per tank 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 Total Heat Loss = 37 38 Steam required for maintaining tank temp 39 40 Total pipe length required 41 42 43 44 45 46 47 48 49 50

Date

Document No:

Rev.

Client : Item No: 31.361 1879.43627 30.84641207 0.004 27.45843524 316.4360554 503.6236239 2 251.811812 76.75224029 2 153.5044806 m ft m Btu/hr/ft2/F ft2 ft Btu/hr/ft2/F Btu/hr/ft2/F Btu/hr/ft2/F 0

Overall Heat Transfer VGO side ho = Steam side hio = Clean coeff Uc = hio ho /( hio + ho ) = Fouling factor Rd = Dirty Coeff UD = ( Uc / Rd ) / ( Uc + 1/Rd ) Area A = Q/ ( UD Dt ) = Total pipe length per tank No of pipes per tank Nt =

10 Length of each pipe

RESULTS: 1442347.263 BTU/hr 727.7402576 kg/hr 153.5044806 m

Date Sht 3 of 3

Description Made by / Revised by Checked by Approved by

Page 3

PROCESS CALCULATION SHEET

Job ID: Title: Tank coil design calculation 1 2 3 4 5 6 7 8 9 10 Minimum ambient temp deg C 11 Temperature of Insulation surface 12 Product temperature deg C 13 Steam inlet temperature deg C 14 15 18 22.89468104 65 158 64.4 149 316.4 F F F 73.210426 F Roof surface area m2 = Roof surface area ft2 Shell Surface area m2 = Shell Surface area ft2 4680.97 50385.57 4359.16 46921.57 Tank dia m Tank height m Client : Item No: 74.5 20

Document No:

Rev.

Surface temperature Calculation:

1.43371 0.15 x

16 Heat transfer coefficient in surrounding h 17 Thickness of insulation(mineral wool)

Thermal conductivity of insulation 19 (x/k)*h 20 Surface temperature deg C

18 21 22 Steam pressure kg/cm2g 23 Steam pressure kg/cm2A 24 Steam saturation temperature

0.025 8.60226 22.89468104 4.8 5.833 315.00 1183.80 1183.80 284.80 899.00 5.28541 0.01760

BTU/hr(ft)^2.F ft BTU/hr(ft).F 73.21043 F

45.72

82.964661 psia Deg F BTU/lb BTU/lb BTU/lb BTU/lb ft3/lb ft3/lb waspwin software waspwin software waspwin software waspwin software waspwin software

25 Enthalpy of superheated steam at supply conditions = 26 Enthalpy of saturated steam at supply pressure = 27 Enthalpy of saturated condensate at supply pressure = 28 Heat available per lb of steam = 29 Specific volume of superheated steam = 30 Specific volume of condensate = 31 32 33 CRUDE specific gravity 34 35 Heat loss from shell 36 hc = 0.3 Dt^0.25 37 delta t F 38 hc 39 Calculation of radiation coeff - hr

0.9

8.810425879 0.516857092 BTU/hr(ft)^2.F

40 hr = 0.173 e [( T1abs/100)^4 - ( T2abs/100)^4]/(T1abs-T2abs) 41 42 43 44 45 46 47 48 Heat loss from roof 49 hc = 0.38 delta t^0.25 50 51 52 53 54 55 57 59

Date Date Sht 1 of 3

T1abs = T2abs = e= hr = hc + hr = Shell Heat Loss Q = (hc+hr)ADt =

533.2104259 524.4 0.8 0.818678533 1.335535625 592868.7985

Rankine Rankine BTU/hr(ft)^2.F BTU/hr(ft)^2.F BTU/hr

173.7435

0.65468565 hr (remains same) = hc+hr = 0.818678533 1.473364183 609087.2542

BTU/hr(ft)^2.F BTU/hr(ft)^2.F BTU/hr(ft)^2.F BTU/hr 12.6 178.4964

Roof Heat Loss Q = (hc+hr)ADt = Combined heat loss from shell and roof Qc = and to take care of wind effects.

1201956.053

BTU/hr

56 Add 20% for combined losses from appurtenences and tank bottom 58 Total Heat Loss = 1442347.263 BTU/hr 422.6879

Description Made by / Revised by Checked by Approved by

Page 4

PROCESS CALCULATION SHEET

Job ID: Title: Tank coil design calculation 1 2 3 4 5 6 7 8 9 11 12 Thermal calculations 13 14 Crude side convection coefficient 15 16 Neglecting metal tube resistance and neglecting steam superheat 17 Hot surface temperature Th = 18 Cold liquid temperature Tc = 19 Temperature Difference Dt = 20 Film temperature tf = 21 Pipe OD do = 22 For a 2" pipe area per ft length 23 24 VGO Properties at film temperature 25 26 Thermal Conductivity of VGO k = 27 VGO Density r = 28 acceleration of gravity g = 29 VGO Specific heat c = 30 Coeff. of thermal expansion b = approx 31 Viscosity m =( 12 centistokes x 0.84 ) = 32 33 hc= 116 (( k^3 r^2 c b / m) ( Dt/do))^0.25 = 34 35 Steam side heat transfer coefficient 36 37 38 No of pipes per tank Nt = 39 Assume each pipe length L = 40 Total condensate load W = 41 Condensate Loading G = W/(0.5 L Nt ) = 42 43 44 Condensate properties at condensing temperature 45 Viscosity m = 46 thermal conductivity k = 47 density r = 48 acceleration of gravity g = 49 50 51 52 Condensing film coeff 53 Pipe OD 54 Pipe ID 55 56

Date

Document No:

Rev.

Client : Item No: 1604.390727 727.7402576 8479.86642 357.3771185 2 178.6885593 0.053 0.002206183 22.49845139 m3/hr m m2 m/s lb/hr kg/hr ft3/hr m3/hr 0

Steam flow rate Steam required for maintaning tank temp Steam required for maitening tank temp Steam volume flow rate ( at inlets) Steam volume flow rate ( at inlets) Number of inlets Flow per pipe Pipe ID Pipe c/s area

10 Steam velocity at inlets

315.00 149 166.00 232.00 2.4 0.62832

F F F F inches ft2/ft

0.067 55.62 416687846 0.52 0.004310345 27 31.361

BTU/hr(ft)2(F/ft) lb/ft3 ft / hr^2 btu/lb/deg F 1/F Centipoises BTU/hr(ft)2F

h(m^2/(k^3 r^2 g))^(1/3) = 1.51 ( 4 G / m)^ ( -1/3) 2 100 1604.390727 16.04390727

12.40 pp 265, 269 12.45

ft lb/hr lb/hr/ft

0.463 0.3973 57.619 416687846 1.51 ( 4 G / m ) ^ (-1/3) = ( m^2/(k^3 r^2 g) )^(1/3) = h= 0.291774432 0.000135193 2158.204 2.4 2.09 hio = h ( ID / OD ) 1879.43627

lb/ft/hr Btu/hr/ft2/(F/ft) lb/ft3 ft / hr^2

waspwin software waspwin software waspwin software

Btu/hr/ft2/F inches inches Btu/hr/ft2/F

Date Sht 2 of 3

Description Made by / Revised by Checked by Approved by

Page 5

PROCESS CALCULATION SHEET

Job ID: Title: Tank coil design calculation 1 2 3 4 5 6 7 8 9 11 12 Length of each pipe 13 No of pipes per tank 14 Total pipe length per tank 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 Total Heat Loss = 37 38 Steam required for maintaining tank temp 39 40 Total pipe length required 41 42 43 44 45 46 47 48 49 50

Date

Document No:

Rev.

Client : Item No: 31.361 1879.43627 30.84641207 0.004 27.45843524 316.4360554 503.6236239 2 251.811812 76.75224029 2 153.5044806 m ft m Btu/hr/ft2/F ft2 ft Btu/hr/ft2/F Btu/hr/ft2/F Btu/hr/ft2/F 0

Overall Heat Transfer VGO side ho = Steam side hio = Clean coeff Uc = hio ho /( hio + ho ) = Fouling factor Rd = Dirty Coeff UD = ( Uc / Rd ) / ( Uc + 1/Rd ) Area A = Q/ ( UD Dt ) = Total pipe length per tank No of pipes per tank Nt =

10 Length of each pipe

RESULTS: 1442347.263 BTU/hr 727.7402576 kg/hr 153.5044806 m

Date Sht 3 of 3

Description Made by / Revised by Checked by Approved by

Page 6

mm

kW

W/m2K kW

kW

Page 7

Anda mungkin juga menyukai

- Heating Coil Sizing For Fuel Oil TankDokumen2 halamanHeating Coil Sizing For Fuel Oil TankAhmed Mujtaba93% (14)

- Steam Coil CalculationDokumen10 halamanSteam Coil CalculationRefqi Kemal Habib100% (2)

- TankjktDokumen57 halamanTankjktAnonymous 20VAru100% (2)

- Coil DesignDokumen7 halamanCoil DesignSajal Kulshrestha100% (2)

- Inbreathing OutbreathingDokumen17 halamanInbreathing OutbreathingInggit100% (2)

- Storage Tank Heat Loss Calcs - Rev.1 31.12.2010Dokumen16 halamanStorage Tank Heat Loss Calcs - Rev.1 31.12.2010Jade GeronimoBelum ada peringkat

- API STD 2000-2009 Calculation for max. flow rates for normal inbreathingDokumen2 halamanAPI STD 2000-2009 Calculation for max. flow rates for normal inbreathingfzhou100% (4)

- Heat Transfer in Jacketed VesselDokumen2 halamanHeat Transfer in Jacketed VesselMuthuKumar Arunachalam0% (1)

- Internal Coil CalculationDokumen19 halamanInternal Coil CalculationMr Incognito100% (3)

- Diameter of Tank Baffle and Coil DimensionsDokumen4 halamanDiameter of Tank Baffle and Coil DimensionsTarmana Antt50% (2)

- Heating Coil Sizing For Fuel Oil TankDokumen2 halamanHeating Coil Sizing For Fuel Oil TankPouria Sabbagh100% (1)

- Design Calculations - Insulation Thickness REV-1Dokumen4 halamanDesign Calculations - Insulation Thickness REV-1delMAK100% (1)

- Sizing For Vaporiser/Flash Vessel: InputsDokumen3 halamanSizing For Vaporiser/Flash Vessel: InputsSaravana ChandranBelum ada peringkat

- Tank Coils - Design and UseDokumen7 halamanTank Coils - Design and UseMartin DanzeBelum ada peringkat

- Weight Estimation of Vessels AppsDokumen28 halamanWeight Estimation of Vessels AppsAlvin Smith60% (5)

- Formulas KilnDokumen53 halamanFormulas KilnNael93% (14)

- TDS Ucarsol AP 804Dokumen9 halamanTDS Ucarsol AP 804Elton SitumeangBelum ada peringkat

- TDS Ucarsol AP 814Dokumen8 halamanTDS Ucarsol AP 814Elton SitumeangBelum ada peringkat

- Margarine 12Dokumen74 halamanMargarine 12the_gunners2004Belum ada peringkat

- Chapter 5 Lecture 2Dokumen30 halamanChapter 5 Lecture 2burhanuddinBelum ada peringkat

- TankHeatingCoil&BoilerCapacityRequirement Rev 2Dokumen1 halamanTankHeatingCoil&BoilerCapacityRequirement Rev 2sooner123456Belum ada peringkat

- Sizing Heating Coil Insulated Fuel TankDokumen2 halamanSizing Heating Coil Insulated Fuel Tankypatels50% (2)

- Half Pipe CalculationDokumen3 halamanHalf Pipe CalculationCaptainTonies0% (1)

- Steam Coil SizingDokumen21 halamanSteam Coil SizingMildogg100% (1)

- Vertical Storage Tank Heat Loss Calcs - Rev.1 31.12.2010Dokumen16 halamanVertical Storage Tank Heat Loss Calcs - Rev.1 31.12.2010jnmanivannanBelum ada peringkat

- InsulationDokumen6 halamanInsulationBrinto VargheseBelum ada peringkat

- Pipe Heat Loss CalculationDokumen10 halamanPipe Heat Loss Calculationingemarquintero67% (3)

- Calculation Overall Heat TransferDokumen4 halamanCalculation Overall Heat TransferDavid LambertBelum ada peringkat

- Sizing of Steam Coil of Insulated Tank Rev 3 PDFDokumen2 halamanSizing of Steam Coil of Insulated Tank Rev 3 PDFdhavalesh1Belum ada peringkat

- Inlet Flow For Out Breathing: Total Pump in m3/hr 20Dokumen9 halamanInlet Flow For Out Breathing: Total Pump in m3/hr 20sonaldivBelum ada peringkat

- Storage-Tank Heat TransferDokumen57 halamanStorage-Tank Heat Transfervitcon87100% (12)

- NT42 Calculation Heat Transfer of Storage Tank Rail TankDokumen2 halamanNT42 Calculation Heat Transfer of Storage Tank Rail TankAnonymous v5uipHBelum ada peringkat

- Calculating heat transfer and temperature change in a crude oil storage tankDokumen3 halamanCalculating heat transfer and temperature change in a crude oil storage tankbadelitamariusBelum ada peringkat

- Design Calculation For Coil in The HFO Tank - TK14 & TK 15Dokumen4 halamanDesign Calculation For Coil in The HFO Tank - TK14 & TK 15chintanBelum ada peringkat

- AST Heating Coil Design Calculation Rev 0Dokumen3 halamanAST Heating Coil Design Calculation Rev 0Pieter Grendel100% (3)

- Vapor Liquid Vertical SeparatorDokumen4 halamanVapor Liquid Vertical SeparatorIoana Popescu100% (1)

- Steam CalculationDokumen27 halamanSteam CalculationRAVI KUMAR CarpenterBelum ada peringkat

- Coil Heat CalculationDokumen2 halamanCoil Heat CalculationTarmana Antt100% (1)

- Design of Limpet Coil as per Appendix EEDokumen10 halamanDesign of Limpet Coil as per Appendix EEmaheshspawar0% (1)

- Half Pipe Coil AgitatedDokumen1 halamanHalf Pipe Coil AgitatedNITINBelum ada peringkat

- Rigorous Heat Loss Program for VesselsDokumen2 halamanRigorous Heat Loss Program for VesselsSapariya Hitesh50% (2)

- Agitator Vessel Design CostingDokumen20 halamanAgitator Vessel Design CostingneelBelum ada peringkat

- Shell Tube Heat Exchanger DesignDokumen7 halamanShell Tube Heat Exchanger DesignMakhdoom Ibad HashmiBelum ada peringkat

- Case D9.03 Storage Tank Heating SystemDokumen3 halamanCase D9.03 Storage Tank Heating SystemBarmar Sbahi0% (1)

- Tank padding calculation summaryDokumen9 halamanTank padding calculation summarykomalrana2007100% (1)

- Insulation ThicknessDokumen10 halamanInsulation ThicknessPratik Ray ChaudhuryBelum ada peringkat

- Tank Heat LossDokumen25 halamanTank Heat Lossdanmaltais100% (3)

- Condensate Line SizingDokumen2 halamanCondensate Line SizingAnonymous oVRvsdWzfBBelum ada peringkat

- Tank design calculations sheet analysisDokumen5 halamanTank design calculations sheet analysisapminshull88% (8)

- Heat Exchanger Rating Calc SheetDokumen14 halamanHeat Exchanger Rating Calc SheetSatria 'igin' Girindra NugrahaBelum ada peringkat

- Ael-2597-Mec-Cl-0305-R0 - Design Calculation of Heating CoilDokumen2 halamanAel-2597-Mec-Cl-0305-R0 - Design Calculation of Heating CoilbecpavanBelum ada peringkat

- Heat ExchangerDokumen124 halamanHeat ExchangerHaiqal AzizBelum ada peringkat

- Steam Coil DesignDokumen2 halamanSteam Coil DesignHendri SinagaBelum ada peringkat

- Tank Venting Rate EstimationDokumen3 halamanTank Venting Rate EstimationOmar KallufBelum ada peringkat

- Pump and Line Sizing CalcDokumen5 halamanPump and Line Sizing CalcMuthuKumar ArunachalamBelum ada peringkat

- Insulation Thickness Calculation for Rectangular and Cylindrical ShapesDokumen13 halamanInsulation Thickness Calculation for Rectangular and Cylindrical ShapeszamijakaBelum ada peringkat

- Heat Exchanger DesignDokumen22 halamanHeat Exchanger DesignRupack HalderBelum ada peringkat

- Re BoilersDokumen42 halamanRe BoilersShashi MashalBelum ada peringkat

- Insulation CalcDokumen4 halamanInsulation Calcjacok22Belum ada peringkat

- Heat Exchanger MEK ProductionDokumen20 halamanHeat Exchanger MEK ProductionSyed Zaighum AbbasBelum ada peringkat

- Design 2-Pass Shell and Tube Heat ExchangerDokumen20 halamanDesign 2-Pass Shell and Tube Heat Exchangerazib100% (1)

- 250 HP Engine For Unmanned HelicopterDokumen52 halaman250 HP Engine For Unmanned HelicopteryanfengzhangBelum ada peringkat

- Observations and CalculationsDokumen3 halamanObservations and CalculationsWaseem YousafBelum ada peringkat

- Formulas of KillanDokumen4 halamanFormulas of KillanGOKULAKRISHNAN N100% (1)

- Antifoam + Activated Carbon Filter For AGRUDokumen1 halamanAntifoam + Activated Carbon Filter For AGRUElton SitumeangBelum ada peringkat

- TDS Ucarsol GT-10 AntifoamDokumen5 halamanTDS Ucarsol GT-10 AntifoamElton SitumeangBelum ada peringkat

- Dowtherm QDokumen2 halamanDowtherm QÖmer LaçinBelum ada peringkat

- LPG Report MasamiDokumen108 halamanLPG Report Masamiwalid19882014Belum ada peringkat

- PotassiumDokumen17 halamanPotassiumSahraoui du NordBelum ada peringkat

- TEG HP Ind in English 2012Dokumen8 halamanTEG HP Ind in English 2012Elton SitumeangBelum ada peringkat

- Teg HP Sales SpecsDokumen1 halamanTeg HP Sales SpecsElton SitumeangBelum ada peringkat

- TDS Ucarsol GT-10 AntifoamDokumen5 halamanTDS Ucarsol GT-10 AntifoamElton SitumeangBelum ada peringkat

- LPG Storage Systems Atmospheric Vs PressurisedDokumen8 halamanLPG Storage Systems Atmospheric Vs Pressurisedraritylim100% (1)

- AIHA ASSE Non-Lab and Lab HazMat PresentationDokumen105 halamanAIHA ASSE Non-Lab and Lab HazMat PresentationElton SitumeangBelum ada peringkat

- A0020-Hydrogen Sulfide PDFDokumen5 halamanA0020-Hydrogen Sulfide PDFElton SitumeangBelum ada peringkat

- Depressuring Flow - Quick Manual MethodDokumen3 halamanDepressuring Flow - Quick Manual MethodElton Situmeang100% (1)

- DPCVDokumen8 halamanDPCVmohanBelum ada peringkat

- Dowtherm QDokumen2 halamanDowtherm QÖmer LaçinBelum ada peringkat

- Simplified Block DiagramDokumen1 halamanSimplified Block DiagramElton SitumeangBelum ada peringkat

- 2725Dokumen11 halaman2725Elton SitumeangBelum ada peringkat

- Olivia Newton-John Lyrics - He Ain't Heavy... He's My BrotherDokumen1 halamanOlivia Newton-John Lyrics - He Ain't Heavy... He's My BrotherElton SitumeangBelum ada peringkat

- Glen Campbell Lyrics - Take My Hand For A WhileDokumen1 halamanGlen Campbell Lyrics - Take My Hand For A WhileElton SitumeangBelum ada peringkat

- Drafting Tools for Engineering GraphicsDokumen44 halamanDrafting Tools for Engineering Graphicsprod_bestBelum ada peringkat

- Engelbert Humperdinck - Release Me LyricsDokumen2 halamanEngelbert Humperdinck - Release Me LyricsElton Situmeang0% (1)

- Sizing Up Your Sump Pump for Maximum PerformanceDokumen4 halamanSizing Up Your Sump Pump for Maximum PerformanceAnonymous wIPMQ5rhBelum ada peringkat

- Cone Roof TankDokumen1 halamanCone Roof TankElton SitumeangBelum ada peringkat

- Class 1 - Introduction To Engineering Graphics PDFDokumen37 halamanClass 1 - Introduction To Engineering Graphics PDFPeeka Prabhakara RaoBelum ada peringkat

- Condensate Line SizingDokumen2 halamanCondensate Line Sizingemmanuilmoulos6339100% (1)

- Biodiesel Dry Wash Ion Exchange Towers - Utah Biodiesel SupplyDokumen7 halamanBiodiesel Dry Wash Ion Exchange Towers - Utah Biodiesel SupplyElton SitumeangBelum ada peringkat

- Auto Cad 2000 TutorialDokumen16 halamanAuto Cad 2000 TutorialrazyzaBelum ada peringkat

- Standar NFPA PDFDokumen3 halamanStandar NFPA PDFElton SitumeangBelum ada peringkat

- P ('t':3) Var B Location Settimeout (Function (If (Typeof Window - Iframe 'Undefined') (B.href B.href ) ), 15000)Dokumen1 halamanP ('t':3) Var B Location Settimeout (Function (If (Typeof Window - Iframe 'Undefined') (B.href B.href ) ), 15000)Elton SitumeangBelum ada peringkat

- Beams - Determinate: Using Area Moment MethodDokumen16 halamanBeams - Determinate: Using Area Moment MethodOmen JettBelum ada peringkat

- Shaft Critical SpeedDokumen8 halamanShaft Critical SpeedkannanjuBelum ada peringkat

- ANNA UNIVERSITY MECHANICAL ENGINEERING SIMULATION LAB EXAMDokumen5 halamanANNA UNIVERSITY MECHANICAL ENGINEERING SIMULATION LAB EXAMAsst.Prof MECH100% (1)

- Week 2 - Vle Part 1Dokumen35 halamanWeek 2 - Vle Part 1dhanieemaBelum ada peringkat

- 13C NMR Spectroscopy of Coumarin DerivativesDokumen18 halaman13C NMR Spectroscopy of Coumarin DerivativesGeorge MoshiashviliBelum ada peringkat

- Cable Sizing PDFDokumen8 halamanCable Sizing PDFkumarBelum ada peringkat

- Blocked Rotor TestDokumen11 halamanBlocked Rotor TestIjabi100% (1)

- Dynamic Parameter Identification of The Universal Robots UR5 PDFDokumen7 halamanDynamic Parameter Identification of The Universal Robots UR5 PDFAyman DamounBelum ada peringkat

- Electrical Circuits & Networks Question BankDokumen6 halamanElectrical Circuits & Networks Question BankMATHANKUMAR.S100% (1)

- CH 04Dokumen17 halamanCH 04Vishal PanwarBelum ada peringkat

- Assignment 11 Rotational MotionDokumen1 halamanAssignment 11 Rotational MotionMrinal TripathiBelum ada peringkat

- At The Completion of The CourseDokumen2 halamanAt The Completion of The Courseoday albuthbahakBelum ada peringkat

- Rebar Pullout Testing PDFDokumen6 halamanRebar Pullout Testing PDFsami_bangash_1Belum ada peringkat

- Lake Ridge Academy 9 - 12 Curriculum GuideDokumen2 halamanLake Ridge Academy 9 - 12 Curriculum GuidevanermedusaBelum ada peringkat

- Becker 1987Dokumen16 halamanBecker 1987Luis Fernando Vergaray AstupiñaBelum ada peringkat

- Unit 2 HydrostaticsDokumen17 halamanUnit 2 HydrostaticsRin MoonBelum ada peringkat

- Degree of Freedom PDFDokumen13 halamanDegree of Freedom PDFAnasBelum ada peringkat

- Understanding the Mole ConceptDokumen23 halamanUnderstanding the Mole ConceptMuyatwa LiksBelum ada peringkat

- Noise Level Calculations: Example #1Dokumen2 halamanNoise Level Calculations: Example #1Susheel WankhedeBelum ada peringkat

- Applied Thermodynamics Tutorial Reciprocating CompressorsDokumen2 halamanApplied Thermodynamics Tutorial Reciprocating CompressorsChris ZiyuenBelum ada peringkat

- Bending Deflection - Macaulay Step Functions: AE1108-II: Aerospace Mechanics of MaterialsDokumen9 halamanBending Deflection - Macaulay Step Functions: AE1108-II: Aerospace Mechanics of MaterialsAyanwale-cole pelumi AkeemBelum ada peringkat

- Partial Differential Equations Muzammil Tanveer PDFDokumen173 halamanPartial Differential Equations Muzammil Tanveer PDFM Irfan IqbalBelum ada peringkat

- Aliasgar Dedanwala - Gizmo Circuits and ResistanceDokumen6 halamanAliasgar Dedanwala - Gizmo Circuits and ResistanceJonan SotoBelum ada peringkat

- V (K / N) R S R A / P: Basic Design Calculation For Nallah at STP - 1Dokumen2 halamanV (K / N) R S R A / P: Basic Design Calculation For Nallah at STP - 1pranBelum ada peringkat

- IME Micro ProjectDokumen4 halamanIME Micro Projectshubhamghodekar76Belum ada peringkat

- ch13 DynamicsDokumen64 halamanch13 DynamicsIfea WongBelum ada peringkat

- Aashto T 99-81Dokumen7 halamanAashto T 99-81ORUSBelum ada peringkat

- Finding Binary Azeotropes Using Thermodynamic RelationshipsDokumen7 halamanFinding Binary Azeotropes Using Thermodynamic Relationshipsshinta sariBelum ada peringkat