BioEthanol From SCBH - Status & Pespective

Diunggah oleh

tvdaihaiHak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

BioEthanol From SCBH - Status & Pespective

Diunggah oleh

tvdaihaiHak Cipta:

Format Tersedia

Bioresource Technology 101 (2010) 47544766

Contents lists available at ScienceDirect

Bioresource Technology

journal homepage: www.elsevier.com/locate/biortech

Production of bioethanol from sugarcane bagasse: Status and perspectives

C.A. Cardona *, J.A. Quintero, I.C. Paz

Departamento de Ingeniera Qumica, Universidad Nacional de Colombia Sede Manizales, Cra. 27 No. 64-60, Manizales, Colombia

a r t i c l e

i n f o

a b s t r a c t

Lignocellulosic biomass is considered as the future feedstock for ethanol production because of its low cost and its huge availability. One of the major lignocellulosic materials found in great quantities to be considered, especially in tropical countries, is sugarcane bagasse (SCB). This work deals with its current and potential transformation to sugars and ethanol, considering pretreatment technologies, detoxication methods and biological transformation. Some modeling aspects are exposed briey. Finally stability is discussed for considering the high nonlinear phenomena such as multiplicity and oscillations, which make more complex the control as a result of the inhibition problems during fermentation when furfural and formic acid from SCB hydrolysis are not absent. 2009 Elsevier Ltd. All rights reserved.

Article history: Received 15 August 2009 Received in revised form 22 October 2009 Accepted 23 October 2009 Available online 28 November 2009 Keywords: Sugarcane bagasse Ethanol Pretreatment Lignocellulosic Stability

1. Introduction For large-scale biological production of fuel ethanol, it is desirable to use cheaper and more abundant substrates. When producing ethanol from maize (made up from starch chains) or sugarcane (in the form of either cane juice or molasses) the raw material constitutes about 4070% of the production cost (Sendelius, 2005; Quintero et al., 2008). By using waste products from forestry, agriculture and industry, the costs of the feedstocks may be reduced. Lignocellulose (complex polymer made up from three carbohydrates: cellulose hemicelluloses and lignin) is considered as an attractive feedstock for the production of fuel ethanol, because of its availability in large quantities at low cost (Cardona and Snchez, 2007; Cheng et al., 2008) and for reducing competition with food but not necessarily with feed. Today the production cost of ethanol from lignocellulose is still too high, which is the major reason why ethanol from this feedstock has not made its breakthrough yet. Many lignocellulosic materials have been tested for bioethanol production as was reviewed by Snchez and Cardona (2008). In general, prospective lignocellulosic materials for fuel ethanol production can be divided into six main groups: crop residues (cane bagasse, corn stover, wheat straw, rice straw, rice hulls, barley straw, sweet sorghum bagasse, olive stones and pulp), hardwood (aspen and poplar), softwood (pine and spruce), cellulose wastes (newsprint, waste ofce paper and recycled paper sludge), herbaceous biomass (alfalfa hay, switchgrass, reed canary grass, coastal Bermudagrass and thimothy grass), and municipal solid wastes

* Corresponding author. Tel.: +57 6 8879300x50417; fax: +57 6 8879300x50452. E-mail address: ccardonaal@unal.edu.co (C.A. Cardona). 0960-8524/$ - see front matter 2009 Elsevier Ltd. All rights reserved. doi:10.1016/j.biortech.2009.10.097

(MSW). Numerous studies for developing large-scale production of ethanol from lignocellulosics have been carried out in the world. However, the main limiting factor is the higher degree of complexity inherent to the processing of this feedstock. This is related to the nature and composition of lignocellulosic biomass (which contain up to 75% of cellulose and hemicelluloses). Cellulose and hemicelluloses should be broken down into fermentable sugars in order to be converted into ethanol or other valuable products (xylans, xylitol, hydrogen and enzymes). But this degradation process is complicated, energy-consuming and non-completely developed (Snchez and Cardona, 2008). With the advent of modern genetics and other tools the cost of producing sugars from these recalcitrant fractions and converting them into products like ethanol can be signicantly reduced in the future. Several reviews have been published on the theme of fuel ethanol production especially from lignocellulosic biomass (Lin and Tanaka, 2006; Cardona and Snchez, 2007; Snchez and Cardona, 2008). Lignocellulosic materials from different crop residues have been used for conversion to ethanol. One of the major lignocellulosic materials found in great quantities to be considered, especially in tropical countries, is sugarcane bagasse (SCB), the brous residue obtained after extracting the juice from sugar cane (Saccharum ofcinarum) in the sugar production process (Martn et al., 2007a). SCB is produced in large quantities by the sugar and alcohol industries in Brazil (Martnez et al., 2003; Hernndez-Salas et al., 2009), India (Martnez et al., 2003; Chandel et al., 2007), Cuba (Martnez et al., 2003), China (Martnez et al., 2003; Cheng et al., 2008), Mxico (Hernndez-Salas et al., 2009), Indonesia (Restuti and Michaelowa, 2007) and Colombia (Quintero et al., 2008). In

C.A. Cardona et al. / Bioresource Technology 101 (2010) 47544766

4755

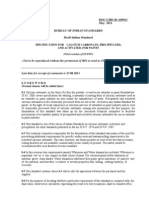

general, 1 ton of sugarcane generates 280 kg of bagasse, and 5.4 108 dry tons of sugarcane are processed annually throughout the world (Cerqueira et al., 2007). About 50% of this residue is used in distillery plants as a source of energy (Pandey et al., 2000); the remainder is stockpiled. Therefore, because of the importance of SCB as an industrial waste, there is great interest in developing methods for the biological production of fuel and chemicals that offer economic, environmental, and strategic advantages (Adsul et al., 2004). In the approximately 80 sugarcane producing countries there is a potential to make better use of the SCB. Subjected to improved energy efciency, sugar producers could supply energy either as co-generated electricity, or as fuel ethanol through cellulose hydrolysis followed by fermentation (Botha and Blottnitz, 2006). The most common use for SCB is the energy production by combustion (Ramjeawon, 2008). In addition, SCB can be used also to produce chemical compounds such as furfural or hydroxymethylfurfural (Almazn et al., 2001), paper paste (Pattra et al., 2008) or ethanol (Laser et al., 2002). The use of SCB in chemistry and biotechnology has been reviewed elsewhere (e.g. Pandey et al., 2000). As raw material, SCB should be analyzed from composition, structure and surface properties. SCB is primarily composed of lignin (2030%), cellulose (4045%) and hemicelluloses (3035%) (Peng et al., 2009). Because of its lower ash content, 1.9% (Li et al., 2002), bagasse offers numerous advantages compared with other agro-based residues such as paddy straw, 16% (Goh et al., 2009), rice straw, 14.5% (Guo et al., 2009) and wheat straw, 9.2% (Zhao and Bai, 2009). Work on structure and surface characterization of SCB has not been done extensively, but some works can be found (Zhao et al., 2007; Quintero and Cardona, 2009). In a previous work (Quintero and Cardona, 2009) SCB was obtained from a small sugarcane juice factory and milled for its structural analysis. Obtained bers had smooth surface layers and characteristic elongations with lengths over 200 lm (this was obtained from SEM micrographs with in a JEOL JSM-5910LV microscope). XRD analysis (Rigaku MiniFlex II unit with CuKa used at 30 kV and 15 mA, diffraction angle ranged from 35 to 2 with a scan speed of 5/min) showed that crust and marrow bagasse exhibit different structures and crystallinity. Crust bagasse presents two diffraction peaks at 2h values of 18.04 and 21.9, while marrow bagasse presents only a peak at 21.86, characteristic of the cellulose structures. It is important to note, that most of the developments in SCB transformation to sugars and ethanol have the common scientic basis with other lignocellulosic materials, due to the fact that there are not considerable qualitative differences in composition and structure. Overall fuel ethanol production from SCB includes ve main steps: biomass pretreatment, cellulose hydrolysis, fermentation of hexoses, separation and efuent treatment (see Fig. 1). Furthermore, detoxication and fermentation of pentoses released during the pretreatment step can be carried out. Solid fraction from pretreatment contains the cellulose which is later hydrolisated, and liquid fraction contains the hemicellulose hydrolysate. Once cellulose hydrolysis is completed, the resulting hydrolysate is fermented and converted into ethanol. This process is called separate hydrolysis and fermentation (SHF). SHF is one of the congurations that have been tested more extensively. Pentose fermentation, when it is carried out, is accomplished in an independent unit. The need of separate fermentations is due to the fact that pentose utilizing microorganisms ferment pentoses and hexoses slower than microorganisms that only assimilate hexoses. Moreover, these microorganisms are more sensitive to the inhibitors and to the produced ethanol. For this reason, the hemicellulose hydrolysate resulting from pretreatment should be detoxied. If the fermentation of the hemicelluloses and cellulose hydrolysates is carried out in a separate way, less liquid volumes

of hydrolysate have to be detoxied. The ideal organism for the production of ethanol would be the one which can utilize pentose and hexose sugars generated by lignocellulose hydrolysis (Chandel et al., 2007). Present paper deals with the uses, pretreatment and biological transformation of SCB into added value products, emphasizing on fuel ethanol production. Potential uses of lignocellulosic biomass depend on its composition and in some extend of its availability. Moreover, the required pretreatment is a function of the structure complexity. Main pretreatment methods for SCB are presented. Potential applications of bagasse hydrolysate and the detoxication methods are discussed. Finally, some modeling and stability aspects are considered. Separation and purication, and efuent treatment technologies are not discussed in this paper, because, these technologies are well established for other types of raw material. Additionally efuent product and wastes are similar, despite the highly variations in raw material composition.

2. Pretreatment methods Lignocellulosic materials do not contain monosaccharides readily available for bioconversion. Instead they contain polysaccharides, such as cellulose and hemicelluloses, which have to be hydrolyzed, by means of acids or enzymes, to fermentable sugars. Enzymatic hydrolysis is a promising way for obtaining sugars from lignocellulosic materials, but the low enzymatic accessibility of the native cellulose is a key problem for biomass-to-ethanol processes. Cellulose in plants is closely associated with hemicelluloses and lignin. The lignin is partly covalently associated with hemicelluloses, thus preventing the access of hydrolytic agents to cellulose. In addition, the crystalline structure of cellulose itself represents an extra obstacle to hydrolysis. A pretreatment is required for removing lignin and hemicelluloses, reducing cellulose crystallinity and increasing the porosity of the material (Keller et al., 2003). This enhances the enzymatic susceptibility of cellulose. An effective pretreatment must preserve the utility of the hemicelluloses and avoid the formation of inhibitors (Laser et al., 2002). An economical pretreatment should use inexpensive chemicals and require simple equipment and procedures (Martn et al., 2007a). Several pretreatment methods have been investigated for different lignocellulosic materials (reviewed by Sun and Cheng (2002); Cardona and Snchez (2007); Snchez and Cardona (2008)), steam explosion, solvent extraction, and thermal pretreatment using acids or bases (Mosier et al., 2005); along with biological pretreatments with white rot fungi (Itoh et al., 2003). Among all these methods, acid pretreatment is still the method of choice in several model processes. Pretreatment methods already investigated for bagasse include acid pretreatment with different acids (Gmez et al., 2004, 2006; Rodriguez-Chong et al., 2004; Chandel et al., 2007; Cheng et al., 2008; Pattra et al., 2008; Hernndez-Salas et al., 2009), steam explosion (Martn et al., 2002a; Sendelius, 2005; Hernndez-Salas et al., 2009), alkaline treatment (Hernndez-Salas et al., 2009, alkaline dewaxed (Peng et al., 2009), biological treatment (Li et al., 2002; Camassola and Dillon, 2009), wet oxidation (Martn et al., 2007a), organosolv pretreatment (Pasquini et al., 2005a, b; Pereira et al., 2007; Tu et al., 2008), liquid hot water pretreatment (Laser et al., 2002) and pretreatments with peracetic acid (Teixeira et al., 1999) or with ammonia water (Kurakake et al., 2001). Table 1 shows some of the most pretreatment methods used for bagasse exploitation with their respective operation conditions and in some cases sugar yields. Higher yields are presented with acid hydrolysis. Little information is presented for alkaline pretreatment because delignication is its main objective.

4756

C.A. Cardona et al. / Bioresource Technology 101 (2010) 47544766

Fig. 1. Processes scheme of fuel ethanol production from sugarcane bagasse. Possibilities for reactionreaction integration are shown inside the shaded boxes: CF, cofermentation; SSF, simultaneous saccharication and fermentation; SSCF, simultaneous saccharication and co-fermentation.

2.1. Acid pretreatment The hydrolysis with dilute acids (sulphuric, hydrochloric or acetic acid are habitual, typically 110% weight) is usually called acid hydrolysis or prehydrolysis and consists in the hydrolysis of the hemicellulosic fraction at moderate temperature (in the range 100150 C). The hemicellulose fraction of SCB represents up to 35% of the total carbohydrates that can be readily hydrolyzed to monomeric sugars by dilute acid. However, the concentration of reducing sugar in the hydrolysate is relatively low due to high liquid/solid ratio during the acid hydrolysis. So the hydrolysate should be concentrated before fermentation (Cheng et al., 2008). The acid medium attacks the polysaccharides, especially hemicelluloses that are easier to be hydrolyzed than cellulose. Therefore, the cellulose and lignin fractions remain almost unaltered in the solid phase and can be further processed, being considered suitable for SCB pretreatment as shown by Gmez et al. (2004, 2006). Depending on the operational conditions, the liquid phase of the hydrolysates will be constituted by sugar (xylose, glucose and arabinose), products of decomposition of the hemicelluloses (such as oligomers from the polymers and acetic acid generated from the hydrolysis of acetyl groups linked to sugars) and/or the decomposition products from monosaccharides (such as furfural, product of dehydration of pentoses, and 5-hydroxymethylfurfural (HMF), product of dehydration of hexoses) (Gmez et al., 2006). These products are growth inhibitors of microorganisms. Therefore, the hydrolysates can be used as fermentation media if the concentration of inhibitors remains low (Gmez et al., 2004). The most used acid is H2SO4, among other acids that can be used such as HCl or HNO3. 2.1.1. Acid pretreatment using sulphuric acid (H2SO4) Pattra et al. (2008) has evaluated the hydrolysis of SCB using H2SO4 at various concentrations (0.257.0% volume) and reaction times (15240 min) at 121 C, 1.5 kg/cm2 in autoclave. Optimal conditions obtained were 0.5% H2SO4 and 60 min, which yielded 24.5 g/L of total sugar. At these conditions the highest glucose concentration was obtained: 11 g glucose/L; 11.29 g xylose/L; 2.22 g arabinose/L; 2.48 g acetic acid/L and 0.12 g furfural/L were ob-

tained. An increase from 0.5% to 1.0% H2SO4 did not affect the glucose concentration in SCB hemicellulose hydrolysate, but when H2SO4 concentration was between 1.0 and 5% H2SO4 glucose concentration decreased. Xylose was found as the main sugar in SCB hemicellulose hydrolysate. In order to increase the reducing sugar production from in the SCB and acid recovering, Cheng et al. (2008) has proposed an acid recycle process and detoxication of hydrolysate performed by electrodialysis. The main problem encountered when treating the lignocellulose with acids is the formation of furan derivatives and other non identied toxic products. This is particularly true in the case of xylans, very easily leading to furfural production. 2.1.2. Acid pretreatment using hydrochloric acid (HCl) Hydrochloric acid has been used for pretreatment of different lignocellulosics (e.g. sorghum straw, SCB, ryegrass and palm oil wastes), however, environmental impact and corrosive properties strongly limits its application. SCB hydrolysis with HCl shows higher yields (see Table 1) compared to other lignocellulosics (Hernndez-Salas et al., 2009) and converting more than 30% by weight to reducing sugars. 2.1.3. Acid pretreatment using phosphoric acid (H3PO4) The interest in the use of H3PO4 is that after neutralization of hydrolysates with NaOH, the salt formed is sodium phosphate (Gmez et al., 2006). This salt can remain in the hydrolysates because it is used as nutrient by microorganisms. Therefore, a ltration operation of is not needed with the consequent advantages: improvement of process protability (avoiding salts removal and decreasing the amount of nutrients needed for fermentation) and positive impact to the environment (the salt formed is not a waste). Gmez et al. (2006) have evaluated the hydrolysis of SCB with phosphoric acid under mild conditions (see Table 1). Using these conditions, 17.6 g of xylose/L; 2.6 g of arabinose/L; 3.0 g of glucose/L, 1.2 g furfural/L and 4.0 g acetic acid/L were obtained. The efciency in these conditions was 4.46 g sugars/g inhibitors and the mass fraction of sugars for dissolved solids in liquid phase was up to 55%. The rate of xylose release increased with the phosphoric acid concentration. Xylose concentrations in hydrolysates at

Table 1 Implemented pretreatments for sugarcane bagasse exploitation. Pretreatment Agent Conditions Yield %w/w of SCBa Dilute acid HCl Acid concentration (1.2% v/v) mL of acid solution/g of bagasse by weight: 15:1. Operation at 121 C and 1.1 kg/cm2 for 4 h Acid concentration (1.2% v/v) mL of acid solution/g of bagasse by weight: 15:1. Operation at 121 C and 1.1 kg/cm2 for 4 h Acid concentration (2.5% v/v) bers size between 2.2 and 10 mm. Operation at 140 C for 30 min. Solid to liquid ratio of 1:10 Acid concentration (1.25%, w/w). Operation at 121 C during 2 h. The biomass at a solid loading of 10% (w/w) Acid concentration (0.5%). Operation at 121 C, 1.5 kg/cm2 during 60 min Acid concentration (4%). Operation at 122 C during 300 min. Water/solid ratio of 8 (g water/g sugarcane bagasse on dry basis) Acid concentration (6%). Operation at 122 C for 9.3 min Base concentration (2% w/v) mL of solution/g of bagasse: 5:1 NaOH: 50 mg/g of bagasse. Operation at 121 C, 1.1 kg/cm2 during 4 h. 0.19 mL of enzyme per gram of bagasse Base concentration 3%, solid to liquid ratio of 1:25 (g/mL) Operation at 50 C for 3 h 37.21 g/L ND For depithed bagasse more than 30% by weight was converted to reducing sugars For pith bagasse Hernndez-Salas et al. (2009) Hernndez-Salas et al. (2009) Chandel et al. (2007) Cheng et al. (2008) Pattra et al. (2008) Gmez et al. (2006) Rodriguez-Chong et al. (2004) Hernndez-Salas et al. (2009) For dewaxed sugarcane bagasse. 74.9% of the original hemicelluloses were hydrolyzed. Xylose was the predominant sugar (79.296.7% of total sugars) Peng et al. (2009) Remarks References

35.37 ND ND ND ND ND 1318

ND 30.29 59.1 24.5 23.2 23.51 ND

C.A. Cardona et al. / Bioresource Technology 101 (2010) 47544766

H2SO4

H3PO4 HNO3 Alkalineenzyme pretreatment Alkaline pretreatment NaOH

NaOH

27.65

ND

Steam explosion

Water Water, SO2 and H2SO4

Operation at 121 C and 1.1 kg/cm2 for 4 h SO2 concentration 2% by weight of water in the bagasse. Acid concentration 0.25 g H2SO4 per 100 g dry matter. 180 C during 5 min Operation at 195 C during 15 min, alkaline pH. Oxygen pressure: 12 bar

ND ND 11.6

ND ND ND Glucose and xylose yields in average 86.3% and 72.0%, respectively Yielding a solid material with nearly 70% cellulose content, hemicelluloses solubilization: 93% of and 50% of lignin. Enzymatic convertibility of cellulose of around 75% Xylose was the main sugar obtained Delignication extent: 94.5% Pulping yield: 32.7%; Residual Klason lignin: 8.7%. Delignication extent: 88.4% Delignication extent: 82.7%. Solid material with nearly 83.53% of a-cellulose

Hernndez-Salas et al. (2009) Sendelius (2005) Martn et al., 2007a

Wet oxidation

Water and oxygen

Organosolv pretreatment

Water and oxygen Supercritical CO2 and 1butanol-water mixture Supercritical CO2 and ethanolwater mixture Dimethyl formamide (DMF)

Operation at 185 C, 5 min, acidic pH. Oxygen pressure: 12 bar Operation at 7 MPa and 190 C. 60% of butanol in the solvent mixture. Reaction time 105 min Operation at 16.0 MPa and 190 C. Ethanolwater (1:1/v:v). Reaction times in the range: 30150 min Operation at 200210 C for 150 min and 4060% DMF

16.1 ND ND ND

ND ND ND ND

Martn et al. (2007a) Pasquini et al. (2005a) Pasquini et al. (2005b) Rezayati-Charani et al. (2006)

SCB: Sugarcane bagasse; ND: non-data available.

4757

4758

C.A. Cardona et al. / Bioresource Technology 101 (2010) 47544766

60 min of reaction were 6.1, 7.3 and 8.6 g/L using H3PO4 concentrations of 2%, 4% and 6%, respectively. 2.1.4. Acid pretreatment using nitric acid (HNO3) Comparison of results obtained using sulphuric and hydrochloric acids (see Table 1) demonstrated that the nitric acid presents similar results for hydrolysis under the evaluated conditions by Rodriguez-Chong et al. (2004) (acid concentration, 26%; reaction time, 0300 min; and temperature, 100128 C). Optimal conditions obtained from kinetic models by Rodriguez-Chong et al. (2004) were: 122 C, 6% HNO3 and 9.3 min. Using these conditions, 18.6 g xylose/L; 2.04 g arabinose/L; 2.87 g glucose/L; 0.9 g acetic acid/L and 1.32 g furfural/L were obtained. The highest xylose concentration (21.0 g/l) was reached after 180 min. 2.2. Alkaline pretreatment Alkaline pretreatment of SCB digests the lignin matrix and makes cellulose and hemicellulose available to enzyme degradation (Pandey et al., 2000). Alkali treatment of lignocellulosic substances such as cereal straw and bagasse disrupts the cell wall by dissolving hemicelluloses, lignin, and silica, by hydrolyzing uronic and acetic esters, and by swelling cellulose. Last decreases the crystallinity of cellulose. By this process, straw and bagasse can be simply fractionated into alkali-soluble lignin, hemicelluloses and residue, which makes easy to utilize them for more valuable products. The end residue (mainly cellulose) can be used to produce either paper or cellulose derivatives. Recently, some important applications for hemicelluloses, such as the production of xylans, have been proposed (Peng et al., 2009). They have evaluated the sequential treatments of dewaxed bagasse with water and 1% and 3% NaOH aqueous solutions yielded 25.1% hemicelluloses from bagasse and accounted for 74.9% of the original hemicelluloses. These results indicated that 1% and 3% NaOH aqueous solutions under these conditions promoted a substantial dissolution of the hemicellulosic polysaccharides and lignin macromolecules. 2.3. Thermal pretreatment

the white rot fungi, microorganism that belong to the class Basidiomycetes and that are capable of degrading a lignocellulose substrate (Pan et al., 2005). Camassola and Dillon (2009) pretreated SCB with the white rot fungus Pleurotus sajor-caju PS2001. Subsequently, they evaluated the use of this biologically pretreated bagasse for the production of cellulases and xylanases by the fungus Penicillium echinulatum. Despite the environmental advantages offered by this type of pretreatment, biological pretreatment using the fungus P. sajor-caju PS2001 was not effective since the enzymatic activities with biologically pretreated SCB were lower than the control treatments carried out with untreated SCB and cellulose. Also, although the enzymatic activities of the culture with biologically pretreated bagasse were lower than the cultures carried out with untreated SCB, it should be noted that the production of enzymes of the cellulose and hemicellulase complex after the production of the mushrooms is another way to add value to this agricultural residue. A marine fungus, Phlebia sp. MG-60, which has been screened from mangrove stands, proved to have excellent lignin degradation ability and selectivity. Li et al. (2002) have incubated this marine fungus, with SCB. With this pretreatment more than 50% of lignin in the SCB was degraded by Phlebia sp. MG-60, and less than 10% of the holocellulose was lost. Without Kirk medium addition, Phlebia sp. MG-60 did not show higher delignication ability or better delignication selectivity than the other white rot fungi. However, when Kirk medium was added to the culture instead of sterilized water, outstanding delignication capability and excellent selective property to delignify SCB were observed. Thus, with proper addition of a nutrient such as Kirk medium, Phlebia sp. MG-60 could efciently degrade lignin in SCB while holocellulose was scarcely damaged. Kirk medium composition was: 1% (w/v) glucose, 1 g/L KH2PO4, 1 g/L Ca(H2PO4), 221 mg/L ammonium tartrate, 500 mg/L MgSO47H2O, 1 mg/L thiamineHCl and 10 ml Kirk mineral solution (Kirk et al., 1978). Other microorganisms evaluated in the degradation of bagasse are several white rot fungi: Phanerochaete chrysosporium ME-466, Phanerochaete sordida YK-624, and Ceriporia sp. MZ-340. 2.5. Wet oxidation

Fractionation and solubilization studies of lignocellulosic materials by thermal treatments have shown the efciency of this technology to improve the yields of extraction of hemicelluloses. Boussarsar et al. (2009) have evaluated the SCB conversion by hydrothermal treatment. Optimal conditions were 170 C for 2 h, reaching higher solubilization of hemicellulose than that at 150 C and lower degradation of sugar monomers than 190 C. However, analysis of thermal hydrolysates shows the presence of xylan oligomers and polymers with large chains. On the other hand, Sendelius (2005) has evaluated the steam pretreatment conditions with respect to nal ethanol yield, using SCB as feedstock. The variables considered were temperature (180, 190 and 205 C), time (5 and 10 min) and impregnating agents (water, 2% SO2 by weight of water in the bagasse and 0.25 g H2SO4 per 100 g dry matter). The most prominent tested pretreatment condition was: SO2-impregnation with a temperature of 180 C during 5 min, which gave a glucose yields in average 86.3% and xylose yields in average 72.0%. The fermentation of these hydrolyzed materials gave an overall ethanol yield of 80%, based on theoretical value. 2.4. Biological pretreatment It is generally known that microorganisms degrade untreated bagasse slowly; therefore, isolation of efcient strains is regarded as an important research area for lignin degradation in SCB. The most promising microorganisms for biological pretreatment are

Wet oxidation (WO) is the process of treating material with water and either air or oxygen at temperatures above 120 C. Two types of reactions occur during WO: a low-temperature hydrolytic reaction and a high-temperature oxidative reaction. It has been demonstrated that combination of alkali and WO reduces the formation of toxic furaldehydes and phenol aldehydes (Klinke et al., 2002). In a recent work, the enzymatic convertibility and the fermentability of bagasse pretreated by WO at different pH values were investigated (Martn et al., 2006). Martn et al. (2007a) have investigated different conditions of wet oxidation (WO) pretreatment on fractionation and enzymatic convertibility of SCB. Variable factors studied were pH, temperature and reaction time, while pressure (12 bar) was kept constant. The pH was adjusted by adding Na2CO3 or H2SO4. The highest cellulose content, nearly 70%, was obtained in the pretreatment at 195 C, 15 min and alkaline pH. The highest sugar yield in the liquid fraction, 16.1 g/100 g, was obtained at 185 C; 5 min and acidic pH (see Table 1). Cellulose enrichment was reached due to removal of hemicelluloses and lignin, as can be deduced from the high degrees of solubilization of hemicelluloses and lignin achieved in the pretreatments leading to bers with higher cellulose content. Although the analysis of the solid fraction in most of the pretreatments showed high degrees of hemicelluloses solubilization, the content of free sugars in the liquid fraction was very low. It is known that wet oxidation mainly catalyses the transfer of hemicelluloses from the solid phase to the liquid phase, but it does not catalyse the hydrolysis

C.A. Cardona et al. / Bioresource Technology 101 (2010) 47544766

4759

of the liberated hemicelluloses molecules. The products of hemicelluloses hydrolysis during WO are not monosaccharides, but sugar oligomers. Reactive oxygen species such as N-methylmorpholine-N-oxide (Kuo and Lee, 2009), sodium hypochlorite and hydrogen peroxide (Lee et al., 2009) in solution have been investigated for its ability to oxidize sugarcane bagasse. 2.6. Organosolv pretreatment Organic solvent or organosolv pulping processes are alternatives to soda or kraft pulping to delignify lignocellulosic materials for the production of paper pulp. For the industrial processes (Kraft and Soda), the burning step is of fundamental importance to recover the inorganic chemicals employed in the pulping. In the organosolv process, the exclusive utilization of organic solvent/ water mixtures eliminates the need to burn the liquor and allows the isolation of the lignins (by distillation of the organic solvent) (Pereira et al., 2007). Formic acid, a typical organosolv system, has been examined under atmospheric pressure to pulp bagasse bers. Tu et al. (2008) showed that efcient bagasse pulping was achieved when the formic acid concentration was limited to 90% (v/v). The delignication of bagasse by 90% formic acid was almost completed after approximately 80 min. Dimethyl formamide has been also used for organosolv pulping of bagasse (Rezayati-charani and Mohammadi-Rovshandeh, 2005; Rezayati-Charani et al., 2006). Other organosolv alternative is its combination with supercritical carbon dioxide. Organosolv-CO2 pulping consists in the utilization of pressurized carbon dioxide as an important part of the pulping liquor (50% alcohol/water mixture and 50% carbon dioxide). This process combines the utilization of a lower amount of organic solvent and facilitates the lignin recovery, by the release of pressure after pulping. This process produces pulp with lower strength properties but in similar yields and in shorter times when compared with the industrial processes (Pereira et al., 2007). SCB delignication was studied combining the utilization of carbon dioxide at high pressures and solvent mixtures, methanol/ water, ethanol/water and n-propanol/water (Pasquini et al., 2005b). The utilization of these different alcohols produced pulps with similar delignication extent but with a continuous decrease in pulp yield with the increase of the alcohols chain length (Pasquini et al., 2005a). To extent the study of the effect of the co-solvent (alcohol/water) in the delignication process Pasquini et al. (2005a, b) have described the utilization of CO2 at sub- and supercritical conditions with 1-butanol/water and ethanol/water as cosolvents in the delignication of SCB. For 1-butanol/water case the higher delignication extent (94.5%) was obtained at 7 MPa, 190 C, 105 min and 60% 1-butanol in the co-solvent mixture. The results also indicate a low selectivity of the process once the lignin removal was accomplished by an extensive hydrolysis of the polysaccharide fraction. The best compromise between lignin removal and polysaccharide preservation was obtained at high pressures and low content of 1-butanol in the co-solvent mixture. For ethanol/water mixture the best results were obtained at 16.0 MPa and 190 C. Under these conditions the delignication extent was in the order 88.4% for SCB. 2.7. Final remarks Dilute sulphuric acid pretreatment has been successfully developed given that high reaction rates can be achieved improving signicantly the subsequent process of cellulose hydrolysis. However, the costs of this type of pretreatment are still higher. The main advantage of dilute acid pretreatment is the higher recovery of sugars derived from hemicelluloses, but concentration of reducing sugars is relatively low due to high liquid to solid ratio. Other

drawbacks include the formation of furan derivatives and other toxic products and the need of an additional concentration step. Alkaline pretreatment decreases the polymerization degree and crystallinity of cellulose by the destruction of links between lignin and other polymers, and breakdown of lignin. Its costs are so high that these methods are not competitive for large-scale plants. Biological pretreatment has low energy requirements and mild environmental conditions. However, these processes are too slow limiting its application at industrial level. Wet oxidation and organosolv pretreatment are the most perspective technologies for SCB hydrolysis at the near future, because both lead to high degree of solubilization of hemicelluloses and lignin, and formation of degradation products is avoided. Last implies the elimination of the detoxication stage. However in the case of organosolv pretreatment large reaction time and high pressure are needed. Moreover, for wet oxidation, products of hydrolysis are oligomers.

3. Cellulose hydrolysis Cellulose obtained from pretreatment should be degraded into glucose (saccharication) using acids or enzymes. In the former case, concentrated or dilute acids can be used. If dilute acids (H2SO4 and HCl) are employed, temperatures of 200240 C at 1.5% acid concentrations are required to hydrolyze the crystalline cellulose, but the degradation of glucose into HMF and other non-desired products is unavoidable under these conditions. One variant of the acid hydrolysis is the use of extremely low acid and high-temperature conditions during batch processes (Ojumu and Ogunkunle, 2005). However, cellulose hydrolysis is currently carried out using microbial cellulolytic enzymes. Enzymatic hydrolysis has demonstrated better results for the subsequent fermentation because no degradation components of glucose are formed although the process is slower. Commercial enzymes have been used to convert SCB to fermentable sugars. Enzymatic hydrolysis of cellulosic materials by cellulase enzymes is the most promising approach to get high product yields critical to economic success (Lynd et al., 1996). To help the enzymes to perform well and degrade the lignocellulose efciently, the bers in the raw material need to be accessible to the enzymes. A pretreatment in some way is needed to expose the bers. If the pretreatment is too harsh, liberated sugars can be degraded to enzyme- and yeast-inhibiting compounds lowering the overall yields. On the other hand, if too weak pretreatment conditions are used this will result in low enzyme accessibility and the same drawbacks. Several pretreatment methods have been evaluated jointly with enzymatic hydrolysis (saccharication). Among them are alkaline pretreatment (Hernndez-Salas et al., 2009), steam explosion (Sendelius, 2005; Hernndez-Salas et al., 2009) and wet oxidation (Martn et al., 2007a). Hernndez-Salas et al. (2009) had optimized an enzyme formulation to process SCB and agave bagasse, which contained Celluclast, Novozyme and Viscozyme L. From alkalineenzymatic hydrolysis of SCB samples, a reduced level of reducing sugar yield was obtained (1120%) compared to agave bagasse (1258%). Glucose concentration was higher in hydrolysates derived from the alkalineenzymatic treatment. Martn et al. (2002a) used a mixture of endo-glucanases and cellobiases to saccharify steam pretreated SCB. The obtained hydrolysate had a sugar composition similar to that reported from chemically treated bagasse. Martn et al. (2007a) has evaluated the effect of wet oxidation pretreatment on fractionation and enzymatic convertibility of SCB. Pretreatment conditions improved the enzymatic convertibility of cellulose. The highest convertibility, 74.9% was achieved in the hydrolysis of the material obtained by pretreatment at

4760

C.A. Cardona et al. / Bioresource Technology 101 (2010) 47544766

195 C, 15 min and alkaline pH. Some xylan convertibility was also observed. Doubling the hydrolysis time from 24 to 48 h led only to some additional conversion, since most of cellulose was already hydrolyzed during the rst 24 h. The low increase of the convertibility at 48 h might be an indication of some degree of denaturation or inactivation of the cellulases. This pretreatment gave also the highest overall glucose yield, 68.9%, which takes into account not only the glucose formed during the enzymatic hydrolysis, but also the losses occurred during the pretreatment. The increase of the enzymatic convertibility is probably related to the low content of lignin and hemicelluloses and the high cellulose content of the remaining solid material. The solubilization of hemicelluloses and lignin and the destruction of their association with cellulose have certainly led to an increase of the accessibility of cellulose to enzymes. Some destruction of the crystalline structure of cellulose and the decrease of its degree of polymerization are other events leading to improvements of the enzymatic convertibility that occurred during pretreatment. Lignin acts as a competitive adsorbent for cellulases and reduces the activity of the adsorbed enzymes (Martn et al., 2007a).

4. Detoxication During pretreatment of lignocellulosics, in addition to the sugars, aliphatic acids (acetic, formic and levulinic acid), furan derivatives furfural and HMF, and phenolic compounds are formed. The existence of these substances is more probably when acid and/or high-temperatures are used. These compounds are known to affect ethanol fermentation performance. Furfural could be generated as a degradation product from pentoses. It was found that furfural contents increase with the concentration of the acid catalysts such as H2SO4 (Pattra et al., 2008).

Table 2 Methods for sugarcane bagasse hydrolysate detoxication. Method Alkaline detoxication Agents Overliming with Ca(OH)2 Previous Pretreatment Steamexplosion dilute acid Conditions pH 910.5 then pH adjustment to 5.56.5 with H2SO4 or HCl

Another inhibitory substances founded in SCB hemicellulose hydrolysate is acetic acid. Acetic acid can be generated when the hydrolysis reaction takes place at the acetyl group of hemicellulose (Rodriguez-Chong et al., 2004). Generally, acetic acid is inhibitory to yeast when its concentration is between 4 and 10 g/L. Maximum concentration of acetic acid obtained for SCB hydrolysates from acid hydrolysis pretreatment with 6% H2SO4 during 60 min was 2.72 g/L, value lower than that for a toxic effect (Pattra et al., 2008). While using 4% H3PO4 during 300 min, the highest value was 4.0 g acetic acid/L (Gmez et al., 2006). On the other hand, a relative low furfural concentration (1.5 g/L) was obtained using 6% H3PO4 at 300 C, although it is over the limit (1.0 g/L) for yeast inhibition. This shows that the decomposition of pentoses to furfural is low and conrms the selectivity of this treatment using phosphoric acid. Several detoxication methods like neutralization, overliming with calcium hydroxide, activated charcoal, ion exchange resins (Carvalheiro et al., 2005) and enzymatic detoxication using laccase (Chandel et al., 2007) are known for removing various inhibitory compounds from lignocellulosic hydrolysates. Table 2 presents main detoxication methods implemented in SCB hydrolysates with their corresponding operation conditions. Percentages of toxic compounds removal are shown. Few methods can remove enough quantities of all toxic substances.

4.1. Neutralization In the operation of neutralization, it is usual to add chemicals that neutralize the acids of the hydrolysates, forming salts. These salts have low solubility and are normally removed by ltration. The concentration of hydrolysates by evaporation is usual to increase the sugar concentration. In this operation, besides water,

Removal (%) Furfural (51%), HMF (51%), phenolic compounds (41%), Acetic acid (0%) Furans (45.8%), phenolics (35.87%) ND

Remarks

References Snchez and Cardona (2008)

Overliming

Acid hydrolysis Acid hydrolysis

ND

Chandel et al. (2007)

Combined alkaline detoxication

KOH and sodium sulte

Microbial detoxication Electrodialysis

Ion exchange resin

Trichoderma reesei Charged membranes and an electrical potential difference Commercial anion exchange resin Activated charcoal Laccase from C. stercoreus

Steamexplosion Acid hydrolysis

pH 10, then pH adjustment to 6.5 with HCl and addition of 1% sodium sulte at 90 C ND Pre-evaporation at 100 C during 15 min. Electrodialysis operation at 20 V. Flow rate 50 L/h Resin to hydrolisate ratio (w/w): 1:10. Regular stirring for 1 h at room temperature ND

Reduction of ketones and aldehydes, removal of volatile compounds

Palmqvist and HahnHgerdal (2000)

Phenolic compounds (80%) Furfural (45%), acetic acid (90%)

Losses of sugar are less of 5%

Palmqvist and HahnHgerdal (2000) Cheng et al. (2008)

Acid hydrolysis

Furans (63.4%), phenolics (75.8%), acetic acid (85.2%) Furans (38.7%), phenolic (57%), acetic acid (46.8%) Phenolics (77.5%)

Chandel et al. (2007)

Activated charcoal

Acid hydrolysis Acid hydrolysis

Chandel et al. (2007)

Enzymes treatment

Incubated in orbital shaker at 100 rpm for 4 h at 30 C

Does not affect furans and acetic acid content. Negligible loss in total sugars and maximum removal phenolic compounds

Chandel et al. (2007)

ND: non-data available.

C.A. Cardona et al. / Bioresource Technology 101 (2010) 47544766

4761

small amounts of growth inhibitors such as acetic acid, furfural and HMF are removed (Carvalho et al., 2002). A detoxication operation by adsorption on charcoal can remove the inhibitors. In this operation, phenolic compounds proceeding from lignin can also be removed. 4.2. Overliming Overliming the hydrolysate has been effective as a detoxication process due to partial removal of toxic inhibitors, such as furfural and 5-hydroxymethylfurfural, although the whole mechanism is not well understood. During overliming, sulphuric acid is removed from the initial hydrolysate by adding lime to adjust the pH and precipitation as gypsum. However, it has been observed that the concentrations of acetic acid before and after the detoxifying treatment were not altered signicantly (Keikhhosro et al., 2006). Another potential drawback of overliming is sugar loss due to hydroxide-catalysed degradation reactions and conversion of sugars into unfermentable compounds (Carvalho et al., 2005). Moreover, the acid cannot be reused any more because it has become salt (Ali et al., 2006). Chandel et al. (2007) have also demonstrated that acetic acid concentration is not altered using overliming but this method led to the removal of furans (45.8%) and phenolics (35.87%). 4.3. Adsorption with activated charcoal Charcoal adsorption decreases the concentrations of both acetic acid and phenolics derived from the SCB hydrolysate. Treatment with activated charcoal caused 38.7%, 57% and 46.8% reduction in furans, phenolics and acetic acid, respectively (Chandel et al., 2007). 4.4. Ion exchange resins Ion exchange treatment has demonstrated to be an efcient method for removing furans (63.4%), total phenolics (75.8%) and acetic acid (85.2%) from a SCB hydrolysate. 4.5. Enzymatic detoxication Treatment with the enzymes like laccase, obtained from the ligninolytic fungus Trametes versicolor, has been shown to increase the ethanol productivity in a hemicellulose hydrolysate of SCB (Chandel et al., 2007). The laccase treatment led to selective removal of total phenolics by 77.5% without affecting furans and acetic acid content of the hydrolysate. 4.6. Electrodialysis Another detoxication method more currently used is electrodialysis (ED), which is an electrochemical separation process in which electrically charged membranes and an electrical potential difference are applied to separate ionic species from an aqueous solution and other uncharged components. Cheng et al. (2008) have evaluated the detoxication of SCB acid hydrolysate by boiling and electrodialysis resulted in a better fermentability of the hydrolysate (see Table 3). Volatile compounds, such as furfural, were stripped by boiling, while acetic acid and sulphuric acid were removed by electrodialysis. After treatment by electrodialysis, 90% of acetic acid in hydrolysate was removed. The losses of glucose, xylose, arabinose, galactose, mannose and cellobiose were lower than 5%. The sulphuric acid and acetic acid in concentrated compartment of ED device are collected and separated by distillation and the sulphuric acid can be reused, which will save the operation cost and

have no environmental impact. ED process reduces the loss of sugar and makes the production of ethanol easier, however, due to the instrument cost, the economical evaluation of ED detoxication is required to be studied further in the actual production of ethanol (Cheng et al., 2008). Chandel et al. (2007) have evaluated the efciency of various detoxication methods (ion exchange treatment, activated charcoal, laccase, overliming and neutralization) (see Table 2) for the removal of inhibitors from SCB hydrolysate and eventually for improving the fermentation of hydrolysate to ethanol using Candida shehatae. Overliming and laccase did not cause any affect on acetic acid levels. Laccase treatment brought about negligible loss in total sugars and maximum removal of phenolic compounds present in acid hydrolysate. Ion exchange treated hydrolysate gave maximum ethanol concentration (8.67 g/L), followed by activated charcoal (7.43 g/L), laccase treatment (6.50 g/L), overliming (5.19 g/L), and neutralized hydrolysate (3.46 g/L). The neutralization of acid hydrolysate alone did not remove toxic compounds to the desired levels, resulting in poor ethanol yield of 0.22 g/g (see Table 3).

5. Ethanol production by fermentation 5.1. Production technologies The conguration employed for fermenting biomass hydrolysates involves a sequential process where the hydrolysis of cellulose and the fermentation are carried out in different units (Snchez and Cardona, 2008). This conguration is known as separate hydrolysis and fermentation (SHF). When this sequential process is employed, solid fraction of pretreated lignocellulosic material undergoes hydrolysis (saccharication). This fraction contains the cellulose in a form accessible to acids or enzymes. Once hydrolysis is completed, the resulting cellulose hydrolysate is fermented and converted into ethanol. Saccharomyces cerevisiae is the most employed microorganism for fermenting the hydrolysates of lignocellulosic biomass. This yeast ferments the hexoses contained in the hydrolysate but not the pentoses. One of the main features of SHF process is that each step can be performed at its optimal operating conditions (especially temperature and pH). When a technological owsheet involving a SHF process is employed, the detoxied hemicellulose hydrolysate can be unied with the cellulose hydrolysate coming from the enzymatic reactor. To increase the amount of sugars converted into ethanol, yeast assimilating the xylose besides glucose can be employed, but in this case the biomass utilization rates are lower than that of microorganisms that only assimilate hexoses. This is explained by the diauxic growth of this type of yeast. To offset this effect, sequential fermentations are employed and both fermentations are performed independently (co-fermentation) (see Fig. 1). One of the main challenges in pentose fermentation lies in the fact that the productivities of pentose utilizing microorganisms are less than those of hexose-fermenting ones. The co-fermentation of lignocellulosic hydrolysates represents other technological option for utilizing all the sugars released during biomass pretreatment and cellulose hydrolysis. This kind of cultivation process aims at the complete assimilation of all the sugars resulting from lignocellulosic degradation by the microbial cells and consists in the use of a mixture of two or more compatible microorganisms that assimilate both the hexoses and pentoses present in the medium. This means that the fermentation is carried out by a mixed culture. Conversion of cellulose into ethanol can be carried out through SSF (see Fig. 1) as in the case of starch. For this conversion, several enzymes with cellulolytic activity (basically endo-glucanases, cel-

4762

C.A. Cardona et al. / Bioresource Technology 101 (2010) 47544766

Table 3 Sugarcane bagasse hydrolisate fermentation. Previous Pretreatment Acid Hydrolysis With H2SO4 Detoxication method Microorganism Conditions Ethanol yield % (w/w of RSa) Batch fermentation at 34 30 C for 14 h with a pH of 5. Air ow 0.1 vvm. Agitation: 150 rpm. Batch fermentation at 0.03 30 C for 14 h with a pH of 5. Air ow 0.1 vvm. Agitation: 150 rpm. Batch fermentation at 14.11 30 C during 48 h. g/L 19 Table 4. Sugarcane bagasse hydrolisate Cheng et al. (2008) fermentation. Productivity of 0.53 g/ L h. Xylose consumption was total and only 60% of arabinose was assimilated Sugar fermented was only 9% Cheng et al. (2008) Remarks References

Electrodialysis Pachysolen tannophilus DW06

Without detoxication

Pachysolen tannophilus DW06

1.9

Nonrecombinant Saccharomyces cerevisiae Without Nondetoxication recombinant Saccharomyces cerevisiae Ion exchange Candida resin shehatae NCIM 3501 Activated Candida charcoal shehatae NCIM 3501 Enzymes Candida (laccase from shehatae NCIM C. stercoreus) 3501 Acid hydrolysis Overliming Candida with HCl shehatae NCIM 3501 Neutralization Candida shehatae NCIM 3501 Alkaline treatment Without Nonand enzymatic detoxication recombinant saccharication Saccharomyces cerevisiae Without Nondetoxication recombinant Saccharomyces cerevisiae Without Adapted xyloseH2SO4-catalysed steam detoxication utilizing pretreatment recombinant Saccharomyces cerevisiae Without detoxication Non-adapted xylose-utilizing recombinant Saccharomyces cerevisiae

Acid hydrolysis with HCl

Without detoxication

For depithed bagasse

Hernndez-Salas et al. (2009)

Batch fermentation at 15.72 30 C during 48 h.

4.7

For pith bagasse

Hernndez-Salas et al. (2009)

Batch fermentation at 30 C during 24 h and 150 rpm. Batch fermentation at 30 C during 24 h and 150 rpm. Batch fermentation at 30 C during 24 h and 150 rpm. Batch fermentation at 30 C during 24 h and 150 rpm Batch fermentation at 30 C during 24 h and 150 rpm Operation at 30 C during 48 h

48

8.67

Chandel et al. (2007)

42

7.43

Chandel et al. (2007)

37

6.50

Chandel et al. (2007)

30

5.19

Chandel et al. (2007)

22

3.46

Chandel et al. (2007)

32.57

12.5 For depithed bagasse

Hernndez-Salas et al. (2009)

Operation at 30 C during 48 h

25.76

12.9 For pith bagasse

Hernndez-Salas et al. (2009)

Operation at 30 C during 24 h

38

ND

Operation at 30 C during 24 h

18

ND

Pretreatment was followed by enzymatic hydrolysis. Strain was isolated from an adaptation culture with increasing concentrations of inhibitors. Ethanol productivity: 2.55 g/(g h) Pretreatment was followed by enzymatic hydrolysis. Ethanol productivity: 1.15 g/(g h)

Martn et al. (2007b)

Martn et al. (2007b)

RS: Reducing sugars; ND: non-data available.

lobiohydrolases and b-glucosidase) are added to the suspension obtained by mixing water with the solid fraction resulting from the pretreatment step and that contains cellulose and lignin. In the same way, process microorganisms (yeasts) are added to this mixture in the bioreactor where SSF is accomplished for immediately converting the formed glucose into ethanol. The increased ethanol concentration in the culture broth allows the reduction of energy costs during distillation. In addition, SSF offers an easier operation and a lower equipment requirement than the sequential process since no hydrolysis reactors are needed. Nevertheless, SSF has the inconvenient that the optimal conditions for hydrolysis and fermentation are different, which implies a difcult control and optimization of process parameters (Claassen et al., 1999). In addition, larger amounts of exogenous enzymes are required (Cardona and Snchez, 2007).

In the case of lignocellulosic biomass, a very promising integrated conguration for bioethanol production is the inclusion of pentose fermentation in the SSF. This process is known as simultaneous saccharication and co-fermentation (SSCF) (see Fig. 1). This conguration implies a higher degree of intensication through its reactionreaction integration. In this case, the hydrolysis of cellulose, the fermentation of glucose released, and the fermentation of pentoses present in the feed stream is simultaneously accomplished in a same single unit. Besides the effectiveness of employed cellulases, the key factor in SSCF is the utilization of an efcient ethanol-producing microorganism with the ability of assimilating not only hexoses (mainly glucose), but also pentoses (mainly xylose) released during the pretreatment step as a result of the hemicellulose hydrolysis. Therefore, genetically modied microorganisms has been developed and successfully proven in SSCF

C.A. Cardona et al. / Bioresource Technology 101 (2010) 47544766

4763

processes for ethanol production from lignocellulosic materials (Cardona and Snchez, 2007). Recombinant strains of Escherichia coli, Zymomonas mobilis and S. cerevisiae capable of hexose and pentose catabolism and high ethanol production have also been constructed. Their use has made the conversion of lignocellulose to ethanol economically feasible (Mohagheghi et al., 2002; Martn et al., 2002b). 5.2. Production results SCB has proven to be a feasible raw material for fuel ethanol production due its relative low lignin content and high production of sugars by appropriate pretreatments. Some of the more currently advances in fuel ethanol production using bagasse reported alcohol yields up to 48% (% w/w of reducing sugars) (see Table 3). Hernndez-Salas et al. (2009) have pretreated the whole SCB and different fractions of it by dilute acid (HCl) and alkaline pretreatment (NaOH). Selected hydrolysates were fermented with a nonrecombinant strain of S. cerevisiae and maximum alcohol yield by fermentation (32.6%) was obtained from the hydrolysate of sugarcane depithed bagasse. Yields for other fractions are shown in Table 3. By the other side, using Pachysolen tannophilus DW06 for fermenting SCB hydrolysate obtained from acid pretreatment (H2SO4) and detoxied with electrodialysis, it was possible to obtain an ethanol yield of 34% (Cheng et al., 2008). Higher yields were obtained by Chandel et al. (2007) with C. shehatae NCIM 3501 fermenting hydrolysates of SCB obtained with dilute acid (HCl) pretreatment and different detoxication methods: 48% with an industrial ion exchange resin (DIAION HPA 25, Mitsubishi Chemical Corporation, Japan), 42% with activated charcoal and 37% with laccase (from C. stercoreus). Lower ethanol yields were obtained with overliming (30%) and neutralization (22%). 6. Energy cogeneration Energy cogeneration is well established process in sugar industry, due to the high quantity of SCB available, which is composed of 50% bre, 48% moisture and 2% sugars. It is normally burnt to generate steam and electricity to meet the energy requirements of the cane sugar factory. The bagasse has a gross caloric value of 19.25 MJ/kg at zero moisture and 9.95 MJ/kg at 48% moisture. The net caloric value of bagasse at 48% moisture is around 8 MJ/ kg. The fact that the sugar cane plant provides its own source of energy from sugar production in the form of bagasse has long been a special feature of the sugar industry. In the traditional approach, sugar factories co-generate just enough steam and electricity to meet their needs. With the availability of advanced co-generation technologies, sugar factories today can produce surplus electricity for sale to the national grid or directly to other electricity users (Quintero et al., 2008; Ramjeawon, 2008). However, in some countries bagasse is usually burned in low-efciency boilers to avoid the need to handle surplus bagasse, and the cogeneration systems work on back pressure steam turbines (BPST) with low pressure at low-temperature (typically 1.921 MPa, 573 K), the process does not produce energy in an efcient, cost-effective manner (Ramjeawon, 2008). Other potential lignocellulosic by-product from sugar factory are the sugar cane agricultural residues (SCAR), which as a rule, are burned just before the harvest in order to facilitate the easier harvesting of cane stalks. Production of each million ton of raw sugar could mean 50,000 ton of SCAR (that is, SCAR with a moisture content of 30% of sugarcane weight) with a lower heat value (LHV) of 10.5 MJ/kg and a bulk density of 180 kg/m3. This amount of SCAR could be substituted for the same quantity of bagasse, leaving the

surplus bagasse to be converted into another kind of energy carrier, such as ethanol, bio-oil, etc. (Ramjeawon, 2008). Main reason for considering fuel ethanol production from SCB is the social and industrial pressure about nding alternative raw materials and agro-industrial residues like SCB that are offered in high quantities in tropical countries. Table 4 shows an example of revenues (based on range values) that a sugar industry placed in a tropical country like Colombia, could obtain by using SCB for producing either ethanol of electricity. As it can be see revenues obtained from ethanol production are higher than that obtained from electricity cogeneration even at low ethanol prices in the market. However, this alternative is not protable at industrial level for the existing mills, because of the high capital investment needed and the low maturity of this technology. In addition, electricity generated at cogeneration systems is very cheap for the mill and heat energy is used in the whole process. Revenue obtained from electricity cogeneration can be higher in other countries like Brazil due to the lowest production cost (0.001090.00885 US$/ kWh) (Moreira, 2000).

7. Xylanases and cellulases production High cost commercial xylanases and cellulases used in the saccharication step for SCB transformation to ethanol can be produced from the same bagasse. Many microorganisms, including lamentous fungi, yeasts and bacteria, have been cultivated in media containing SCB or its hydrolysate. The use of SCB as low cost raw material for xylanase production by Bacillus circulans D1 in submerged fermentation has been investigated (Bocchini et al., 2005). The microorganism was cultivated in a mineral medium containing hydrolysate of bagasse or grass as carbon source. High production of enzymes was obtained during growth in media with bagasse hydrolysates (8.4 U/mL) and in media with grass hydrolysates (7.5 U/mL). Xylanase production in media with hydrolysates was very close to that obtained in xylan containing media (7.0 U/mL); and this fact conrms the feasibility of fermenting this agro-industrial byproducts by B. circulans D1 as an alternative to save costs on the enzyme production process. The media containing hydrolysates of SCB, with initial sugar concentration from 2.5 to 10.0 g/L, can be employed in place of the control medium, since they afforded xylanase productions equal or higher than that obtained in the medium with xylan. This replacement implies economical advantages for xylanase production process, mainly regarding to the commercial xylan high cost and the availability and low cost of sugarcane (Bocchini et al., 2005). SCB hydrolysates is an efcient alternative to reduce the costs of xylanase production in submerged fermentation, since these materials are often available in tropical countries, as an inexpensive source of components that propitiate the bacterial growth and the enzyme production.

Table 4 Revenue obtained from using 1 ton of sugarcane bagasse for fuel ethanol production or electricity cogeneration in Colombia. Ethanol Yield per ton of SCB Production Cost Selling price* Revenue Revenue per ton of SCB

a b c d e

Units

a

Electricity 200600 0.0280.034c 0.0330.07c,e 0.0010.042 0.225.2

a

Units kWh US$/kWh US$/kWh US$/kWh US$

150236 0.260.33b 0.9300.980d 0.60.720 90170

L US$/L US$/L US$/L US$

Botha and Blottnitz (2006). Luo et al. (2009). Ministry of the Environment (2005). Proexport Colombia (2008). Federacin de Biocombustibles (2009).

4764

C.A. Cardona et al. / Bioresource Technology 101 (2010) 47544766

Other strains like Penicillium janthinellum NCIM 1171 and Trichoderma viride NCIM 1051 have been evaluated in production of cellulase and xylanase enzymes from chemically treated SCB (Adsul et al., 2004). Higher xylanase and b-glucosidase activities were detected in the medium with bagasse as compared to the values obtained with pure cellulose powder. Bagasse treated with NaClO2 during 4 h at 70 C gave high yields of xylanase (130 IU/ml) and b-glucosidase activities (2.3 IU/ml) for both P. janthinellum and T. viride (Adsul et al., 2004). 8. Mathematical modeling The modeling of the hydrolysis of a polysaccharide is very complicate. Multiple factors related to the lignocellulosic material (size, particle shape, structure, accessibility of proton to heterocyclic ether bond, etc.) and to the reaction medium (type of acid, concentration, temperature, time, etc.) affect the hydrolysis. The solution of compromise between the complexity of a rigorous model and the search of equations modeling the empirical data in a simple and satisfactory way have conducted to the general use of pseudohomogeneous, irreversible and rst order kinetics that make easy the calculations without to sacrice the theory basis. The simplied models for the study of the kinetics in hydrolysis process using acids began with the work of Saeman for the hydrolysis of douglas r wood using sulphuric acid (Saeman, 1945). The hydrolysis of cellulose was studied establishing the following model:

Cellulose ! Glucose ! Decomposition products HMF

where, k1 (min1) is the rate for release of glucose from cellulose and k2 (min1) is rate for glucose decomposition. This model considers the hydrolysis of cellulose to release glucose that in severe conditions is decomposed into HMF. Both reactions (release and decomposition) were considered irreversible and rst order. The model of Saeman was also applied to the hydrolysis of the hemicellulosic fraction (Tllez-Luis et al., 2002). The model of Saeman can be applied to other polysaccharides; therefore the model can be generalized for the decomposition of any polymer. The generalized polymer could be cellulose, xylan, araban, etc. Kinetic parameters of the above mentioned models for hydrolysis pretreatment with phosphoric acid (Gmez et al., 2006) and nitric acid (RodriguezChong et al., 2004) has been reported. Other efforts have been made in modeling delignication process of bagasse with formic acid (Tu et al., 2008). 9. Stability of fermentation systems based on SCB In general, more efcient pretreatment technologies, detoxication methods and the construction of microorganism strains capable to ferment lignocellulosic materials have different advances during last years. However, other restrictions of the fermentation processes related to original microorganism have not been passed. One of them is the existence of nonlinear phenomena such as multiplicity and oscillation. The complexity of stability can be increased as a result of the inhibition problems during fermentation when furfural and formic acid from SCB hydrolysis are present in the bioreactor. It is generally considered that the nonlinear phenomena are unfavorable for stable operations in industrial fermentation. The nonlinear analysis of oscillatory fermentations with Z. mobilis indicates that with a change in the parameters, these simple oscillations bifurcate in more complex phenomena such as totally developed chaos (Garhyan and Elnashaie, 2004). Recombinant strains of Z. mobilis are common microorganisms used in SCB transformation to ethanol (Mohagheghi et al.,

k1

k2

2002) and oscillations can be expected as an important issue in the bioreactor design and control. From different studies about behavior of continuous cultures of S. cerevisiae, it has been established that various operation variables inuence the stability of processes with this microorganism. In anaerobic cultures, it was seen that the inhibitory action of ethanol leads to unstable states. Efforts for using yeast strains with the ability to ferment all lignocellulose-derived sugars include the use and modication of S. cerevisiae with high inhibitor tolerance to acetic acid, furfural and formic acid (Hahn-Hgerdal et al., 2007). In the case of SCB hydrolysis, acetic acid is the key inhibitor formed at higher proportion. There is no study in literature about the inuence of this type of inhibitors on stability, but massive production of bioethanol from SCB needs this type of information for process design and performance. If this inhibition is increased by acetic acid during fermentation of sugars from SCB hydrolysis not only ethanol production can be reduced, but also stability characteristics of the process get more complex. For example, addition of acetate (10 g/L) or furfural (2 g/L), in concentrations similar to those found in SCB hydrolysates, decreased cell mass formation and growth rate in almost all strains of industrial S. cerevisiae (GarayArroyo et al., 2004). The wide variability of responses to the different environmental stress conditions tested show that no general rules can be assumed for different S. cerevisiae strains, and that these responses are highly dependent on their genetic and environmental backgrounds. From here stability of the process can be predicted to be complex. Trends in bioethanol production from SCB and other lignocellulosic materials show the high potential of process integration. The development of processes to produce ethanol by coupled saccharication and fermentation of SCB can be analyzed. Here, the acetic acid and furfural removal should be coupled to the entire process (simultaneous sacharication and cofermentation process SSCF) and stability problems derived from the presence of these inhibitors must be accounted. The study of steady states would allow determining the optimal operation conditions of both processes. Until now, there are not reports about stability studies for SCB hydrolysis and fermentation to ethanol. It is an important challenge in the development of technologies for ethanol production from SCB. Moreover, nowadays, due to wide variety of feedstocks, industrial yeast strains are exposed to constant environmental changes including ethanol accumulated along the process, solute concentration, medium ionic strength, and toxins or inhibitory substances that can affect the stability of fermentation (Garay-Arroyo et al., 2004; Zhao and Bai, 2009). Therefore, the design of new processes that involve fermentation processes must be accompanied of a stability study to formulate suitable operation strategies.

10. Perspectives, challenges and conclusions An increased use of biofuels would contribute to sustainable development by reducing greenhouse-gas emissions and the use of non-renewable resources. In recent years it has been suggested that, instead of traditional feedstocks, cellulosic biomass (cellulose and hemicellulose), including SCB could be used as an ideally inexpensive and abundantly available source of sugar for fermentation into transportation fuel ethanol. The efciency of biomass conversion to ethanol depends upon the ability of the microorganism used in the process to utilize these diverse carbon sources and amount of fraction present in biomass. The cost of ethanol production from SCB is relatively high based on current technologies. Pretreatment continues to be the most important step in ethanol production from SCB. It is expected, in the next future, that technologies can impact more easily this step rather than genetic

C.A. Cardona et al. / Bioresource Technology 101 (2010) 47544766

4765

modication to sugarcane strains (with the purpose of reducing lignin in the stalks). This is explained by the fact that the development and transfer of this type of sugarcane strains to the agriculture should take long time. Additionally, sugar factories linked to the sugarcane growing sector (usually owning most of the crops) can choice the status quo instead of investing in new projects. Promising pretreatment methods as organosolv and wet oxidation will be the most studied in the coming years. Cellulose hydrolysis developments are high dependent on the pretreatment method from the point of view of the obtained enzyme accessibility and inhibitors production. New developments are more related to the efcient in situ cellulases production from the SCB to be used in the hydrolysis step. Detoxication developments in the next years will be weak (appointing to integration in one step of different detoxication methods) in contrast to the genetic modications of fermenting microorganisms that can tolerate desired concentrations of inhibitors. Integrated congurations as SSF and SSCF are the top efcient technologies to be analyzed and conrmed at pilot and industrial levels before its wide use in industry. Energy cogeneration as well as xylanases and cellulases production from SCB will stay as a real alternative for adding high value to this residue. At the same way, energy cogeneration for the sugar factory needings and electricity supply to the grid will be always the main barrier to the use of SCB for ethanol production. Other perspective of research and development in ethanol production from SCB is the analysis of the stability in bioreactors in the form of single units as well as integrated congurations. Most of the sugarcane juice and molasses based ethanol production process suffer a lot of problems regarding stability. The existence of new inhibitors in the ethanol process from SCB supposes new stability problems for this technology. So the design and introduction of high scale SCB use for ethanol production in the industry requires serious analysis of this problem. According to the above mentioned perspectives rst main challenge for successful use of SCB as raw material in fuel ethanol production is to reduce hydrolysis costs to make SCB a cheaper substrate like molasses and other directly fermentable materials. Second challenge is process optimization, including detoxication technologies and in situ cellulase enzyme production. Third challenge includes maintaining a stable performance of the genetically engineered microorganisms in commercial scale fermentation operations. The future trends for improving the pretreatment of lignocellulosic feedstocks also include the production of genetically modied plant materials with higher carbohydrate content or modied plant structure to facilitate pretreatment in milder conditions or using hemicellulases. Other challenges are not described in this paper, but the most important concern is how to propose bioethanol production from SCB as a real, economical and environmental alternative to burning or cogeneration in sugar mills. Although bioethanol production has been greatly improved by new technologies, there are still challenges that need further investigations and developing more efcient pretreatment technologies for the lignocellulosic biomass and integrating the optimal components into economic ethanol production systems. Acknowledgements The authors express their acknowledgments to the National University of Colombia at Manizales for funding different research projects in fuel ethanol production and lignocellulosics exploitation. References

Adsul, M.G., Ghule, J.E., Singh, R., Shaikh, H., Bastawde, K.B., Gokhale, D.V., Varma, A.J., 2004. Polysaccharides from bagasse: applications in cellulase and xylanase production. Carbohydr. Polym. 57, 6772.

Ali, M., Mark, R., Daniel, J.S., 2006. Conditioning hemicellulose hydrolysates for fermentation: effects of overliming pH on sugar and ethanol yields. Process Biochem. 41, 18061811. Almazn, O., Gonzlez, L., Glvez, L., 2001. The sugarcane, its byproducts and coproducts. Sugar Cane Int. 7, 38. Bocchini, D.A., Oliveira, O.M.M.F., Gomes, E., Da Silva, R., 2005. Use of sugarcane bagasse and grass hydrolysates as carbon sources for xylanase production by Bacillus circulans D1 in submerged fermentation. Process Biochem. 40, 3653 3659. Botha, T., Blottnitz, H.V., 2006. A comparison of the environmental benets of bagasse-derived electricity and fuel ethanol on a life-cycle basis. Energy Policy 34, 26542661. Boussarsar, H., Rog, B., Mathlouthi, M., 2009. Optimization of sugarcane bagasse conversion by hydrothermal treatment for the recovery of xylose. Bioresour. Technol.. doi:10.1016/j.biortech.2009.07.019. Camassola, M., Dillon, A.J.P., 2009. Biological pretreatment of sugar cane bagasse for the production of cellulases and xylanases by Penicillium echinulatum. Ind. Crops Prod. 29, 642647. Cardona, C.A., Snchez, O.J., 2007. Fuel ethanol production: process design trends and integration opportunities. Bioresour. Technol. 98, 24152457. Carvalheiro, F., Duarte, L.C., Lopes, S., Paraj, J.C., Pereira, H., Grio, F.M., 2005. Evaluation of the detoxication of brewerys spent grain hydrolysate for xylitol production by Debaryomyces hansenii CCMI 941. Process Biochem. 40, 1215 1223. Carvalho, W., Silva, S.S., Converti, A., Vitolo, M., Felipe, M.G.A., Roberto, I.C., Silva, M.B., Manchilha, I.M., 2002. Used of immobilized Candida yeast cells for xylitol production from sugarcane bagasse hydrolysate. Appl. Biochem. Biotechnol. 98100, 489496. Carvalho, W., Santos, J.C., Canilha, L., Silva, S.S., Perego, P., Converti, A., 2005. Xylitol production from sugarcane bagasse hydrolysate: metabolic behaviour of Candida guilliermondii cells entrapped in Ca-alginate. Biochem. Eng. J. 25, 2531. Cerqueira, D.A., Rodrigues, G., Meireles, C.D., 2007. Optimization of sugarcane bagasse cellulose acetylation. Carbohydr. Polym. 69, 579582. Chandel, A.K., Kapoor, R.K., Singh, A., Kuhad, R.C., 2007. Detoxication of sugarcane bagasse hydrolysate improves ethanol production by Candida shehatae NCIM 3501. Bioresour. Technol. 98, 19471950. Cheng, K.K., Cai, B.Y., Zhang, J.A., Ling, H.Z., Zhou, Y.J., Ge, J.P., Xu, J.M., 2008. Sugarcane bagasse hemicellulose hydrolysate for ethanol production by acid recovery process. Biochem. Eng. J. 38, 105109. Claassen, P.A.M., van Lier, J.B., Lpez Contreras, A.M., van Niel, E.W.J., Sijtsma, L., Stams, A.J.M., de Vries, S.S., Weusthuis, R.A., 1999. Utilisation of biomass for the supply of energy carriers. Appl. Microbiol. Biotechnol. 52, 741755. Federacin de Biocombustibles, 2009. Current Price of Fuel Ethanol. Available on: <www.fedebiocombustibles.com/>. Gmez, S., Ramrez, J.A., Garrote, G., Vzquez, M., 2004. Manufacture of fermentable sugar solutions from sugar cane bagasse hydrolyzed with phosphoric acid at atmospheric pressure. J. Agric. Food Chem. 52, 41724177. Gmez, S., Gonzlez-Cabriales, J.J., Ramrez, J.A., Garrote, G., Vzquez, M., 2006. Study of the hydrolysis of sugar cane bagasse using phosphoric acid. J. Food Eng. 74, 7888. Garay-Arroyo, A., Covarrubias, A.A., Clark, I., Nio, I., Gosset, G., Martnez, A., 2004. Response to different environmental stress conditions of industrial and laboratory Saccharomyces cerevisiae strains. Appl. Microbiol. Biotechnol. 63, 734741. Garhyan, P., Elnashaie, S., 2004. Static/dynamic bifurcation and chaotic behavior of an ethanol fermentor. Ind. Eng. Chem. Res. 43, 12601273. Goh, C.S., Tan, K.T., Lee, K.T., Bhatia, S., 2009. Bio-ethanol from lignocellulose: status, perspectives and challenges in Malaysia. Bioresour. Technol.. doi:10.1016/ j.biortech.2009.08.080. Guo, G.L., Hsu, D.C., Chen, W.H., Chen, W.H., Hwang, W.S., 2009. Characterization of enzymatic saccharication for acid-pretreated lignocellulosic materials with different lignin composition. Enzyme Microb. Technol. 45, 8087. Hahn-Hgerdal, B., Karhumaa, K., Fonseca, C., Spencer-Martins, I., Gorwa-Grauslund, M.F., 2007. Towards industrial pentose-fermenting yeast strains. Appl. Microbiol. Biotechnol. 74, 937953. Hernndez-Salas, J.M., Villa-Ramrez, M.S., Veloz-Rendn, J.S., Rivera-Hernndez, K.N., Gonzlez-Csar, R.A., Plascencia-Espinosa, M.A., Trejo-Estrada, S.R., 2009. Comparative hydrolysis and fermentation of sugarcane and agave bagasse. Bioresour. Technol. 100, 12381245. Itoh, H., Wada, M., Honda, Y., Kuwahara, M., Watanabe, T., 2003. Bioorganosolve pretreatment for simultaneous saccharication and fermentation of beech wood by ethanolysis and white rot fungi. J. Biotechnol. 103, 273280. Keikhhosro, K., Giti, E., Mohammad, J.T., 2006. Production of ethanol and mycelial biomass from rice straw hemicellulose hydrolyzate by Mucor indicus. Process Biochem. 41, 653658. Keller, F.A., Hamilton, J.E., Nguyen, Q.A., 2003. Microbial pretreatment of biomass. Appl. Biochem. Biotechnol. 105108, 2741. Kirk, T.K., Schultz, E., Connors, W.J., Lorenz, L.F., Zeikus, J.G., 1978. Inuence of culture parameters on linin metabolism by Phanerochaete chysosporium. Arch. Microbiol. 117, 277285. Klinke, H.B., Ahring, B.K., Schmidt, A.S., Thomsen, A.B., 2002. Characterization of degradation products from alkaline wet oxidation of wheat straw. Bioresour. Technol. 82, 1526. Kuo, C.H., Lee, C.K., 2009. Enhanced enzymatic hydrolysis of sugarcane bagasse by N-methylmorpholine-N-oxide pretreatment. Bioresour. Technol. 100, 866 871.

4766