Organogram of LNT

Diunggah oleh

Siddhartha BoraDeskripsi Asli:

Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Organogram of LNT

Diunggah oleh

Siddhartha BoraHak Cipta:

Format Tersedia

Introduction

L&T Larsen & Toubro Limited, or L&T, is an Indian multinational with business interests in engineering, construction, manufacturing, IT and financial services. It is headquartered at Mumbai. With an annual turnover of $14 billion, it stands out as one of the leading Indian engineering organization.

L&T Heavy Engineering L&T's Heavy Engineering division manufactures and supplies custom designed and engineered critical equipment and systems to the core-sector industries and the defence sector. It is one of the most important divisions of L&T. Through its quality products and flawless designs , it has become the preferred supplier of equipment for customers in India and abroad. Its state-of-the art manufacturing facilities, capable of meeting the challenges of technology, quality conformance requirements and timely delivery ensures its cost competitiveness, giving it an edge over its competitors. Some of its production units include Powai Works (Mumbai), Hazira Works (Gujarat), Coimbatore Works, Ranoli Works, Strategic Systems Complex, Talegaon and Sohar, Oman. L&T Heavy Engineering, Hazira Manufacturing Complex L&T Hazira Manufacturing Complex (HZMC) near Surat, Gujarat is one of the largest production facility of L&T . Production commenced at this complex in November 1987. It is now emerging as major growth centre with production facilities for heavy engineering, oil & gas equipments and ship building facilities. In addition to it, power plant equipments, forging unit, power plant auxiliaries are present here. HZMC manufactures extremely diverse range of products, designs equipments and processes and manufactures hi-tech fabricated equipment for core sectors and process industries. It serves a wide range of customers in India and abroad. L&T Heavy Engineering, HZMC is responsible for manufacturing high end products like end shields for nuclear reactors, steam generators etc.

Inception and Growth L&T was founded in 1938 by two Danish engineers, Henning Holck-Larsen and Soren Kristian Toubro. Based in Mumbai, they started with supplying dairy equipments imported from Denmark. Due to wartime constraints, they started manufacturing dairy equipment indigenously. These products were a success, and L&T got recognition as a reliable fabricator with high standards. They also made forays into the business of repair and refit of ships by forming a new company, Hilda Ltd. They also started two repair and fabrication shops. In 1944, ECC was incorporated. By then, they started much collaboration with foreign manufacturers. In 1945, L&T signed an agreement with Caterpillar, USA, for marketing earthmovers. They raised additional equity capital, and Larsen & Toubro Private Limited came into being on 7th February 1946. In

December 1950, L&T became a Public Company with a paid-up capital of Rs.2 million. Two of the important projects undertaken by L&T were the Amul Dairy at Anand and Blast Furnaces at Rourkela Steel Plant. By 1964, L&T had adapted its capabilities to update some of the best technologies. They grew rapidly in the ensuing decade, and by 1973 became one of the top Indian companies. Mission L&T has a unique mission. Through its mission statement, it articulates its desire to be a professionally maintained Indian multinational, committed to total customer satisfaction and and enhancing shareholder value. L&Tites shall be an innovative, entrepreneurial and empowered team constantly creating value and attaining global benchmarks. L&T shall foster a culture of caring, trust and continuous learning while meeting the expectations of the employees stakeholders, and society. The L&T vision reflects the collective goal of the company. It was drafted through a large scale interactive process which engaged employees at every level, worldwide. The mission statement reflects L&Ts desire to become a learning organization and achieve high goals. The mission statement of L&T Heavy Engineering Division states that L&T will strive to become the worlds best organization in engineering, manufacture and integration of custom-built, technologyintensive equipment and systems, creating significant value for customers, stakeholders and society. Contextual Dimensions Size L&T Heavy Engineering Division Hazira Manufacturing Complex is an ASME approved workshop with N and NPT stamps. The site spreads across an area of 900,000 with a shop area of 70,000 . It ranks as the largest heavy engineering manufacturing facility in India. It has a large equipment manufacturing facility with an area of 200,000 . It has an employee strength of 1450 at Hazira.

Technology The technology in L&T Heavy Engineering is non-routine. It manufactures custom designed equipments specific to the requirements of its customers. L&T Heavy Engineering operates at the upper end of the technology spectrum. For over six decades, it has become a leader in introducing new processes, products and materials into manufacturing sector. In different spheres of L&T's operations, technology is the key enabling agent, strengthening its leadership position, and sustaining its competitive edge over competitors. With it's strong engineering capabilities and state-of-the-art manufacturing facilities, L&T's Heavy Engineering has established a strong reputation in global markets for quality products and designs. It manufactures and supplies precision, custom-designed and engineered critical equipment and systems to the core sector industries. These industries include oil and gas, refinery, cracker, petrochemicals, fertilizer, chemicals, thermal and nuclear power, aerospace, and systems and equipment for defense applications.

Heavy Engineering has pioneered the manufacturing technology, which has been achieved through indigenous technology development. Through its quality products and innovative designs, L&T's Heavy Engineering has established a reputation in the global market . In India, it is by far the most preferred supplier of almost all the core industries. It is the most important manufacturer and supplier of custom designed and engineered critical equipment and systems to the core-sector industries and also the defence sector. Globally, it remains the preferred supplier of equipment for a portfolio of products. With its state-of-the art manufacturing facilities, capable of meeting the challenges of technology, quality conformance and delivery, L&T has ensured cost competitiveness of its products. Its manufacturing plants are among the finest in the world, with processes streamlined to achieve high efficiency and benchmarked to the latest cutting-edge technologies. The technological achievement of L&T got its ultimate recognition when it was awarded the contract for the manufacturing of the 3800 ton ITER Cryostat for the International Thermonuclear Experimental Reactor ITER). The ITER cryostat will become the largest high-vacuum pressure chamber ever built. The cryostat forms the vacuum-tight container surrounding the ITER vacuum vessel and the superconducting magnets and acts essentially as a very large refrigerator. Mr. M.V. Kotwal, member of L&T Board and president of L&T Heavy Engineering, stated: "L&T is proud to be part of this mammoth global collaborative research to build a greener planet. Environment L&T is a multinational organization with operations in many countries in the world. Through its upper high end heavy engineering products, it has already created many loyal customers for whom it has become the go to man. In India, it remains the leading vendor to most of the core industries. The infrastructure spending by government and corporate expansion plans will continue to drive L&T Heavy Engineering divisions business. In spite of stiff competition from new entrants like ABB, Alstom etc, L&T Heavy Engineering still have an edge due to its ability to execute complex projects and increased operational efficiency. However, the key concern is the slowdown in infrastructure spending by governments and reduction in capital expenditure plans of companies across the world. Sharp increase in the prices of key raw materials such as steel, bitumen remains another bottleneck. Also, delay in realization of payments is a threat to the working capital position. The divisions order book is well diversified with projects ranging f rom complex nuclear boilers to procurement and commissioning activities. The orders are also diversifies across industries like power, oil and gas, defence etc. A well diversified order book ensures that slowdown in one sector does not affect the companys performance. Also, its geographical spread gives it a cushion against unforeseen risks like political turmoil in a country. Thus, an well diversified order book and the geographical spread de-risks the division from sudden shocks. The increase in spending by the Govt. of India through the PPP route is a positive sign for L&T Heavy Engineering. L&T Heavy engineering is going to play a leading role in the 12th plan projects. Moreover, the prospect of further opening the defence sector to private players presents a huge opportunity to L&T Heavy Engineering.

In light of the above discussion, it can be said that L&T Heavy Engineering faces a stable business environment in near future. However, it must strive to maintain its leading position, especially to contain the threats posed by competitors like ABB etc. Also, there may be sudden slump in some sectors like the nuclear power sector where a sudden accident may lead to the cancellation of all the orders. In case of Hazira, the threat to nuclear power is very significant as several projects related to nuclear power is going on there. Culture It features in the fifth position in the list of Ten Best Places to Work At survey conducted by Business Today for the year 2013. The top four being software giants, it is the only top company involved in heavy engineering that stands out in the survey. L&T acknowledges that People are the most valuable resource and key differentiator in realizing their vision. The corporate culture at L&T offers the employees them freedom at work place, opportunities to learn and grow as an individual as well as a professional. L&T also believes that providing the employees with challenging assignments is important to bring about a sense of professional fulfilment in them. The company also encourages employees to develop entrepreneurial skills, thereby, enabling and empowering them to take measured risks. Employee participation is promoted by inviting suggestions for improvements, opinions about the projects and open houses that discuss any key issue. One of the key competencies of L&T is the highly skilled technical in its ranks. All positions in L&T Heavy Engineering are staffed by highly skilled engineers and technicians. To ensure that the workforce adheres to the precise requirements of all sectors, continuous specially structured training programmes are conducted throughout the year. Competitive remuneration guarantees that the attrition rate is very low. Also, the employees take pride to be a part of an organization as diverse as L&T. L&T employees treat their colleagues with dignity and respect, irrespective of diversity. Employees are encouraged to express their views without fear. They engage in social work for the development of the community and other humanitarian causes. There is a large number of women working in a genderfriendly environment. At L&T Heavy Engineering, Hazira, the work culture of the parent company is closely emulated. The core values mentioned above are evident from the experiences of employees who work there.

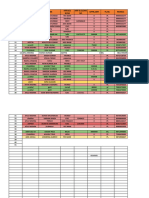

Executive Chairman

CEO & Managing Director

Chief Financial Officer

PresidentMachinery & Industrial Products

President-Electrical Business Group

President-ECC (Infrastructure & Construction)

President- Heavy Engineering Division

PresidentHydrocarbon & Power

President-Infotech

Sr. EVP- Corporate HR

EVP- Process Plant & Nuclear

EVP-Defence & Aerospace (Further structure not disclosed due to strategic reasons)

Executive Assistant

Personal Assistant

Powai-Hazira Coordination Cell

VP-Powai

VP-Hazira

GM-Marketing & PMG

GM- QA, QC & NDE

GM-Manufacturing

Head-EHS & Team of 10

Head- HR-IR-TQM Team of 25

Head- Finance & Accounts Team of 30

Head- IT & Team of 15

DGM-Marketing Team of 10

DGM- QA Team of 10

DGM-Welding Engineering Team of 20

DGM-Production Engineering Team of 10

DGM-Planning Team of 20

DGM-Fabrication Shop Cluster-1 Team of 350

DGM- Fabrication Shop Cluster-2 (Team of 260)

DGM-Fabrication Shop Cluster-3 Team of 400

DGM-Machine Shop Team of 80

DGM-Maintenance Team of 80

DGM-Logistics Team of 5

DGM PMG Team of 20

DGM-QC Team of 40

Shop Incharge-1

Shop Incharge-2

Shop Incharge-3

Shop Incharge-4

DGM-TOC Cell Team of 10

DGM-NDE Team of 30

Shop Co-ordinator

DGM-Purchase Team of 20

Supervisor Shift-1

Supervisor Shift-2

Supervisor Shift-3

Shift Workers (20 nos,)

Shift Workers (20nos.)

Shift Workers (20nos.)

Parts of the Organization

L&Ts Heavy Engineering Divisions facilities at Hazira has allthe elements of the five different parts that an organization can have as per Mintzberg. 1. Strategic Apex: The strategic apex consists of all the managers at the level of VicePresident and above who partake in all the strategic divisions of the organization. 2. Technostructure: It consists of various departments that help in standardization of various processes like the Theory of Constraints (TOC) Cell, Production Engineering, Quality Assurance (QA), Total Quality Management (TQM) and Welding Engineering Departments. 3. Support Staff: These organizations provide support to the organization outside the operating workflow like the Finance & Accounts (F&A), Human Resources (HR), Industrial Relations (IR), Environment, Health & Safety (EHS) and Information Technology (IT) departments. 4. Operating Core: The operating core consists of all workers, supervisors, machine operators, purchase and logistics staff that are part of the main operating workflow that make the actual product. 5. Middle Line: All other deparments and personnel form part of the middle line like the Marketing, Project Management Group (PMG), Planning and Quality Control (QC) departments etc.

Structural Dimensions

1. How are the kind of works taken up by Powai & Hazira differentiated between? The Manufacturing facilities of L&T- HED are spatially differentiated. As the manufacturing facilities in Powai is land-locked within the metropolis of Mumbai, it only takes up manufacturing of heavy equipments that are small and medium in size (upto 400 metric tonnes) that can be transported through the roads in Mumbai to the required port or inland destination. On the other hand, Hazira being strategically located along the Tapi riverfront has access to waterways through which large equipments up to 1500 metric tonnes can be manufactured and transported through ports around the world. Thus both locations have their own independent organizational setups which closely interact with one another and can shift manufacturing of complete equipments depending on their needs after decision is taken through the co-ordination cell at the Vice-President level. 2. What is the degree of formalization at various levels of the organization at L&T HED-Hazira? As the organization is in the business of manufacturing custom-built, technology intensive equipments and systems, the level of formalization is high across the organization. Although the organization relies on direct supervision over the workers and mutual adjustment at the

worker level, they perform within the boundaries of worker rule book and Hazira specific manufacturing standards. At the division level, the organization adheres to various international standards like ASME, ISO-9001 (Quality Standard), ISO-14001 (Environmental Standard), OHSAS-18001 (Health & Safety Standard) as a result of which the organization has its own written down quality, environment, health and safety policy manuals that is disseminated to each employee throughout the organization. It works according to the ASME standards at all stages of manufacturing (from procurement of raw materials to final dispatch of equipment) that requires for maintaining written down procedures and protocols to achieve the quality parameters. 3. What is the degree of specialization and professionalism at various levels of the organization at L&T HED-Hazira? The degree of specialization decreases as we move up in the organization. Specialization is extensive both horizontally and vertically at the worker level as they perform only a fixed range of tasks of either welding or fitting. As we move above the worker level, the range of task increases from technical to co-ordination to administrative tasks. This also happens across the various departments of the organization which have their own range of tasks. The level of professionalism increases as we move up in the hierarchy of the organization which stars from 11-13years of education at supervisor level to 16-18 years of education plus years of experience at higher levels of the organization. 4. How are decisions taken at various levels of the sorganization, i.e. what is the mode of centralization and hierarchy of authority in the organization. The hierarchy of authority in the organization as represented in the organogram shows the span of control at various levels of the organization. The organization follows a model of selective horizontal and vertical decentralization in which both formal and informal power is diffused in the organization to work constellations at various levels consisting of crossfunctional teams across departments containing various mixtures of line managers, staff and operating specialists. For example, right from the bidding of a manufacturing contract for equipment to its final dispatch, a cross-functional team of Marketing, PMG (project management group), Planning, Quality Control, Welding Engineering and Production Engineering is constituted at the manager level (below Deputy General Managers DGMs) to carry out the project and has the decision making authority with respect to all the aspects of the concerned project. A project later on involves the lower hierarchies of each department along with the shop floor professionals to execute the project. 5. How is co-ordination achieved across various departments of the organization?

Within the departments, co-ordination is achieved through standardization of inputs through selection of qualified personnel at all levels. Co-ordination between departments is achieved through mutual adjustments at upper levels of hierarchy and through standardization of processes at lower levels by various software modules for Enterprise Resource planning (ERP) like BaaN, SAP and Product Lifecycle Management (PLM). At the Strategic Business Unit (SBU) and division level, standardization of outputs through performance control is followed like for example, the sales growth achieved by a SBU r division in a given quarter or year is compared vis a vis other units/ divisions.

Anda mungkin juga menyukai

- Divya Dissertation MainDokumen25 halamanDivya Dissertation Mainnaga sai sridivya amirapuBelum ada peringkat

- HRD at JSWDokumen128 halamanHRD at JSWchanDRASUNILBLYBelum ada peringkat

- HR Policies in LANCODokumen50 halamanHR Policies in LANCOSureshJaiswalBelum ada peringkat

- Job Analysis L&TDokumen72 halamanJob Analysis L&TChandan SrivastavaBelum ada peringkat

- Project Management - L&D - Sep 2018Dokumen26 halamanProject Management - L&D - Sep 2018Hem NarayanBelum ada peringkat

- Sap HRMSDokumen35 halamanSap HRMSKing KhanBelum ada peringkat

- AFCONS Insight July 2014Dokumen8 halamanAFCONS Insight July 2014Anonymous i3lI9MBelum ada peringkat

- Infosys Peer Review at Board LevelDokumen6 halamanInfosys Peer Review at Board LevelVishal SainiBelum ada peringkat

- JSW Steel LimitedDokumen72 halamanJSW Steel LimitedShashi BhagnariBelum ada peringkat

- Airtel - A Case StudyDokumen12 halamanAirtel - A Case StudyGirjesh ChohanBelum ada peringkat

- Cricket Rules EnglishDokumen65 halamanCricket Rules EnglishmalgariBelum ada peringkat

- HRMS FileDokumen17 halamanHRMS FileRadhika ChhabraBelum ada peringkat

- Trident Campus Mba PresentationDokumen36 halamanTrident Campus Mba PresentationArpita MukherjeeBelum ada peringkat

- Performance Appraisal CycleDokumen11 halamanPerformance Appraisal CycleMunroe BuckBelum ada peringkat

- Competency Map at Land TDokumen4 halamanCompetency Map at Land TStany D'melloBelum ada peringkat

- On BHEL and Its Organisation StructureDokumen17 halamanOn BHEL and Its Organisation StructureAnkit Mehta0% (1)

- Manpower Planning PPT at L&TDokumen29 halamanManpower Planning PPT at L&TShrihari Samla0% (1)

- Arushi VijayvargiaDokumen33 halamanArushi VijayvargiaRahul PatelBelum ada peringkat

- Competency Mapping TelcoDokumen64 halamanCompetency Mapping TelcoRaghu CkBelum ada peringkat

- NTPCDokumen19 halamanNTPCShail SinghBelum ada peringkat

- HR ListDokumen153 halamanHR ListSohan Sikarwar100% (2)

- Training and Development at LancoDokumen33 halamanTraining and Development at Lancoriddhi tulshianBelum ada peringkat

- Aditi Wahi ResumeDokumen2 halamanAditi Wahi ResumejaimatasheraBelum ada peringkat

- Mahindra & Mahindra: Talent Acquisition Career PlanningDokumen3 halamanMahindra & Mahindra: Talent Acquisition Career PlanningEsha PandeyBelum ada peringkat

- UH MBA Degree PlanDokumen6 halamanUH MBA Degree PlanCaesar ZTinuBelum ada peringkat

- Talent Management in Manufacturing Industry 1Dokumen22 halamanTalent Management in Manufacturing Industry 1Durgadevi BBelum ada peringkat

- Organizational Structure: This Study Resource WasDokumen5 halamanOrganizational Structure: This Study Resource Wasyogica3537Belum ada peringkat

- Cil HR Vision (Final)Dokumen45 halamanCil HR Vision (Final)Navin ShuklaBelum ada peringkat

- Introduction of OngcDokumen11 halamanIntroduction of OngcPIYUSH RAWAT100% (2)

- HRMProject Group7 SecADokumen20 halamanHRMProject Group7 SecAprerana jainBelum ada peringkat

- Steel Authority of India Limited Performance AppraisalDokumen36 halamanSteel Authority of India Limited Performance AppraisalShveta Kaushal100% (1)

- NTPCDokumen35 halamanNTPCGaurav Singh100% (1)

- HR Practices at Reliance Broadcast.Dokumen51 halamanHR Practices at Reliance Broadcast.Nehal KapadiaBelum ada peringkat

- HR EssentialsDokumen7 halamanHR EssentialsAman BansalBelum ada peringkat

- GE - 2decades of Transformation - Rollno 21Dokumen3 halamanGE - 2decades of Transformation - Rollno 21aruntce_kumar9286Belum ada peringkat

- Project Report Titles For MBA in Production ManagementDokumen5 halamanProject Report Titles For MBA in Production Managementebrandingindia1Belum ada peringkat

- Amdocs PMSDokumen9 halamanAmdocs PMSsandeep_leo088714Belum ada peringkat

- Apoorwa Dutt DelhiDokumen5 halamanApoorwa Dutt DelhiAnju KhasyapBelum ada peringkat

- Davangere University: Master of Business AdministrationDokumen45 halamanDavangere University: Master of Business AdministrationShilpaBelum ada peringkat

- Matrix Structure (Organizational Chart) - CreatelyDokumen3 halamanMatrix Structure (Organizational Chart) - CreatelyCielo VegaBelum ada peringkat

- NCC - Corp - Brochure PDFDokumen28 halamanNCC - Corp - Brochure PDFTlvs MurthyBelum ada peringkat

- Performance Management System (NTPC, Shaktinagar, Singrauli)Dokumen30 halamanPerformance Management System (NTPC, Shaktinagar, Singrauli)Aliya SizraBelum ada peringkat

- Job Descriptions White PaperDokumen11 halamanJob Descriptions White PaperashrafaliomarBelum ada peringkat

- BLDPA-Journal - 22 03 2017Dokumen68 halamanBLDPA-Journal - 22 03 2017AppSecurityBelum ada peringkat

- Resume JP Gupta ResumeDokumen2 halamanResume JP Gupta ResumeJPGUPTA47Belum ada peringkat

- Study On Methods of Performance ApprisalDokumen49 halamanStudy On Methods of Performance ApprisalSiddharth Gupta100% (1)

- PQ 318 Pillar 01 Pre Seen Case Study - With QuestionsDokumen5 halamanPQ 318 Pillar 01 Pre Seen Case Study - With QuestionsRomali KeerthisingheBelum ada peringkat

- HR Strategy 12Dokumen105 halamanHR Strategy 12renu09guptaBelum ada peringkat

- University Campus Relations LinkedInDokumen9 halamanUniversity Campus Relations LinkedIngp.mishraBelum ada peringkat

- In HC Deloitte India Annual Compensation Trends Survey Report Fy 2016 Noexp PDFDokumen24 halamanIn HC Deloitte India Annual Compensation Trends Survey Report Fy 2016 Noexp PDFRekha AranhaBelum ada peringkat

- Darwin BoxDokumen2 halamanDarwin Boxkarunabhavani 373Belum ada peringkat

- NHRD JournalDokumen136 halamanNHRD JournalPiyusha Sunil AmreBelum ada peringkat

- HR Final ProjectDokumen12 halamanHR Final ProjectGhazi ButtBelum ada peringkat

- EHS Code of Practice - Trainee's SafetyDokumen3 halamanEHS Code of Practice - Trainee's SafetyHolly SmithBelum ada peringkat

- Bharat Heavy Electrical LimitedDokumen27 halamanBharat Heavy Electrical LimitedSoniya Omir VijanBelum ada peringkat

- Senior HR Professional Certified SAP HCM Professional: Tuhin Kumar TahDokumen4 halamanSenior HR Professional Certified SAP HCM Professional: Tuhin Kumar TahAnil SharmaBelum ada peringkat

- Company Profile 2010@ Larsen and ToubroDokumen17 halamanCompany Profile 2010@ Larsen and ToubroAnkur Dubey100% (1)

- L&TDokumen36 halamanL&Takhilesh1818Belum ada peringkat

- Sustanable Environment Management Project: Submitted To: Submitted By: Jitendra SainiDokumen11 halamanSustanable Environment Management Project: Submitted To: Submitted By: Jitendra SainiJiten SainiBelum ada peringkat

- Strategic Project On L&TDokumen28 halamanStrategic Project On L&T21E4114 Nithyashree IBelum ada peringkat

- Assignment 2Dokumen5 halamanAssignment 2Siddhartha BoraBelum ada peringkat

- Community Radio and CSRDokumen1 halamanCommunity Radio and CSRSiddhartha BoraBelum ada peringkat

- Experimental Learning Exercise-01Dokumen7 halamanExperimental Learning Exercise-01Siddhartha Bora100% (2)

- The Appraisal ApprehensionDokumen3 halamanThe Appraisal ApprehensionSiddhartha BoraBelum ada peringkat

- Critically Endangered Species BrochureDokumen8 halamanCritically Endangered Species BrochureSiddhartha BoraBelum ada peringkat

- Llanos de Juna Resort Project Feasibility Study (BSA-5A) 2014-2015Dokumen208 halamanLlanos de Juna Resort Project Feasibility Study (BSA-5A) 2014-2015snsdean100% (1)

- Ranchi Women's CollegeDokumen5 halamanRanchi Women's Collegevarsha kumariBelum ada peringkat

- HDFC and Sbi ReportDokumen45 halamanHDFC and Sbi ReportÂShu KaLràBelum ada peringkat

- Business PlanDokumen5 halamanBusiness PlanSEGA CYBERBelum ada peringkat

- GE-International Journal of Management Research: © Associated Asia Research Foundation (AARF)Dokumen12 halamanGE-International Journal of Management Research: © Associated Asia Research Foundation (AARF)Prasanth KumarBelum ada peringkat

- Maximo Change Management Quick Reference Guide v1.0Dokumen5 halamanMaximo Change Management Quick Reference Guide v1.0ajayc50Belum ada peringkat

- IOSA Program Manual (IPM) Edition 14Dokumen151 halamanIOSA Program Manual (IPM) Edition 14Eurico RodriguesBelum ada peringkat

- A Study On Consumer Behaviour About Remanufactured Electronic Gadgets in Indian MarketDokumen10 halamanA Study On Consumer Behaviour About Remanufactured Electronic Gadgets in Indian MarketarcherselevatorsBelum ada peringkat

- Amritsar To Kolkata Z1JZ4: Air India AI-480Dokumen3 halamanAmritsar To Kolkata Z1JZ4: Air India AI-480Rakesh DebnathBelum ada peringkat

- AWS High Performance ComputingDokumen47 halamanAWS High Performance ComputingNineToNine Goregaon East MumbaiBelum ada peringkat

- What Is A Job Safety AnalysisDokumen2 halamanWhat Is A Job Safety AnalysisAnonymous LFgO4WbIDBelum ada peringkat

- BOK-Checklist of Tools, Equipment, Supplies and Materials, and FacilitiesDokumen2 halamanBOK-Checklist of Tools, Equipment, Supplies and Materials, and FacilitiesMark MarasiganBelum ada peringkat

- 100 Best Business BooksDokumen8 halaman100 Best Business BooksGiang Huong VuBelum ada peringkat

- Btled He Final ExamDokumen8 halamanBtled He Final ExamVignette San AgustinBelum ada peringkat

- Economies of ScaleDokumen15 halamanEconomies of ScaleChandrasekhar BandaBelum ada peringkat

- TT BookDokumen869 halamanTT BookGert VeljoenBelum ada peringkat

- 2017/eur/pdf/DEVNET 2023 PDFDokumen45 halaman2017/eur/pdf/DEVNET 2023 PDFSayaOtanashiBelum ada peringkat

- Dutch Lady Milk Industries Berhad-2Dokumen16 halamanDutch Lady Milk Industries Berhad-2Navinya Gopala Krishnan100% (2)

- May 22Dokumen2 halamanMay 22digiloansBelum ada peringkat

- Sources of Exchange-Rate Volatility: Impulses or Propagation?Dokumen14 halamanSources of Exchange-Rate Volatility: Impulses or Propagation?Anonymous xjWuFPN3iBelum ada peringkat

- Tata Docomo PPT IMC ToolsDokumen65 halamanTata Docomo PPT IMC Toolsbandhhath100% (1)

- 10 - Pdfsam - AEDITED AC3059 2013&2014 All Topics Exam Solutions Part IDokumen10 halaman10 - Pdfsam - AEDITED AC3059 2013&2014 All Topics Exam Solutions Part IEmily TanBelum ada peringkat

- SAP FI OverviewDokumen118 halamanSAP FI OverviewMian IrfanBelum ada peringkat

- A Brief History of Wal-MartDokumen8 halamanA Brief History of Wal-MartLeena PalavBelum ada peringkat

- 04 - Invesco European Bond FundDokumen2 halaman04 - Invesco European Bond FundRoberto PerezBelum ada peringkat

- Conversation QuestionsDokumen4 halamanConversation QuestionsAlidem AlvarezBelum ada peringkat

- GreenpeaceDokumen6 halamanGreenpeacePankaj KolteBelum ada peringkat

- NEW TRC Volunteer Application FormDokumen4 halamanNEW TRC Volunteer Application FormMark J ThompsonBelum ada peringkat

- HBC 2103 Mathematics For BusinessDokumen4 halamanHBC 2103 Mathematics For BusinessJohn MbugiBelum ada peringkat

- Project Management Professional (PMP) Training &NEWDokumen792 halamanProject Management Professional (PMP) Training &NEWAmer Rahmah100% (7)