Ceramic Waste

Diunggah oleh

Shahab SadqpurDeskripsi Asli:

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Ceramic Waste

Diunggah oleh

Shahab SadqpurHak Cipta:

Format Tersedia

International Journal of Engineering Trends and Technology (IJETT) - Volume4 Issue6- June 2013

Ceramic Waste : Effective Replacement Of Cement For Establishing Sustainable Concrete

Amitkumar D. Raval1, Dr.Indrajit N. Patel2, Prof. Jayeshkumar Pitroda3

Student of final year M.E. C E & M, B.V.M. Engineering college, Vallabh Vidyanagar 2 Applied Mechenics Department, BBIT, Vallabh Vidyanagar-Gujarat-India 3 Assistant Professor& Research Scholar, Civil Engg Department, B.V.M. Engineering College, Vallabh Vidyanagar-Gujarat-India

1

Abstract Ceramic waste is one of the most active research areas that encompass a number of disciplines including civil engineering and construction materials. Ceramic waste powder is settled by sedimentation and then dumped away which results in environmental pollution, in addition to forming dust in summer and threatening both agriculture and public health. Therefore, utilization of the ceramic waste powder in various industrial sectors especially the construction, agriculture, glass and paper industries would help to protect the environment. It is most essential to develop eco-friendly concrete from ceramic waste. In this research study the (OPC) cement has been replaced by ceramic waste powder accordingly in the range of 0%, 10%, 20%, 30% 40%, & 50% by weight of M-20 grade concrete. Concrete mixtures were produced, tested and compared in terms of compressive strength to the conventional concrete. These tests were carried out to evaluate the mechanical properties for 7, 14 and 28 days. As a result, the compressive strength achieved up to 30% replacing cement with ceramic waste.This research work is concerned with the experimental investigation on strength of concrete and optimum percentage of the partial replacement by replacing cement via 0%, 10%, 20%, 30%, 40% and 50% of ceramic waste. Keeping all this view, the aim of the investigation is to study the behavior of concrete while replacing theceramic waste with different proportions in concrete. KeywordsCeramic Waste, Compressive Strength, Eco-Friendly, Industrial Waste, Low Cost, OPC Cement, Sustainable I INTRODUCTION

notified areas have been marked for dumping. This leads to serious environmental and dust pollution and occupation of a vast area of land, especially after the powder dries up so it is necessary to dispose the Ceramic waste quickly and use in the construction industry.As the ceramic waste is piling up every day, there is a pressure on ceramic industries to find a solution for its disposal. The advancement of concrete technology can reduce the consumption of natural resources. They have forced to focus on recovery, reuse of natural resources and find other alternatives. The use of the replacement materials offer cost reduction, energy savings, arguably superior products, and fewer hazards in the environment.

II EXPERIMENTAL MATERIALS A. Materials a) Ceramic waste The principle waste coming into the ceramic industry is the ceramic powder, specifically in the powder forms. Ceramic wastes are generated as a waste during the process of dressing and polishing. It is estimated that 15 to 30% waste are produced of total raw material used, and although a portion of this waste may be utilized on-site, such as for excavation pit refill, The disposals of these waste materials acquire large land areas and remain scattered all around, spoiling the aesthetic of the entire region. It is very difficult to find a use of ceramic waste produced. Ceramic waste can be used in concrete to improve its strength and other durability factors. Ceramic waste can be used as a partial replacement of cement or as a partial replacement of fine aggregate sand as a supplementary addition to achieve different properties of concrete.

Indian ceramic production is 100 Million ton per year. In the ceramic industry, about 15%30% waste material generated from the total production. This waste is not recycled in any form at present. However, the ceramic waste is durable, hard and highly resistant to biological, chemical, and physical degradation forces. The Ceramic industries are dumping the powder in any nearby pit or vacant spaces, near their unit although

ISSN: 2231-5381

http://www.ijettjournal.org

Page 2324

International Journal of Engineering Trends and Technology (IJETT) - Volume4 Issue6- June 2013

TABLE-2 PHYSICAL PROPERTIES OF (OPC) CEMENT PROPERTY Specific Gravity Consistency Initial setting time Final setting time c) Aggregate Aggregates are the important constituents in concrete. They give body to the concrete, reduce shrinkage and effect economy. One of the most important factors for producing workable concrete is a good gradation of aggregates. Good grading implies that a sample fraction of aggregates in required proportion such that the sample contains minimum voids. Samples of the well graded aggregate containing minimum voids require minimum paste to fill up the voids in the aggregates. Minimum paste means less quantity of cement and less water, which are further mean increased economy, higher strength, lower shrinkage and greater durability. d) Coarse Aggregate Materials SiO2 Al2O3 Fe2O3 CaO MgO P2O5 K2O Na2O SO3 CLTiO2 SrO2 Mn2O3 L.O.I Ceramic Powder (%) 63.29 18.29 4.32 4.46 0.72 0.16 2.18 0.75 0.10 0.005 0.61 0.02 0.05 1.61 The fractions from 20 mm to 4.75 mm are used as coarse aggregate. The Coarse Aggregates from crushed Basalt rock, conforming to IS: 383 is being use. The Flakiness and Elongation Index were maintained well below 15%. e) Fine aggregate Those fractions from 4.75 mm to 150 microns are termed as fine aggregate. The river sand is used in combination as fine aggregate conforming to the requirements of IS: 383. The river sand is washed and screen, to eliminate deleterious materials and oversize particles. TABLE-3 PROPERTIES OF FINE AGGREGATE, COURSE AGGREGATE

Property Fine Aggregate 3.35 2.38 1753 1.20 Coarse Aggregate 20 mm 10 mm down down 7.54 2.76 1741 1.83 3.19 2.69 1711 1.35

IS CODE IS : 8112 - 1989 3.12 33 30 minimum 600 maximum

Figure: 1. Ceramic waste powder Source: Kohinoor tiles, Himmatnagar, Gujarat

Figure: 2. Microscopic Views of Ceramic

Particles

Source: SVNIT, Surat, Gujarat TABLE1 CHEMICAL PROPERTIES OF CERAMIC WASTE

Source: GEO TEST HOUSE, Baroda, Gujarat b) Cement (OPC) The Ordinary Portland Cement of 53 grades conforming to IS: 8112 is beingused.

Fineness modulus Specific Gravity Bulk Density (gm/cc) Water absorption (%)

ISSN: 2231-5381

http://www.ijettjournal.org

Page 2325

International Journal of Engineering Trends and Technology (IJETT) - Volume4 Issue6- June 2013

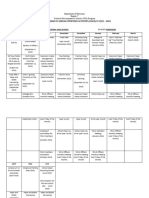

f) Water Water is an important ingredient of concrete as it actually participates in the chemical reaction with cement. Since it helps to from the strength giving cement gel, the quantity and quality of water are required to be looked into very carefully. IV EXPERIMENTAL SET UP TABLE-6 DESIGN MIX PROPORTION FOR VARIOUS CONCRETE Sr. No. III DESIGN MIX A mix M20 grade was designed as per Indian Standard method (IS 10262-2009) and the same was used to prepare the test samples.The design mix proportion is done in Table 4. TABLE-4 DESIGN MIX PROPORTION FOR (M20 MIX)

W (Lit) C

(Kg/m3)

Concrete Type A0 A1 A2 A3 A4 A5

1 2 3 4 5 6

OPC cement Replacement with Ceramic waste Standard Concrete 10% replacement 20% replacement 30% replacement 40% replacement 50% replacement

F.A.

(Kg/m3)

C.A. (Kg/m3) 20mm 10mm

Chemical Admixture

EXPERIMENTAL METHODOLOGY The evaluation of ceramic waste for use as a replacement of cement material begins with the concrete testing. Concrete contains cement, water, fineaggregate, coarse aggregate and grit. With the control concrete, i.e. 10%, 20%, 30%, 40%, and 50% of the cement is replaced with ceramic waste,the data from the ceramic waste is compared with data from a standard concrete without ceramic waste. Three cube samples were cast on the mould of size 150*150*150 mm for each 1:1.80:3.84 concrete mix with partial replacement of cement with a w/c ratio as 0.52 were also cast. After about 24 h the specimens were de-moulded and water curing was continued till the respective specimens were tested after 7, 14 and 28 days for compressive strength test. Compressive strength

By weig ht, [kg] By volu me, [m3]

169.30

325.50

730.20

759.20

506.10

2.0

0.52

1.00

1.80

2.35

1.49

W= Water, C= cement, F.A. = Fine Aggregate, C.A. = Coarse Aggregate

TABLE-5 CONCRETE DESIGN MIX (M20 MIX) PROPORTIONS

Sr. No

Concrete Type

Concrete Design Mix Proportion

W/C ratio

C 1.00 0.90 0.80 0.70

F.A. 1.80 1.80 1.80 1.80

C.A. 3.84 3.84 3.84 3.84

C.W 0.10 0.20 0.30

1 2 3 4

A0 A1 A2 A3

0.52 0.52 0.52 0.52

Compressive strength tests were performed on compression testing machine using cube samples. Three samples per batch were tested with the average strength values reported in this paper. The loading rate on the cube is 35 N/mm2 per min. The comparative studies were made on their characteristics for concrete mix ratio of 1:1.80:3.84 with partial replacement of cement with Ceramic waste as 10%, 20%, 30%, 40% and 50%.

5 6

A4 A5

0.52 0.52

0.60 0.50

1.80 1.80

3.84 3.84

0.40 0.50

ISSN: 2231-5381

http://www.ijettjournal.org

Page 2326

International Journal of Engineering Trends and Technology (IJETT) - Volume4 Issue6- June 2013

TABLE -7 COMPRESSIVE STRENGTH OF CUBES (150X150X150) FOR M25 MIX AT 7, 14, 28 DAYS Concrete Type A0 A1 A2 A3 A4 A5 Average Compressive Strength [N/mm2] 7 days 23.55 21.98 20.38 18.60 16.48 14.95 14 days 28.44 26.64 24.33 21.24 18.97 17.63 28 days 30.40 28.14 26.46 22.98 19.68 18.33 V. ECONOMIC FEASABILITY

TABLE- 8 COSTS OF MATERIALS Figure: 3 Percentage Replacement of Ceramic waste V/S Compressive Strength (N/mm2) of Concrete for M20 mix at 7, 14 and 28 days

Sr. No. 1 2 3 4

Materials Cement (OPC 53 grade) Fine aggregate (Regional ) Coarse aggregate (Regional ) Ceramic waste

Rate (Rs/Kg) 6.40 0.60 0.65 0.20

TABLE - 9 TOTAL COST OF MATERIALS FOR M20 DESIGNE MIX CONCRETE (1:1.80:3.84) PER m3

Consumption of Design Mix Proportions For M20 Concrete (1:1.80:3.84) C F.A. C.A. C.W. Admixture Total Cost /m3 % Cost Saving

C.T.

A0 A1 A2 A3 A4 A5

325.50 292.95 260.40 227.85 195.30 162.75

730.20 730.20 730.20 730.20 730.20 730.20

1265.30 1265.30 1265.30 1265.30 1265.30 1265.30

0.00 32.55 65.10 97.65 130.20 162.75

2.00 2.00 2.00 2.00 2.00 2.00

5325.53 5100.51 4875.49 4650.48 4425.91 4200.44

4.22 8.45 12.67 16.89 21.12

VI. CONCLUSION Based on experimental investigations concerning the compressive strength of concrete, the following observations are made:

(a) The Compressive Strength of M20 grade Concrete increases when the replacement of Cement with Ceramic Powder up to 30% replaces by weight of Cement and further replacement of Cement with Ceramic Powder decreases the Compressive Strength.

ISSN: 2231-5381

http://www.ijettjournal.org

Page 2327

International Journal of Engineering Trends and Technology (IJETT) - Volume4 Issue6- June 2013

(b) Concrete on 30% replacement of Cement with Ceramic Powder, Compressive Strength obtained is 22.98 N/mm2 and vice-versa the cost of the cement is reduced up to 12.67% in M20 grade and hence it becomes more economical without compromising concrete strength than the standard concrete. It becomes technically and economically feasible and viable. (c) Utilization of Ceramic waste and its application are used for the development of the construction industry, Material sciences. (d) It is the possible alternative solution of safe disposal of Ceramic waste. REFERENCES [1] Ceramic Manufacturing Industry, EUROPEAN COMMISSION, August 2007 A. Piccolroaz, D. Bigoni and A. Gajo, An elastoplastic framework for granular materials becoming cohesive through mechanical densification. Part I - small strain formulation. European Journal of Mechanics A: Solids, 2006, 25, 334-357. ASTM C 125, Standard Terminology Relating to Concrete and Concrete Aggregate, 1994 Annual Book of ASTM Standards Csar Medina1, M.I.Snchez de Rojas, Moiss Fras and Andrs Juan, Using Ceramic Materials in Ecoefficient Concrete and Precast Concrete Products, Spain C. Medina Martnez, M.I.Guerra Romero, J. M. Morn del Pozo and A. Juan Valds, USE OF CERAMIC WASTES IN STRUCTURALS ONCRETES, 1st Spanish National Conference on Advances in Materials Recycling and Eco Energy Madrid, 12-13 November 2009 David Pearce and Giles Atkinson, The concept of sustainable development: an evaluation of its usefulness ten years after brundtland, CSERGE Working Paper PA 98-02 D. Bigoni, Nonlinear Solid Mechanics: Bifurcation Theory and Material Instability. 2012, Cambridge University Press. Grard Valenduc, Patricia VendraminScience, Technological

[9]

[10]

[11]

[12]

[13]

[2]

[14]

[15]

[3]

[4]

[16]

[17]

[5]

[6]

[18]

[7]

[19]

[8]

Innovation and Sustainable Development,International Conference Science for a Sustainable SocietyRoskilde, 27-29/10/97 Hasnat Dewan, Re-Defining Sustainable Human Development to Integrate Sustainability and Human Development GoalsThompson Rivers University, Canada. .B.TOPU And M.CANBAZ, Utilization of crushed tile as aggregate in concrete, Iranian Journal of Science & Technology, Transaction B, Engineering, Vol. 31, No. B5, pp. 561-565, 2007 Philip J. Vergragt, How Technology Could Contribute to a Sustainable World, GTI Paper Series, 2006 P.K. Mehta, Puzzolanic and cementitious by products as mineral admixtures for concrete, fly ash, silica fume, slag and other mineral byproducts in concrete, ACI SP (79)(01)(1983) Sustainable Development: An Introduction, Internship Series, Volume-I, Centre for Environment Education, 2007 STRATEGYFOR SUSTAINABLE CONSTRUCTION HM Government,JUNE 2008 K. S. Al-Jabri, A. W. Hago, R. Taha, A. S. Alnuaimi and A. H. Al-Saidy Strength and Insulating Properties of Building Blocks Made from Waste Materials, Journal of Materials in Civil Engineering, 2009, Vol.21, No. 5,page no: 191197 Fernando and Said Compressive strength and durability properties of ceramic wastes based concrete, Materials and Structures, 2009, vol. 44,page no:155167 K.Abdullah, M.W.Hussin, F.Zakaria , R.Muhamad, Z.Abdul Hamid POFA : A Potential Partial Cement Replacement Material in Aerated Concrete, Proceedings of the 6th AsiaPacific Structural Engineering And Construction Conference, (APSEC 2006), 2006 Weerachart Tangchirapat, Tirasit Saeting, Chai Jaturapitakkul, Kraiwood Kiattikomol, AnekSiripanichgorn Use of waste ash from palm oil industry in concrete, Waste Management, 2007, vol.27, page no: 8188. Yadav Ishwar Singh, Maneek Kumar and Shweta Goyal, Laboratory Investigations Of The Properties Of Concrete containing Recycled Plastic Aggregates, M.Tech Thesis, Thapar University, 2008.

ISSN: 2231-5381

http://www.ijettjournal.org

Page 2328

International Journal of Engineering Trends and Technology (IJETT) - Volume4 Issue6- June 2013

AUTHORS BIOGRAPHY

Amitkumar Dipakbhai Raval was born in 1990 in Anand District, Gujarat. He received his Bachelor of Engineering degree in Civil Engineering from the Birla Vishwakarma Mahavidyalaya,Sardar Patel in 2011. At present he is Final year student of Master`s Degree in Construction Engineering and Management from Birla Vishwakarma Mahavidyalaya, Gujarat Technological University. He has a paper published in international journals.

Dr. I. N. Patel was born in 1964 in Anand city. He received his Bachelor of Engineering degree in Civil (Structural) Engineering from the Sardar Patel University in 1986. In 2007 he received his Master's Degree in M.E. Structural Engineering from the Sardar Patel University. In 2012 he received his PhD Civil Engineering, SVNIT, Surat, Gujarat. He joined B. & B. Institute of Technology as a faculty where he is Assistant Professor in Applied Mechanics Department with a total experience of 25 years in the field of Research, Designing and education. He has published 12 papers in National Journals /Conferences and 14 papers in International Journals/Conferences. Prof. Jayeshkumar R. Pitroda was born in 1977 in Vadodara City. He received his Bachelor of Engineering degree in Civil Engineering from the Birla Vishvakarma Mahavidyalaya, Sardar Patel University in 2000. In 2009 he received his Master's Degree in Construction Engineering and Management from Birla Vishvakarma Mahavidyalaya, Sardar Patel University. He joined Birla Vishvakarma Mahavidyalaya Engineering College as a faculty where he is Assistant Professor of Civil Engineering Department with a total experience of 12 years in the field of Research, Designing and education. He is guiding M.E. (Construction Engineering & Management) Thesis work in the field of Civil/ Construction Engineering. He has papers published in National Conferences and International Journals.

ISSN: 2231-5381

http://www.ijettjournal.org

Page 2329

Anda mungkin juga menyukai

- Slip CastingDokumen13 halamanSlip CastingRishi DasguptaBelum ada peringkat

- Ceramic Waste Aggreagte in Concrete Seminar Report PDFDokumen11 halamanCeramic Waste Aggreagte in Concrete Seminar Report PDFMahaManthraBelum ada peringkat

- 20 Faust Porcelain Vitreous EnamelsDokumen9 halaman20 Faust Porcelain Vitreous Enamelsyanda prBelum ada peringkat

- Enamel LingDokumen6 halamanEnamel LingAwo Òkànràn DuuruBelum ada peringkat

- Vitreous Enamel Coatings Degradation FactorsDokumen7 halamanVitreous Enamel Coatings Degradation FactorsFernando BarreraBelum ada peringkat

- 45 Manufacturing ProcessDokumen45 halaman45 Manufacturing ProcessOtunba Olakunle Sunday AjayiBelum ada peringkat

- CHARU Ceramics Industry Ltd BackgroundDokumen8 halamanCHARU Ceramics Industry Ltd BackgroundZareen Rashid ChoudhuryBelum ada peringkat

- Aluminium EnamelDokumen5 halamanAluminium EnamelbahramrezaeiBelum ada peringkat

- Casting Process Overview: Sand Mould Preparation and Pattern MakingDokumen31 halamanCasting Process Overview: Sand Mould Preparation and Pattern MakingChirag TaterBelum ada peringkat

- Ha SpongeDokumen45 halamanHa SpongeSantoso NugrohoBelum ada peringkat

- Fórmulas de PatinasDokumen4 halamanFórmulas de Patinasdefensormaldito100% (2)

- Testing The Thermal Properties of Advanced Ceramics: Standard Guide ForDokumen16 halamanTesting The Thermal Properties of Advanced Ceramics: Standard Guide ForSakarin Waiyakul100% (1)

- Ceramic Raw Materials To GlassesDokumen133 halamanCeramic Raw Materials To GlassesM.AbubakarBelum ada peringkat

- Found AryDokumen401 halamanFound AryVraj PatelBelum ada peringkat

- Metal Casting Design: Mold and Gating System Design, Directional Solidification, and TroubleshootingDokumen7 halamanMetal Casting Design: Mold and Gating System Design, Directional Solidification, and TroubleshootingzidaaanBelum ada peringkat

- Effect of Soaking On Phase Composition and Topography and Surface MicrostructureDokumen9 halamanEffect of Soaking On Phase Composition and Topography and Surface MicrostructureRafaelBelum ada peringkat

- Antibacterial Additive For GlazeDokumen1 halamanAntibacterial Additive For Glazemd azizur RahamanBelum ada peringkat

- Observation of Defects in Cast Iron Castings by Surface AnalysisDokumen19 halamanObservation of Defects in Cast Iron Castings by Surface Analysisgonzalo gimenez100% (1)

- An Introduction To Shaw Process by MustaDokumen14 halamanAn Introduction To Shaw Process by MustaMarthinBelum ada peringkat

- Pyrotek - SIVEX - Ceramic FoamDokumen2 halamanPyrotek - SIVEX - Ceramic FoamajoilhamBelum ada peringkat

- Metal-Casting Process and EquipmentDokumen18 halamanMetal-Casting Process and EquipmentZulfikarUdenBelum ada peringkat

- Mg Superplasticity TechniquesDokumen23 halamanMg Superplasticity TechniquesashvaniBelum ada peringkat

- Metal CoastingDokumen20 halamanMetal CoastingPranay Gaddam0% (1)

- Curvature Evolution in Porcelain Tile During FiringDokumen12 halamanCurvature Evolution in Porcelain Tile During Firingمحمد رمضانBelum ada peringkat

- Permanent Mold CastingDokumen15 halamanPermanent Mold CastingEka RosmitaliaBelum ada peringkat

- Metallic Materials Casting and Sintering ProcessesDokumen23 halamanMetallic Materials Casting and Sintering ProcessesgayeBelum ada peringkat

- Types of Sands Used in MouldsDokumen20 halamanTypes of Sands Used in Mouldsdhaya53Belum ada peringkat

- Pilkington Float GlassDokumen27 halamanPilkington Float GlassVivek RanganathanBelum ada peringkat

- Material Safety Data Sheet for Copper OxideDokumen8 halamanMaterial Safety Data Sheet for Copper OxideSuarez Nuñez ElizabethBelum ada peringkat

- Cones and Buller RingsDokumen6 halamanCones and Buller RingsTravis WoodBelum ada peringkat

- Plastic Injection MoldingDokumen24 halamanPlastic Injection Moldingmechhandbook100% (1)

- Flame Spray Drying Equipment, Mechanism, and Perspectives by Mariia Sobulska, Ireneusz ZbicinskiDokumen159 halamanFlame Spray Drying Equipment, Mechanism, and Perspectives by Mariia Sobulska, Ireneusz ZbicinskiJose Bermeo VBelum ada peringkat

- Electroplating Cost Calculation - RefDokumen12 halamanElectroplating Cost Calculation - RefJitendra PatilBelum ada peringkat

- As 1774.23.1-2001 Refractories and Refractory Materials - Physical Test Methods Abradability Index - ObliqueDokumen2 halamanAs 1774.23.1-2001 Refractories and Refractory Materials - Physical Test Methods Abradability Index - ObliqueSAI Global - APACBelum ada peringkat

- Casting Rubber PlasticDokumen14 halamanCasting Rubber PlasticAnonymous AmOgamBelum ada peringkat

- What Is AnodizingDokumen5 halamanWhat Is AnodizingSuleman Khan0% (1)

- Ceramic Processing Techniques and PropertiesDokumen13 halamanCeramic Processing Techniques and PropertiesHitesh BhatiaBelum ada peringkat

- Modeling and Mold MakingDokumen75 halamanModeling and Mold MakingTiberiu TdlBelum ada peringkat

- Metal Colouring TechniquesDokumen1 halamanMetal Colouring TechniquestobiBelum ada peringkat

- FluxDokumen9 halamanFluxking59Belum ada peringkat

- Colorants and Opacifiers PDFDokumen7 halamanColorants and Opacifiers PDFSiddharthapachisiaBelum ada peringkat

- Polishing Principles: Understanding the Science Behind Surface FinishingDokumen4 halamanPolishing Principles: Understanding the Science Behind Surface FinishingMafteian LiviuBelum ada peringkat

- Ceramics 1 MCG2361 2016Dokumen42 halamanCeramics 1 MCG2361 2016Jessica BarhomaBelum ada peringkat

- Slip CastingDokumen24 halamanSlip CastingKrishma PatelBelum ada peringkat

- Vacuum CastingDokumen2 halamanVacuum CastingRaheel Ahmed KhanBelum ada peringkat

- Ceramic Raw Material PreparationDokumen3 halamanCeramic Raw Material PreparationHarish Kuppusamy100% (1)

- ME 312 Manufacturing Technology: Ceramics Shaping and ProcessingDokumen17 halamanME 312 Manufacturing Technology: Ceramics Shaping and ProcessingVikrant SharmaBelum ada peringkat

- Introduction To Glass Science and Technology: J.E. Shelby, Alfred University, NY, USADokumen1 halamanIntroduction To Glass Science and Technology: J.E. Shelby, Alfred University, NY, USA0312_kalpanaBelum ada peringkat

- Hot Green Sand ProblemsDokumen5 halamanHot Green Sand ProblemsbvphimanshuBelum ada peringkat

- Moulding ProcessesDokumen10 halamanMoulding ProcessesChinmay Das67% (3)

- Machinable Glass CeramicsDokumen29 halamanMachinable Glass CeramicsHarsha VardhanaBelum ada peringkat

- Brac Bank Authrization FormDokumen2 halamanBrac Bank Authrization Formzahir haque100% (1)

- Casting of Cobalt Chromium AlloysDokumen31 halamanCasting of Cobalt Chromium AlloysYesha Shah100% (2)

- Introduction To PistonDokumen10 halamanIntroduction To PistonAkimRee100% (1)

- Controlling The Chemistry and The and The Section Size Is Very ImportantDokumen2 halamanControlling The Chemistry and The and The Section Size Is Very ImportantHeuzerGomesBelum ada peringkat

- Calculation of Thermal Expansion Coefficient of Glasses 1976 Journal of Non Crystalline SolidsDokumen9 halamanCalculation of Thermal Expansion Coefficient of Glasses 1976 Journal of Non Crystalline SolidsGarlapati Srinivasa RaoBelum ada peringkat

- Fire More For Less PDFDokumen5 halamanFire More For Less PDFJose Vicente Nuguid ErictaBelum ada peringkat

- Advanced Materials '93: Ceramics, Powders, Corrosion and Advanced ProcessingDari EverandAdvanced Materials '93: Ceramics, Powders, Corrosion and Advanced ProcessingShigeyuki SomiyaBelum ada peringkat

- Stone Waste in India For Concrete With Value Creation OpportunitiesDokumen8 halamanStone Waste in India For Concrete With Value Creation OpportunitieskalamjBelum ada peringkat

- Cement enDokumen23 halamanCement enShahab SadqpurBelum ada peringkat

- PaperDokumen10 halamanPaperHilary WatsonBelum ada peringkat

- Geopolymer Concrete ThesisDokumen72 halamanGeopolymer Concrete Thesisyogeshgurubaran100% (7)

- Astm C 642 90 Calidad Del ConcretoDokumen3 halamanAstm C 642 90 Calidad Del ConcretoBayron Medina Ospina0% (1)

- 1Dokumen6 halaman1basanth_712982Belum ada peringkat

- Resistance of Fly Ash Based GeopolymerDokumen6 halamanResistance of Fly Ash Based GeopolymerShahab SadqpurBelum ada peringkat

- Geopolymer - Carbon Footprint - 2013Dokumen6 halamanGeopolymer - Carbon Footprint - 2013Shahab SadqpurBelum ada peringkat

- Performance of 3rd Generation Locally Available Chemical Admixtures in The Production of SCCDokumen11 halamanPerformance of 3rd Generation Locally Available Chemical Admixtures in The Production of SCCShahab SadqpurBelum ada peringkat

- Initial Gantt chart setup in MS ProjectDokumen12 halamanInitial Gantt chart setup in MS ProjectShahab SadqpurBelum ada peringkat

- Pacheco Torgal Et Al. 2012Dokumen6 halamanPacheco Torgal Et Al. 2012Like HalimBelum ada peringkat

- AdmixturesDokumen44 halamanAdmixturesRavi TejaBelum ada peringkat

- FFFFFFFFFDokumen22 halamanFFFFFFFFFShahab SadqpurBelum ada peringkat

- Thesis Proposal TemplateDokumen3 halamanThesis Proposal TemplateShahab SadqpurBelum ada peringkat

- Influence LineDokumen5 halamanInfluence LineShahab SadqpurBelum ada peringkat

- Mixx of ConcereDokumen3 halamanMixx of ConcereShahab SadqpurBelum ada peringkat

- Pce Admixture Effect of Hydration ....Dokumen13 halamanPce Admixture Effect of Hydration ....Shahab Sadqpur0% (1)

- Hy Trog RaphDokumen2 halamanHy Trog RaphShahab SadqpurBelum ada peringkat

- Ultra High Strength ConcreteDokumen29 halamanUltra High Strength ConcreteShahab Sadqpur88% (8)

- StatementDokumen2 halamanStatementShahab SadqpurBelum ada peringkat

- Project 1 WbsDokumen1 halamanProject 1 WbsShahab SadqpurBelum ada peringkat

- HelloDokumen1 halamanHelloShahab SadqpurBelum ada peringkat

- Zero Cement ConcreteDokumen2 halamanZero Cement ConcreteShahab SadqpurBelum ada peringkat

- Concrete Mix DesignDokumen2 halamanConcrete Mix DesignShahab SadqpurBelum ada peringkat

- Zero Cement ConcreteDokumen2 halamanZero Cement ConcreteShahab SadqpurBelum ada peringkat

- Khemendra Kumar Wimco ReportDokumen84 halamanKhemendra Kumar Wimco ReportAshutoshSharmaBelum ada peringkat

- YES O CAPA 2023 2024Dokumen4 halamanYES O CAPA 2023 2024sheilaBelum ada peringkat

- Radioactive Waste Management Multiple Choice Questions RWM MCQsDokumen13 halamanRadioactive Waste Management Multiple Choice Questions RWM MCQsChishinga Mulenga MiltonBelum ada peringkat

- Activated Sludge Aeration Tank Calculations-US Units Final-Locked-11!12!18Dokumen30 halamanActivated Sludge Aeration Tank Calculations-US Units Final-Locked-11!12!18Cristian Ortiz100% (1)

- Standard Operating Procedure For De-Contamination Facility For Barrels/ Containers Used For Handling of Wastes/ ChemicalsDokumen8 halamanStandard Operating Procedure For De-Contamination Facility For Barrels/ Containers Used For Handling of Wastes/ ChemicalsShital 2Belum ada peringkat

- CPP Project Group 1Dokumen21 halamanCPP Project Group 1Mazi ParaBelum ada peringkat

- Phil Green Building Code Presentation by RMCARINGAL v2Dokumen74 halamanPhil Green Building Code Presentation by RMCARINGAL v2Micah San JuanBelum ada peringkat

- Osmena vs. Orbos FactsDokumen16 halamanOsmena vs. Orbos FactsGian Tristan MadridBelum ada peringkat

- Kisumu LPG Plant EIADokumen172 halamanKisumu LPG Plant EIAboipora50% (4)

- CHAPTER II (Awareness and Practices On Solid Waste Management)Dokumen15 halamanCHAPTER II (Awareness and Practices On Solid Waste Management)Jayson CiprianoBelum ada peringkat

- Home Waste: Proper Waste Disposal Management Concept PaperDokumen3 halamanHome Waste: Proper Waste Disposal Management Concept PaperMURIELLE YAWAN100% (5)

- Environment Analysis of NokiaDokumen36 halamanEnvironment Analysis of Nokiaswathisekar43200% (2)

- Manual Tank Cleaning & Decontamination Support ServicesDokumen22 halamanManual Tank Cleaning & Decontamination Support ServicesLee Hunter Jr100% (1)

- LEM 168 MR v5Dokumen8 halamanLEM 168 MR v5put saputraBelum ada peringkat

- MSDS C011 Defoamer V - 0.3Dokumen5 halamanMSDS C011 Defoamer V - 0.3Cementation StimulationBelum ada peringkat

- Egypt's Universal Health Insurance ESCPDokumen8 halamanEgypt's Universal Health Insurance ESCPola bakryBelum ada peringkat

- Commercial Scale Mixed Plastics Recycling 19 6 FINAL FINAL VERSIONDokumen164 halamanCommercial Scale Mixed Plastics Recycling 19 6 FINAL FINAL VERSIONtruongngvBelum ada peringkat

- (ICSCI 2019) Presentation Priyo r3Dokumen10 halaman(ICSCI 2019) Presentation Priyo r3psesotyoBelum ada peringkat

- Part 2 + Part 3Dokumen43 halamanPart 2 + Part 3Trúc Nguyễn Thị ThanhBelum ada peringkat

- GARBAGE MANAGEMENT MANUALDokumen21 halamanGARBAGE MANAGEMENT MANUALAnant Ajithkumar100% (1)

- Community Health Needs of Barangay Antipolo OldDokumen13 halamanCommunity Health Needs of Barangay Antipolo OldMica B.Belum ada peringkat

- Hindware Homes product catalog with sanitaryware, faucets, and vanity shower detailsDokumen56 halamanHindware Homes product catalog with sanitaryware, faucets, and vanity shower detailsCivil SiteBelum ada peringkat

- Nypass: SECTION 1: Identification of The Substance/mixture and of The Company/undertakingDokumen12 halamanNypass: SECTION 1: Identification of The Substance/mixture and of The Company/undertakingSelk CLBelum ada peringkat

- Capnograph: Service ManualDokumen42 halamanCapnograph: Service ManualEdward Pérez Aranguren100% (1)

- Is Recycling Worth ItDokumen21 halamanIs Recycling Worth Itapi-252236011100% (1)

- Msds Iron PowderDokumen5 halamanMsds Iron PowdermulyadiBelum ada peringkat

- Vigan CityDokumen19 halamanVigan CityShobi DionelaBelum ada peringkat

- Health9 - q1 - Mod3 - Environmental Issues - v3Dokumen24 halamanHealth9 - q1 - Mod3 - Environmental Issues - v3Arnaldo Jr. CarbonBelum ada peringkat

- HUTCHISON GROUP Small SizeDokumen39 halamanHUTCHISON GROUP Small SizeAhmadfadli SaputraBelum ada peringkat

- Eco Health Center-An Innovative Approach To Municipal Slid Waste ManagementDokumen23 halamanEco Health Center-An Innovative Approach To Municipal Slid Waste ManagementAmalkpBelum ada peringkat