Roof-Based Electric Generator

Diunggah oleh

Marionn FajardoDeskripsi Asli:

Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Roof-Based Electric Generator

Diunggah oleh

Marionn FajardoHak Cipta:

Format Tersedia

CHAPTER 1

PROBLEM AND ITS BACKGROUND

Electricity is one of the basic forms of energy. It is associated with electric charge, a property of certain elementary particles such as electrons and protons that make up the atoms of matter. Furthermore, electricity is generated, transmitted, and converted into heat, light, motion, and other forms of energy through natural and man-made processes. There are different sources of electricity. They fall into two categories: renewable and non-renewable energy. Renewable energy comes from sources that naturally renew, or will not run out in our lifetime. These resources include the sun, wind, moving water, organic plant and waste material (biomass); and the Earths heat (geothermal). On the other hand; non-renewable energy comes from sources that will run out or will not be replenished. Examples of these resources are fossil fuels that are found within the rocks of the Earths surface and formed by natural processes such as anaerobic decomposition of buried dead organisms that lived millions of years ago in the form of concentrated biomass. Electricity is a versatile form of energy. It can be converted efficiently into other forms of energy and it can be stored. Because of this property, electricity propels the advancement of modern technology and because of this development, it became a necessity for the people in contemporary times. Without it, life will be more difficult and slow-paced. Likewise, many aspects of our living have improved a lot because of

electricity especially in the field of communication specifically electrical powered gadgets such as mobile phones and computers which are developed that made communication easier and faster. As long as there is a source of power for these devices, distance communication will not be a problem anymore. Another aspect of life that is affected by electricity is work: people need electricity to operate machineries and equipment needed to finish their work. Equally in the same importance, electricity is vital in transportation. Nowadays, trains in our country utilizes electricity to operate. Also, some cars and buses already use electricity instead of gas that is eco-friendly. At home, we use appliances in order to feel more comfortable and almost all of these appliances are powered up by electricity. To sum it up, electrical energy makes our lives easier. In order to address this great demand in electrical energy, new power plants are needed. In the research conducted by the International Energy Agency last 2012, 81.1% of the world primary power source in 2010 comes from fossil fuels. Burning of these fossil fuels emit large amounts of carbon dioxide which has the largest contribution in greenhouse gases. Accumulation of greenhouse gases leads to global warming that results in the long-term increase of retention of the suns heat around Earth. As a matter of fact, Earths temperature has increase in the rate of about 0.05 degrees Celsius per decade since 1998 through 2012 as stated in the report of International Panel in Climate Change (IPCC). In response to this alarming situation, there are various conventions that has been conducted around the globe. In one of these conventions, Ben Caldecott said that If we cant stop change, we must adapt. In parallel to this, the researchers recognize the importance of electricity as a vehicle for transformation of our society through

technological innovations and discoveries. Also, the researchers are cognizant of the present situation wherein technology causes pollution which disturbs the ecological balance resulting in the destruction of the ozone layer. The researchers recognized that one possible way is to harness this additional heat and convert it into useful electrical energy by converting the heat emitted by the roof of the houses into electricity. The heat produced by the roof is suitable to be an energy source since it is an absorbed thermal energy then it became a heat reservoir. The challenge for the researchers is to make a system which possesses efficiency and capability of manipulating this heat energy to transform it into a new form that will benefit the residents but the conversion will be harmless to the users and to the environment as well.

Statement of the Problem The researcher would like to explore the possibility of developing a device that will convert unused heat energy into useful electrical energy. Specifically, this research will answer the following questions: 1. What system will be developed to convert unused heat by the heat source directly into electricity? 2. Is the thermal energy from the heat source sufficient to produce electrical energy? 3. What system will be developed in order to maintain the desired power output even there is a temperature variation? 4. Will the device to be developed beneficial to the end users in terms of: 4.1 Functionality

4.2 Efficiency and effectiveness 4.3 Durability 4.4 Initial cost

Objective of the Study The research study aimed at developing a device that will harness and utilize the unused heat radiated by the roof into useful electricity in such a way that the device be able to charge a power bank and the end users will not exert too much effort in operating and maintaining the system.

Significance of the Study This research will be beneficial to the following: 1. Residents of Bulacan This study will benefit them by having a device that will directly convert the unused thermal energy given off by the heat source into electrical energy that requires minimum supervision and less maintenance. 2. College of Engineering- This study will encourage them to develop other eco-friendly devices that will convert unused thermal energy to electrical energy. 3. Future Researchers From this research, different innovations in engineering systems can be developed. The group found out that different companies from different countries already fabricated and use thermally powered machines. This proves the feasibility and

practicality of the study. Further study in this topic will benefit the society and also the academic community.

Scope and Delimitations The system is focused in utilizing the unused radiated heat by the roof in the residential areas of Bulacan to convert it into useful electrical energy. This electrical energy is capable of charging a power bank. They used the power bank model number PWB-085-M for the system. In order to produce electricity, the thermoelectric module with model number TEC1-12706 must have a cold side and hot side to achieve temperature difference. In this study, 10 thermoelectric modules were used in the device developed. It was placed under the roof, where heat can be easily radiated, of the respondents living in the residential area of Bulacan. The system is temperature dependent. If there is no heat radiated, including the rainy season, the system is will not generate any voltage since it requires temperature difference. The system should generate minimum of 2Vdc in order for the DC-DC converter to work and amplify the input voltage up into higher direct current voltage. The researchers tested the system in an annealed galvanized iron cold rolled steel roof 0.4 mm thick with the following reference standard PNS 201 and JIS G 3312.

Notes in Chapter 1 Caldecott, Ben. "If we can't stop change, we must adapt". The Guardian. Date Accessed October 3, 2013 http://www.theguardian.com/commentisfree/cifgreen/2009/mar/11/copenhagen-climate-change Morales, Alex. Global Warming Slowdown Seen as Emissions Rise to Record. Bloomberg. September 28, 2013. Date Accessed October 3, 2013 www.bloomberg.com/news/2013-09-27/global-warming-slowdown-seen-as-emissionsrise-to-record.html Electricity. The Columbia Encyclopedia, 6th ed.. 2013. Date Accessed October 2, 2013. http://www.encyclopedia.com/doc/1E1-electricity.html 2012 Key World Energy Statistics. International Energy Agency. Date Accessed October 3, 2013 http://www.iea.org/publications/freepublications/publication/kwes.pdf

CHAPTER 2

THEORETICAL FRAMEWORK

This part of the study includes theories, literature, and studies applicable to the development of the project that the researchers would like to explore. Also, includes conceptual framework, statement of hypothesis, and the definition of terms significant in this research.

Relevant Theories The following theories are significant in the development of discussions to further expound crucial details in this study. Heat Transfer. White (1988) defines heat transfer as a branch of applied thermodynamics that analyzes the rate at which heat is transferred across system boundaries that are subjected to specific temperature difference conditions. It also estimates the rate at which heat transfers and the temperature distribution of the system during the process. There are three modes of heat transfer: conduction, radiation and convection. Conduction is an exchange of energy by direct interaction between molecules and by the

drift of electrons of a substance containing temperature differences. Convection is the mode of heat transfer in which energy is transported by moving fluid particles. Radiation is the process of transferring thermal energy in the form of electromagnetic waves emitted by atomic and subatomic agitation at the surface of a body through a vacuum or a nearly transparent gas such as oxygen and nitrogen. Heat transfer concerns the movement of heat particles from a hotter surface to a less hot surface. In this project, the harnessed heat by the roof directly from the sun is transferred to the galvanized iron through the concept of conduction and convection. Thermodynamics. It is the branch of physical sciences that treats of various phenomena of energy and the related properties of matter, especially the laws of transformation of heat into another other forms of energy or vice versa. (Faires and Simmang 1978). There are three laws of thermodynamics but for this project the researchers focus only on the first two laws. The First Law of Thermodynamics is also called as the energy balance. It is an expression of the conservation of energy principle, and it asserts that energy is a thermodynamic property. It states that during an interaction, energy can change from one form to another but the total amount of energy remains constant. That is, energy cannot be created nor destroyed (Cengel and Boles 2011). The Second Law of Thermodynamics relies on two statements. The first one is the Kelvin-Planck statement which states that it is impossible for any

device that operates on a cycle to receive heat from a single reservoir and produce a net amount of work. The second is the Clausius statement which expressed as follows: It is impossible to construct a device that operates in a cycle and produces no effect other than the transfer of heat from a lower-temperature body to a higher-temperature body (Cengel and Boles 2011). Just like what the two laws stated, thermal energy can change from one form to another but it cannot be converted 100 percent. Therefore, the heat coming from the roof will not be converted 100 percent into electrical energy. Thermoelectricity. Chandler (2010) defines thermoelectricity as a two way process. It can refer either to the way a temperature difference between one side of a material and the other can produce electricity, or reverse: the way applying an electric current through a material can create a temperature difference between its two sides, which can be used to heat or cool things without combustion or moving parts. Thermoelectricity encompasses three separately identified effects which are commonly known as Thermoelectric Effects. These effects are Seebeck Effect, Peltier Effect and Thomson Effect. Seebeck Effect the phenomenon whereby an electrical current will flow in a closed circuit made up of two dissimilar metals when the junctions of the metals are maintained at two different temperatures

(Thermoelectric Technical Reference). Peltier Effect is the inverse of Seebeck effect, when electric current is passed in a circuit consisting of two dissimilar metals, heat is

evolved at one junction and is absorbed on the other junction. There is heat absorption or generation at the junction depending on the direction of current flow (Avadhanulu and Kshirsagar 2013).

Thomson Effect. The effect is caused by charged carriers within the material diffusing from the hotter side to the cooler side, similarly to the way gas expands when it is heated (Chandler 2010). Thermoelectricity is significant in the researchers study. The thermocouple, which is the main material needed in the said project, is governed by the concept of Seebeck effect in order to produce electricity. Power Electronics. According to Grob (1997) the subject of electronic devices means semiconductor components such as diodes, transistors, and integrated circuits. These are commonly used for amplifiers, oscillators, rectifiers and digital circuits. In order for the project to be capable of producing ample amount of electricity, the system is composed of different electronic devices such as diodes, transistors, and amplifiers. Engineering Materials. The definition of the academic field of Materials Science & Engineering stems from a realization concerning the every application of materials: it is the properties of the material that give it value. A material may be chosen for its strength, its electrical properties, resistance to heat or corrosion, or a host of other reasons; but they all relate to properties (Charles, Crane and Furness 1997).

Thermal conductivity is the property of material to conduct heat. It is the product of thermal diffusivity, density and specific heat of the material Shind and Goela 2006). The strength and thermal conductivity of some of the materials like metal plates and heat spreaders used in the project are the main factors in determining what type of materials are needed in the project. The strength of a material tells whether the project will be durable for a long period of time and the thermal conductivity tells whether the materials conduct heat efficiently.

Related Literature The subsequent writings contain origin and design consideration that will further discuss the project.

History of Thermoelectricity In 1821, Thomas J. Seebeck discovered that an electromotive force or a potential difference could be produced by a circuit made from two dissimilar wires when one of the junctions was heated. This called the Seebeck effect. In 1834, after 13 years, Jean Peltier discovered the reverse process, that the passage of an eletric current through a thermocouple produces heating or cooling

depending on its direction. This is called the Peltier effect. Although the two effects were demonstrated to exist, it was very difficult to measure each effect as a property of the material because the Seebeck effect is always associated with two dissimilar wires and

the peltier effect is always followed by the additional joule heating that is heat generation due to the electrical resistance of passage of the current. Joule Heating was discovered in 1841 by James P. Joule. In 1854, William Thomson ( later Lord Kelvin ) discovered that if a temperature difference exists between any two points of a current-carrying conductor, heat is either liberated or absorbed depending on the direction of current and materials, which is in addition to Peltier heating. This is called the Thomson effect. He also studied the relationships between the three effects thermodynamically, showing that the Electrical Seebeck effect results from a combination of the thermal Peltier and Thomson effects. Although the Thomson effect itself is small compared to the other two, it leads to very important and useful relationship, which is called the Kelvin relationship. During and after the world wars thermoelectricity was actively studied for use in valuable technologies, primarily cooling as well as power generation for military as well as civilian uses. The political and economic importance of such devices made advances more difficult and slow to publicize particularly between the Eastern European and Western countries. By the 1950s, generator efficiencies had reached 5% and cooling from ambient to below 0 C was demonstrated which has ultimately lead to some viable industries. Many thought Thermoelectrics would soon replace conventional heat engines and refrigeration and interest and research in thermoelectricity grew rapidly at major appliance corporations such as Westinghouse, universities and national research laboratories. However, by the end of 1960s, the progress about Thermoelectricity slowed down because of some discussions and dismantled research programs. In between 1920

and 1970, it is the period of excitement and disappointment of thermoelectric applications. After this period, the reliability and simplicity of thermoelectricity enables niche applications for this solid-state technology even while conventional processes are more efficient. Besides thermocouples, a small but stable industry produced Peltier coolers which now produce coolers for a variety of products ranging from optoelectronics, small refrigerators and seat cooling/heating systems. The need for reliable, remote power sources provides some niche applications for thermoelectric power generation. In 1990s, the interest in thermoelectricity renewed with the influx new ideas. While some of these ideas have shown to be ineffective, others have led to entirely new classes of complex thermoelectric materials. Also, during this time, the global need for alternative sources of energy has revived interest in commercial applications and stimulated interest in developing inexpensive and environmentally-friendly

thermoelectric materials.

DESIGN CONSIDERATION

HEAT SOURCE (ROOF)

POWER GENERATION (PELTIER MODULE)

VOLTAGE CONDITIONING CIRCUIT

POWERBANK

FIG. 1 Block Body Diagram of the system

Thermoelectric Cooler (TEC) A thermoelectric cooler (TEC), sometimes called a thermoelectric module or Peltier cooler, is a semiconductor-based electronic component that functions as a small heat pump (Thermoelectric Technical Reference). When DC voltage is applied to the module, heat will be moved through the module from one side to the other. The surface where heat energy is absorbed becomes cold while the opposite surface where heat energy is released becomes hot. The basic concept behind thermoelectric cooling is the Peltier Effect. The device cannot only pump appreciable amounts of heat, it also suitable to be used as DC power supply (Avadhanulu and Kshirsagar 2013). The device can convert heat energy directly to electricity. When a temperature gradient is created across the thermoelectric device, a DC voltage develops across the terminals. When a load is properly connected, electrical current flows. The advantage of using TEC as a transducer is it has no moving parts and therefore, needs substantially less maintenance (Avadhanulu and Kshirsagar 2013). In this research, a TEC device was primarily used to utilize the thermal energy in roof and convert it into useful electricity. The TEC model TEC1-12706 was used. It has 127 couples and has physical dimensions of 40 mm x 40 mm x 3.5 mm. To maximize the low output voltage of the TEC, the researchers connected 10 TECs in series to give a better output voltage. To be able to produce electricity, a TEC should have a hot side, which is the roof, and a cold side to produce temperature gradient, hence, electricity was produced. To have an optimal efficiency, the TEC should have adequate cooling. The cooling system that

the researchers used was a combination of heat sinks and water. The heat sinks were soaked in water to provide additional cooling.

Heat Sink A heat sink is a device to effectively absorb or dissipate thermal energy from the surrounding (air) using extended surfaces as fins and spines. Heat sinks are used in a wide range of applications where efficiency heat dissipation is required. The most common design of a heat sink is a metal device with many cooling fins, which is referred to as s fin array. The heat sink performance is improved by increasing either thermal conductivity of the fins, the surface of the fins, or the heat transfer coefficient (Lee 2010). In the set-up, heat sink was used to draw the heat away from the hot side of the TEC. Six heat sinks are covered by the aluminum pan filled with water.

Water In this set-up, it increased the heat pumping performance of the module.

Thermal Paste Thermal paste is a viscous fluid substance, originally with properties akin to grease, which increases the thermal conductivity of a thermal interface by filling microscopic air-gaps present due to the imperfectly flat and smooth surfaces of the components; the compound has far greater thermal conductivity than air (but far less than metal). In electronics, it is often used to aid a component's thermal dissipation via a heat sink. (Thermal Grease n.d.)

The thermal grease in this project was applied on both side of the TEC to increase its thermal conductivity, hence, effectively absorb heat from the heat source and easily dissipate heat to the heat sink. On the other hand, the thermal grease spread on the cooling side increased the heat transfer between the TEC and heat sink so that the heat sink will dissipate heat better.

DC-DC Converter DC-DC Converter converts an available DC (direct current) input voltage rail to another more desirable or usable output voltage level (Maniktala 2006). DC-DC Converter is an electronic device that makes DC electric power efficient from one voltage level to another. It can be viewed as a DC transformer that delivers the load as DC voltage or current at different levels. This DC transformation is performed by electronic switching means, not by electromagnetic means like in conversional transformer. The DC-DC converters can be divided as into two main types: soft-switching converters and hard-switching pulse width modulation (PWM) converters (Rashid 2011). Soft-switching converter technique involves many methods implementing resonance characteristics. On the other hand, PWM Converter is a modulation technique that conform the width of the pulse, formally the pulse duration, based on modulator signal information. One of its advantage is it has a low component count, high efficiency, constant frequency operation, and relatively simple control. It also has high conversion ratios for both step-down and step-up applications. The PWM are further classified into four topologies: buck, boost, buck-boost, and buck converter.

In this research, PWM boost topology was used to step-up the output voltage delivered by the power generator TEC. eDC-2420 step up DC-DC converter, 33 mm x 16 mm PCB dimension was used to amplify the voltage produced by the Thermoelectric cooler into the desired output. The device can generate up to 27 VDC output from a single +5VDC input. Higher output power (current) can be obtained with higher input voltage. Figure 2 shows the schematic diagram of eDC-2420 step up DC-DC converter.

FIG. 2 Schematic Diagram of DC-DC Converter

Voltage Regulator A voltage regulator generates a fixed output voltage of a preset magnitude that remains constant regardless of changes to its input voltage or load conditions (Voltage Regulator General Design Fundamentals). In this study, voltage regulator was used to maintain a constant voltage needed to charge the power bank.

Power Bank A power bank is a device used to put energy into a secondary cell or rechargeable battery by forcing an electric current through it. The charging protocol depends on the size and type of the battery being charged. In this study, a power bank with a model of PWB-O85-M was used to charge a cellphone.

Related Studies The following study done by the researchers were compared to the findings gathered from these studies. Different studies were conducted and these proved the significances of various factors and how they complement the production of ideal outcome of project. Farmer (2007) studied different types of transducer (piezoelectric generator, thermoelectric generator, photovoltaic, and electromagnetic harvesting) in order to find some basic ways to compare their relative energy densities, and if possible, comparative energy densities. His study also introduced methods of combining them to produce a hybrid, multiple energy domain harvesting devices. However, the researcher only managed to combine piezoelectric and electromagnetic generator.

The researcher of this study tested the thermoelectric generator in an automobile exhaust to convert waste heat from the vehicle to recharge a nickel metal hydride battery. Due to the low power output of the transducer, they studied on how to step up the voltage output through the use of either switching circuit or a DC-DC converter. However, the circuit was proven to be somewhat difficult to implement, so a DC-DC device was applied as a possible solution because of its high efficiency and low power requirement. The transducers were connected electrically in series. Thermal grease was used in each of the TEG to decrease the heat leakage between the two faces of the ceramic plate and to improve the thermal conductivity. An aluminum plate was mounted to the hot side of the generators to spread the heat equally and in order to adapt to the round shape of the catalytic converter. An aluminum fin heat sink was used to dissipate heat from cold side. A piece of wire was wrapped around the device and the exhaust pipe several times and was twisted with pliers to hold the TEG device flush against the hot metal surface for the greatest amount of heat transfer. This study had an advantage of having a constant heat source for the hot side of the TEG which will produce a higher output. On the other hand, several disadvantages of the study are it did not have a constant temperature gradient and it did not have a constant output voltage. This output voltage was not used for practical applications. This study and the study conducted by the researchers are the same because of the materials used. Both of the studies used thermoelectric coolers that acted as generator. It also used a DC-DC converter to amplify the output voltage.

Deriquito et al. (2010) also used the thermoelectric device to harness power from an automobile system, but this time, the thermoelectric device used was primarily designed for power generation purposes. In their research Implementation of Microcontroller-Based Heat-to-Power Converter Using Thermoelectric Generator (TEG) Transducer Arrays in an Automobile System, the TEG modules in this project were used to harness heat of the primary muffler of a typical car. The hot side was attached to a copper plate while an aluminum heat sink was attached to the cold side. The electrical power harnessed was fed to a set of circuitry that regulated it and fed it to a charging circuit that charged a secondary battery. This secondary battery (aside from the cars primary battery) was used to power up a portable DVD player, an mp3 player, and a mobile phone charger. Aside from this, the TEG also powered up the microcontroller that turned off the cars external lights through a relay when the lights are left on after the car has been turned off. The control circuit had an override which allowed the user to stop the microcontroller from turning off the external lights if the user extensionally left them on. Simulation was conducted before actual attachment to the automobile. Actual driving was also done to fully test the system. Data were gathered to test which parameters (speed, RPM, temperature) affects the output of the system. The factors affecting the performance of the system were also determined. Moreover, the lifespan of the battery was investigated with and without the TEG charging the secondary battery. Since the power required by the system itself was only minimal compared to the power capability of the secondary battery itself, the rest of the power was implemented in certain applications in the automobile itself namely LCD TV, DVD player, mp3 player,

phone charger and a current-sense monitoring circuit for the cars external lights park lights, headlights and the signal lights. The current-sense monitoring circuit also provided input to the microcontroller whether or not the headlights are left on when the engine is not running anymore. The lights were automatically switched off at a certain time after the lights were left on. Also, an override switch was provided for the user to disable the turning off of lights if the user intended to leave it on. All the circuits in the system send and receive data through the interface circuit which serves as the systems backbone. The performance of the system was greatly affected by its physical set-up, the heat generated by the exhaust system, ambient air, material strength of the thermoelectric generator, road condition and the weather during testing. During the study, it was observed that proper heat transfer was very important. The cold side temperature should always be kept low in order to achieve greater power. Also, when the distance is farther and the vehicle is faster, greater combustion takes place that is why it was concluded that power generation will be maximized at highways. Another observation was about the battery used in the system. The battery was not capable of powering up two or more loads at the same time. It must be continually charged by the Thermoelectric Generator Module to supply more loads for greater lengths of time because slower charging of the battery means longer hours of powering up the said loads. This study is different in the researchers study in terms of source of heat and thermoelectric module used. They used the cars exhaust system as the source of heat

which was converted into power while in the study, researchers made use of the heat radiated by the roof. This study made use of thermoelectric generator with model number HZ-14 while the researchers used TEC1-12706. They made use of aluminum as heat sink. The studies were the same because they are both used DC-DC converter to boost the voltage. Both of them also used microcontrollers to monitor voltages. They also have almost the same loads.

Cruz, Enero and Samonte (2011) used the thermoelectric cooler as a generator to convert the waste heat of an air conditioning unit. In their study entitled The Optimization of Thermoelectric Generator Array for Harnessing Electrical Power from Air Conditioning Unit, the group developed a system that harnessed heat from the compressor of an air conditioning unit and converted it into electrical energy through the use of thermoelectric generator modules that were attached to it. This power created by the thermoelectric generator module is used to charge a battery. The circuit that comprised the system was designed by the proponents to evaluate the performance of the system as well as to produce an optimal output. Since the power required by the system is quite minimal, the rest of the power in the battery went to a certain small voltage loads to charge like mobile phones, mp3 players, LED Lamps, and as such. The study was greatly affected by different factors. First is the environmental temperature. When the system was placed outside, the output of the system is lower than expected. Another factor that affected the output of the system was the dissipating of

heat from hot side to the cold side of the thermoelectric generator, thus, lowering the systems output. The difference of these two studies was the source of heat. This study made use of the heat coming from the air conditioning units compressor. Both of these studies made use of DC-DC converter to boost the output voltage produced by the system. They almost have the same electrical loads to be powered up.

Yu, Paul and Bhunia (2008) characterized the thermoelectric energy harvested from the wasted heat in a microprocessor based on the change in temperature between processor die surface and environment. The researchers used the commercially available TEG in microprocessor in modeling, analyzing and measuring the thermoelectric energy conversion. The researcher developed analytical model to accurately estimate the recycled energy considering the non-uniformity of temperature distribution in the die surface. Different possible arrangements for TEG in the processor were experimented to know best possible configuration that can provide optimum power. The experiment showed that the best position was when TEG was attached on the section of the copper plate which was exactly above the CPU with upper surface being cooled using cold surface. The said configuration can harvest ~7mW of power from the processor for average workload. The researchers concluded that the possible application of the recycled energy, even if it is only in several mW, was to drive an electro-osmosis system to cool the CPU. Electro-osmosis is considered as an efficient cooling mechanism for modern microprocessors which driving voltage may vary from mV to several volts depending on its dimension.

The system made in the study produced only a small amount of power which cannot be used in practical applications. The main difference of this study and the study to be conducted, like the previous studies, is the heat source. The source of heat that was converted into electrical energy was the central processing unit (CPU) of a computer. The same with the study to be conducted, this study used thermoelectric coolers as generators.

Eakburanawat and Boonyaroonate (2006), with the study Development of a Thermoelectric Battery-Charger With Microcontroller-based Maximum Power Point Tracking Technique where the objective of the study was to develop a thermoelectric generator (TEG) battery charger that used waste heat or another heat source as the direct input power. In the study, an electric heater was used as a heat source to supply heat energy to the hot side of TEG. A heat sink and a cooling fan was used to maintain a constant cold side temperature. Single-ended primary inductance converter (SEPIC) DC-DC converter was applied and controlled by a microcontroller with the maximum power point tracking (MPPT) to condition the output current. The input impedance of the DC-DC converter was controlled directly by changing the duty cycle of the gate driving signal. The value of the battery-charging current was directly controlled by the duty cycle of the pulse width modulation (PWM) control signal, which was applied to the DC-DC converter. An output power increased results to both a higher output current and a higher PWM control signal duty cycle, until the maximum power was transferred to the load. The system had a maximum charging power of 7.99 W which was better than direct charging by approximately 15%.

The design of the system is shown in Figure 3. The power generator was consisted of six TEG modules connected electrically in series. The SEPIC DC-DC converter was consisted of a RFP50N06 power MOSFET rated at 60V 50A. The output of a SEPIC DC-DC converter was connected to a 6 V, 12 Ah battery. The MPPT controlsystem made of the 8-bit ATMEL microcontroller unit T89C51AC2 and features 5-I/O port, 8-bit PWM on-chip, 10-bit resolution A/D converter with 8 multiplexed inputs and the signal conditioner. The microcontroller unit used by the control program measured the signals required for the power flow control. The signal conditioner made of a 0.5 carbon-metal film resistor was connected in series with the battery to measure the charged current from the system and sent it to the non-inverting amplifier circuit. The output signal of a non-inverting amplifier was sent to the internal A/D converter of a microcontroller to convert it to digital data to be used in the control program. The output PWM channel of a microcontroller was connected to the complementary transistors to amplify the output PWM signal.

FIG.3 The Schematic diagram of proposed system

This study was tested in a controlled environment and was not tested in an actual application. The only aim of this study was to charge a battery and not for practical use such as lighting a bulb or powering up a light electrical load. It did not even monitor the charging of the battery, which could damage the battery due to overcharging. It used a cooling fan and an aluminum heat sink for its cooling system. It had a microcontroller as a component and it was used to control the duty cycle of the gate driving the signal of the DC-DC converter to amplify the output voltage. Both studies used DC-DC converters for amplification of the output voltage.

On the other hand, Russel (2011) used the thermoelectric cooler to develop a cooling system for computer chip to improve reliability and prevent premature failure. The researcher in this project focused on the system level cooling using a hybrid thermal management system which involves thermoelectric cooler (TEC) modules, heat pipes and an air cooled heat sink. Russel combined the two methods in cooling electronic packages: passive and active techniques. The hybrid thermal management system considered here was consisted of two thermally parallel paths: (i) a conventional heat pipe based passive path and (ii) a TEC based active path. The passive path was consisted of heat pipes and heat spreaders with a finned heat sink and the TEC path was consisted of two TEC modules with a second set of heat pipes and heat sink. Figure 5 shows the schematic diagram of the hybrid thermal management system.

The TEC in the system was not always electrically on, when the temperature in the die surface is tolerable, the cooling system of chip is heat pipes which will be cooled by the fin heat sink by the ambient temperature by natural convection. But at higher ambient temperatures or high processor heat loads, the thermoelectric cooler electrically turned on with the necessary amount of current that kept the chips temperature below its safe operating temperature. Figure 4 shows the schematic diagram of the hybrid thermal management system.

FIG 5: Schematic of the hybrid thermal management system.

The advantage of this hybrid system compare to the conventional computer chip cooling system was that there was thermoelectric cooler that turned on and off depending on the temperature needed for the chip to operate at its safe mode. This study is mainly different from the researchers study because the TECS in Russels study were used as cooling system and its cooling effect was controlled depending on the temperature needed. Another difference was the heat load. A computer chip had a smaller heat load compared to heat radiated by the roof and other heat sources.

Conceptual Framework INPUT PROCESS OUTPUT

Infoware

Thermoelectricity Heat Transfer Power Electronics Peltier Effect Seebeck Effect Energy Conversion Engineering Materials Technoware Peltier Module DC-DC Converter Powerbank Thermal Paste Heat Sink Voltage Regulator Aluminum Plate G.I. Metal Plate Infrared Thermometer Multi-tester Soldering Iron Rivets Bolts and Nuts Water Spray Paint Silicon Sealant Humanware Engineers Electronic Technician Orgaware DLSU Linkages

Planning Identifying problem Data Gathering Circuit Design Component Familiarization

System Development Feasibility Design Cooling System Design Fabrication Testing Evaluation

ROOF-BASED ELECTRIC GENERATOR

FIG.6 Conceptual Framework

Figure 6 shows the processes involved in the study of converting the radiated heat by roof into useful electricity. On the Input side, the researchers showed the different Engineering theories that are needed to considered in developing the energy conversion system, the materials and measuring instruments to be used. This also includes the experts that are knowledgeable in their respective fields. The Process side is composed of different courses of action that has to be done in order to accomplish the project. This includes planning, where data gathering, circuit design, and familiarization of components takes place, system development where feasibility and cooling system design happens, fabrication, testing and evaluation. The output side is the product of Input and Process side, which is the utilization of radiated heat by roof converted into electricity using thermoelectric module for household use.

Hypothesis The researchers believe that it is feasible to convert the thermal energy from any heat source within the household to a useful electrical energy. The system developed was able to convert the heat radiated by the roof into useful electrical energy.

Definition of Terms

Active Technique is a method of cooling electronic packages which require external power to cool the electronics. Coefficient of Performance (COP) of a heat pump is the ratio of the heating or cooling provided over the electrical energy consumed. The COP provides a measure of performance for heat pumps that is analogous to thermal efficiency for power cycles. Conductor is any type of material that permits the flow of electric charges in one or more directions. Couple A pair of thermoelectric elements of one N-type and one P-type connected electrically in series and thermally in parallel. Because the input voltage to a single couple is quite low, a number of couples normally are joined together to form a "module." DC voltage refer to power systems that use only one polarity of voltage, and to refer to the constant, zero-frequency, or slowly varying local mean value of a voltage. Die Another term for chip. Duty Cycle The percent of time that an entity spends in an active state as a fraction of the total time under consideration. Electrical generator Device that converts mechanical energy into electrical energy Electro-osmosis is the motion of liquid induced by an applied potential across a porous material, capillary tube, membrane, microchannel, or any other fluid conduit. Energy Harvesting The process by which energy is derived from external sources captured, and stored. Error Amplifier The most commonly encountered in feedback unidirectional voltage control circuits where the sampled output voltage of the circuit under control is fed back and compared to a stable reference voltage. Heat Pipes A heat pipe or heat pin is a heat-transfer device that combines the principles of both thermal conductivity and phase transition to efficiently manage the transfer of heat between two solid interfaces. Heat Pump A device that transfers heat energy from a heat source to a heat sink against a temperature gradient. Heat pumps are designed to move thermal energy opposite the direction of spontaneous heat flow.

Junction An interface in a semiconductor device between regions with different electrical characteristics. Maximum power point tracking (MPPT) is a feature of power equipment that enables it to follow the ever-changing maximum power point of a PV array - typically solar panels, though optical power transmission systems can benefit from similar technology throughout the day in order to deliver the most power possible. Negative Feedback Occur when the result of a process influences the operation of the process itself in such a way as to reduce changes. Passive Technique Defined as those where no external power is required for cooling the electronic packages Relative Energy Densities The amount of energy stored in a given system or region of space per unit volume or mass, though the latter is more accurately termed specific energy. Signal Electrical waveform that contains information. Transducer A device that converts a signal in one form of energy to another form of energy. Transformer A static electrical device that transfers energy by inductive coupling between its winding circuits. Topology A relative arrangement of parts or elements. Viscosity A fluid property related to the interaction between fluid molecules that determines the fluids resistance to sheering forces and flow.

Notes in Chapter 2 Avadhanulu, M.N. and P.G. Kshirsagar. A Textbook of Engineering Physics for B.E., B.Sc. (Engg.), rev. ed. Ram Nagar, New Delhi: S. Chand, 2013. Bellis, Mary. How a Battery Works. About.com. Date Accessed September 19, 2013, http://inventors.about.com/od/bstartinventions/ss/How-A-Battery-Works.htm. Born, M. Natural Philosophy of Cause and Chance. London: Oxford University Press, 1949. Boylestad, Robert, and Louis Nashelsky. Electronic Devices and Circuit Theory. 7th ed. Upper Saddle River, New Jersey: Prentice Hall, 1998. Brain, Marshall. How Lithium-ion Batteries Work. How Stuff Works. Date Accessed Sepeterber 19, 2013, http://electronics.howstuffworks.com/everyday-tech/lithium-ionbattery1.htm Cengel, Yunus A., and Michael A. Boles. Thermodynamics: An Engineering Approach. 7th ed. Singapore: McGraw-Hill, 2011. Cruz, Robert Anthony M., Nob Dek S. Enero, and Edgar Francis O. Samonte. The Optimization of Thermoelectric Generator Array for Harnessing Electrical Power from Air Conditioning Unit. BSECE thesis, De La Salle University, 2011. Deriquito, Marieselle T. et al. Implementation of Microcontroller-Based Heat-to-Power Converter Using Thermoelectric Generator (TEG) Transducer Arrays in an Automobile System. BSECE Thesis, De La Salle University, 2010. Dyer, Stephen A. (ed.). Survey of Instrumentation and Measurement. New York: John Wiley & Sons, 2001. Eakburanawat, Jensak and Itsda Boonyaroonate. Development of a Thermoelectric Battery-Charger with Microcontroller-Based Maximum Powerpoint Tracking Technique. Applied Energy 83, no. 7 (July 2006): 687-704. Date Retrieved August 10, 2013, doi:http://dx.doi.org/10.1016/ j.apenergy.2005.06.004. Faires, Virgil Moring and Clifford Max Simmang. Thermodynamics, 6th ed. New York: Macmillan Publishing, 1978. Gridling, Gunther, and Bettina Weiss. Introduction to Microcontrollers. February 26, 2007.Date Accessed September 19, 2013, http://ti.tuwien.ac.at/ecs/teaching/courses /mclu/theory-material/Microcontroller.pdf.

Justin R. Farmer. A Comparison of Power Harvesting Techniques and Related Energy Storage Issues. MSME thesis, Virginia Polytechnic Institute and State University, 2007. Date Retrieved July 28, 2013, http://scholar.lib.vt.edu/theses/ available/etd-05212007200815/. Kamal, Raj. Microcontrollers: Architecture, Programming, Interfacing and System Design. New Delhi: Pearson Education India, 2009. Lee, Ho Sung. Thermal Design: Heat Sinks, Thermoelectrics, Heat Pipes, Compact Heat Exchangers, and Solar Cells. Hoboken, New Jersey: John Wiley & Sons, 2010. Liangtao Zhu. Adaptive Control of Sinusoidal Brushless DC Motor Actuators. Ph.D. diss., Michigan Technilogical University, 2008. Date Retrieved September 20, 2013, http://books.google.com.ph. Malvino, Albert Paul. Electronic Principles. 6th ed. New York: Glencoe/McGraw-Hill, 1999. Maniktala, Sanjaya. Switching Power Supplies A - Z. Burlington, MA: Newnes, 2006. Pollock, Daniel D. The Theory and Properties of Thermocouple Elements. ASTM, 1971. Rashid, Muhammad H, ed. Power Electronics Handbook : Devices, Circuits, and Application Handbook. 3rd ed. Burlington, MA: Butterworth-Heinemann, 2011. Russel, Md. Kamrul I. A Hybrid Thermoelectric Cooler Thermal Management System for Electronic Packaging. MASc thesis, McMaster University, 2011. Date Retrieved July 28, 2013, http://digitalcommons.mcmaster.ca/opendissertations/4972/. Starke, Michael Ralf. Thermoelectrics for Cooling Power Electronics. MS thesis, University of Tennessee, 2006. Date Retrieved September 19, 2013, http://trace.tennessee .edu/utk_gradthes/1797. White, Frank M. Heat and Mass Transfer. Reading, Massachussetts: Addison-Wesley Publishing, 1988. Yoder, Jesse. "Thermocouple technology: A matter of resistance and metal." InTech, March 2000: 76-77. Date Retrieved September 21, 2013, http://search.proquest.com/docview/ 208823914?accountid=141440 Yu Zhou, Somnathand Paul and Bhunia. "Harvesting Wasted Heat in a Microprocessor Using Thermoelectric Generators: Modeling, Analysis and Measurement," Design,

Yu Zhou, Paul, Somnathand and Bhunia. "Harvesting Wasted Heat in a Microprocessor Using Thermoelectric Generators: Modeling, Analysis and Measurement," Design, Automation and Test in Europe, 2008. DATE '08 , vol., no., pp.98,103, 10-14 March 2008 Date Retrieved September 19, 2013, doi: 10.1109/DATE.2008.4484669 Batteries. Date Accessed September 21, 2013 http://www.autoshop101.com/f orms/h6 .pdf. Battery (electricty). Wikipedia. Date Accessed http://en.wikipedia.org/wiki/Battery_(electricity) September 19, 2013,

Brief History of Thermoelectrics. Caltech Materials Science. Date Accessed October 3, 2013. http://thermoelectrics.caltech.edu/thermoelectrics/history.html Chapter 1: Intorduction to Microcontrollers - Architecture and Programming 8051 MCU MikroElektronika. Mikroe Date Accessed September 19, 2013, http://www.mikroe.com/chapters/ view/ 64/chapter-1-introduction-to-microcontrollers/ Chapter One - Introduction to Microcontrollers. New Age Publishers. Date Accessed September 19, 2013, http://www.newagepublishers.com/samplechapter/001599.pdf LED Lamp. Wikipedia. Date Accessed September 19, 2013.http://en.wikipedia.org /wiki /LED_lamp PIC Microcontroller. Wikipedia. Date Accessed September 15, 2013, http://en.wikip edia. org/wiki/PIC_microcontroller Thermal Grease. Wikipedia. Date Accessed September 15, 2013 http://en.wikipedia.org /wiki/Thermal_grease Thermoelectric Technical Reference, Ferrotec. Date Retrieved September 18, 2013 http://thermal.ferrotec.com/technology/thermoelectric/thermalRef01/ Understanding How a Voltage Regulator Works. Analog. Date Accessed September 21, 2013, http://www.analog.com/static/imported-files/pwr_mgmt/PM_vr_design_ 08451a.pdf

CHAPTER 3

RESEARCH METHODOLOGY

This chapter includes the research method/s, sources of data, data gathering procedures, research instruments, respondents, and data processing and statistical treatment.

Research Method Applied Research is the application of the results of pure research. This is the efficacy of theories and principles. In this type of research, the problem is already identified and a new system, device or method is applied to solve the problem. The researchers used the applied method to find ways to utilize the unused heat in the residential roof. It may investigate ways to develop a system that will produce a system based on engineering principles, laws, and theories that may be tested by the respondents.

Sources of Data The study will use primary and secondary sources of data. Primary data refers to the collection of data for the first time. This data is collected for some specific purpose. Primary research is more expensive and time consuming but it will give better results than secondary data. There are several methods that can be used for research like interviews, questionnaire, surveys, observation, focus group, and sampling. Secondary research method includes data that have been already collected by and readily available

from other sources. They are gathered from published statistics like census, housing and social data, published textbooks like Engineering textbooks, technical books, Encyclopedias, through internet research and documentation. Data Gathering Techniques and Procedures Data are collection of numbers, quantities, or records used as basis for drawing conclusion or making inferences. Data are what research is searching for and which are subjected to analysis, statistical procedures and interpretation so that inferences, principles, or generalization are drawn. There are two methods used in gathering data for this project. These are through observation, and questionnaire through acceptability test. Figures are gathered during observation and related concepts are being used in making the project. Last but not the least, the use of a questionnaire, which includes questions for the respondents prepared by the researchers. It is reliable and dependable source for data gathering. Research Instruments Questionnaire has been defined as a list of planned, written question related to a particular topic, with space provided for indicating the response to each question, intended for submission to a number of persons for reply. It is simply a set of question which, when answered properly by required number of properly selected respondent, will supply the necessary information to complete a research study. Questionnaires are used since it is reliable, it is easy to create, easy to understand and easy to answer. Questionnaires also reduce the uncomfortable feeling of the

respondent during interviews where there is eye contact between the interviewer and the interviewee.

Respondents The researchers have chosen the residents of Bulacan province. According to the 2010 Census of Population and Housing, Bulacan had a population of 2,924,433 people, the highest population in Region 3, which means that here, many are consuming electrical power. Also, if the respondents will be coming from here, it will be more convenient for the researchers since most of them are from here. Data Processing and Statistical Treatment The researchers used descriptive statistics to organize and evaluate the data that may be gathered using the research instruments chosen. Descriptive statistics are mathematical procedures for organizing and

summarizing numerical data. Mean is the arithmetic average of the scores. It is calculated by adding up all of the scores and dividing up all of the scores and dividing that total by the number of scores. The mean is the appropriate measure of central tendency when the data represent either an interval or ratio scale. Standard Deviation is the most frequently used of variability. The standard deviation is the most stable and appropriate measure of variability when the data represent either an interval or ratio scale. It includes every score in the calculation scores in the distribution of scores. By knowing the mean and standard deviation of a set of scores, you will have a good idea of what your distribution of scores look like. This will become much clearer in the impending discussion of the normal curve.

Notes in Chapter 3

Calderon, Jose F. and Expectacion C. Gonzales. Methods of Research and Thesis Writing. Mandaluyong City : National Book Store, 1993. Lunenburg, Fred C. and Beverly J. Irby. Writing a Successful Thesis or Dissertation : Tips Strategies for Students in the Social and Behavioral Sciences. Thousand Oaks, CA : Corwin Press, 2008. 2010 Census on Population and Housing. National Statistics Office. Date Retrieved December 24, 2012 http://www.census.gov.ph/sites/default/files/attachments/hsd/pressrelease/Central%20 Luzon.pdf

CHAPTER 4 PRESENTATION, ANALYSIS AND INTERPRETATION

This chapter presents the labelled isometric view of the project, detailed step by step fabrication procedures of the whole project. Instructions on how to operate the project, maintenance and essential trouble shooting procedures to address the encountered problems, detailed project costing, summary and interpretation of the acceptability test.

Detailed step-by-step Fabrication Procedures of the Project

1. Materials to be used (Aluminum bar, Galvanized Iron sheet) were measured based on the specifications given by the researchers.

2. The aluminum bar was cut to make an aluminum plate which will be the water container and cover for the cooling system of the project

3. The GI sheet which will act as the heat spreader was cut based on the size fit on the top of the aluminum water container

4. The cut aluminum was bent to form the water container.

5. The GI sheet, aluminum plate, and aluminum water container was drilled for assembly

6. Silicon sealant was applied between the aluminum plate and the aluminum pan.

7. The aluminum plate was pressed against the aluminum pan. After putting the plate on the pan, the copper tube which will be the passageway of water was cut and then attached to the pan.

8. Using rivets, each part were assembled based on the researchers specifications and design.

9. After the pan and the sheets were fabricated, 10 thermoelectric coolers (TEC112706) were arranged, but not yet fixed (for estimate), on the aluminum sheet and the wires were cut to the desired length.

10. After arranging the TECs, they were soldered for them to be connected in series. Every connection was wrapped with electrical tape to avoid disconnection.

11. Before fixing the TECs on the aluminum plate permanently, rubber were placed on the plate to act as stoppers so the TECs will not move once they are placed on the plate.

12. Thermal paste was applied on every space where the TECs will be placed.

13. TECs were fixed on the plate and thermal paste was also applied on every TEC.

14. The GI plate was already placed above the TECs and it was attached using bolts and knots.

15. Figure 7 shows the Voltage Conditioning Circuit used in this project.

FIG.7 Schematic Diagram of the Voltage Conditioning Circuit

16. Prepare the electronic components for the voltage conditioning circuit. The designed circuit was tested on a bread board before soldering it on a strip board. Troubleshooting was done to know if there are problems on the design.

17. After troubleshooting, the circuit was soldered on the strip board.

18. Put the circuit in a plastic enclosure.

Instructions on how to Operate the Power Harnessing Device 1. Put a maximum amount of 750ml of water in the pan through the tubes. 2. Clog each tube using rubber stoppers to avoid spillage of water. 3. Place the device carefully under the roof. 4. Connect the power bank into the device to store the generated electricity. 5. Once the power bank is full through the help of its indicator, safely disconnect the power bank and the device. 6. The generated electricity is now ready to use.

Maintenance Observation of the device must be done regularly to avoid possible damages of its parts. Also, TEC modules must remain in its dry place always. This will ensure that the device will operate properly and continuously without further ado. Troubleshooting 1. Leakage in the device. Remove the water through the tubes. Unscrew the bolts from the device and safely remove the TEC modules to avoid getting wet. Only place ample amount of sealant on the affected area and let it dry. Replace the TEC modules carefully on its original place. Screw the bolts with its nuts to secure the device.

2. Device is not Charging. Remove other materials carefully (water, bolts and nuts, galvanized iron metal sheet). After removing all materials, check if the connection of the TEC modules wires are still properly connected. If not, using soldering iron and soldering lead, connect the red wire with the black wire and so on (following series connection). If the user cant do the soldering works, consult the experts.

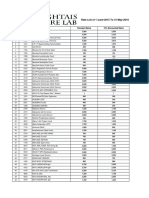

Detailed Project Costing

Price Subtotal Price(pesos) 110 11

Materials

Quantity

Size/Model (pesos)

Aluminum Pan Bolts

1 6

25cm x 12cm x 2.5cm 2cm length, 2mm diameter

110/pc 11/50pcs

Capacitor

1 1 1 1 2 1

220F/ 16v 2200F/ 16v 220F/ 25v 2200F/ 35v 1000F/ 35v 220F/ 50v 1N4001 eDC2420 Roll 27cm x 14cm 80mm x 40.5mm x 15mm n/a 2mm diameter KH-6 PWB-085-M 1k/ 0.5W

1.50/pc .50/pc 3 5 10/pc 4/pc 1/pc 139 15/roll 120/pc 39/pc 1/pc 49/ 50pcs 28/pc 480/pc 4/pc

1.5 .50 3 5 20 4 6 139 15 120 234 1 49 28 480 4

Diode DC/DC converter Electrical Tape Galvanized Iron Metal Sheet Heat Sink LED Square Nuts Plastic Enclosure Power Bank Resistor

6 1 1 1 6 1 6 1 1 1

Soldering Lead

Roll

69/roll Price

69 Subtotal Price(pesos) 90 30 130 3000 30 15 17 300

Materials

Quantity

Size/Model (pesos)

Spray Paint Strip Board Thermal Paste Thermoelectric Cooler Voltage Regulator Washer Wire Labor and Other Materials (Aluminum plate, Metal tube, Rivets, Sealant) Total

1 1 2 10 1 6 2m

400 ml 9cm x 7cm 20 ml 4cm x 4cm x 3.5cm LM7809 2mm diameter Solid wire/ No. 22

90/bottle 30/pc 65/bottle 300/pc 30/pc 15/50pcs 8.50/meter

4912

The Roof-Based Electric Generator project costs 4912 pesos including the materials used and the payment for the labor of the project.

Tabular summary of Acceptability Test SUMMARY OF ACCEPTABILITY TEST Variable Functionality 1. The device functions according to its intended 39 11 0 purpose 2. The device can produce the expected outputs 16 34 0 in a given period of time 3. The device is convenient to use and easy to 25 24 1 operate 4. The device is comparable to the existing or 0 19 12 similar device OVERALL 0 0 0 0 0 0 4.78 SA 4.32 A 4.48 A 5 4 3 2 1 V.I.

7 12 2.76 MA 4.37 A

Variable Reliability 1. There is consistency on the outputs/outcomes

2 1

V.I.

16 27

7 3 5 4

0 0 4.18 A 0 0 4.4 A

2. The device can meet/satisfy the users needed 23 24 outputs 3. The device is reliable in terms of strength, 21 24 capacity, and performance 4. High degree of security can be obtained when 23 23 using the device OVERALL

0 0 4.32 A 0 0 4.38 A 4.32 A

Variable Efficiency and Effectiveness

2 1

V.I.

1. The device meets the users objectives and 35 15 requirements

0 0 4.7

SA

2. The device can be used to its maximum design 27 21 capacity 3. The device operates efficiently and effectively 21 27 4. The device can enhance individuals learning 38 12 and skills OVERALL

2 2 0

0 0 4.5 0 0 4.38 0 0 4.76

SA A SA

4.585 SA

Variable

2 1

V.I.

1. The device can operate accurately with 27 17 minimum maintenance 2. The device can be adapted to changes in its 18 27 working condition 3. Trouble shooting/repair can easily be done. 23 17 4. The device can be operated accurately to its 23 24 operating time. OVERALL

6 5 9 3

0 0 4.42 A 0 0 4.26 A 1 0 4.24 A 0 0 4.4

A

4.33 A

Interpretation of the Acceptability Test Most of the end users agreed that the device functions according to its intended purpose. They also agreed that the device produce expected outputs in a given period of time, that it is convenient and easy to use. The respondents moderately agreed that the device is comparable to similar or existing device. In terms of reliability, the end users agreed that there is consistency on the devices output/outcome. They have also agreed that the device can meet their needs and it is reliable in terms of strength, capacity, and performance. Based on the acceptability test, the end users strongly agreed that the device is effective and efficient. They believe that the device has met their objectives and requirements and that the device can enhance individuals learning and skills.

Lastly, in terms of accuracy, the end users agreed that the device is accurate. They accept as true that the device can operate accurately with minimum maintenance. They agreed that it can adapt to changes in its working condition, and that trouble shooting can be easily done. The results of the acceptability test proves that the study is feasible enough.

CHAPTER 5 SUMMARY, FINDINGS, CONCLUSION AND RECOMMENDATION

The researchers observed that temperature is increasing rapidly due to climate change. Instead of wasting that heat, the group came up with the proposed device to harness that heat and convert it into electricity. This proposed device will not only recycle the unused heat but also gives convenience to the users when electricity shortage occurs. The study includes the design, fabrication and test of functionality. Each material is warily chosen to withstand different thermal conditions the device may conduct. In this project, aluminium plate, galvanized iron metal sheet and thermoelectric modules are used in the main part of the project. The design is cautiously prepared to ensure that the device will work properly and efficiently. The fabrication is done to ensure that the device is in its accurate size, alignment and positioning which can only be done by experienced experts in fabrication. This requires reasonable expenditures that is economical and provides good investment. The test of functionality is attained when the end-users are done with the acceptability tests provided by the researchers. The end-users are the residents within the province of Bulacan. The test offers answers which prove the feasibility of the study.

Findings During the acceptability testing of the device, the researchers found out the following positive and negative results. Positive results: 1. The device enhances individuals knowledge about new and modern technologies. 2. It can provide the minimum of 2 volts and a regulated voltage of 5 voltage which is sufficient enough to charge a power bank. 3. It is economic friendly due to the utilization of the unused heat. 4. It can provide electricity at times of power shortage

Negative results: 1. The electronic circuit are sensitive to sudden tremors that may cause glitch of the device. 2. The device may not provide the same outputs because of the varying temperature of the heat radiated by the roof.

Conclusion Upon analyzing the results, the researchers concluded the following based on the results: 1. The device is effective and functions according to its intended purpose. It is possible to directly convert thermal energy into electricity from a low temperature source like roof. The study is conducted to provide a device that harnesses unused heat and convert it into electricity. The acceptability tests forms were given to 50 different respondents. Respondents are residents within Bulacan province; plain housewives, college students, government employees, successful engineers, and retired senior citizens. According to the acquired data, most of the respondents think that the device is recommended to use as long as there is heat available thus it can adapt to changes in terms of its working conditions. Some says that the safety of the device and its durability must be well guaranteed though the device is timely due to climate change.

Recommendations The researchers welcome the ideas to further improve the study. After receiving the comments and suggestions from the respondents, the group has come up with the following recommendations: 1. Design a cooling system in order to maintain more desirable temperature difference that is more effective with this project. 2. Some potential alternative heat sources can be condenser of refrigerators and smoldering charcoal. 3. Design an adjustable handle to improve the support of the device. 4. Design a more efficient circuit to shorten the charging time of the power bank.

ROOF-BASED ELECTRIC GENERATOR

A Thesis Proposal Presented to the faculty of the department of Mechanical Engineering College of Engineering BULACAN STATE UNIVERSITY

In Partial Fulfillment Of the Requirements for the Degree of Bachelor of Science in Mechanical Engineering

By:

Bulaong, Robertson C. Capiral, Raymart T. Castillo, Mark Rod N. Crisostomo, Rose Margarette S. Fajardo, Marione T. Qui o, Rolando Jr. R.

Engr. Felizardo S. Camilon, Jr.

Thesis Adviser

Anda mungkin juga menyukai

- Related LiteratureDokumen11 halamanRelated LiteratureKim BagotBelum ada peringkat

- Thesis It!!!Dokumen20 halamanThesis It!!!Arthur Maderse Ramo Jr.100% (1)

- Analysis of The Eye of A NeedleDokumen3 halamanAnalysis of The Eye of A NeedleAlexandria Styles67% (3)

- 352 ML of Chlorine Under A Pressure of 680Dokumen5 halaman352 ML of Chlorine Under A Pressure of 680EllaAdayaMendiolaBelum ada peringkat

- Made By: Alas Architectural FirmDokumen16 halamanMade By: Alas Architectural FirmFortune Floresca100% (1)

- Energy Harvesting From Road Pavements Using Thermoelectric Generators at Tuguegarao City, PhilippinesDokumen47 halamanEnergy Harvesting From Road Pavements Using Thermoelectric Generators at Tuguegarao City, PhilippinesSofia Delos SantosBelum ada peringkat

- Final Report OJTDokumen17 halamanFinal Report OJTSonic HedgehogBelum ada peringkat

- Final Revised Manuscript of ResearchDokumen35 halamanFinal Revised Manuscript of ResearchKay Laguna100% (1)

- Science 8Dokumen3 halamanScience 8Julia Geonzon Labajo100% (1)

- PEC Lesson 1Dokumen27 halamanPEC Lesson 1John Oyan EstilloreBelum ada peringkat

- Project Proposal - Variable DC Power SupplyDokumen10 halamanProject Proposal - Variable DC Power SupplyNoman NaimatBelum ada peringkat

- DC Motors and Generators Reflection PaperDokumen1 halamanDC Motors and Generators Reflection PaperMicah TayagBelum ada peringkat

- Sta. Elena Integrated School 4 Periodical Examination in Science 7Dokumen3 halamanSta. Elena Integrated School 4 Periodical Examination in Science 7Hazale AzasBelum ada peringkat

- Lightning Arrester Circuit Breaker: Description Symbol Description SymbolDokumen25 halamanLightning Arrester Circuit Breaker: Description Symbol Description Symbolpeter vanderBelum ada peringkat

- GRADE 7 QuestionnaireDokumen7 halamanGRADE 7 QuestionnaireKay Tracey Urbiztondo80% (5)

- Power ProblemsDokumen4 halamanPower ProblemsKelvin AbellaBelum ada peringkat

- Literature ReviewDokumen5 halamanLiterature ReviewLarenze Pelagio Dimaandal100% (2)

- Eu 2-M2-3a-Surname, First NameDokumen3 halamanEu 2-M2-3a-Surname, First NamePoker FaceBelum ada peringkat

- Design and Fabrication of Canal Cleaner Machine in Replacement For Manual Cleaning of Canal in Molugan El Salvador, Misamis OrientalDokumen10 halamanDesign and Fabrication of Canal Cleaner Machine in Replacement For Manual Cleaning of Canal in Molugan El Salvador, Misamis OrientalJonabel Lenares BorresBelum ada peringkat

- Activity 1: Let'S Check!Dokumen6 halamanActivity 1: Let'S Check!Arlyn RagudosBelum ada peringkat

- Chapter 5energy Freq WavlghCalcDokumen1 halamanChapter 5energy Freq WavlghCalcPatrice MendozaBelum ada peringkat

- Mathematics: Quarter 2 - Module 2: Problems Involving Polynomial FunctionsDokumen16 halamanMathematics: Quarter 2 - Module 2: Problems Involving Polynomial FunctionsRIZAL ZANORTE0% (1)

- Age, Work, Mixture, Digit, Motion ProblemsDokumen16 halamanAge, Work, Mixture, Digit, Motion ProblemsDebbie Abaoag CariñoBelum ada peringkat

- Eng10 - Q1 - Module1 - Lesson1 - Task18, 19 and 20 - in Your Own Words - Imprint in Print - Design - Dealing With Personal ChallengesDokumen5 halamanEng10 - Q1 - Module1 - Lesson1 - Task18, 19 and 20 - in Your Own Words - Imprint in Print - Design - Dealing With Personal ChallengesShaniah Sumaoang0% (1)

- Sample Power LayoutDokumen1 halamanSample Power LayoutKenneth PamintuanBelum ada peringkat

- Week3 Lesson3 PDFDokumen54 halamanWeek3 Lesson3 PDFMARKDANIEL ALAYONBelum ada peringkat

- Types of Computer System ErrorDokumen3 halamanTypes of Computer System ErrorasdasdadBelum ada peringkat

- EE114-1 Homework 2Dokumen2 halamanEE114-1 Homework 2Renzo AlvizBelum ada peringkat

- Combol PDFDokumen3 halamanCombol PDFJay Em Kristel MengulloBelum ada peringkat

- Piezoelectric FloormatDokumen43 halamanPiezoelectric FloormatEuri Espiritu100% (1)

- Interfacing Blynk IOT Platform For Monitoring Temperature and Humidity in Poultry FarmDokumen3 halamanInterfacing Blynk IOT Platform For Monitoring Temperature and Humidity in Poultry FarmInternational Journal of Innovative Science and Research TechnologyBelum ada peringkat

- Sci9 Q4 Mod7Dokumen23 halamanSci9 Q4 Mod7Althea Faye MonterialBelum ada peringkat

- Procedure in Interpreting The Tolerance of ResistorDokumen11 halamanProcedure in Interpreting The Tolerance of ResistorDave Fontejon50% (2)

- Water Waste Collector Research MaterialDokumen12 halamanWater Waste Collector Research MaterialJanna May Villafuerte100% (1)

- Literature Review HydroelectricDokumen3 halamanLiterature Review HydroelectricAiman Hanan57% (7)

- Review of Related Literature Rev 3Dokumen21 halamanReview of Related Literature Rev 3Richelle Piollo0% (1)

- Free Fall ACTIVITYDokumen2 halamanFree Fall ACTIVITYraquel rosales0% (1)

- SpeechDokumen1 halamanSpeechRosalie AbaoBelum ada peringkat

- DraftModule - ENGG 406 Engineering ManagementDokumen438 halamanDraftModule - ENGG 406 Engineering ManagementWingel LullabyBelum ada peringkat

- Theoretical and Conceptual DUWTRWHDokumen6 halamanTheoretical and Conceptual DUWTRWHReynil LabriagaBelum ada peringkat

- 12Dokumen4 halaman12Gerald AbenojaBelum ada peringkat

- Science 9 Physics Curve Me On An InclineDokumen3 halamanScience 9 Physics Curve Me On An InclineNouiea Bernardelle Acabal0% (1)

- Reflection Paper About Construction SafetyDokumen7 halamanReflection Paper About Construction SafetytheothersideBelum ada peringkat

- African LAnd Snail Shells As An Additive Components For Hollow Blocks MAking 1Dokumen17 halamanAfrican LAnd Snail Shells As An Additive Components For Hollow Blocks MAking 1Elizabeth Reyes FullaBelum ada peringkat

- Solid Homework 2Dokumen4 halamanSolid Homework 2nadaynBelum ada peringkat

- Soal Latihan FisikaDokumen54 halamanSoal Latihan FisikaGinanjar Dika100% (1)

- Cogon Fiber in Earth Brick As A Sustainable Building Material - ReportDokumen74 halamanCogon Fiber in Earth Brick As A Sustainable Building Material - ReportLEKI DORJIBelum ada peringkat

- Allowable Ampacities of Insulated ConductorsDokumen2 halamanAllowable Ampacities of Insulated ConductorsJohn Paks100% (2)

- Tle10 - Ia - Eim - q2 - Mod5 - Basicelectricalmaterials - Symbolsfoundinelectricalplan - v3 (53 Pages)Dokumen19 halamanTle10 - Ia - Eim - q2 - Mod5 - Basicelectricalmaterials - Symbolsfoundinelectricalplan - v3 (53 Pages)michelle divinaBelum ada peringkat

- Activity 4.3: A. Geothermal Power Plants in The PhilippinesDokumen5 halamanActivity 4.3: A. Geothermal Power Plants in The PhilippinesYuan Andrei Santos100% (2)

- CHAPTER 1 Solar Powered Power BankDokumen9 halamanCHAPTER 1 Solar Powered Power BankDiane LogroñoBelum ada peringkat

- g-10 Activity Unit2Dokumen10 halamang-10 Activity Unit2marjja millanBelum ada peringkat

- Chapter 2Dokumen8 halamanChapter 2Troy Gold100% (1)

- Critique PaperDokumen3 halamanCritique PaperaljohnBelum ada peringkat

- Answer Sheet in 2nd Unit Test in Science 10Dokumen1 halamanAnswer Sheet in 2nd Unit Test in Science 10RODJHEN ANNE P. BARQUILLA100% (1)

- Electric Potential and Potential Difference: Lesson 3.2Dokumen48 halamanElectric Potential and Potential Difference: Lesson 3.2EllyBelum ada peringkat

- Simulab Activity 1.1. Electrical Components, Devices, Instruments and SymbolsDokumen6 halamanSimulab Activity 1.1. Electrical Components, Devices, Instruments and SymbolsGrace Bello100% (1)

- Battery Electrolyte Experiments From Mango, Pineapple, and Dragon Fruit Waste Research PaperDokumen29 halamanBattery Electrolyte Experiments From Mango, Pineapple, and Dragon Fruit Waste Research PaperKelvin SabastianBelum ada peringkat

- Naga City Science High SchoolDokumen37 halamanNaga City Science High SchoolYna ForondaBelum ada peringkat

- Energy Harvesting Charger Using Thermo-Electric AmplifiersDokumen55 halamanEnergy Harvesting Charger Using Thermo-Electric AmplifiersPj PenachosBelum ada peringkat

- Ace of Spades + Outlaw 125 2019Dokumen85 halamanAce of Spades + Outlaw 125 2019Nelson RodrigoBelum ada peringkat

- Electrical Inspections: Infrared ThermographyDokumen28 halamanElectrical Inspections: Infrared ThermographyManish RajBelum ada peringkat

- Air Tunnels: Submitted By: Priyanka Sinha SK MD Sibli Akram Ananya Sreyansri NandaDokumen8 halamanAir Tunnels: Submitted By: Priyanka Sinha SK MD Sibli Akram Ananya Sreyansri NandaPriyanka SinhaBelum ada peringkat

- HSE Plan For RSPL ProjectDokumen10 halamanHSE Plan For RSPL ProjectSaibabu SiripurapuBelum ada peringkat

- Inventory of Flood Bund PunjabDokumen26 halamanInventory of Flood Bund PunjabguildkeyBelum ada peringkat

- YearbookDokumen55 halamanYearbookGODWIN IRIMORENBelum ada peringkat

- Board of Technical Education Uttar Pradesh Lucknow: CODE 2298Dokumen2 halamanBoard of Technical Education Uttar Pradesh Lucknow: CODE 2298Md Shaaz100% (1)

- 100% Chemical-Free Solution For Organic Farming: Where Health Is A HabitDokumen2 halaman100% Chemical-Free Solution For Organic Farming: Where Health Is A Habitamit4118Belum ada peringkat

- X-Ray Radiation and Gamma RadiationDokumen13 halamanX-Ray Radiation and Gamma RadiationVence MeraBelum ada peringkat

- IBH Link UA Manual PDFDokumen302 halamanIBH Link UA Manual PDFjavixl1Belum ada peringkat

- Darmoatmodjo 2023Dokumen7 halamanDarmoatmodjo 2023mayaBelum ada peringkat

- FEED Deliverable List (Sample) : Project InformationDokumen3 halamanFEED Deliverable List (Sample) : Project Informationamilasri100% (1)

- Radiant ThinkingDokumen4 halamanRadiant Thinkingeehwa88Belum ada peringkat

- E2788-11 Standard Specification For Use of Expanded Shale, Clay and Slate (ESCS) As A Mineral Component in The Growing Media and The Drainage Layer For Vegetative (Green) Roof SystemsDokumen3 halamanE2788-11 Standard Specification For Use of Expanded Shale, Clay and Slate (ESCS) As A Mineral Component in The Growing Media and The Drainage Layer For Vegetative (Green) Roof SystemsSatya kaliprasad vangaraBelum ada peringkat

- Standard MissileDokumen2 halamanStandard Missilemadox_3m100% (1)

- Norma ASTM C171Dokumen2 halamanNorma ASTM C171Jony Gutiérrez100% (1)

- Rate List of 1-June-2015 To 31-May-2016: S.No Code Test Name Standard Rates 15% Discounted RatesDokumen25 halamanRate List of 1-June-2015 To 31-May-2016: S.No Code Test Name Standard Rates 15% Discounted RatesMirza BabarBelum ada peringkat

- Thermal Imaging Tech ResourceDokumen20 halamanThermal Imaging Tech Resourceskimav86100% (1)

- Psychological Factors Influencing Technology Adoption A Case S - 2021 - TechnovDokumen17 halamanPsychological Factors Influencing Technology Adoption A Case S - 2021 - Technov6helmi6nauval6Belum ada peringkat

- Project Final PDFDokumen98 halamanProject Final PDFNgonidzashe MhukaBelum ada peringkat

- PerthDokumen21 halamanPerthjohn_wlmns3929Belum ada peringkat

- 0 Act Sunum 2020 NewwDokumen58 halaman0 Act Sunum 2020 NewwPınar AdsızBelum ada peringkat

- 00 Calculator Techniques 02Dokumen5 halaman00 Calculator Techniques 02Sealtiel1020Belum ada peringkat

- Civil 416Dokumen2 halamanCivil 416tskh11Belum ada peringkat

- Harrington SOAP NoteDokumen5 halamanHarrington SOAP NoteDanielle100% (4)

- Ronstan Regatta Watch InstructionsDokumen7 halamanRonstan Regatta Watch InstructionsMatt HartmanBelum ada peringkat