Chapter 4 Injection Test

Diunggah oleh

ZakariarayDeskripsi Asli:

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Chapter 4 Injection Test

Diunggah oleh

ZakariarayHak Cipta:

Format Tersedia

!

Theprocedureforthetypecurveanalysis(Figure13)canbeoutlinedasfollows(Earlougher,1977;

Horne, 1995):

o o r

(A0 u-sing the same scale as that ofthe type curve' The daia are plotted as 1og Ap versus log horizontal grid lines oveg thJother by keeping the vertical and The curves are then ;;;t;" found' is paratlel until the best match fixed point pressure and time values are read from some The best match i, "t"*r-""Jtr,e Ltuandtou' it"J p"i"t) on both $aphs, LPM'pDM'

For infinire acting system, the

permeabilitv-T-:".ff?ut

*n

storativitv are given

6v't'"

"'pt""lil+i

(3.3s)

= l-6),

=

kh /At\

c,h

ir&\h)*

0.001 0.0r

0.1

l0

tum

FIGUR-E l4: fllustration of a derivative plot (Home, 1995)

*

0

e

Until a few decades ago, the plotted data and the type curyes were compared by hand. The use of computers and software developed for well testing, such as Well Tester used in Iceland (introduced in Chapter 4), make the calculation ofthe derivative much easier, and this has become one ofthe major tools in well test analysis methods (Bourdarot, 1998; Gringarten,2008). 3.6 Deconvolution

e

ui

\peconvolution has received much attention recently (Von Schroeter et al., 2001; Levitan, 2005; Ilk et

fl., 2005; Levitan et a1.,2006). Deconvolution is not a new interpretation but a new tool to process pressule and flow mte data (Gringarten, 2008). According to the general definition, the aim of deconvolution is to calculate the impulse response of the system, based on the pressure response and both constant and varying flow rates.

The data used for deconvolution are bettel from built up data than drawdown data, because of their good quality compared to dlawdown data. The deconvolution does not assume a reservoir model but it assumes a mathematical rnodel. It is a direct method using non-linear regression compared to the conventional methods used for well testing. Changing skin, changing wellbore storage, missing or incon'ect initial pressule and gaps in the data can have a significant effect on the shape of the deconvolved type curves (Gringarten, 2008).

The steps for the deconvolution method can be described as follows:

FIGURE

rr, lrurtrutlon ofa type.uru. *ur.nrnlfor

an interference test (Earlougher' 1977)

'3.5 Pressure derivative Plot TheintroductionofthepressurederivativeintheS0'sbyBourdetandothers(Bourdetetal.,1983; had of well test interpretation, which until that time Bourdet et al., lggg),*nrroi."J,r,. science derivative the with analysis. curve type the and pro, mostly been based on ,t" **i-igrriii.i" In during a tes period is considered forthe analysis' aooroach, the time l.u," o' "t'*g"-iiftt"'o respect to the logarithm with taken is partiai-derivative ,h" r"girn", oid", to emphasise the .adiai ilo"* a rff {eiura"t et at., le83). rhe derivative plot (Figure 14) provides il;; #r;;"i "orr, advantage of (Lt) andfog (tfr) versus log (^t!

:

(Lp)versus log simultaneous presentation of log characteristics that to,display in,a single g.uiir many different porritr" i, it that is plot the derivative 1995)' (Home' plots *oufa-oth.t*iL require different

:::

. . o o o . .

The partial derivative

tff

is assumed,

The starting point, 4 on the type cuwe is assumed, The derivative is then integrated to obtain the type curve, The type curve is superposed with flow rates, The calculated results are compared with the measured data, The total error is quantified, The derivative is rnodified and the procedurc repeated until the minimum error square sense is found.

in a

least

.\

I

Resewoitpermeability,wellborestorageand.skin.canbedetermineddirectlyusingthemeasured oith" derivative has been reached' when the

curve and irs derivative

pr;id;; ,i,"iii" *r1ir*ion

flowatearlytimecorrespondstopurewellborestorage,plssureandpressurederivativecurveswill ;";;;;;;'r"t, riopr.t..uigt" line on the log-log plot (Horne' 1995)'

il

t1

be used in order to estimate the reservoir properties. Different deconvolution methods and mathematical formulas can be found in Von Schroeter et al., 2001; Levitan, 2005; IIk et a1.,2005; Levitan et al.,2006.

The deconvolution method rmoves the restriction for a shut in, but does not remove the need for type curves. The final |esult of this identification method is an estimate of a tlpe curve. This type curve can

ii

Ii

[li t1 1t

20

2t

4. INJECTION TESTS

4.1 Introduction AcommonprocedureinlcelandandelsewhereistoperformaStep-rateinjectiontestSoonafterthe into the injection tests consist of injJcting cold water dri6ing and completion of tir"-ior"toie. The temperature (pressure and temperature

pressure and borehole and simultaneourry."*.aag downhole injection test, opposite orofiles are analysed

i, ch"p;-it.iie

to the production test, causes an

In.i"ut. of the pressure in the well'

-;t;;;tr-y Thewofoldpurposeoftheinjectiontestistostimulatethewellandtoobtaindatathatcanbe of rhe formation together with the skin g," t#rriliri;; analvsed to calculare al 2006)' is;;nur.ton et al., I 98 l; Axelsson et '

index (ll)' is evaluated durins iniection test is the injectivity Another characteristic of the borehole that the reflect to believed is and well of an inj"Jtion The injectivity ina"* preaicir"'tie';;;;;";.. the reservoir permeability' It is defined better the ;alue, success of the *ell, meantng in the to it" change in'reservoir pressure measured by the ratio of the change

FIGURE 15: Pressute changes during step rate injection test for RN-l7b Figure 15 shows the steps ofthe injection test and the pressure response for each step. A small hump on the pressure response for step I is observed, which could be an indication ofan error from the tool during measurement. Step 2 shows a pressure drop towards the end ofthe step and this could indicate a small opening in the reservoir. The last step, step 3 indicates a fallofftest and it can be observed that the pressure did not reach equilibrium at the end ofthe test. For this reason, it was decided to disregard this step in the modelling.

borehole:

tifi$t;;;;il; "ii":".,i*"fi.*i.t"

,, -aJ ,,_Lp

$.t)

1 \

ThenumedcalsoftwareWellTesterV.l.0'0(Juliussonetal.,2008)isusedformodellingand software that was developed at the l.{

Tester is a computer calculation of the reservoir puru*"i".r. well multistep manipulation and analysis of well.tests (mainly a." *'t (lsoR) GeoSurvey Iceland (Juliusson et "rai. is dividld into six simple steps process Thi fields. g"oit".n,"t injection tests) in lcelandi" al., 2008):

The well test model selected for RN-l7b assumed a homogeneous reservoir, constant pressure boundary, constant skin and a wellbore storage. The pressure gauge depth was an input into the and the data were cleaned. Using this model, a non-linear regression analysis was performed I Pro8ram / to find the parameters of the model that best fit the data. The best model was calculated by considering

step

I and 2, respectively

and then, both steps together.

/'?

.ParfimetersiTheestimltionofthereservoirtemperafureandpressure,thewellboreradius, are fed into the program in

of injection steps are defined; oModiff:Thisstepisdesignedtoclean,resampleand.correctthedatafortemperature

of the well test; variatilns within the wellboie during the course

the viscosiry oftn" this steP; Set stepi:The number

n"iilil"

p"."rlty r"a,f,. totafco*pressibility

The results from the regression analysis for step I and step 2 are shown graphically in Figure B.1 and B.2. Figure I 6 shows the best model calculated for RN- l7b. The estimation of the parameters obtained on the basis of the steps and model selected for both step 1 and 2 (Table 1) indicate a permeabilitythickness of I Dm, a storativity of 7'10-8 m34Pa.m2; and an injectivity index of 1.3 (L/s)ibar. The values ofthe permeability+hickness and the injectivity index can be interpreted as a poor permeability in this part ofthe reservoir although the skin is negative.

.Model:Inthisstep,themostappropriatemodelforthereservoirbeinginvestigatedisselected. with the pressure data on a log.log scale To achieve this, the derivativi plot is use<i, along

graPh.

.Modelall:Thistabisdesignedtofindthemodelparametersthatgivethebestcorrespondence betweenamulti-stepmodelanddataset,modelingallstepstogether.--. ofthe modeling' program prepares a report ofresults at the end

ReportiThe

storativity and the used t?-estimate the transmissivity, the In the following Section 4.2, Well Tester is of the results summary the gives 4 3 RN-Zf . iection injectivity indices for *"ff, iff.i-iiU, nf.f-iS *a from Well Tester. FIGURE l6: Fit between model and measured data for step I and 2 for well RN-17b t.

!

I

4.2 Well Tester modelling 4.2.1 RN-l7b injection test

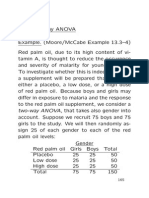

TABLE l: Summary of the results from non-linear regression parameter estimate

using injection test data from well RN- I 7b Step

i)

WellRN-lTbisadirectionalwellanditwasdrille<lin2003toameasureddepth,MDof30TTm(True of drilling test inxN-17b started just after completion vertical deprh, TvD is 2g0a mi. rr," hJr"i"" the same day and the injection rates wefe performed ** t".t io:"Lio'" three-stei in December 200s. A test was to zo.l t ls, respectivcly. The total injection from 20.1 to 30.3 us; 303 ;il.; ur and44.9

done in

Transmissivity

(m3(Pa.s))

1.08.10*

1.4.10-E

1. t

Storativify

(mr(Pa.m2))

Permeability

thickness Skin

-0.7

Injectivity

index

lTlml

0.9

1.24

(Lis)/bar

1.5

4.5.10'

3.03.10-8 7.04.10-8

to a depth of 2300 m' hours with a pressure gauge being lowered

land2

-0.9

-0.7

I

1.7

.31

4't

0-8

1.02

7)

23

I i I

I

4.2.2 RN-f

injection test

4,2,3 RN-23 injection test RN-23 is a directional well that was drilled in early 2006 and completed in late March at a depth of 1924 m. A three step rate i4jection test was performed after driliing with a pressure gauge being lowered to a depth of 1330 m. The three step injection rates were from 65 to 30 L/s; 30 to 45 L/s and fs,to 60 L/s, respectively The wetl test model selected for RN-23 assumed a dual porosity reservoir, infinite boundary, constant skin and a wellbore storage. Figure l9_shows the steps of the injection test and the pressure response for each step. It can be observed that data are missing in the pressure response foi step l. Foi this reason, this step was not considered in the modelling. Therefore, the best model was cilculated by consideiing only pressure build-upfor step 2 and 3, respectively and then, both steps together. The iressure guuj" d"pth *u. un input and the data were cleaned. results from the regressiin analysis ior the iniividuat iteps (step _The 2 and step 3) are shown graphically in Figure B.5 and 8.6.

Figure 20 shows the best match calculated for RN-23 forboth step 2 and step 3. The results in Table 3 show a permeability+hickness of 29 Dm, a storativity of 2.10-7 mr/Pa.m2 ani an injection index of 36 (L/s)/bar.

Borehole RN-18 was drilled vertically to a depth

;j;;ii;;

LA and 218.2 L/s to 25 L/s, respectively (Figure The two step injection rates were from 30. 1 L/s to 48.2 a dual porosity reservoir, constant pressure assumed for RN-18 selected model if,1-*[fi iest porosiry behaviour is a pressure effect which dual The storage. constant skin and a wellbore heterogeneity ofthe-reservoir',This effect is is common in natural fractured.es".uoi.s; it'indicates the porosity' The dual pressure transients in reseivoir that have distinJt and secondary gauge depth prissure The (Home, 1995). plot a derivative on porosity effect is shown as u *inirnr].

of t8l5 m and completed in January 2005' Two gauge being lowered to a depth of 1740 m' pressure a with rests were performed afterwards

iii. ilnj|ry,

""lr*"ii"

f,

was an input into the

prog*;

and the data

*tt"

ileanid. The best model was calculated by

together' consiaering step 1 and stip 2, respectively and then, both steps

FIGURE I 7: Pressure changes during step rate injection test for RN-

I8

\r

I

t:

lt

of3'5 IIsins this reservoir model and after calculations, the best fit indicate a permeability-thickness 4.3 (Lls)lbar with a negative skin of index injectivity an and il,""Hr;ilr, "fJloi.lipu.,o, analysis for step I and step 2 are shown tf,g"r" is ,ra table 2). The results from the regresiion

graphically in Figure B'3 and B.4. is higher than the one calculated for The permeability-thickness and.the injectivity index for RN-18 This could mean that either RN-18 the reservoir. part of this in permeaUitity RN-l7b showing a better a steam cap' into is drilled that it or 7b ini"rr..t, more iermeable features than RN-l TABLE2:Summaryoftheresultsfromnon-linearregressionparameterestimate

using ir.rjection test data from well RN-18

\I

FIGURE 19: Pressure changes for step-rate injection test for RN-23

t\

4.9.

I .5.10'8

l0{

2.8.10-8

3.4'10-8

4.7.rc8 FIGURE 20: Fit between model and measured data for step 2 and 3 for well RN-23

TABLE 3: Summary of the results from non-linear regression parameter estimate

using injection test data from well RN-23

Step

Transmissivity

Storativity

(mJ(Pa-mr))

l.14.10-

Permeability

thickness

Injectlvity

Skin

-4.3

(m{Pa.s))

1.4'

,

3

/Dm)

t2.4

40.6

(Llsl/lrqr

-t.02

-2.5 33.2 39.9

index

l0-'

4.6.101

FIGUREIS:Fitbetweenmodelandmeasureddataforstepland2forwellRN-18

2and3

8.3.10'

I

3.3.10'

.7.10.7

28.9

36.2

24

25

the other and th injectivity indx values for RN-23 are higher than for .The 't*o permeability-thickness well RN-23 is iens, RN- l7b and nr.r-l 8. rlre explanation of the results found here could be that part of th cap in this irn"rr".Ung more permeable i"utur", o, that, the well is intersecting a steam negative skin The the of value high the by confirmed is also p..*"ubility good reservoir. The cap' a steam intersects storativity vaiue is high meaning that RN-23

5. ANALYSES OF PRI,SSURE AND TEMPERATURE PROFTLES 5.1 Introduction

4,3 SummarY

The results in Table

of different transmissivity, storativity and permeability values To calculate the permeabilily, a constant reservoir respectively. for RN-17b, RN-18 and nN-23, thickness of2000 m was assumed.

give a summary

of temperature and pressure with depth are a valuable tool in gaining information on the physical conditions ofthe reservoir and well performance. In geophysics the torm "log" indicates continuous measurement of a parameter with time or, in space carried out in boreholes (Steftinsson and Steingrimsson, 1990). The basic measurements made in geothermal wells are pressure and temperature logs orprofiles. The logs are normally measured overthe full depth of the wellbore. The well may be shut in, flowing or under injection (Grant and Bixley, 201 l).

The downhole profiles

The purpose of analysing downhole data is therefore to deduce from the logging made within the dynamic fluid inside the wellbore the properties of the reservoir around the well. However, caution must be taken when interpreting logs as measurements are not made directly in the reservoir but in the well where intemal flows and boiling can cause disturbances and give misleading results even though the well is shut in (Stefinsson and Steingrimsson, 1990).

Analyses oftemperature and pressure profiles during warrn up leads to an estimation ofthe formation temperature and the initial reservoir pressure as well as the location of the feed zones. Temperature measurements during fluid injection or production can indicate the feed or loss zones under the test conditions. The feed zones or permeable zones are the regions where hot and cold water flows in and out of a well and usually show up as temperature anomalies, either hot or cold.

I

TABLE 4: Summary of the results for wells RN-17b, RN-18 and RN-23

TransmissivitY

(m3/Pa's)

Well RN-I7b RN-I8

RN-23

StorativitY

(m3/Pa'm2;

Permeability

thickness

fl)m)

0.9

4.1

PermeabilitY (mD)

0.5

2.1 14.5

InjectivitY

Skin

-0.7

index

flls)/bar

t.3

4.3 36.2

l. l4.l

0'

4.5.10'

4.7.10'8

1.7.10'7

3.4.10.8

3.3.10'

28.9

-0.8 -2.5

has the lowest The results indicate that RN-23 has the highest transmissivity, while RN-l7b and RN-

t."rr*irririty.

u

that well iiJ. in" penneability values sh'ow high permeabitity in RN-23. Considering RN-23 is drilled into well that be could permeability th. of uulu" t igt tt r s, i;, ;*;t irom well nr.r" permeable fracfirres

for RN-18 The transmissivity of RN-23 is Jne order of magnitude higher than

RN-23 is not

(relative permeabilitils are considered) and/or that it intersects more .r"uln "up reservoir could be explained as a than RN-18. The poor permeability ofRN-17b in this part ofthe measured in this.well (see sub temperature to the high due reservoir'rocks the of tt,"rr*t (Bjdmsson and Bddvarsson, "*purrion matrix rock in the voids closed of sr"tion S.Z.Z; increasing the number intersect as manv ;;;6j.-Th;;;r, p"rr.u'titity of RN-17b can also simply mean that the well does not than in the central part of the itre outskirts at permeabte is less ,r..ruoi. the that or fractures

geothermal field.

/(Dowdle and cobb, 1975) through the BERGHITI program (Helgason, 1993) from the ICEBOX software package (Arason et a1.,2004). The Horner method is an analysis method based on the straight line relationship btween the wellbore temperature, f and the logarithm of relative time, r

called the Homer time, where

In this study, the formation temperature is estimated by using an analytical method, the Horner method

r = toiAt

un6

t, is the circulation time that

is the time that the well has

been cooled by the drilling fluid, andAt is the time since the circulation ofdrilling fluid was stopped. The measured wellbore temperature at a given depth from several temperature logs is plotted against Iog (r,). This plot is a straight line that intersects the vertical line r = l, corresponding to A/ @, at the

formation temperature. The boiling point curve was considered when estimating the formation temperature to determine if there is boiling in the borehole and at which depth. The boiling point curve for an individual borehole was calculated assuming initial water level and the program BOILCURV from ICEBOX was used for

this purpose. The initial pressure condition ofthe wells is estimated by feeding the evaluated formation temperature into the program PREDYP @j<imsson, 1993), from the ICEBOX package. The program computes pressure in a static fluid column with known temperature. The water level (or wellhead pressure) is required for the calculation and is adjusted until the calculated profile matches the measured pressure at the pivot point. The pivot point shows the depth to and pressure at the best feed zone in the borehole and can be considered as the actual pressure value in the reservoir.

of magnitude for RN-l7b and RN-18 The storativity values for the three wells are of the same order stated higher for RN-23. The high storativity value for RN-23 could be as RNof wells test the injection "rJ*'"fmagnitude for "r" factors "rJ The skin cap. a steam into uUou" f"""o." the will is aritiEa wells iii, nN-rs and RN-23 are estimated -0.7, -0.8 and -2.5, respectively. This indicates stimulated and/or fractured zone in the reservoir'

benveen the well and the The injectivity index is used as a rough estimate of the connectivity of magnitude higher ;;;;";ftG.;r.rvoir. The results show-an injectivity index which is one order for RN-23 and indices injectivity the of The-values RN-lib. and to RN-18 ior nN-23-as compared 6. in chapter wells the same for [N_ I A u." .o.p..rd *ith the productivity indices

the Reykjanes wells RN-12, RN-17B, RN-18, RN-23 and RN-29. The temperature and pressure measurements in these wells were performed during injection, wann up and flowing of the wells. 5.2 Temperature and pressure analyses

In the following sections (5.2 to 5.3), the temperature and pressure profiles are analysed to locate the feed zones, pivot points and estimate the initial reservoir pressure and the formation temperatures for

In this section, the temperature and pressure profiles for wells RN-12, RN-17B, RN-18, RN-23 and RN-29 are interpreted to identify the main feed zones and locate the pivot point of each well where

possible.

26 27

Anda mungkin juga menyukai

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- Sample of A Project ProposalDokumen30 halamanSample of A Project Proposalmozziemecca100% (5)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (399)

- HW3 F13Dokumen4 halamanHW3 F13Joe ChoBelum ada peringkat

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- Lecture Name:-Spatial Analysis Prof. S.K.Ghosh Dept of Civil EnggDokumen119 halamanLecture Name:-Spatial Analysis Prof. S.K.Ghosh Dept of Civil EnggAr Abhinav SrivastavBelum ada peringkat

- Physical Chemistry Reference 2Dokumen33 halamanPhysical Chemistry Reference 2Kuo SarongBelum ada peringkat

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- Future of Outbound Travel in Asia PacificDokumen44 halamanFuture of Outbound Travel in Asia PacificAnonymous P1dMzVxBelum ada peringkat

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (895)

- Box Behnken Experimental DesignDokumen9 halamanBox Behnken Experimental DesignJose Luis MoltoBelum ada peringkat

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- Reasoning in AiDokumen14 halamanReasoning in AipriyankaBelum ada peringkat

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- PTHT End SemDokumen11 halamanPTHT End SemCh PrasadBelum ada peringkat

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (588)

- Lecture 8 ANOVADokumen44 halamanLecture 8 ANOVARush-d Salaman100% (1)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- L-Moments, TL-Moments Estimation and Recurrence Relations For Moments of Order Statistics From Exponentiated Inverted Weibull DistributionDokumen9 halamanL-Moments, TL-Moments Estimation and Recurrence Relations For Moments of Order Statistics From Exponentiated Inverted Weibull DistributionSEP-PublisherBelum ada peringkat

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (73)

- Design of A Vertical Thermosyphon ReboilerDokumen6 halamanDesign of A Vertical Thermosyphon ReboilerhurrikenBelum ada peringkat

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- Variables in ResearchDokumen43 halamanVariables in ResearchRhino Balintong100% (1)

- Predicting FootballDokumen3 halamanPredicting FootballRicardo SantosBelum ada peringkat

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- 2 Way AnovaDokumen20 halaman2 Way Anovachawlavishnu100% (1)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (344)

- Supplement BastinDokumen25 halamanSupplement BastinBenoît JacquetBelum ada peringkat

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (266)

- Which Statistical Tests To UseDokumen1 halamanWhich Statistical Tests To UsePam FajardoBelum ada peringkat

- ManSci Ch. 4Dokumen11 halamanManSci Ch. 4Tin RobisoBelum ada peringkat

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- Physical Meaning of SMDokumen39 halamanPhysical Meaning of SMVikas MehtaBelum ada peringkat

- MASH Multiple Regression RDokumen5 halamanMASH Multiple Regression Rsheilaabad8766Belum ada peringkat

- President Obama 2012 Victory SpeechDokumen6 halamanPresident Obama 2012 Victory Speechapi-291574045Belum ada peringkat

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- Kolmogorov Smirnov Test For NormalityDokumen11 halamanKolmogorov Smirnov Test For NormalityIdlirBelum ada peringkat

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2219)

- Journal of Hydrology: Regional Studies: Getachew Tegegne, Dong Kwan Park, Young-Oh KimDokumen18 halamanJournal of Hydrology: Regional Studies: Getachew Tegegne, Dong Kwan Park, Young-Oh KimGlacier RamkissoonBelum ada peringkat

- Kalman Filtering Book PDFDokumen83 halamanKalman Filtering Book PDFBHUVANESWARI ABelum ada peringkat

- Sample questions on statistics and data analysisDokumen4 halamanSample questions on statistics and data analysisfxl0120Belum ada peringkat

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- Critical particle diameter and efficiency of a cyclone separatorDokumen5 halamanCritical particle diameter and efficiency of a cyclone separator;(Belum ada peringkat

- D5191Dokumen6 halamanD5191Manuel GuzmanBelum ada peringkat

- Standardization of Volumetric GlasswareDokumen8 halamanStandardization of Volumetric GlasswareJIEHASMARTBelum ada peringkat

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (120)

- Water Level Measurements and InterpretationDokumen7 halamanWater Level Measurements and InterpretationDenzilBelum ada peringkat

- Exp 1Dokumen5 halamanExp 1sju65Belum ada peringkat

- Statistics For Educational ResearchDokumen3 halamanStatistics For Educational Researchkhaza100% (1)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)