1 s2.0 S221282711300512X Main

Diunggah oleh

patilsspJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

1 s2.0 S221282711300512X Main

Diunggah oleh

patilsspHak Cipta:

Format Tersedia

Available online at www.sciencedirect.

com

ScienceDirect

Procedia CIRP 11 (2013) 139 144

2nd International Through-life Engineering Services Conference

Friction stir welding of Al alloys: analysis of processing parameters affecting mechanical behavior

Pasquale Cavaliere*

Department of Innovation Engineering, University of Salento, Lecce 73100, Italy * Corresponding author. Tel.: +39 0832 297357; fax: +39 0832 297357. E-mail address: pasquale.cavaliere@unisalento.it

Abstract Friction Stir Welding is a well known solid state joining technology. Many processing conditions and materials properties affect the microstructural evolution and mechanical behavior of the produced joints. The main parameters involved in the welding process have been studied and the results presented in the present paper. The fatigue life and crack behavior of several aluminum alloys FSW joints have been presented. The analysis was conducted through employing a multi-objective optimization tool capable of correlating all the material properties and processing parameters to the final mechanical performances of the welds. 2013 by Elsevier B.V. 2013 The TheAuthors. Authors.Published Published by Elsevier B.V. nd International Through-life Engineering Selection and under responsibility of of the International Scientific Committee of the Selection andpeer-review peer-review under responsibility the International Scienti c Committee of "2 the 2nd International Through-life Services Conference" the Programme Chair Ashutosh Tiwari. Engineering Servicesand Conference and the Programme Chair Ashutosh Tiwari

Keywords: FSW; Fatigue properties; crack behavior; optimization.

1. Introduction Thousands of papers have been published in the last 20 years on Friction Stir Welding (FSW). The solid state joining technology is well known; a complete description of processing, physical and mechanical behavior can be found in [1, 2]. In the recent literature, such technology is becoming very promising in repairing technology especially in the case of Al aeronautical structures [3-5]. Actually, due to safety and legal constrictions and to maintenance procedures, the analyses and the control of welding parameters in order to obtain high resistance, uniform microstructure and fatigue performances become fundamental in the case of such technology. Many papers are presented in the literature on microstructural, physical and mechanical behavior of friction stir welded Al-alloys, only few papers focus on the effect of processing parameters to obtain joints good efficiency in terms of tensile and fatigue properties. In [6] the authors show the results of an optimization study of tool geometry in order to improve the tensile properties of FSW joints. In [7, 8] the authors focus the attention on the effect of tool rotation speed,

advancing speed and tool geometry on fatigue strength of 5083 alloy. The effect of processing parameters on residual stresses affecting crack initiation and propagation and fatigue life in 2XXX alloys is described in [9-18]. A review on fatigue properties of FSW joints is described in [19]. Fatigue crack behavior of 7XXX alloys is shown in [20-23]. Fatigue behavior of 6XXX alloys is described as a function of processing parameters in [24-29]. The paper is aimed to give a contribution to the understanding of all the main variables affecting solid state joining performances and quality. The contribution can be useful also in the prospective of further FSW international standardization to weld and repair. The employed multi-objective optimization software is modeFRONTIER (ESTECO), through which a set of input parameters, governing the FSW process, was defined. It was possible to evaluate the weight of the processing parameters with respect to the final performances and the correlations between different sets of parameters [30, 31].

2212-8271 2013 The Authors. Published by Elsevier B.V.

Selection and peer-review under responsibility of the International Scientic Committee of the 2nd International Through-life Engineering Services Conference and the Programme Chair Ashutosh Tiwari

doi:10.1016/j.procir.2013.07.039

140

Pasquale Cavaliere / Procedia CIRP 11 (2013) 139 144

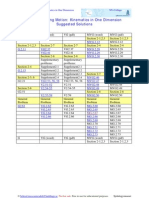

2. Experimental procedure The materials under investigation were different heat and non heat treatable aluminium alloys from 2XXX, 3XXX, 5XXX, 6XXX and 7XXX series. Sheets with different thicknesses were friction stir welded by employing various welding advancing and rotating speeds of the tools, such tools were all threaded ones and they were characterized by different height and shoulder diameter. The welds were performed by employing different tools inclinations. The machine used for the production of the joints was instrumented with a Kistler three channel load cell in order to record both forces along the tool axis, hereon denoted as FZ, and along the welding direction, hereon denoted as FX, for all the produced welds. Acquisition scan rate changed as a function of the rotating speed in order to record two time samples per tool revolution, in all the examined conditions. All the sheets were machined before tests in order to eliminate surface inhomogeneities. Tensile tests were performed in order to evaluate the mechanical properties obtained in the different welding conditions. The Residual Stresses (RS) were also calculated in longitudinal direction respect to the loading one, by employing the sin2� method. The RS were measured in longitudinal direction, being the one affecting the crack tip stress field. The tensile tests were carried out at room temperature using a MTS 810 testing machine with initial strain rate of 10-3 s-1. Specimens were sectioned in the perpendicular direction to the weld line by employing an electrical discharge machine (EDM), the tensile specimens measured 12 mm width, 80 mm length for a gauge length of 25 mm. Endurance fatigue tests were performed by a resonant electromechanical testing machine under constant loading control, with sine wave loading (TESTRONICTM 25 25 kN, produced by RUMUL, SUI) in high cycles regimes. The cyclic fatigue tests were conducted under axial stress amplitude control mode with different loading ratios. The fatigue specimens gauge dimensions measured 12.5-mm width, 50-mm length and tests were performed up to failure. The fatigue crack propagation experiments were performed by employing single edge (1 mm) notched specimens obtained on the advancing side. The FSW, in fact, does not produce a symmetric deformation respect to the center line of the advancing tool. Due to such inhomogeneities, when a clock wise direction rotation is employed, the less resistant zone results the one on the advancing side of the tool. Due to materials, thicknesses and tool differences they were taken some choices to build the database. The base materials indication come through the hardness. The effect of the tool dimension is indicated into the database through the shoulder diameter/pin height ratio. Revolutionary pitch effect is indicated into the database. A broader discussion is necessary for the indication of the residual stresses, they were measured in five different points, for each sheet the distance between the measurement points were equal to the sheet thickness; after the calculation it was calculated the area of the plot residual stress-distance from the weld center (on the advancing side of the tool); the value of such area, for each experimental condition was used as the indication of the residual stresses effect into the database. The effect of processing parameters

on the tensile mechanical properties was underlined through the ration between the FSW properties and base materials ones for yield stress, UTS and elongation (%). Fatigue properties were evaluated through the ratio between the stress at 104, 105, 106 and 107 cycles of the FSW and base materials ones (%). The crack behavior was evaluated through the ratio between the �K values at 6E-3, 7E-4, E-5 and 2E-6 mm/cycle of the FSW and base materials ones (%). In such a way it was possible to have uniform values to be employed together into the database. Now it is possible to indicate as inputs: Base material properties, thickness, tool geometry, tool rotation speed, tool advancing speed, revolutionary pitch, tool inclination, Fz welding force (in stationary conditions), fatigue load ratio; and as outputs: residual stresses, tensile properties, fatigue and crack propagation properties. The experimental design consists of 136 input and output conditions obtained from experimental data. 3. Results and discussion Many different results should be put in evidence concerning the relationships between the different processing parameters. The main welding parameters, which can be controlled in the FSW process for a given tool, are the rotational speed of the tool, the traverse speed of the tool, the axial force of the tool shoulder on the workpiece, the angle of contact between the tool and the workpiece, tool geometry and revolutionary pitch. Vertical force was inserted into the database because it is strongly larger with respect to the other two and, in particular, it is generally recognized as the force limiting the welding machine design and the main force influencing tool wear or fracture particularly during the plunge stage. Processing parameters in FSW affect temperature profile/heat input, defects, microstructure and residual stresses. Generally, the welding force decrease as increasing the revolutionary pitch, the welding force increases as decreasing the tool inclination angle.

Fig. 1. Welding force in Z direction as a function of the base material hardness and of the revolutionary pitch.

Pasquale Cavaliere / Procedia CIRP 11 (2013) 139 144

141

The welding force decreases with increasing base material hardness up to a minimum around 140 HV, then the welding force increases with increasing the base material hardness (Figure 1). Finally it was observed that the welding force increases with increasing the rate tool shoulder/pin height. Such factor is fundamental in analyzing the effect of welding conditions on consequent mechanical properties. Many factors are involved, first of all variation of the pin design did have an effect on the welding force which directly opposes translation of the tool; during the translational stage the forging pressure exerted by the shoulder generates the vertical force. Normally the severe plastic deformation of material during FSW decreases for thicker sheets. In this way all the heating and material mixing is affected by the dimensions.

By taking a look to the outputs, it can be underlined that Yield strength of the joints increases as increasing the welding force at intermediate values of the revolutionary pitch (Figure 2). At higher values of revolutionary pitch it is generally observed a strong decrease in mechanical properties, such condition is indicative of a decrease of material stirring and sufficient heating to avoid joints defects. At too low values of revolutionary pitch the excess of heating leads to high material tearing and consequently to high microstructural inhomogeneities in the joint. Ductility increases as increasing the welding force from low to intermediate values of the revolutionary pitch, and increases as increasing the tool inclination angle. UTS decreases as increasing the ratio tool shoulder/pin eight up to a minimum, then it starts to increase as increasing the ratio; UTS increases as increasing the welding force (Figure 3). The difference between tensile strength of the joints and of the base metal is mainly governed by the heating generated during welding, such heating is governed by the welding conditions and by the geometry of the tool, such aspect is very critical for precipitation hardening alloys.

Fig. 2. Yield strength as a function of the welding force and of the revolutionary pitch.

In particular, the transition zone between TMAZ and HAZ is strongly influenced by the geometric conditions (thickness, tool geometry), this is well known as the weaker section of FSW joints governing tensile and fatigue behavior, for this reason, in the present study, a large emphasis was put on such a factor.

Fig. 4. Residual stresses as a function of the base material hardness and of the ratio tool shoulder/pin eight.

Fig. 3. UTS as a function of the ratio tool shoulder/pin eight and of the welding force.

Heating and cooling is also strongly related to the ductility of the joints, in fact, if softening acts on the weld line necking is anticipate and, as a consequence, such aspect strongly reduces elongation of the joints. It can be underlined that such aspect can be monitored through the analysis of softening effect on elongation. In the present study such factor was monitored through the calculation of the reduction in hardness with respect to the base material. The main softening effect is observed in the 7XXX and Li-2XXX alloys, the alloys that are less effected from softening are the 3XXX and 5XXX series materials. In such alloys, improvement in tensile and fatigue properties is expected for those welding conditions inducing higher levels of heat input if compared with precipitation hardening alloys. In heat treatable alloys, in fact, excess in heating can lead to overageing and then to dissolution of hardening precipitates and/or particles coarsening.

142

Pasquale Cavaliere / Procedia CIRP 11 (2013) 139 144

The microstructural evolution acting during FSW are accompanied by significant residual stress changes. Both tensile and compressive residual stresses exist within the weld. Residual stresses increases as increasing the base material hardness up to a maximum and then they start to decrease as increasing the base material hardness; the same behavior is observed as a function of the ratio tool shoulder/pin eight (Figure 4). Residual stresses increase as increasing the revolutionary pitch and they increase as increasing the welding force up to a maximum, then residual stresses decrease as increasing the welding force (Figure 5).

6). Fatigue limit increases for residual stresses going from a compressive to a tensile state up to a maximum and then it decreases as increasing tensile residual stresses; contemporary, fatigue limit increases as increasing the welding force up to a maximum and then decreases as increasing the vertical force (Figure 7). In previous studies the compressive aspect of residual stresses has been explained as due to very complex thermal and rigid clamping used during FSW process.

Fig. 7. Fatigue limit as a function of the residual stresses and of the welding force. Fig. 5. Residual stresses as a function of the revolutionary pitch and of the welding force.

By comparing different fatigue behavior it is convenient to indicate the fatigue strength in terms of stress at a fixed reference value of number of cycles to failure, the first reference value was taken at 107 cycles to failure.

For fixed geometry conditions and revolutionary pitch, in fact, high Fz forces lead to an excessive flash in the weld (also governed by the tool inclination), while low vertical forces produce excessive tearing of the material. In such condition it is observed a strong drop of fatigue properties mainly observed in heat treatable alloys.

Fig. 6. Fatigue limit as a function of the revolutionary pitch and of the base material hardness.

Fig. 8. Fatigue limit as a function of the tool rotation speed and of the ratio tool shoulder/pin eight.

The fatigue limit increases as increasing the revolutionary pitch up to a maximum and then it starts to decrease as increasing the revolutionary pitch; the same behavior has been observed as a function of the base material hardness (Figure

Too small tools, in fact, does not lead to an optimal mixing and stirring of material, while too big tools produce an excessive heating with a strong softening effect and with large microstructural inhomogeneities. As a general behavior, the

Pasquale Cavaliere / Procedia CIRP 11 (2013) 139 144

143

fatigue efficiency decreases as increasing the revolutionary pitch. Heat treatable alloys resulted much more sensitive to welding conditions variation if compared to non age hardenable materials. The fatigue limit decreases as increasing the tool rotation speed for intermediate values of the ratio tool shoulder/pin eight (Figure 8). So for each set of processing conditions there is an optimal set of pin and shoulder diameter that should be employed to obtain good fatigue performances. Actually, the main differences between the crack behavior of the FSWed joints and the base material is observed at low �K, such difference tends to decrease as increasing �K. Normally, it is accepted that such behavior is due to the aspect that the crack grow into a material with different microstructural and mechanical properties, at the beginning into the HAZ and into the TMAZ which are characterized by lower stiffness with respect to the parent material; when the crack starts to grow into the recrystallized nugget the situation strongly varies. The nugget is, in fact, strongly recrystallized and it is characterized by finer grains; normally the finer grains favor the increase of crack growth but, in the case of FSW nuggets, such situation is inversed leading to a similar behavior between the crack growth in the nugget and in the parent material. Generally, �K calculated at a value of da/dN of 6E-3 mm/cycle decreases as increasing residual stresses up to a minimum and then it increases as increasing residual stresses; it decreases as increasing the welding force (Figure 9); compressive residual stresses lead to a decrease in crack growth rate so it is much more difficult to observe a crack initiation in this zone, tensile residual stresses lead to an increase in crack growth rate. The worst crack behavior was observed in those joints with less compressive state close to the crack tip and characterized by a strong increase of residual stresses toward high tensile state. In addition the coupled effect of microstructure changes and increase of residual stresses toward tensile state lead to an acceleration of crack growth with respect to the parent material behavior.

increasing R, in fact the increase of maximum load level leads the residual stress to be a negligible portion of the total stress acting on the material. �K increases as increasing base material hardness, contemporary it increases as increasing the revolutionary pitch up to a maximum, then it decreases as increasing the revolutionary pitch. �K has a sinusoidal behavior as a function of low values of the ratio tool shoulder/pin eight and it decreases as increasing the tool rotation speed (Figure 10). By focusing on the FSW joints and on the parent material behavior it can be underlined how, crack initiation is strongly governed by microstructural features and residual stresses; in the Paris region, all the joints assume a general behavior which is closer to the parent material one; the cracks accelerate with a rate proportional to the increase in residual stresses and to the difference in microstructure depending on processing parameters governing heating and stirring of the material. In particular excess of heating, at constant mixing conditions, leads to strong softening of HAZ and TMAZ with local enhanced mechanical properties differences with the nugget zone (in which the rate of dynamic recrystallization is mainly governed by material mixing then by revolutionary pitch and tool inclination). In addition, as underlined by different authors, such microstructural features decrease crack closure contribution with consequent increase in crack growth rate. Such behavior is normally characterized by a transition from ductile to brittle fracture appearance on the fracture surfaces; such behavior is favored, in the heat treatable alloys, when heating conditions lead to precipitate coarsening due to overageing effects.

Fig. 10. �K as a function of the rotation speed and of the ratio tool shoulder/pin eight.

Fig. 9. �K as a function of the residual stresses and of the welding force.

For those specimens tested at different load ratios it can be underlined that the effect of residual stresses decreases as

It is also important, in the present analysis, to employ the so called scatter matrix that allows to immediately recognize how much the different variables are correlated between them, actually the parameters are strongly correlated if the corresponding value in the table are distant from zero in a range between -1 and 1, if the value is 1 the parameters are directly correlated, while if the value is -1 the parameters are inversely correlated. From such matrix it is also possible to

144

Pasquale Cavaliere / Procedia CIRP 11 (2013) 139 144

[10] Ma YE, Staron P, Fisher T, Irving PE. Size effects on residual stress and fatigue crack growth in friction stir welded 2195-T8 aluminium Part I: Experiments. Int J Fat 2011; 33: 14171425. [11] Ali A, Brown MW, Rodopoulos CA, Gardiner S. Characterization of 2024-T351 Friction Stir Welding Joints. J Fail Anal Prev 2006; 6(4): 8396. [12] Milan MT, Bose Filho WW, Ruckert COFT, Tarpani JR. Fatigue behaviour of friction stir welded AA2024-T3 alloy: longitudinal and transverse crack growth. Fat Fract Eng Mat Struct 2008; 31: 526538. [13] Pouget G, Reynolds AP. Residual stress and microstructure effects on fatigue crack growth in AA2050 friction stir welds. Int J Fat 2008; 30: 463472. [14] Fratini L, Pasta S, A.P. Reynolds AP. Fatigue crack growth in 2024T351 friction stir welded joints: Longitudinal residual stress and microstructural effects. Int J Fat 2009; 31: 495500. [15] Golestaneh AF, Ali A, Zadeh M. Modelling the fatigue crack growth in friction stir welded joint of 2024-T351 Al alloy. Mater Des 2009; 30: 29282937. [16] Malarvizhi S, Balasubramanian V. Effect of welding processes on AA2219 aluminium alloy joint properties. Trans non Ferr Met Soc China 2011; 21: 962-973. [17] Cavaliere P, Cabibbo M, Panella F, Squillace A. 2198 AlLi plates joined by Friction Stir Welding: Mechanical and microstructural behavior. Mater Des 2009; 30: 36223631. [18] Malarvizhi S, Balasubramanian V. Effects of Welding Processes and Post-Weld Aging Treatment on Fatigue Behavior of AA2219 Aluminium Alloy Joints. J Mater Eng Perf 2011; 20(3): 359-367. [19] Biro AL, Chenelle BF, Lados DA. Processing, Microstructure, and Residual Stress Effects on Strength and Fatigue Crack Growth Properties in Friction Stir Welding: A Review. Met Trans 2012; 43B: 1622-1637. [20] Gemme F, Verreman Y, Dubourg L, Wanjara P. Effect of welding parameters on microstructure and mechanical properties of AA7075-T6 friction stir welded joints. Fat Fract Eng Mat Struct 2011; 34: 877886. [21] Hatamleh O, Lyons J, Forman R. Laser peening and shot peening effects on fatigue life and surface roughness of friction stir welded 7075-T7351 aluminum. Fat Fract Eng Mat Struct 2007; 30: 115130. [22] Hatamleh O, Forth S, Reynolds AP. Fatigue Crack Growth of Peened Friction Stir-Welded 7075 Aluminum Alloy under Different Load Ratios. J Mater Eng Perf 2010; 19(1): 99-106. [23] Pao PS, Gill SJ, Feng CR, Sankaran KK. Corrosion-fatigue crack growth in friction stir welded Al 7050. Scripta Mater 2001; 45: 605-612. [24] Costa JD, Ferreira JAM, Borrego LP, Abreu LP. Fatigue behaviour of AA6082 friction stir welds under variable loadings. Int J Fat 2012; 37: 816. [25] Moreira PMGP, de Oliveira FMF, de Castro PMST. Fatigue behaviour of notched specimens of friction stir welded aluminium alloy 6063-T6. J Mater Proc Tech 2008; 207: 283292. [26] Cavalierea P, Squillace A, Panella F. Effect of welding parameters on mechanical and microstructural properties of AA6082 joints produced by friction stir welding. J Mater Proc Tech 2008; 200: 364372. [27] Cavaliere P, De Santis A, Panella F, Squillace A. Thermoelasticity and CCD analysis of crack propagation in AA6082 friction stir welded joints. Int J Fat 2009; 31: 385392. [28] Moreira PMGP, de Figueiredo MAV, de Castro PMST. Fatigue behaviour of FSW and MIG weldments for two aluminium alloys. Theor Appl Fract Mech 2007; 48: 169-177. [29] Moreira PMGP, de Jesus AMP, Ribeiro AS, de Castro PMST. Fatigue crack growth in friction stir welds of 6082-T6 and 6061-T6 aluminium alloys: A comparison. Theor Appl Fract Mech 2008; 50: 8191. [30] Cavaliere P, Perrone A. Analysis of dangerous emissions and plant productivity during sintering ore operations. Ironmak Steelmak 2013; 40: 9-24. [31] Cavaliere P, Perrone A, Tafuro P, Primavera V. Reducing emissions of PCDD/F in sintering plant: numerical and experimental analysis. Ironmak Steelmak 2011; 38: 422-431.

observe the different weight of all the parameters, the more the value differs from 0 the more it influence the corresponding variable. By taking a look at the influence of the processing parameters on the mechanical properties of the joints it should be underlined that, tensile properties are strongly dependent on the ratio tool shoulder/pin eight and on tool inclination with an inverse proportionality, and on the tool rotation speed. The welding force is mainly dependent on the base material hardness, on the ratio tool shoulder/pin eight and on the tool inclination. Residual stresses show the same behavior. The fatigue limit is strongly dependent on welding force, on residual stresses (both with direct proportionality), on the tool rotation speed and on the ratio tool shoulder/pin eight, on the base material hardness and on the tool inclination. The �K value at 6E-3 mm/cycle is dependent on the material hardness, tool geometry, inclination and rotating speed and it is directly related to welding force and residual stresses. 4. Conclusions In the present study the effect of processing parameters on tensile, fatigue and crack behavior of several aluminum alloys is described. The experimental data were employed to build a database capable of developing a model useful for predicting mechanical performances of FSW joints. It was underlined the different weight of processing parameters on final performances of the welds. The quality of the model was evaluated through the potential error calculation of each output monitored during the analysis. References

[1] Mishra RS, Ma ZY. Friction stir welding and processing. Mater Sci Eng 2005; R50: 1-78. [2] Simar A, Brchet Y, de Meester B, Denquin A, Gallais C, Pardoen T. Prog Mater Sci 2012; 57: 95183. [3] Li B, Shen Y. The investigation of abnormal particle-coarsening phenomena in friction stir repair weld of 2219-T6 aluminum alloy. Mater and Des 2011; 32: 3796-3802. [4] Han B, Huang Y, Lv S, Wana L, Feng J, Fu G. AA7075 bit for repairing AA2219 keyhole by filling friction stir welding. Mater and Des 2013; 51: 25-33. [5] Hu J, Ding LL, Guo BX, Fang WP. Technical research of friction stir welding repair in aeroplane aluminium alloy damage. Adv Mater Res 2010; 154-155: 1262-1265. [6] Blignault C, Hattingh C, James MN. Optimizing Friction Stir Welding via Statistical Design of Tool Geometry and Process Parameters. J Mater Eng Perf 2012; 21(6): 927-935. [7] Hong S, Kim S, Lee CG, Kim SJ. Fatigue crack propagation behavior of friction stir welded 5083-H32 Al alloy. J Mater Sci 2007; 42: 98889893. [8] Lombard H, Hatting DG, Steuwer A, James MN. Optimising FSW process parameters to minimise defects and maximise fatigue life in 5083H321 aluminium alloy. Eng Fract Mech 2008; 75: 341354. [9] Lemmen HJK, Alderliesten RC, Benedictus C. Fatigue initiation behaviour throughout friction stir welded joints in AA2024-T3. Int J Fat 2010; 32: 1928-1936.

Anda mungkin juga menyukai

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- Quiz Contest - Imtex 2019Dokumen1 halamanQuiz Contest - Imtex 2019patilssp0% (1)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (587)

- IC Workshop Materials 09 - Rapid Prototyping & Manufacturing TechnologiesDokumen33 halamanIC Workshop Materials 09 - Rapid Prototyping & Manufacturing TechnologiespatilsspBelum ada peringkat

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (894)

- Circular AvishkarDokumen1 halamanCircular AvishkarpatilsspBelum ada peringkat

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- Operations ResearchDokumen5 halamanOperations ResearchZheejae Lao-atenBelum ada peringkat

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (399)

- Modrobs VeDokumen38 halamanModrobs VepatilsspBelum ada peringkat

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (73)

- AICTE Norms - Engg. CourseDokumen18 halamanAICTE Norms - Engg. CoursejeysamBelum ada peringkat

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- Pro Engineering Educator 1Dokumen10 halamanPro Engineering Educator 1patilsspBelum ada peringkat

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- (the Lean Guidebook Series) Mascitelli, Ronald_ Mascitelli, Ronald-The Lean Design Guidebook _ Everything Your Product Development Team Needs to Slash Manufacturing Cost-Technology Perspectives (2004)Dokumen320 halaman(the Lean Guidebook Series) Mascitelli, Ronald_ Mascitelli, Ronald-The Lean Design Guidebook _ Everything Your Product Development Team Needs to Slash Manufacturing Cost-Technology Perspectives (2004)patilssp100% (1)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- FSW A DenquinDokumen24 halamanFSW A DenquinpatilsspBelum ada peringkat

- DFGRTDokumen11 halamanDFGRTpatilsspBelum ada peringkat

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- MFG Tooling - 10 Prog Tools-2 PDFDokumen11 halamanMFG Tooling - 10 Prog Tools-2 PDFFlo FlorinBelum ada peringkat

- EScholarship 51r6b592Dokumen10 halamanEScholarship 51r6b592patilsspBelum ada peringkat

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- Press Tool Design CourseDokumen2 halamanPress Tool Design CoursepatilsspBelum ada peringkat

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- T 50102117121Dokumen5 halamanT 50102117121patilsspBelum ada peringkat

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2219)

- DFGDokumen12 halamanDFGpatilsspBelum ada peringkat

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- WDokumen11 halamanWpatilsspBelum ada peringkat

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (344)

- Aluminum 7075: Microstructure and Current Research Through The Use of In-Situ X-Ray DiffractionDokumen20 halamanAluminum 7075: Microstructure and Current Research Through The Use of In-Situ X-Ray DiffractionOliveira400Belum ada peringkat

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (265)

- IiuuDokumen6 halamanIiuuRavi ShankarBelum ada peringkat

- FSPDokumen1 halamanFSPpatilsspBelum ada peringkat

- Aluminum 7075: Microstructure and Current Research Through The Use of In-Situ X-Ray DiffractionDokumen20 halamanAluminum 7075: Microstructure and Current Research Through The Use of In-Situ X-Ray DiffractionOliveira400Belum ada peringkat

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- RPDokumen10 halamanRPpatilsspBelum ada peringkat

- Admission 2014-15 Brochure FinalDokumen34 halamanAdmission 2014-15 Brochure FinalArchana RajanBelum ada peringkat

- AAM Joining 3 Friction Stir WeldingDokumen15 halamanAAM Joining 3 Friction Stir WeldingpatilsspBelum ada peringkat

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- Proceedings of The Institution of Mechanical Engineers, Part B - Journal of Engineering Manufacture-2010-Rajakumar-1175-91Dokumen18 halamanProceedings of The Institution of Mechanical Engineers, Part B - Journal of Engineering Manufacture-2010-Rajakumar-1175-91patilsspBelum ada peringkat

- The Great Chhatrapati Shivaji MaharajDokumen14 halamanThe Great Chhatrapati Shivaji MaharajpatilsspBelum ada peringkat

- Ijmerr 4ff3026e5f7fbDokumen11 halamanIjmerr 4ff3026e5f7fbpatilsspBelum ada peringkat

- InTech-Reverse Engineering and Fem Analysis For Mechanical Strength Evaluation of Complete Dentures A Case Study PDFDokumen15 halamanInTech-Reverse Engineering and Fem Analysis For Mechanical Strength Evaluation of Complete Dentures A Case Study PDFpatilsspBelum ada peringkat

- Introduction to Noise and Vibration Control CourseDokumen4 halamanIntroduction to Noise and Vibration Control CoursepatilsspBelum ada peringkat

- Advising Flow ChartDokumen1 halamanAdvising Flow ChartpatilsspBelum ada peringkat

- Forces On Curved Surfaces PDFDokumen9 halamanForces On Curved Surfaces PDFSunny MaitangBelum ada peringkat

- Duncan R - 6 - 3.2: SpecificationDokumen2 halamanDuncan R - 6 - 3.2: SpecificationJosé Angel PinedaBelum ada peringkat

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (119)

- Tutorials in Power ElectronicsDokumen66 halamanTutorials in Power ElectronicsAbdullah Al AsikBelum ada peringkat

- Induction NotesDokumen15 halamanInduction NotesKartikBelum ada peringkat

- Design of Springs: An OverviewDokumen12 halamanDesign of Springs: An OverviewKTMOBelum ada peringkat

- A Seminar Report On Wireless Electricity (Witricity)Dokumen24 halamanA Seminar Report On Wireless Electricity (Witricity)Ganeswar Majhi100% (1)

- Fluids and forcesDokumen22 halamanFluids and forcesLeo WongBelum ada peringkat

- Electric Dipole in an External FieldDokumen14 halamanElectric Dipole in an External FieldMustafa RamadanBelum ada peringkat

- Astm E4-03Dokumen9 halamanAstm E4-03柏斯材料科學檢驗有限公司公司Belum ada peringkat

- Boost Closed LoopDokumen10 halamanBoost Closed Loopzakaria1500Belum ada peringkat

- Technical Specifications For Door Trim Panel Assembly: PDF Created With Pdffactory Pro Trial VersionDokumen15 halamanTechnical Specifications For Door Trim Panel Assembly: PDF Created With Pdffactory Pro Trial VersionDiego CamargoBelum ada peringkat

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- Mikroniek - Professional Journal On Precision EngineeringDokumen68 halamanMikroniek - Professional Journal On Precision EngineeringViñu LittleMonkey0% (1)

- CH2 Describing Motion, Kinematics in One DimensionDokumen38 halamanCH2 Describing Motion, Kinematics in One DimensionEpic WinBelum ada peringkat

- DC Motor Speed Control BC201Dokumen24 halamanDC Motor Speed Control BC201ROSEMARIO PORFIRIOBelum ada peringkat

- Working Principle of I - P ConverterDokumen4 halamanWorking Principle of I - P ConvertersandystaysBelum ada peringkat

- General Physics 1: Quarter 2 - Module 3 Periodic MotionDokumen33 halamanGeneral Physics 1: Quarter 2 - Module 3 Periodic MotionSalinas SalinasBelum ada peringkat

- Z-Learning 101 - Basics of Motors and Motor ControlsDokumen44 halamanZ-Learning 101 - Basics of Motors and Motor ControlsridwantpBelum ada peringkat

- Gen Physics q2 Module 1Dokumen3 halamanGen Physics q2 Module 1Lawrence Sean MotinBelum ada peringkat

- Important Questions - APS - IDokumen3 halamanImportant Questions - APS - IAakash MehtaBelum ada peringkat

- InterferenceDokumen15 halamanInterferenceShamim khanBelum ada peringkat

- 307D, 311D, 312D, 315D, 319D, 320D, 323D, M313D, M315D, M316D, M318D, and M322D Excavators Ai R Conditioning Electrical SystemDokumen2 halaman307D, 311D, 312D, 315D, 319D, 320D, 323D, M313D, M315D, M316D, M318D, and M322D Excavators Ai R Conditioning Electrical SystemDed IvanovichBelum ada peringkat

- Visokonaponski Vodovi: Električni ParametriDokumen24 halamanVisokonaponski Vodovi: Električni ParametrimilanovsdBelum ada peringkat

- Electric Charges & Fields Question PaperDokumen6 halamanElectric Charges & Fields Question PaperBolt FFBelum ada peringkat

- Chapter 8 Nature of LightDokumen45 halamanChapter 8 Nature of LightjellBelum ada peringkat

- Microwave Engineering PPTsDokumen59 halamanMicrowave Engineering PPTssrinivas19821982Belum ada peringkat

- Kinematic Analysis of Speed Skater's Leg Movement in Corner TurnDokumen11 halamanKinematic Analysis of Speed Skater's Leg Movement in Corner TurnDanielGreigBelum ada peringkat

- MV & LV SWGR, METHOD STATEMENTDokumen106 halamanMV & LV SWGR, METHOD STATEMENTMohammed Nouzal100% (1)

- VFD Manual PDFDokumen60 halamanVFD Manual PDFray1coBelum ada peringkat

- Self-Excited GenratorDokumen6 halamanSelf-Excited GenratorYasirBelum ada peringkat

- HTS Fault Current Limiter Concept Based on Non-Inductive CoilsDokumen5 halamanHTS Fault Current Limiter Concept Based on Non-Inductive CoilsNurdiansyahBelum ada peringkat