Plant Layout - Pumps 1. 2. 3. 4. 5

Diunggah oleh

Rahul LavandJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Plant Layout - Pumps 1. 2. 3. 4. 5

Diunggah oleh

Rahul LavandHak Cipta:

Format Tersedia

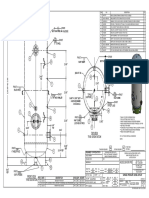

Plant Layout - Pumps Table of Contents 1. General 2. Centrifugal Pumps 3. Reciprocating Pumps 4. Rotary Pumps 5. Pump Drivers 6.

Pump Harness Piping

1. General 1.1 Definition In this context a pump is defined as a machine used to ene!ate a p!essu!e diffe!ential in o!de! to p!opel li"uid th!ou h a pipin system f!om one location to anothe!. 1.2 Types of Pump The th!ee basic types of pump a!e cent!ifu al# !ecip!ocatin # and !ota!y. $ee belo% fi u!es. Cent!ifu al pumps a!e the most common. They a!e mo!e economic in se!&ice and !e"ui!e less maintenance than othe! types. 'otation of the impelle! blades p!oduces a !eduction in p!essu!e at the cente! of the impelle!. This causes li"uid to flo% onto the impelle! f!om the suction no((le th!o%n out%a!ds alon the blades by cent!ifu al fo!ce lea&in the blade tips &ia the pump &olute finally lea&in the discha! e no((le# in a smooth# nonpulsatin flo%. 'ecip!ocatin pumps a!e used %he!e a p!ecise amount of li"uid is !e"ui!ed to be deli&e!ed# also %he!e the deli&e!y p!essu!e !e"ui!ed is hi he! than can be achie&ed %ith othe! types. The li"uid is mo&ed by means of a piston in a cylinde! afte! bein d!a%n into the cylinde!# th!ou h an inlet &al&e# as the piston mo&es do%n the cylinde!. )s the piston mo&es bac*

up the cylinde! the li"uid is discha! ed at a p!e-set p!essu!e cont!olled by deli&e!y &al&e. The li"uid is e+ected f!om the cylinde! into the pipin system in pulses %hich a!e t!ansmitted to the suction and discha! e pipin # thus hold do%ns could be !e"ui!ed on the pipin system. 'ota!y pumps a!e used to mo&e hea&y o! &e!y &iscous fluids. These employ mechanical means such as ea!# cam and sc!e%# to mo&e the fluid.

2. Centrifugal Pumps 2.1 Net Positive Suction Head Cent!ifu al pumps must ha&e thei! suction lines flooded at all times. The suction pipin has to be desi ned to a&oid ca&itations o! p!e&ent &apo! ente!in the pump. The!efo!e# suction lines should fall continuously fo! a sufficient hei ht f!om o&e!head sou!ce to pump. The minimum &e!tical hei ht !e"ui!ed f!om sou!ce to pump suction is called the ,et Positi&e $uction -ead# .,P$-/. This is c!itical fo! efficient pump ope!ation and must not be !educed. 0essel ele&ations a!e often dependent on the ,P$- of its associated pump. $ee belo% fi u!es. 2.2 Pump Types

The!e a!e th!ee basic types of cent!ifu al pumps. -o!i(ontal d!i&e shaft %ith pump d!i&e mounted !emote f!om the line# &e!tical d!i&e shaft %ith pump and d!i&e mounted on the line# &e!tical ba!!el type %ith di!ect imme!sion suction facility. In each case the type !efe!s to d!i&e shaft di!ection. The most common is the ho!i(ontal %ith its shaft in the ho!i(ontal# &e!tical in line pumps ha&e thei! shafts &e!tical and the pump is installed in the pipe line# as a &al&e must be. 0e!tical can pumps a!e usually sin le sta e# but ho!i(ontal and &e!tical can types can be multi-sta ed to obtain hi he! deli&e!y p!essu!es. 2. Suction Piping for Hori!ontal Pumps "ine Si!e $uction pipin is usually one o! t%o line si(es la! e! than the pump suction no((le si(e. $uction pipin mo!e than t%o si(es la! e! should be "ue!ied %ith P!ocess 1epa!tment. Suction No!!le #rientation Cent!ifu al pumps a!e supplied %ith suction no((les on the end of pump casin # axially in line %ith impelle! shaft# also on top o! side of pump casin . 2sually pumps a!e specified %ith end o! top suction fo! ene!al se!&ices. $ide suction pumps# %ith side discha! e a!e f!e"uently selected fo! la! e %ate! duty. )lso side suction - side discha! e pumps can be obtained in multi-sta e fo!m fo! hi he! p!essu!e

diffe!entials. These pumps tend to become &e!y lon # so if plot space is ti ht# conside!ation should be i&en to pu!chasin the pump in &e!tical fo!m %ith a sump at !ade. $ee belo% fi u!es. $le%i&ility of Suction "ines Consistent %ith ood pipin p!actice# pump suction lines should be as sho!t as possible# but %ith enou h flexibility to abso!b any pipe mo&ement caused by tempe!atu!e diffe!entials and to maintain pump no((le loads to %ithin those pe!mitted by pump &endo!. 3o! fu!the! details !efe! to section on pipin flexibility. Suction "ine $ittings 1ue to suction line bein la! e! than the suction no((les# !educe!s a!e !e"ui!ed in the line. 'educe!s should be as close as possible to no((le. 4ccent!ic !educe!s %ill be used %ith the flat on top fo! ho!i(ontal pumps. $ee belo% fi u!es. 3o! pumps %ith suction and discha! e no((les on top of casin # ca!e must be ta*en to ensu!e that the flats on eccent!ic !educe!s a!e o!ientated so that suction and discha! e lines do not foul each othe!. $ee belo% fi u!es. Temporary Startup Strainers )ll pumps must ha&e a tempo!a!y sta!tup st!aine! in the suction line to p!e&ent any pipe deb!is dama in the pump. $t!aine!s %ill be located bet%een pump suction bloc* &al&e and pump. $t!aine!s a!e a&ailable

in the follo%in styles 5 flat# bas*et# conical and bath o! 6tee7 type. 3o! bas*et and conical types a !emo&able spool piece must be p!o&ided do%nst!eam of suction bloc* &al&e# %hich must not inte!fe!e %ith line suppo!ts. 8oth types ha&e the ad&anta e that the pipin is left undistu!bed and st!aine! element can be !emo&ed simply by !emo&in the blind flan e on the tee# thus lea&in the pipin and suppo!ts undistu!bed. $ee belo% fi u!es. 2.' Disc(arge Piping for Hori!ontal Pumps "ine Si!e 9ene!ally# discha! e pipin is one o! t%o si(es la! e! than the pump discha! e no((le si(e. Disc(arge "ine $ittings 1ue to discha! e line bein la! e! than the discha! e no((le eccent!ic !educe!s a!e !e"ui!ed in the line. 'educe!s should be as close as possible to the no((le# %ith top suction - top discha! e pumps# ca!e must be ta*en to ensu!e that the flats on eccent!ic !educe!s a!e o!ientated so that the lines do not foul each othe!. ) p!essu!e au e is located in the discha! e line# and should be upst!eam of the chec* and ate &al&es %hich a!e usually flan ed to ethe! %ith a d!ip!in bet%een them. :hen a le&el s%itch fo! pump p!otection is installed in the discha! e line# upst!eam

of bloc* &al&es# ensu!e ood access fo! maintenance of s%itch. To enable ood access to &al&e hand%heels and ease of suppo!tin # the discha! e line should be tu!ned flat afte! !educe!# and the line an led a%ay f!om the no((le to enable the line to be suppo!ted f!om !ade. $ee belo% fi u!es. )&oid suppo!tin la! e lines f!om pipe!ac* st!uctu!es if possible# this enables minimum si(e beam sections to be used and bette! access fo! pump !emo&al and maintenance. 2.) Side Suction and Disc(arge Hori!ontal Pump This type of pump is usually installed in a la! e duty se!&ice %ith la! e bo!e lines. ,e&e! connect an elbo% flan e fittin ma*eup to the no((le of suction line comin do%n to the pump. $upply a st!ai ht piece of pipe t%o pipe diamete!s lon bet%een the no((le and elbo%. The t%o diamete! pipe len th can be eliminated if the elbo% is in the ho!i(ontal# only eliminate pipe len th if a&ailable space is ti ht. $ee belo% fi u!es 2.* +ertical Pumps 0e!tical pumps# also called can type o! ba!!el type a!e used %hen a&ailable ,P$- is &e!y lo% o! nonexistent. +ertical ,n-"ine Pumps

This type of pump is mounted di!ectly into the pipe line# as a &al&e %ould be. 3o! smalle! si(es# the pipin system suppo!ts the pump and moto!# thus it is essential that the line is suppo!ted local to the pump to p!e&ent the line mo&in %hen the pump is !emo&ed. )lso ensu!e that the!e is ood access to pump fo! maintenance and %ithd!a%al %ith no o&e!head obst!uctions fo! liftin out pump. La! e! si(e in-line pumps ha&e feet o! lu s on the casin fo! suppo!tin f!om !ade o! steel%o!*. +ertical Can or .arrel Type 2sually this type of pump is installed in coolin to%e! %ate! ci!culatin se!&ice# !etention ponds# and applications %he!e ,P$- is lo% and suction is ta*en f!om a sump belo% !ade. In most cases# the!e is no suction pipin to be conside!ed# but the discha! e line must be !outed to ensu!e ood access fo! pump maintenance# %ith no o&e!head obst!uctions fo! pump !emo&al by a c!ane. $ee belo% fi u!es.

. Reciprocating Pumps .1 Types of Pumps The!e a!e th!ee classes of !ecip!ocatin pumps# piston# plun e! and diaph!a m. Piston pumps a!e ene!ally used %he!e medium to hi h deli&e!y p!essu!es a!e !e"ui!ed# such a hi h p!essu!e flushin of &essel inte!io!s# etc. These can be obtained in multi-cylinde! fo!m and can be sin le o! double actin . Plun e! pumps a!e usually used fo! mete!in o! p!opo!tionin . 3!e"uently a &a!iable speed d!i&e o! st!o*e ad+ustin mechanism is p!o&ided to &a!y the flo% as desi!ed. 1iaph!a m pumps a!e in&a!iably ai! d!i&en and &e!y compact# also the!e a!e no seals o! pac*in exposed to the li"uid bein pumped %hich ma*es them ideal fo! handlin ha(a!dous o! toxic li"uids. These a!e often used fo! sump pump out. $ee belo% fi u!es.

'. Rotary Pumps '.1 Types of Pumps The!e a!e t%o main classes of !ota!y pumps# ea! o! sc!e%.

9ea! pumps a!e usually employed to pump oils and nonab!asi&e fluids. $c!e% pumps a!e usually used to pump hea&y &iscous fluids and nonab!asi&e slud es. )pa!t f!om maintainin ood access to pumps fo! ope!ation and maintenance each case should be t!eated on an indi&idual basis.

). Pump Drivers ).1 Types of Pump Drivers The th!ee most common types of d!i&e! a!e the elect!ic moto!# diesel en ine# and steam tu!bine. 5.2 4lect!ic moto!s a!e the most common pump d!i&e! and a!e of the totally enclosed# flame p!oof type suitable fo! (one 1 use. Thei! si(es !an e f!om small to &e!y la! e %hich !e"ui!e thei! o%n coolin systems. 5.3 1iesel en ines a!e usually to be found as d!i&e!s fo! fi!e-%ate! pumps %hich a!e housed in a sepa!ate buildin a%ay f!om the main complex. 5.4 $team tu!bines used fo! pump d!i&e!s a!e ussualy sin le sta e and the pump that they d!i&e a!e in&a!iably fo! standby se!&ice .spa!e/. ).'.1 Steam No!!le #rientation

The steam inlet no((le is usually on the !i ht hand side %hen &ie%ed f!om the pump couplin end of the tu!bine %ith the exhaust on the left hand side as standa!d. Tu!bines can be pu!chased %ith inlet and exhaust on the same side. This means that the pipin desi ne! can place the exhaust connection eithe! on the same o! opposite side f!om the inlet. 9ene!ally opposite side location of no((les !esults in less pipin con estion. ).'.2 ,nlet Piping $team inlets a!e fu!nished %ith st!aine!s as pa!t of the tu!bine fo! p!otection a ainst pipe deb!is# the!efo!e inlet pipin must be desi ned %ith a !emo&able section fo! st!aine! !emo&al. $team supply to tu!bines must be moistu!e f!ee at all times# othe!%ise dama e to the tu!bine %ill occu! if condensate ente!s the tu!bine %hile it is !unnin . To sepa!ate condensate f!om steam a boot-le must be installed up st!eam of the inlet bloc* &al&e. The t%o basic tu!bine installations a!e manual sta!tup o! automatic sta!tup. The manual sta!tup %ill ha&e a ate &al&e in the steam supply nea! the tu!bine inlet. 2pst!eam of the bloc* &al&e a boot-le must be installed %ith connections fo! blo%-do%n and steam t!ap to !emo&e any condensate in the steam supply. 3o! automatic sta!tup the ate &al&e is !eplaced %ith !emote ope!ated cont!ol &al&e# the boot-le and t!aps a!e still !e"ui!ed upst!eam as fo! manual sta!tup.

$team t!aps should be p!o&ided to *eep the tu!bine casin f!ee f!om condensate. These can be installed at the casin lo% point if a connection is p!o&ided o!# on the outlet pipin if the casin d!ains into the outlet system. ,ote the!e must be a t!ap befo!e any &e!tical !ise %hich could fo!m a poc*et %he!e condensate could collect. ).'. /arm-up .ypass ;n automatic sta!tup a %a!m-up bypass must be p!o&ided a!ound the cont!ol &al&e. This bypass is usually a 617 lobe &al&e# and is pa!tially opened to allo% steam to *eep the tu!bine constantly %a!m and slo%ly tu!nin to p!e&ent the shoc* of hot steam ente!in a cold tu!bine# and eliminate dama e to tu!bine blades. 3o! manual sta!tup it is !ecommended that a %a!m-up bypass be installed# but the +ob flo%sheets %ill o&e!n. :hen a %a!m-up bypass is installed a steam t!ap on the casin *eeps the system f!ee of condensate. $ee belo% fi u!es. ).'.' 0%(aust Piping Tu!bine exhausts a!e !outed eithe! to a closed exhaust steam system o! to atmosphe!e. :hen exhaust is to a closed system the!e must be a bloc*

&al&e bet%een tu!bine and main heade!# this bloc* is al%ays open du!in no!mal conditions and only closed fo! tu!bine maintenance o! !emo&al. Thou ht should be i&en to locatin exhaust bloc* &al&e on the pipe!ac* immediately befo!e lines ente! main heade!# this %ill p!e&ent accidental closu!e of this &al&e. If the exhaust line is !outed to atmosphe!e# the steam t!ap on tu!bine casin %ill not be installed# but !eplaced by ate &al&e pa!tially open to allo% condensate to d!ain off f!om casin . $ee belo% fi u!es. ).'.) Rotor /it(dra1al <ost small tu!bine casin s a!e split alon thei! ho!i(ontal axis and enou h space abo&e the tu!bine should be *ept clea! to allo% fo! the top section of casin to be lifted clea! of !oto! by c!ane. $ee belo% fi u!es.

*. Pump Harness Piping <ost pumps !e"ui!e exte!nal se!&ices to be piped to them fo! bea!in coolin # bea!in lub!ication# seal flushin # &entin and d!ainin . These !e"ui!ements %ill be sho%n on utility flo%sheets# and it is the pipin desi ne!s !esponsibility to ensu!e that the actual eo !aphic location of pumps %ith ha!nesses a!e co!!ectly sho%n on the flo%sheets. Thou h should be i&en to !unnin subheade!s to !oups of pumps that ha&e ha!ness !e"ui!ements. These subheade!s must be si(ed and ma!*ed on flo%sheet maste!s. 8ecause b!anch lines to indi&idual pumps a!e small diamete!# i.e. = mm# it is ad&isable to ta*e b!anch connections f!om the top of subheade!s. This %ill eliminate pipe deb!is ettin into the b!anch line and into the pump bea!in s# etc. Ca!e should be ta*en to ensu!e ha!ness pipin does not inte!fe!e %ith ood ope!ation and maintenance space.

9ea!-Type 'ota!y Pump -a&in T%o Impelle!s

Conical )nd 8as*et $t!aine!s

The abo&e dia !ams indicate co!!ect and inco!!ect methods of attachin suction pipin . 3i . 1 $ho%s ai! poc*et fo!med alon uppe! side of pipe by sin concent!ic !educe!. 3i . 2 .)/ -o!i(ontal ell di!ectly into pump suction !esults in an unbalanced th!ust on pump bea!in s. .8/ 2se spool piece 3 pipe diamete!s lon o! lon !adius ell %ith cente! &e!tical &ane. .C/ <ay be installed %ith o! %ithout spool piece but 2 pipe diamete!s spool is p!efe!!ed.

3i . 3 $ho%s p!ope! method of connectin pump suction to a suction heade! in o!de! to a&oid ai! poc*ets. 3i . 4 'ep!esents a common e!!o! made suction pipin to a cent!ifu al pump by placin pipin o&e! an emban*ment of a !ese!&oi!# o! othe! obst!uction. S2CT,#N P,P,NG3 The suction pipin should be as di!ect and sho!t as possible. In ene!al it should be one o! t%o si(es la! e! than pump no((le. If chan es f!om one pipe si(e to anothe! a!e necessa!y# standa!d !educe!s should be used. Co!!ect and inco!!ect %ays a!e sho%n in the pictu!e !efe!!ed to abo&e.

)2T;<)TIC $T)'T-2P

<),2)L $T)'T-2P

Anda mungkin juga menyukai

- Specifications WWTP Parshall FlumeDokumen572 halamanSpecifications WWTP Parshall Flumen_zeinounBelum ada peringkat

- Veolia Environnement: A Profile of The World's Largest Water Service Corporation (U.S. Version)Dokumen20 halamanVeolia Environnement: A Profile of The World's Largest Water Service Corporation (U.S. Version)Food and Water WatchBelum ada peringkat

- Tables of Piping Standards - PittsburghDokumen166 halamanTables of Piping Standards - PittsburghzhangamecBelum ada peringkat

- 102 Productivity Hacks For InventorDokumen102 halaman102 Productivity Hacks For InventorSimon PetersenBelum ada peringkat

- V 21302 - Rev.2 CDokumen133 halamanV 21302 - Rev.2 Cpandiangv100% (1)

- Ansymss SP-69: Standard PracticeDokumen16 halamanAnsymss SP-69: Standard PracticekjhgBelum ada peringkat

- ELEGL02Dokumen26 halamanELEGL02Ariel Anibal AparicioBelum ada peringkat

- Ad204-600-G-02727 Piping Classification Rev 2Dokumen343 halamanAd204-600-G-02727 Piping Classification Rev 2Manohar SeetharamBelum ada peringkat

- Process Industry Practices PipingDokumen5 halamanProcess Industry Practices Pipingraobabar21Belum ada peringkat

- Heat Tracing CatalogDokumen37 halamanHeat Tracing CatalogRAJADURAI SINGH DHARMARAJBelum ada peringkat

- BARKA IWP Quality Procedure Numbering and Communication PhilosophyDokumen24 halamanBARKA IWP Quality Procedure Numbering and Communication PhilosophyRaul Dolo QuinonesBelum ada peringkat

- Jacketed Ball Valves LeafletDokumen2 halamanJacketed Ball Valves LeafletSherif EltoukhiBelum ada peringkat

- 660 Gallon TankDokumen2 halaman660 Gallon Tankleeconner3Belum ada peringkat

- Liquid Piping FundamentalsDokumen4 halamanLiquid Piping FundamentalsDhanraj VasanthBelum ada peringkat

- Astm A 733-03Dokumen4 halamanAstm A 733-03jcBelum ada peringkat

- Pw610 Pwi BBDokumen2 halamanPw610 Pwi BBAbdulBelum ada peringkat

- HandSafetyBook PDFDokumen100 halamanHandSafetyBook PDFahmar javedBelum ada peringkat

- System GuideDokumen218 halamanSystem Guidethanh_79Belum ada peringkat

- M4 U4 Bracket FabricationDokumen26 halamanM4 U4 Bracket FabricationKaliya PerumalBelum ada peringkat

- 12 - OLGA UGM Curtin PresentationDokumen40 halaman12 - OLGA UGM Curtin PresentationGui Do Esp100% (1)

- Hoppers (Rectangle To Rectangle) : Industrial InsulationDokumen14 halamanHoppers (Rectangle To Rectangle) : Industrial InsulationAlvaro A. Kalle GonzalesBelum ada peringkat

- Presentation ON: AUTOCAD 2015Dokumen23 halamanPresentation ON: AUTOCAD 2015Sahil Bhati0% (1)

- Water tank specsDokumen7 halamanWater tank specsMakulay Ang BuhayBelum ada peringkat

- AMICON - Butterfly ValvesDokumen16 halamanAMICON - Butterfly ValvesAnees OlasserilBelum ada peringkat

- European Standard Norme Européenne Europäische NormDokumen13 halamanEuropean Standard Norme Européenne Europäische NormTsrinivasanTBelum ada peringkat

- Process Piping Design & Construction As Per ASME B 31.3 PDFDokumen12 halamanProcess Piping Design & Construction As Per ASME B 31.3 PDFDRASTIBelum ada peringkat

- E3d Errors New FileDokumen13 halamanE3d Errors New FileOwais AhmedBelum ada peringkat

- Seamless Stainless Tubes For Hydraulic and Instrumentation SystemsDokumen10 halamanSeamless Stainless Tubes For Hydraulic and Instrumentation Systemsfezzeh kabiri kenariBelum ada peringkat

- ISA Control Valve Data Sheet GuideDokumen1 halamanISA Control Valve Data Sheet GuidechandruhbkkBelum ada peringkat

- Shell & Tube Heat Exchanger (STHE) Overpressure Protection From Tube RuptureDokumen33 halamanShell & Tube Heat Exchanger (STHE) Overpressure Protection From Tube RuptureMohamed Sayed AbdoBelum ada peringkat

- PDMS - Haunch Member CreationDokumen371 halamanPDMS - Haunch Member Creationonlykarnan100% (1)

- Agbami Project Control Valve Detail DrawingDokumen237 halamanAgbami Project Control Valve Detail DrawingRobert BurtonBelum ada peringkat

- Tank Blanketing and Vapor Recovery Solutions: Application MapDokumen1 halamanTank Blanketing and Vapor Recovery Solutions: Application Mapดั๊มพ์ วาสนาทิพย์Belum ada peringkat

- Pipeway Control Drawing ProceduresDokumen6 halamanPipeway Control Drawing Proceduresmengelito almonteBelum ada peringkat

- Norma Awwa C-207Dokumen14 halamanNorma Awwa C-207Clau QuilodranBelum ada peringkat

- BB 1 - 1 Estapa - Pump WorksDokumen2 halamanBB 1 - 1 Estapa - Pump WorksMarco Pompa ReyesBelum ada peringkat

- Detergent Alkylates - World Markets To 2025 ProspectusDokumen27 halamanDetergent Alkylates - World Markets To 2025 ProspectusRafflesia GroupBelum ada peringkat

- CV FormateDokumen1 halamanCV Formateps bastimalookBelum ada peringkat

- 7770865e - 6187064 - 01 Technical Specification Ros 6180 Rev 00Dokumen10 halaman7770865e - 6187064 - 01 Technical Specification Ros 6180 Rev 00bondsivamaniBelum ada peringkat

- SMP 7086 4 Data Aqu BK (1) .JPGDokumen78 halamanSMP 7086 4 Data Aqu BK (1) .JPGSlim.BBelum ada peringkat

- PumpWorks 610 Capabilities Brochure PDFDokumen20 halamanPumpWorks 610 Capabilities Brochure PDFfatamorgganaBelum ada peringkat

- General Specification: Welding - MaterialsDokumen15 halamanGeneral Specification: Welding - MaterialsGil-Alain EgnakouBelum ada peringkat

- PFD & PID Eng Toolbox InternetDokumen21 halamanPFD & PID Eng Toolbox InternetFransiska Adelia FroggersBelum ada peringkat

- 50 Question Related To ValvesDokumen24 halaman50 Question Related To ValvesNjat HakimBelum ada peringkat

- BN-DG-C01K Plant Layout PumpsDokumen16 halamanBN-DG-C01K Plant Layout Pumpshalder_kalyan9216Belum ada peringkat

- s1fnmdl3sm PDFDokumen27 halamans1fnmdl3sm PDFMaintenanceBelum ada peringkat

- 1722 Piping Drafting Instruc GuideDokumen26 halaman1722 Piping Drafting Instruc GuideRizwan Ashraf100% (2)

- PIP PNC00002 Abbreviated Piping Terms and AcronymsDokumen7 halamanPIP PNC00002 Abbreviated Piping Terms and AcronymsFrancisco José Hernández GómezBelum ada peringkat

- Control Choke Valve 9000Dokumen8 halamanControl Choke Valve 9000sabi_shi100% (2)

- Camisas Refrigeracion Flowsleeves Pi-058 GB 2013-06-12Dokumen38 halamanCamisas Refrigeracion Flowsleeves Pi-058 GB 2013-06-12daniel2rialBelum ada peringkat

- Bomba OblDokumen24 halamanBomba OblJos RicardoBelum ada peringkat

- Solidworks Routing GuideDokumen25 halamanSolidworks Routing GuideFa ChBelum ada peringkat

- Cad-Cam-Cim Lab Manual Me804Dokumen49 halamanCad-Cam-Cim Lab Manual Me804Vivek Patil100% (1)

- Piping in Fluid Transport ProcessDokumen39 halamanPiping in Fluid Transport ProcessVamsi KrishnaBelum ada peringkat

- Bs en Iso 14122 Part 2 PDFDokumen16 halamanBs en Iso 14122 Part 2 PDFadasadBelum ada peringkat

- Hydraulic Institute StandardDokumen2 halamanHydraulic Institute StandardKhalid AmeedBelum ada peringkat

- Classification and Designation of Common Pump TypesDokumen3 halamanClassification and Designation of Common Pump TypesPradeep KumarBelum ada peringkat

- Maintaining Centrifugal PumpsDokumen4 halamanMaintaining Centrifugal Pumpsaserf251Belum ada peringkat

- Oxygen Concentrator Repair and TroubleshootingDokumen4 halamanOxygen Concentrator Repair and TroubleshootingSirgut TesfayeBelum ada peringkat

- Qdoc - Tips - General Guidelines of Pump Piping LayoutDokumen8 halamanQdoc - Tips - General Guidelines of Pump Piping LayoutAmjadali ChoudhariBelum ada peringkat

- NRG 200Dokumen64 halamanNRG 200Rahul LavandBelum ada peringkat

- Stainless Steel Grades 2008 01Dokumen2 halamanStainless Steel Grades 2008 01Rahul LavandBelum ada peringkat

- 1 Piping CostingDokumen33 halaman1 Piping Costingamoldhole97% (34)

- Pipe Supports Asia — Cryogenic Factory Insulation ComparisonDokumen28 halamanPipe Supports Asia — Cryogenic Factory Insulation ComparisonRahul LavandBelum ada peringkat

- Ssociates, Inc.: Heat Transfer CementDokumen2 halamanSsociates, Inc.: Heat Transfer CementRahul LavandBelum ada peringkat

- Basics of Stress RelievingDokumen5 halamanBasics of Stress Relievingabhishek198327Belum ada peringkat

- 2-4 Dichlorophenol and Fe-TiO2Dokumen7 halaman2-4 Dichlorophenol and Fe-TiO2Rahul LavandBelum ada peringkat

- Galvanic Corrossion & The Prevention.Dokumen27 halamanGalvanic Corrossion & The Prevention.Jayakrishnan RadhakrishnanBelum ada peringkat

- Different Forms of Corrosion - Intergranular Corrosion - Weld DecayDokumen2 halamanDifferent Forms of Corrosion - Intergranular Corrosion - Weld DecayRahul LavandBelum ada peringkat

- ASTM Cross Reference Material Specification of FittingsDokumen2 halamanASTM Cross Reference Material Specification of FittingsSharif HasnatBelum ada peringkat

- I Rod Nu Bolt Product OverviewDokumen6 halamanI Rod Nu Bolt Product Overviewjamehome85Belum ada peringkat

- CHARLIE's - Liberal Allowable Stress RangeDokumen3 halamanCHARLIE's - Liberal Allowable Stress RangeRahul LavandBelum ada peringkat

- Safetrace: Dls Steam TracerDokumen2 halamanSafetrace: Dls Steam TracerRahul LavandBelum ada peringkat

- Heat Transfer CompoundsDokumen8 halamanHeat Transfer CompoundsMahmoud Al HomranBelum ada peringkat

- Safetrace: Dls Steam TracerDokumen2 halamanSafetrace: Dls Steam TracerRahul LavandBelum ada peringkat

- S-Mart Gasket TypesDokumen8 halamanS-Mart Gasket TypesdjvhBelum ada peringkat

- Safetrace: Dls Steam TracerDokumen2 halamanSafetrace: Dls Steam TracerRahul LavandBelum ada peringkat

- Heat Transfer Compounds - Thermon - Home - 1pdfDokumen2 halamanHeat Transfer Compounds - Thermon - Home - 1pdfRahul LavandBelum ada peringkat

- NPSHDokumen7 halamanNPSHRahul LavandBelum ada peringkat

- Safetrace: Dls Steam TracerDokumen2 halamanSafetrace: Dls Steam TracerRahul LavandBelum ada peringkat

- Tray OrientationDokumen2 halamanTray OrientationRahul LavandBelum ada peringkat

- Heat Transfer Compounds: Installation ProceduresDokumen8 halamanHeat Transfer Compounds: Installation ProceduresRahul LavandBelum ada peringkat

- Chem Engg Plant LayoutDokumen48 halamanChem Engg Plant Layouteysl86% (14)

- Area Classification GuideDokumen42 halamanArea Classification Guideowenh796100% (4)

- Astm F1166 PDFDokumen228 halamanAstm F1166 PDFRahul Lavand100% (4)

- Flange Gasket Basics GFDokumen8 halamanFlange Gasket Basics GFsenioor2004Belum ada peringkat

- GasketDokumen2 halamanGasketRahul LavandBelum ada peringkat

- Original Gasket Technology GuideDokumen40 halamanOriginal Gasket Technology GuideAtty AttyBelum ada peringkat

- Refining ProcessDokumen23 halamanRefining ProcesstndeshmukhBelum ada peringkat

- EE35T-Designing Substation Earthing SystemsDokumen9 halamanEE35T-Designing Substation Earthing SystemsOmkar SheteBelum ada peringkat

- Transformer ProtectionDokumen5 halamanTransformer ProtectionMuhammed DemirBelum ada peringkat

- Operation and Maintenance of EHV EquipmentDokumen26 halamanOperation and Maintenance of EHV Equipmentdheerajdodda1Belum ada peringkat

- CB 1Dokumen10 halamanCB 1sherif ahmed moussaBelum ada peringkat

- Tabla Alerta UPSDokumen18 halamanTabla Alerta UPSWalter Achaya LevaBelum ada peringkat

- Fte Monitor LCDDokumen85 halamanFte Monitor LCDcaragyBelum ada peringkat

- Megger - Boletín #1 Sobre Interruptores de Potencia - Funcionamiento-TiposDokumen7 halamanMegger - Boletín #1 Sobre Interruptores de Potencia - Funcionamiento-TiposRicardoRomeroBelum ada peringkat

- Transformer Testing Guide - Insulation, Ratio, Temperature, Vector GroupDokumen2 halamanTransformer Testing Guide - Insulation, Ratio, Temperature, Vector GroupVinod WaliBelum ada peringkat

- Tpr6 Series Gas Insulated Rmus: D 6.6 U1 / U3 Type Bus Coupling Unit With 630 A DisconnectorDokumen24 halamanTpr6 Series Gas Insulated Rmus: D 6.6 U1 / U3 Type Bus Coupling Unit With 630 A DisconnectorAmirudin KhafiBelum ada peringkat

- KOKM 072 Xa 10 - 1VLC000600 Rev. 2, en 2016 - 12 - 08Dokumen7 halamanKOKM 072 Xa 10 - 1VLC000600 Rev. 2, en 2016 - 12 - 08TetianaBelum ada peringkat

- 2.u#1 11KV Switchgear Testing Book-2 PDFDokumen219 halaman2.u#1 11KV Switchgear Testing Book-2 PDFSabyasachi PatraBelum ada peringkat

- Electrical Operation Manual HandbookDokumen150 halamanElectrical Operation Manual HandbookVeny Martiani100% (2)

- Coren Technical ReportDokumen30 halamanCoren Technical ReportWilson Henry100% (3)

- Commutation Methods of SCR PDFDokumen2 halamanCommutation Methods of SCR PDFDanielle0% (1)

- Time Sheet Bulanan Periode April 2023Dokumen13 halamanTime Sheet Bulanan Periode April 2023Suto WijoyoBelum ada peringkat

- Well CompletionDokumen25 halamanWell CompletionNeshav100% (7)

- LSS 132kV and 33kV Protection Coordination Scope of Work R1Dokumen2 halamanLSS 132kV and 33kV Protection Coordination Scope of Work R1mohd hazimBelum ada peringkat

- Assignment 1 - 21Dokumen4 halamanAssignment 1 - 21Umair MansoorBelum ada peringkat

- Trafoindo Catalogue Oil Immersed Transformers PDFDokumen2 halamanTrafoindo Catalogue Oil Immersed Transformers PDFCrimson XBelum ada peringkat

- Annexure-24 - 20191-5793-0305-SLD FOR LT PANEL'S-Ver.-1-SLD FOR MAIN PCCDokumen1 halamanAnnexure-24 - 20191-5793-0305-SLD FOR LT PANEL'S-Ver.-1-SLD FOR MAIN PCCvamshikdavBelum ada peringkat

- In This Catalogue: Power and High VoltageDokumen88 halamanIn This Catalogue: Power and High VoltageMohammad NasarBelum ada peringkat

- L6-PDS-01-H-5215-S-40213-B - 220kV PRTN SCH DRG D10+R1 22033kVTfr TIB97ADokumen94 halamanL6-PDS-01-H-5215-S-40213-B - 220kV PRTN SCH DRG D10+R1 22033kVTfr TIB97ASatish KumarBelum ada peringkat

- NikhilDokumen15 halamanNikhilAkash SainiBelum ada peringkat

- Ground Fault Current CalculationDokumen4 halamanGround Fault Current Calculationparthaju100% (1)

- Seminar On Voltage SagDokumen37 halamanSeminar On Voltage SagBiswajit SwainBelum ada peringkat

- Design Basis EIL STDDokumen21 halamanDesign Basis EIL STDMARIMUTHUBelum ada peringkat

- Main EB Transformer - 33KV/11KV (8000KVA) ReadingsDokumen30 halamanMain EB Transformer - 33KV/11KV (8000KVA) Readingsiotaathi tBelum ada peringkat

- PeerlessDokumen12 halamanPeerlessRizalBelum ada peringkat

- Discharge Nozzle Load Analysis for Fire Water Pump P-05ADokumen22 halamanDischarge Nozzle Load Analysis for Fire Water Pump P-05ASeptian FirdausBelum ada peringkat

- GIS Substation1Dokumen26 halamanGIS Substation1Sherif MoussaBelum ada peringkat