Sites Process Steelcastings Pages Materials

Diunggah oleh

chand_yelDeskripsi Asli:

Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Sites Process Steelcastings Pages Materials

Diunggah oleh

chand_yelHak Cipta:

Format Tersedia

3/13/2014

www.rexnord.com/sites/process/steelcastings/Pages/Materials.aspx?platformkey=1&businessunitkey=80570&nodekey=-44003

Alloy Cast Steel Designation and Chemistry

Moly-Telastic is a medium carbon, chromium-molybdenum type cast steel which is similar to an AISI 4135 specification, except with reduced chromium content. It can be heat treated by annealing or normalizing and tempering to an approximate hardness of 180 HB for all section sizes.

No. 1 Gearalloy is a medium carbon, chromium-nickel-molybdenum type cast steel used for applications requiring higher harden ability than Falk Moly-Telastic. It is similar to an AISI 8630 steel, but higher in alloy content.

No. 2 Gearalloy is a low carbon (0.20% nominal), chromium-nickel-molybdenum type cast steel containing 0.04-0.06% vanadium for grain refinement in gear castings. Chemistry is similar to an AISI 8620 steel, but higher in alloy content. This is our standard cast steel for carburized and hardened gears and has comparable harden ability to an AISI 4320 H steel. It is also used in the through-hardened, quenched, and tempered heat treat condition to a maximum hardness range of 245-285 HB for impact applications (this condition is not intended for gearing or wear applications).

No. 3 Gearalloy has higher carbon and molybdenum content than No. I Gearalloy This results in higher harden ability for increased section size or higher hardness ranges for quench and temper heat treatment. It is similar to an "8633" steel (not a standard AISI designation) but higher in alloy content.

http://www.rexnord.com/sites/process/steelcastings/Pages/Materials.aspx?platformkey=1&businessunitkey=80570&nodekey=-44003

1/9

3/13/2014

www.rexnord.com/sites/process/steelcastings/Pages/Materials.aspx?platformkey=1&businessunitkey=80570&nodekey=-44003

No. 4 Gearalloy has higher carbon content than No. 3 Gearalloy. This results in the highest harden ability alloy cast steel (maximum section size or maximum hardness) intended for hardening by quench and temper The harden ability is equivalent to an AISI 4340. Chemistry is similar to an AISI 8640 steel but higher in alloy content.

No. 6 Gearalloy has the same carbon content as No. 4 Gearalloy but has increased alloy content. This enables hardening by normalize and temper heat treatment to higher hardness ranges (325-365 HB maximum) than can be achieved with No. 4 Gearalloy normalized and tempered. No. 6 Gearalloy is not intended to be quench hardened because of quench cracking susceptibility.

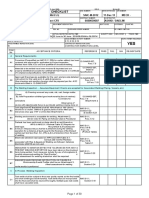

Moly-Telastic and No. I through No. 4 and No. 6 Gearalloy grades of alloy cast steel do not, by intent, conform to specific standard SAE or AISI steel designations regarding carbon and alloy content, but contain modified carbon and generally higher alloy content for improved depth of hardening (harden ability). The chemical analyses for our Moly-Telastic and Gearalloy grades of alloy cast steels are shown in Table 1. TABLE 1 - Chemical Analyses of Our Alloy Steels* Type Moly Telastic AISI 4135 No. 1 Gearalloy AISI 8630 No. 2 Gearalloy** AISI 8120 No. 3 Gearalloy AISI 8633*** No. 4 Gearalloy AISI 8140 No. 6 Gearalloy % Carbon 0.30-0.40 0.33-0.38 0.27-0.37 0.28-0.33 0.17-0.23 0.18-0.23 0.30-0.37 0.30-0.37 0.38-0.45 0.38-0.43 0.38-0.45 % Manganese 0.70-1.00 0.70-0.90 0.70-1.00 0.70-0.90 0.70-1 00 0.70-0.90 0.70-1.00 0.70-0.90 0.70-1.00 0.75-1.00 1.05-1.35 % Chromium 0.40-0.65 0.80-1.10 0.60-0.90 0.40-0.60 0.60-0.90 0.40-0.60 0.60-0.90 0.40-0.60 0.60-0.90 0.40-0.60 0.90-1.20 % Nickel ... ... 0.60-0.90 0.40-0.70 0.60-0.90 0.40-0.70 0.60-0.90 0.40-0.70 0.60-0.90 0.40-0.70 0.60-0.90 % Molybdenum 0.15-0.25 0.15-0.25 0.30-0.40 0.15-0.25 0.30-0.40 0.15-0.25 0.40-0.50 0.15-0.25 0.40-0.50 0.15-0.25 0.55-0.60

2/9

http://www.rexnord.com/sites/process/steelcastings/Pages/Materials.aspx?platformkey=1&businessunitkey=80570&nodekey=-44003

3/13/2014

www.rexnord.com/sites/process/steelcastings/Pages/Materials.aspx?platformkey=1&businessunitkey=80570&nodekey=-44003

No. 6 Gearalloy No Similar AISI Grade No. 5 Gearalloy - Discontinued

0.38-0.45

1.05-1.35

0.90-1.20

0.60-0.90

0.55-0.60

* Percent phasphorus and sulfur (both 0.030% max.) are less than ASTM A148 permitted maximums of 0.05% and 0.06%, respectively. Silicon content is typically 0.45% ** No. 2 Gearalloy also contains 0.04-0.06% vanadium for grain refinement. Vanadium additions are also available for other grades when required. *** "8633" is not a standard AISI designation. Our alloy cast steels can be heat treated to meet the strength requirements of ASTM A148 (High Strength Steel Castings for Structural Purposes) up to grade 165-150. Minimum tensile ductility values (elongation and reduction of area) for corresponding strength levels are shown in Table 2. Other alloy cast steels which meet your specifications can be furnished for special pressure, low temperature and high temperature applications. The selection of the appropriate alloy cast steel depends upon specified chemistry, hardness, strength and design considerations. We will assist you in the proper selection of the appropriate grade to meet your design requirements.

Machinability and Processing

Alloy grades of cast steels (Moly-Telastic and Gearalloy grades) are readily machinable and ductile, due to our ladle deoxidation practice which uses primarily calcium and not aluminum. This, in itself, can easily result in lowering machining costs by as much as 15%. A well equipped sand laboratory monitors sand molding and core making practices. A sodium silicate sand binder is exclusively used in our core making process. This high grade material requires no oven curing, is environmentally safe, and drastically reduces potential metal solidification defects. Pattern molding can accommodate items up to 150" in diameter or diagonal. Beyond 150'*. We utilize sweep or pit molding. The largest pits measure 24' x 50' x 7.5' and 36' x 36'x 10'. The use of aluminum is limited to castings less than 8T finish weight, as it develops aluminum oxides and decreases machinability. Aluminum content used is less than 0.020%. The index of machinability, shown in Table 10, is based on hardness and is related to machinability of B1112 steel (100%). TABLE 10 - Machinability Index Hardness, HB 210-250 225-265 245-285 265-305 Per Cent Index 66 57 50 43

3/9

http://www.rexnord.com/sites/process/steelcastings/Pages/Materials.aspx?platformkey=1&businessunitkey=80570&nodekey=-44003

3/13/2014

www.rexnord.com/sites/process/steelcastings/Pages/Materials.aspx?platformkey=1&businessunitkey=80570&nodekey=-44003

285-325 300-340 335-375 350-390

38 33 28 25

Although microstructure considerations, as well as hardness, determine machinability, our machinability rating system is based on tool life as a function of cutting speed (surface feet per minute).

Mechanical Properties

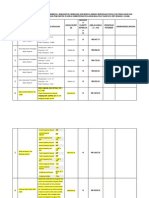

Mechanical properties of steel castings are generally determined from test bars machined from standard ASTM A781 test coupons. These test coupons may be attached to the casting or cast separately. Minimum tensile properties, obtained from standard cast test coupons, for our alloy cast steels are shown in Table 2. Table 2 - Minimum Tensile Properties of Our Alloy Cast Steel TYPE Heat Treatment Hardness HB Tensile Minimum Tensile Properties Yield % Elongation in % Reduction in Area

Strength PSI Strength PSI 2 Inches Annealed or Moly-Telastic Normalized & Tempered 160 (Minimum)

80,000

45,000

23

35

210-250 225-265 245-285 Qenched & Tempered 245-295@ 265-305@ 270-310@ 285-325@ 300-340@

90,000 100,000 110,000 115,000 118,000 120,000 130,000 135,000

60,000 70,000 80,000 85,000 90,000 95,000 100,000 110,000

15 14 13 12 11 11 10 9

35 33 31 29 28 28 26 23

Moly-Telastic

210-250 225-265

90,000 100,000

60,000 70,000

15 15

35 33

No.1

Normalized &

http://www.rexnord.com/sites/process/steelcastings/Pages/Materials.aspx?platformkey=1&businessunitkey=80570&nodekey=-44003

4/9

3/13/2014

www.rexnord.com/sites/process/steelcastings/Pages/Materials.aspx?platformkey=1&businessunitkey=80570&nodekey=-44003

Gearalloy

Tempered

245-285 255-295 265-305

110,000 115,000 118,000

80,000 85,000 90,000

13 12 11

31 29 28

245-285** 255-295** 265-305** No.1 Gearalloy Quenched & Tempered 270-310 285-325 300-340 310-350 335-375

110,000 115,000 118,000 120,000 130,000 135,000 140,000 150,000

80,000 85,000 90,000 95,000 100,000 110,000 115,000 125,000

13 12 11 11 10 9 9 8

31 29 28 28 26 24 23 20

No. 2 # Gearalloy

Water Quenched & Tempered

210-250 225-265 245-285

90,000 100,000 110,000

60,000 70,000 80,000

20 20 18

45 45 42

245-285 No. 3 Gearalloy Normalized & Tempered 255-295 265-305 285-325

110,000 115,000 118,000 130,000

80,000 85,000 90,000 100,000

13 12 11 10

31 29 28 26

265-305** 270-310** 285-325** 300-340 310-350 No. 3 Gearalloy Quenched & Tempered 335-375 350-390

118,000 120,000 130,000 135,000 140,000 150,000 157,000

90,000 95,000 100,000 110,000 115,000 125,000 130,000

11 11 10 9 9 8 7

28 27 26 23 22 20 16

5/9

http://www.rexnord.com/sites/process/steelcastings/Pages/Materials.aspx?platformkey=1&businessunitkey=80570&nodekey=-44003

3/13/2014

www.rexnord.com/sites/process/steelcastings/Pages/Materials.aspx?platformkey=1&businessunitkey=80570&nodekey=-44003

360-400 375-415 390-430 400-445

160,000 170,000 175,000 180,000

135,000 140,000 145,000 150,000

6 5 5 5

12 10 10 10

265-305 No. 4 Gearalloy Normalized & Tempered 285-325 300-340

118,000 130,000 135,000

90,000 100,000 110,000

9 8 6

22 18 15

310-350 335-375 No. 4 Gearalloy Oil Quenched & Tempered 350-390 360-400 375-415 390-430

140,000 150,000 157,000 160,000 170,000 175,000

115,000 125,000 130,000 135,000 140,000 145,000

9 8 6 6 5 5

22 20 12 12 10 10

300-340 No. 6 Gearalloy Normalized & Tempered 310-350 325-365

135,000 140,000 145,000

110,000 115,000 120,000

6 5 4

15 13 9

@ Rough machine before heat treating. ** This hardness can also be obtained by normalizing and tempering. # Unless carburized hardened, No. 2 Gearalloy is for through hardened impact applications and not for gearing or wear applications. Test bar results for tensile ductility (per cent elongation and reduction of area) and impact strength may not be representative of actual castings due to harden ability and section size considerations. Strength properties such as tensile, yield, and to a lesser degree, endurance or fatigue strength, show better correlation between test bars and actual castings, provided hardnesses are equivalent. For further information regarding the limitations of test bar data, please contact our Materials Technology Department through your local Rexnord account executive.

Impact Properties

Typical Charpy V-Notch impact strengths for Moly-Telastic and No. I through No. 4 Gearalloys are shown in Tables 3

http://www.rexnord.com/sites/process/steelcastings/Pages/Materials.aspx?platformkey=1&businessunitkey=80570&nodekey=-44003 6/9

3/13/2014

www.rexnord.com/sites/process/steelcastings/Pages/Materials.aspx?platformkey=1&businessunitkey=80570&nodekey=-44003

through 6. These values were obtained from separate cast keel blocks and 5.0 & 10.0 inch test sections. Impact strength is also a function of heat treatment, hardness and test temperature. Impact properties were evaluated at T/3 depth for test sections. Table 3 is the typical Charpy V-Notch impact strength for Moly-Telastic cast steel in a 5.0 test section in the normalized and tempered (N&T) condition at 160-200 HB. TABLE 3 - Moly-Telastic Cast Steel (5.0" section) Normalized & Tempered 160-200HB Temperature Ft-lbs. -20oF 7 0oF 11 70oF 22 150oF 44 212oF 52

Impact strength in the quenched and tempered condition is higher than for the normalized and tempered condition. Specific data may be obtained upon request. For applications requiring higher impact strength, due to shock loading and/or low ambient temperatures, No. I or No. 2 Gearalloy is recommended depending on the specified hardness. Table 4 shows the typical Charpy V-Notch impact strength (ft-lbs.) for keel blocks of No. I Gearalloy cast steel, as a function of heat treatment and specified hardness. TABLE 4 - No. 1 Gearalloy Cast Steel Keel Blocks (2.0" section) Heat Treat Hardness, HB 225-265 Quenched and Tempered 265-305 300-340 -50oF -20oF 0oF 70oF 150oF 212oF 37 21 16 49 26 21 58 35 24 67 51 39 69 55 46 77 57 48

Table 5 shows the typical Charpy V-Notch impact strength for No. 2 Gearalloy cast steel at 70*F in the water quenched and tempered condition at 207-223HB. TABLE 5 - No. 2 Gearalloy Cast Steel (5.0" Section) Impact Strength Heat Treat Hardness, HB (ft. lbs.) 65 55

207 Water Quenched & Tempered 217-223

http://www.rexnord.com/sites/process/steelcastings/Pages/Materials.aspx?platformkey=1&businessunitkey=80570&nodekey=-44003

7/9

3/13/2014

www.rexnord.com/sites/process/steelcastings/Pages/Materials.aspx?platformkey=1&businessunitkey=80570&nodekey=-44003

Table 6 shows the typical Charpy V-Notch impact strength for No. 4 Gearalloy cast steel (5" and 10" section thickness) according to hardness in the oil quenched and tempered condition. TABLE 6 - No. 4 Gearalloy Cast Steel (5" and 10" section thickness) Hardness, HB 311 Quenched and Tempered 277 302 326 Test Temperature 70oF 212oF 70oF 212oF Impact Size Strength (ft. lbs.) 5" 5" 10" 10" 16 38 18 16

Heat Treat

Metallurgical Considerations

Harden Ability Control of melting is accomplished through computer-aided harden ability (Di) calculations, coupled with statistical process control in order to ensure uniform response to heat treatment. The ideal critical diameter (Di) is defined as the diameter of a round that can be quenched under ideal conditions (ice brine) in order to obtain a 50% martensitic microstructure at the center of the section. The multiplication factors for calculating (Di) harden ability, which vary according to ASTM grain size, carbon, and individual alloy content, are available in literature and from the Materials Technology Department. Cast (Di) harden ability ranges, established in our Melt Shop as acceptance criteria for our heats, are shown in Table 7. TABLE 7 - Cast Hardenability Range Inches Grade Moly-Telastic No. 1 Gearalloy No. 2 Gearalloy No. 3 Gearalloy No. 4 Gearalloy No. 6 Gearalloy (DI) Range, Inches 3.1-4.9 5.3-7.8 4.0-6.2 6.4-9.3 7.9-11.4 13.6-19.2

The harden ability ranges are presented for reference purposes only and should not be considered as part of a material specification. They are intended to illustrate the degree of control used during manufacturing to assist in the production

http://www.rexnord.com/sites/process/steelcastings/Pages/Materials.aspx?platformkey=1&businessunitkey=80570&nodekey=-44003 8/9

3/13/2014

www.rexnord.com/sites/process/steelcastings/Pages/Materials.aspx?platformkey=1&businessunitkey=80570&nodekey=-44003

and heat treatment of castings, and may be subject to slight modification. Jominy End Quench Jominy end quench harden ability ranges from testing alloy cast steels per ASTM A255 are shown in Figures I through 4. For the same reason cited above for (Di), these Jominy end quench curves should not be part of a material specification. harden ability ranges in Figures I through 4 are narrower than those for wrought AISI designations, as illustrated in Figure 4 for No. 4 Gearalloy. Jominy end quench curves were not developed for No. 6 Gearalloy as the curves were expected to be nearly horizontal and No. 6 Gearalloy is not quench hardened.

Weldability

Moly-Telastic and Gearalloy grades can be welded satisfactorily, providing that necessary preheating and post-heating precautions are followed. Minimum preheating temperatures are shown in Table 9. TABLE 9 - Minimum Preheat Temp. GRADE Moly-Telastic No. 1 Gearalloy No. 2 Gearalloy No. 3 Gearalloy No. 4 Gearalloy No. 6 Gearalloy Minimum Preheat Temp. oF 300oF* 350oF 200oF 350oF 400oF 400oF

* In most instances, a 300oF minimum preheat is sufficient. Higher preheat temperature is not necessary unless extensive welding is required. The maximum preheat temperature should not be greater than 200 F above the minimum required. Minimum preheat temperature should be maintained during welding by torch heating and monitored by temperature indicating pencils or a surface pyrometer. The stress relieving temperature should be 1000-1250F for annealed castings and 50-1 00F below the final tempering temperature for normalized and tempered or quenched and tempered castings of all grades. Whenever possible, furnace preheating and post-heating are preferred to local heating with large torches. The choice of electrodes and welding techniques is normally governed by the nature and position of the weld and the mechanical properties required. Low hydrogen type manual arc weld rods, or CO2 shielded flux core process wire, selected on the basis of the required strength, are recommended. When the deposited weld metal is designed to meet the tensile properties of the casting, welding before heat treating, using heat treatable electrodes, e.g., 4340, is recommended.

http://www.rexnord.com/sites/process/steelcastings/Pages/Materials.aspx?platformkey=1&businessunitkey=80570&nodekey=-44003

9/9

Anda mungkin juga menyukai

- Duplex Stainless Steel AL 2205™ Alloy: (UNS S31803 and S32205)Dokumen6 halamanDuplex Stainless Steel AL 2205™ Alloy: (UNS S31803 and S32205)Dell_RevanBelum ada peringkat

- 254-SmoDokumen12 halaman254-SmoDanem Halas100% (1)

- Stainless Steel Grade 904LDokumen5 halamanStainless Steel Grade 904LMadan YadavBelum ada peringkat

- Aisi 4140Dokumen3 halamanAisi 4140BayuPrasetyaPutraBelum ada peringkat

- 6 MoDokumen8 halaman6 MoJodan AsiborBelum ada peringkat

- How To Weld Fully Austenitic Stainless SteelsDokumen20 halamanHow To Weld Fully Austenitic Stainless SteelsCarlos Bermejo AlvarezBelum ada peringkat

- ENB 04 0553 Rev B Bearing Materials Technical InformationDokumen4 halamanENB 04 0553 Rev B Bearing Materials Technical Informationmanasha majhiBelum ada peringkat

- Steel Cleanliness ReportDokumen8 halamanSteel Cleanliness ReportSiva SubramaniBelum ada peringkat

- SUJDokumen11 halamanSUJamit2688Belum ada peringkat

- Userguide For SSDokumen26 halamanUserguide For SSehsan4uBelum ada peringkat

- Ruukki Hot Rolled Steels Processing of Material WeldingDokumen11 halamanRuukki Hot Rolled Steels Processing of Material Weldingprince5621Belum ada peringkat

- 65 45 12 Ductile IronDokumen2 halaman65 45 12 Ductile IronD_D_76100% (1)

- High Temperature Brazing AlloysDokumen0 halamanHigh Temperature Brazing AlloysvkmsBelum ada peringkat

- Material SpecificationDokumen50 halamanMaterial SpecificationSangyt Karna0% (2)

- Ductile Iron Casting Specfications and Details All StandardsDokumen15 halamanDuctile Iron Casting Specfications and Details All StandardsN.Palaniappan100% (1)

- Steel UserguideDokumen50 halamanSteel UserguideBhanu Pratap ChoudhuryBelum ada peringkat

- Carbon Steels (1 000, 11 00, 1 200, and 1500 Series)Dokumen18 halamanCarbon Steels (1 000, 11 00, 1 200, and 1500 Series)Kerem Cengiz KılıçBelum ada peringkat

- NTN Bearings MaterialsDokumen2 halamanNTN Bearings MaterialsCristina Andreea CrissyBelum ada peringkat

- Heat Treatment Processes for Different MaterialsDokumen31 halamanHeat Treatment Processes for Different MaterialsvinayakBelum ada peringkat

- SAE InternationalDokumen12 halamanSAE InternationalMukesh Gupta100% (1)

- Sae j468-1988 Zinc Alloy Ingot and Die Casting CompositionsDokumen3 halamanSae j468-1988 Zinc Alloy Ingot and Die Casting CompositionsAnonymous 7ZTcBn100% (1)

- Welding Practice For Duplex-1 PDFDokumen18 halamanWelding Practice For Duplex-1 PDFBipin Rohit100% (1)

- AVESTA How To Weld Duplex SteelDokumen20 halamanAVESTA How To Weld Duplex SteelGMacella100% (1)

- SOW 09380SB2T SpecSheetDokumen2 halamanSOW 09380SB2T SpecSheetAi NayBelum ada peringkat

- SAE steel grades chartDokumen10 halamanSAE steel grades chartMukesh GuptaBelum ada peringkat

- New Microsoft Word DocumentDokumen56 halamanNew Microsoft Word DocumentshabeekmBelum ada peringkat

- Cut FasterDokumen5 halamanCut Fasterpipedown456Belum ada peringkat

- Ca 15Dokumen2 halamanCa 15naraen9790579455Belum ada peringkat

- Welding of Ferritic/martensitic Stainless Steels: Job KnowledgeDokumen2 halamanWelding of Ferritic/martensitic Stainless Steels: Job KnowledgeMuhammed SulfeekBelum ada peringkat

- Untapped 410Dokumen8 halamanUntapped 410negodesalvadorBelum ada peringkat

- 010 - AR200 Product Data Sheet 2012 04 01Dokumen2 halaman010 - AR200 Product Data Sheet 2012 04 01Baihaki StBelum ada peringkat

- Valve Material ApplicationDokumen16 halamanValve Material Applicationswapneel_kulkarniBelum ada peringkat

- AISI 4140 - 42Cr4Mo2Dokumen2 halamanAISI 4140 - 42Cr4Mo2rajbir_singh75% (4)

- AISI 1015: Digest DDokumen2 halamanAISI 1015: Digest DGovinda RajBelum ada peringkat

- Alloy Steel Castings Table 1Dokumen16 halamanAlloy Steel Castings Table 1takumi_zBelum ada peringkat

- Stainless Steel PlateDokumen19 halamanStainless Steel PlateHarsh AdvaniBelum ada peringkat

- Carbon Steel: Application Material GroupDokumen27 halamanCarbon Steel: Application Material Groupharishkumar.ravichandranBelum ada peringkat

- Alloy Steels 8620: Chemistry DataDokumen6 halamanAlloy Steels 8620: Chemistry DataVijay PalBelum ada peringkat

- A 447Dokumen27 halamanA 447superman3kBelum ada peringkat

- S31803Dokumen2 halamanS31803Elliott RussellBelum ada peringkat

- Steel GradesDokumen8 halamanSteel GradesvijayguravBelum ada peringkat

- Free Machining Steel BrochureDokumen4 halamanFree Machining Steel BrochureKunal PandeyBelum ada peringkat

- Ductile Iron SpecificationsDokumen12 halamanDuctile Iron SpecificationsDouglas BooyensBelum ada peringkat

- Alloy 625 Spec SheetDokumen3 halamanAlloy 625 Spec SheetLinnie McleodBelum ada peringkat

- 468 PDFDokumen4 halaman468 PDFJoshua WalkerBelum ada peringkat

- V410065 en US FactSheet Main 01Dokumen1 halamanV410065 en US FactSheet Main 01Janeth MendozaBelum ada peringkat

- Aalco Metals LTD - Stainless Steel - 201 201L 202 204 200 Series - 97Dokumen3 halamanAalco Metals LTD - Stainless Steel - 201 201L 202 204 200 Series - 97sgupta_192494Belum ada peringkat

- ST Stainless CatalogueDokumen71 halamanST Stainless CatalogueBenjamin RattharojthakunBelum ada peringkat

- 904LDokumen5 halaman904LManish542Belum ada peringkat

- Oxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonDari EverandOxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonBelum ada peringkat

- Oxy-Acetylene Welding and Cutting Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonDari EverandOxy-Acetylene Welding and Cutting Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonBelum ada peringkat

- Boiler Making for Boiler Makers - A Practical Treatise on Work in the ShopDari EverandBoiler Making for Boiler Makers - A Practical Treatise on Work in the ShopPenilaian: 4.5 dari 5 bintang4.5/5 (2)

- Sheet Metalwork on the Farm - Containing Information on Materials, Soldering, Tools and Methods of Sheet MetalworkDari EverandSheet Metalwork on the Farm - Containing Information on Materials, Soldering, Tools and Methods of Sheet MetalworkBelum ada peringkat

- The Working of Steel: Annealing, Heat Treating and Hardening of Carbon and Alloy SteelDari EverandThe Working of Steel: Annealing, Heat Treating and Hardening of Carbon and Alloy SteelBelum ada peringkat

- Machining of Stainless Steels and Super Alloys: Traditional and Nontraditional TechniquesDari EverandMachining of Stainless Steels and Super Alloys: Traditional and Nontraditional TechniquesBelum ada peringkat

- The Working of Steel Annealing, Heat Treating and Hardening of Carbon and Alloy SteelDari EverandThe Working of Steel Annealing, Heat Treating and Hardening of Carbon and Alloy SteelPenilaian: 5 dari 5 bintang5/5 (4)

- Chilli PannerDokumen8 halamanChilli Pannerchand_yelBelum ada peringkat

- Egg Omlet Nutrition InformationDokumen2 halamanEgg Omlet Nutrition Informationchand_yelBelum ada peringkat

- BHS RPMDokumen16 halamanBHS RPMchand_yelBelum ada peringkat

- Batch Continuous MixingDokumen44 halamanBatch Continuous Mixingssmith2007Belum ada peringkat

- MS Flat Sections and Angles SpecificationsDokumen11 halamanMS Flat Sections and Angles Specificationschand_yelBelum ada peringkat

- NAWA Spiral ClassifierDokumen2 halamanNAWA Spiral ClassifierChandra ShekarBelum ada peringkat

- Panner PasandaDokumen16 halamanPanner Pasandachand_yelBelum ada peringkat

- Paneer Cooked in Cashew Sauce / Shahi PaneerDokumen9 halamanPaneer Cooked in Cashew Sauce / Shahi Paneerchand_yelBelum ada peringkat

- Rugged Heavy-Duty Mobile Jaw Crusher StationDokumen2 halamanRugged Heavy-Duty Mobile Jaw Crusher Stationchand_yelBelum ada peringkat

- Elec Grs Pumps 203seriesDokumen5 halamanElec Grs Pumps 203serieschand_yelBelum ada peringkat

- McNAWA - Feeder BreakerDokumen8 halamanMcNAWA - Feeder Breakerchand_yelBelum ada peringkat

- NAWA Grizzly FeederDokumen2 halamanNAWA Grizzly Feederchand_yelBelum ada peringkat

- Std11 CommEng PDFDokumen360 halamanStd11 CommEng PDFSparkdstudios VenkyBelum ada peringkat

- Vemana PadyaluDokumen35 halamanVemana Padyalusunsign100% (1)

- Elec Grs Pumps 203seriesDokumen5 halamanElec Grs Pumps 203serieschand_yelBelum ada peringkat

- Cabinet MinistersDokumen4 halamanCabinet MinistersShailendra SBBelum ada peringkat

- Elec Grs Pumps 203seriesDokumen5 halamanElec Grs Pumps 203serieschand_yelBelum ada peringkat

- WwwDokumen1 halamanWwwchand_yelBelum ada peringkat

- Elec Grs Pumps 203seriesDokumen5 halamanElec Grs Pumps 203serieschand_yelBelum ada peringkat

- Rotary Seal Design GuideDokumen434 halamanRotary Seal Design GuideBhargav Suvagiya100% (3)

- Elec Grs Pumps 203seriesDokumen5 halamanElec Grs Pumps 203serieschand_yelBelum ada peringkat

- Hazardous Duty Motors: Data, Facts and DetailsDokumen2 halamanHazardous Duty Motors: Data, Facts and Detailschand_yelBelum ada peringkat

- Personal GrowthDokumen17 halamanPersonal Growthchand_yelBelum ada peringkat

- RFQ 006Dokumen7 halamanRFQ 006chand_yelBelum ada peringkat

- Sites Process Steelcastings Pages MaterialsDokumen9 halamanSites Process Steelcastings Pages Materialschand_yelBelum ada peringkat

- B.Tech. (CCC) IV Year (NR) Results - March, 2012: HTNO:07063A3651 Name: S Jayakumar Father Name: YYYDokumen1 halamanB.Tech. (CCC) IV Year (NR) Results - March, 2012: HTNO:07063A3651 Name: S Jayakumar Father Name: YYYchand_yelBelum ada peringkat

- Sandvik ASRi ENGDokumen8 halamanSandvik ASRi ENGchand_yel50% (2)

- MathsafirstyrsyllabusnewDokumen3 halamanMathsafirstyrsyllabusnewMohammed RiyazuddinBelum ada peringkat

- CM Classic Lodestar Manual September 2016 Industrial 83874 627-T SPDokumen95 halamanCM Classic Lodestar Manual September 2016 Industrial 83874 627-T SPChuyy GoBelum ada peringkat

- Why Solder Bumps WrinkleDokumen3 halamanWhy Solder Bumps WrinklepeleniusBelum ada peringkat

- Die CastingDokumen9 halamanDie CastingBhushan SalunkeBelum ada peringkat

- Materials and Processes PDFDokumen28 halamanMaterials and Processes PDFBala SundaramBelum ada peringkat

- Chem ImplementationDokumen4 halamanChem ImplementationJaydaHunteBelum ada peringkat

- B 93 - B 93M - 15Dokumen4 halamanB 93 - B 93M - 15phaindikaBelum ada peringkat

- SAIC M 2012 (Structural Welding)Dokumen30 halamanSAIC M 2012 (Structural Welding)rubda11100% (1)

- Die Casting Guide: Processes, Advantages & ApplicationsDokumen10 halamanDie Casting Guide: Processes, Advantages & ApplicationsJimyVillaBelum ada peringkat

- NEMA Premium® Motors for Hazardous LocationsDokumen2 halamanNEMA Premium® Motors for Hazardous LocationsEvelyn Hachiri CoricazaBelum ada peringkat

- Melting Pour Aluvian GoldDokumen2 halamanMelting Pour Aluvian GoldRosinaldo Araújo LimaBelum ada peringkat

- Selection of Filler Metal For WeldingDokumen21 halamanSelection of Filler Metal For WeldingRegu vlogsBelum ada peringkat

- WPS (AsmeDokumen8 halamanWPS (AsmeMohammad Elhedaby100% (6)

- 1.2 Mechanical Design: 1.2.1 Material Selection Based On Corrosion ResistanceDokumen12 halaman1.2 Mechanical Design: 1.2.1 Material Selection Based On Corrosion ResistanceYusuf Shano100% (1)

- Soldering, Brazing and WeldingDokumen18 halamanSoldering, Brazing and WeldingJaydeep Nayak100% (1)

- ISCAR Industries BrochureDokumen92 halamanISCAR Industries BrochureAnonymous CYdagIBelum ada peringkat

- Din 1652-3 Grade 16Mncr5 Treated To Ferritic-Pearlite Structure and Cold-DrawnDokumen3 halamanDin 1652-3 Grade 16Mncr5 Treated To Ferritic-Pearlite Structure and Cold-DrawnairkadBelum ada peringkat

- r05011801 Metallurgical AnalysisDokumen5 halamanr05011801 Metallurgical AnalysisSRINIVASA RAO GANTA100% (1)

- Presperse Catalog - Europe Asia 12-2011 PDFDokumen13 halamanPresperse Catalog - Europe Asia 12-2011 PDFponian9338Belum ada peringkat

- Wellforce Membrane Tanks: For Potable Water Pressure SystemsDokumen2 halamanWellforce Membrane Tanks: For Potable Water Pressure Systemsqwerty_conanBelum ada peringkat

- Peka SC Year 3Dokumen11 halamanPeka SC Year 3joepcw1578Belum ada peringkat

- Valve Body Bolt Temp Rating For ValvesDokumen4 halamanValve Body Bolt Temp Rating For ValvesVinothkumarBelum ada peringkat

- 10 DIY Kettle BellDokumen7 halaman10 DIY Kettle BellcagedraptorBelum ada peringkat

- Magnets for Industry: Powerful Solutions for All ApplicationsDokumen50 halamanMagnets for Industry: Powerful Solutions for All Applicationssalty.mothBelum ada peringkat

- API Schmidt BrettenDokumen28 halamanAPI Schmidt Brettenvictor abrajan100% (1)

- Civil Engineering Objective Type Questions BookDokumen764 halamanCivil Engineering Objective Type Questions Bookajaydevmalik100% (3)

- Cored Wires for Iron Foundry TreatmentDokumen6 halamanCored Wires for Iron Foundry TreatmentamitkkambleBelum ada peringkat

- Rating 460.8 m3h - 108m - CEP 150-630-250.0kW-1500rpm-380V-3Ph-50HzDokumen3 halamanRating 460.8 m3h - 108m - CEP 150-630-250.0kW-1500rpm-380V-3Ph-50HzTrung TrịnhBelum ada peringkat

- Abrasion IndexDokumen3 halamanAbrasion IndexIan Afri WijayaBelum ada peringkat

- JIS G4103 Grade SNCM439: Matmatch Is Trusted by 2 Million+ Engineers and Product Developers Each YearDokumen4 halamanJIS G4103 Grade SNCM439: Matmatch Is Trusted by 2 Million+ Engineers and Product Developers Each YearsaputraBelum ada peringkat

- Tender Specifications and Prices for Workshop Equipment ProcurementDokumen12 halamanTender Specifications and Prices for Workshop Equipment ProcurementWak Tun0% (1)