Understandingthe Adafruit Motor Shie

Diunggah oleh

toutiwaiDeskripsi Asli:

Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Understandingthe Adafruit Motor Shie

Diunggah oleh

toutiwaiHak Cipta:

Format Tersedia

Understanding the Adafruit Motor Shield Library

I've recently been working on a small robotics project using the Arduino platform with the Adafruit motor shield. I'm an experienced applications programmer but a complete novice at electronics and embedded programming, so I find it challenging to understand how the hardware design and the code relate to each other. I've been going through the motor shield schematic and the code library to try to understand them both in detail, and I thought it might be helpful to other beginning Arduinists if I were to write up what I've figured out so far. At least for now I will focus on DC motor control because that's what I've been working on and have learned the most about.

Basic DC Motor Control

Let's set aside speed control for a moment and first walk through how the motors are turned on and off.

The Motor Drivers and Shift Register

The motor shield can control up to four DC motors using two L293D dual H-bridge motor driver ICs. You can read the datasheet for details, but the main thing to know is that each IC has four digital inputs and can control two motors bidirectionally. The inputs are in pairs, and each pair controls a motor. For example, if pin 2 is set high and pin 7 is set low, motor 1 is turned on. If the inputs are reversed, the motor is again on but its direction of rotation is reversed, and if both are set low then the motor is off. There are other possible configurations but this is the one supported by the motor shield. So obviously the thing to do is wire eight pins from the Arduino to the eight inputs on the two ICs, right? That's what I imagined at first, but it's WRONG!! Pins are a scarce resource, and the motor shield design makes an extra effort to conserve them. The inputs to the motor drivers are actually wired to the outputs of a 74HCT595N 8-bit shift register. This IC lets you feed in bits serially, but it then presents them as parallel outputs. It's controlled by four digital inputs, so effectively it lets you control eight inputs to the motor drivers (thus four motors) using four pins of the Arduino. At this point we can start to look at code. #define #define #define #define #define #define #define MOTOR1_A MOTOR1_B MOTOR2_A MOTOR2_B MOTOR4_A MOTOR4_B MOTOR3_A 2 3 1 4 0 6 5 Here are some constants defined in AFMotor.h:

#define MOTOR3_B 7Clearly, MOTOR1_A and MOTOR1_B have to do with controlling motor 1 bidirectionally, MOTOR2_A and MOTOR2_B are related to motor 2, etc. But what do the values mean? It turns out these are the bit numbers in the output of the shift register, as you can see in this detail of the schematic:

The pins labeled QA through QH are the parallel output pins, and you can think of them as bits 0 through 7. (The numbers immediately to the right of the IC are pin numbers rather than bit numbers, although they mostly coincide. QA is bit zero. The datasheet calls them Q0 through Q7 so I'm not sure why the schematic uses a different convention). As you can see, Motor 1 is controlled by bits 2 and 3, Motor 2 by bits 1 and 4, etc. Motors 3 and 4 are actually reversed between the code and the schematic, but I'm pretty sure that's just a bug. The pins shown on the left are the four input pins plus the supply voltage. It takes some study of the datasheet to understand the inputs, so here's a brief description of each: DIR_EN -- the enable input, active low; it has a pull-up resistor to disable the outputs until an AFMotorController is created in the code, as we'll see. DIR_SER -- the data input. DIR_CLK -- A rising edge on this input causes the data bit to be shifted in and all bits shifted internally.

DIR_LATCH -- A rising edge causes the internally-stored data bits to be presented to the parallel outputs. This allows an entire byte to be shifted in without causing transient changes in the parallel outputs.

Almost ready to look at more code!

But first a brief digression.

Ports

Arduino tutorials like Ladyada's teach you how to read and write pins one at a time using digitalRead and digitalWrite, but it turns out there's also a way to read and write them in groups, called "ports". You should definitely read this explanation, but here are the salient points: PORTD maps to digital pins 0 to 7, but you shouldn't use bits 0 and 1. PORTB maps to digital pins 8 to 13; the two high-order bits are not used. There are three C macros corresponding to each port: DDRB/DDRD -- these are bitmasks that control whether each pin in the port is an input or output. 1 means output. Assigning a value to one of these is like calling pinMode once for each pin in the port. PORTB/PORTD -- if you read one of these, it's like doing a digitalRead on each pin in the port. If you assign to one of them, it's like doing a digitalWrite on each pin. PINB/PIND -- like PORTB/PORTD but read-only.

When I say setting DDRB is like calling pinMode a bunch of times, I mean it has the same end result. However, it sets the mode on all the pins all at once so it's inherently faster than multiple calls to pinMode. The same remark applies to PORTB/PORTD as opposed to digitalRead and digitalWrite.

Defining the Shift Register Inputs

Okay, finally we can understand this fragment from AFMotor.h: #define LATCH 4 #define LATCH_DDR DDRB #define LATCH_PORT PORTB #define CLK_PORT PORTD #define CLK_DDR DDRD #define CLK 4 #define ENABLE_PORT PORTD #define ENABLE_DDR DDRD #define ENABLE 7 #define SER 0 #define SER_DDR DDRB #define SER_PORT PORTB

Clearly these four groups of #defines correspond one-to-one with the inputs to the shift register, and specifically they define the relationship between Arduino pins and shift register inputs: Shift register input DIR_LATCH DIR_CLK DIR_EN DIR_SER Port B D D B Bit # of port 4 4 7 0 Arduino digital pin # 12 4 7 8

We'd better check this against the schematic and make sure we're understanding it correctly:

J1 corresponds to digital pins 0-7, and J3 to pins 8-14 (which you can verify on the Arduino schematic), so it looks like the schematic and the code line up.

AFMotorController

The mechanics of pushing values out to the shift register are encapsulated in a C++ class named AFMotorController. There is an instance of this class declared in AFMotor.cpp; this instance is used by the classes AF_DCMotor and AF_Stepper. AFMotorController declares two member functions: enable() and latch_tx(). The latch_tx() function is responsible for updating the outputs of the shift register with the bits of the global variable latch_state, which is declared as:

static uint8_t latch_state; Here's the body of latch_tx() with pseudocode comments added by me: void AFMotorController::latch_tx(void) { uint8_t i; LATCH_PORT &= ~_BV(LATCH); SER_PORT &= ~_BV(SER); for (i=0; i<8; i++) { CLK_PORT &= ~_BV(CLK); // - Set DIR_LATCH low // - Set DIR_SER low // - For each bit of latch_state: // - Set DIR_CLK low // // // // // // // // - If the current latch_state is - Set DIR_SER else: - Set DIR_SER bit of set: high low

if (latch_state & _BV(7-i)) SER_PORT |= _BV(SER); else SER_PORT &= ~_BV(SER); CLK_PORT |= _BV(CLK);

- Set DIR_CLK high; the rising edge shifts DIR_SER into the shift register

// - Set DIR_LATCH high; the // rising edge sends the stored // bits to the parallel outputs }This function looks rather cryptic at first glance, but the key is that _BV(i) is a macro which evaluates to a byte having only the ith bit set. It's defined in avr/str_defs.h as: #define _BV(bit) (1 << (bit))Knowing that, you can easily work out how the following two statements set a single bit of SER_PORT to high and low respectively. The same idiom is used everywhere in this code so it's worthwhile to think through it if you're not used to doing bit manipulations. SER_PORT |= _BV(SER); SER_PORT &= ~_BV(SER); The enable() function initializes the ports, then clears and enables the shift register outputs. Until the outputs are enabled, they are in the high impedance state, i.e. effectively turned off. This function is simple, so here it is verbatim (including original comments): void AFMotorController::enable(void) { // setup the latch LATCH_DDR |= _BV(LATCH); ENABLE_DDR |= _BV(ENABLE); CLK_DDR |= _BV(CLK); SER_DDR |= _BV(SER); latch_state = 0; latch_tx(); // "reset"

} LATCH_PORT |= _BV(LATCH);

ENABLE_PORT &= ~_BV(ENABLE); // enable the chip outputs! }

AF_DCMotor

As described in the motor shield library documentation, you control a motor by instantiating an AF_DCMotor object with the appropriate motor number (1 through 4), then use the run() function to turn the motor on and off. AF_DCMotor also has a setSpeed() function, but

we'll return to that in the next section when we look at speed control. Here's the run() function with a few comments from me. This function breaks naturally into two sections; one in which we figure out which shift register outputs need to be set, and one in which we set them. void AF_DCMotor::run(uint8_t cmd) { uint8_t a, b; /* Section 1: choose two shift register outputs based on which * motor this instance is associated with. motornum is the * motor number that was passed to this instance's constructor. */ switch (motornum) { case 1: a = MOTOR1_A; b = MOTOR1_B; break; case 2: a = MOTOR2_A; b = MOTOR2_B; break; case 3: a = MOTOR3_A; b = MOTOR3_B; break; case 4: a = MOTOR4_A; b = MOTOR4_B; break; default: return; } /* Section 2: set the selected shift register outputs to high/low, * low/high, or low/low depending on the command. This is done * by updating the appropriate bits of latch_state and then * calling tx_latch() to send latch_state to the chip. */ switch (cmd) { case FORWARD: // high/low latch_state |= _BV(a); latch_state &= ~_BV(b); MC.latch_tx(); break; case BACKWARD: // low/high latch_state &= ~_BV(a); latch_state |= _BV(b); MC.latch_tx(); break; case RELEASE: // low/low latch_state &= ~_BV(a); latch_state &= ~_BV(b); MC.latch_tx(); break; } }

Speed Control

The speed of the DC motors is controlled using pulse-width-modulation (PWM). The idea of PWM is to control the power to a motor using a high-frequency square wave. When the square wave signal is on the motor is powered, and when the signal is low the power

is turned off. The speed of the motor is controlled by the fraction of time the controlling signal is on. The Arduino can generate square waves for PWM on pins 3, 5, 6, 9, 10, 11. The wiring of the PWM pins for speed control is straightforward. On the motor driver ICs, in addition to the two control inputs for each motor, there is an enable input. If it is set low then the motor is not powered regardless of the state of the other two pins. Four of the PWM pins are wired directly to the four enable inputs on the two motor drivers. This detail from the schematic shows two PWM inputs to the driver for motors 1 and 2.

While the wiring is easy to understand, the code requires some explanation. It directly accesses internal registers of the ATmega processor, and the only detailed documentation I could find was in the datasheet. So let's dive in. The ATmega processor has three timer/counter modules that can be used to generate a PWM signal. They are numbered 0, 1, and 2, and I'll refer to them as TC0, TC1, TC2. Conveniently the motor shield schematic uses the same numbering, so in the above figure you can see that TC2 is being used to control motors 1 and 2. Basically, the way the TC modules work is that a clock increments a counter on each clock cycle. Each TC has two associated comparison registers and two associated output pins; a pin can be set low or high depending on a comparison between the counter and the corresponding register. The modules can be configured in various operating modes, but in the "Fast PWM" mode that is used by the library, the output pin is set high each time the counter sets back to zero and set low when the counter reaches the comparison value, which therefore acts as the speed setting. TC0 and TC2 each have an 8-bit counter, which is why the speed range for the motors is 0-255. Each TC module is controlled by two registers. TCCR2B, which have the following bit layouts: TC2 is controlled by registers TCCR2A and

The comparison registers are identified as OCR2A and OCR2B. The avr headers define assignable macros with names identical to the register names as given in the datasheet. With this background, the following code becomes fairly clear. This is a brief excerpt of the AF_DCMotor constructor, which is initializing speed control for motor 1: // use PWM from timer2A TCCR2A |= _BV(COM2A1) | _BV(WGM20) | _BV(WGM21); // fast PWM, turn on oc0 TCCR2B = freq & 0x7; OCR2A = 0; DDRB |= _BV(3); break; This can really only be understood in full detail by looking at the tables in the datasheet, which I don't want to reproduce here. However, here is a brief description of what these specific bit settings mean: WGM20 = 1, WGM21 = 1: selects the "fast PWM" mode described above. COM2A1 = 1, COM2A0 = 0: in fast PWM mode, causes the output to be set low when the comparison value is reached. OCR2A = 0: initializes the comparison value (i.e. the speed setting) to zero. Three low-order bits of TCCR2B; chooses the frequency of the PWM signal. DDRB bit 3 set high: sets the pin mode for the pin corresponding to output 2A. This is pin 11. This correspondence is defined by the ATmega chip itself and can't be changed. TC0 has analogous control registers, just with "2" replaced by "0" in the names. Finally, here's the body of the setSpeed() function. register for the appropriate motor: void AF_DCMotor::setSpeed(uint8_t speed) { switch (motornum) { case 1: OCR2A = speed; break; case 2: OCR2B = speed; break; case 3: OCR0A = speed; break; case 4: OCR0B = speed; break; } } All it does is set the comparison

One thing I had hoped to understand out of all this but haven't completely figured out is why no frequency control is supported for motors 3 and 4. TC0 has the same 3 bits for controlling the frequency that TC2 has, so it should be possible. It may have to do with the fact that TC0 and TC1 share the same prescaler, and TC1 is used to control the servos; but I'm not sure.

Conclusion

Hope this helps. Michael Koehrsen 5/26/2009

Anda mungkin juga menyukai

- RAEFGC BookCorrectionsDokumen14 halamanRAEFGC BookCorrectionstoutiwaiBelum ada peringkat

- Batavia Digital MenuDokumen8 halamanBatavia Digital MenutoutiwaiBelum ada peringkat

- 2011 - ART SeriesDokumen2 halaman2011 - ART SeriestoutiwaiBelum ada peringkat

- Art 708-A, Art 710-A, Art 712-A, Art 722-A, Art 715-A, Art 725-ADokumen12 halamanArt 708-A, Art 710-A, Art 712-A, Art 722-A, Art 715-A, Art 725-AtoutiwaiBelum ada peringkat

- Circle Tangent Intersect ProofDokumen5 halamanCircle Tangent Intersect ProoftoutiwaiBelum ada peringkat

- Hanna - Anti-Lullaby: Composed By: Karen O Transcribed By: Crazyryoga 62Dokumen1 halamanHanna - Anti-Lullaby: Composed By: Karen O Transcribed By: Crazyryoga 62toutiwaiBelum ada peringkat

- Air Quality SchematicsDokumen8 halamanAir Quality SchematicstoutiwaiBelum ada peringkat

- C480 Release Note EnglishDokumen2 halamanC480 Release Note EnglishtoutiwaiBelum ada peringkat

- BookDokumen20 halamanBooktoutiwaiBelum ada peringkat

- Paroles Back On The Chain Gang PretendersDokumen1 halamanParoles Back On The Chain Gang PretenderstoutiwaiBelum ada peringkat

- Playist 1 DimancheDokumen1 halamanPlayist 1 DimanchetoutiwaiBelum ada peringkat

- Value Qty References Description Mouser Reference CapacitorsDokumen2 halamanValue Qty References Description Mouser Reference CapacitorstoutiwaiBelum ada peringkat

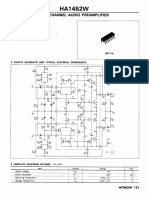

- Audio PreampsDokumen3 halamanAudio PreampstoutiwaiBelum ada peringkat

- HA1452 DatasheetDokumen5 halamanHA1452 DatasheettoutiwaiBelum ada peringkat

- Read - Me FW 1.03.07.R - SB3.0 - 5.0-1av-40Dokumen3 halamanRead - Me FW 1.03.07.R - SB3.0 - 5.0-1av-40toutiwaiBelum ada peringkat

- KR-4500 Service Notes PDFDokumen31 halamanKR-4500 Service Notes PDFtoutiwai100% (1)

- Roland KR 4700 Service NotesDokumen36 halamanRoland KR 4700 Service Notestoutiwai100% (3)

- Roland KR 4700 5000 Owner ManualDokumen114 halamanRoland KR 4700 5000 Owner Manualtoutiwai100% (1)

- Kenwood KM200 Series DemontageDokumen17 halamanKenwood KM200 Series DemontagetoutiwaiBelum ada peringkat

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (588)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (74)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2259)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (121)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- Acsm Last ReportDokumen37 halamanAcsm Last Reportjassimnowshad40Belum ada peringkat

- PPT-DC To DC ConverterDokumen28 halamanPPT-DC To DC ConverterHimaja Mcc N100% (1)

- PV Charge Controller User Manual: SBL-2402 (48V/2A)Dokumen4 halamanPV Charge Controller User Manual: SBL-2402 (48V/2A)Abdualrahman KdhBelum ada peringkat

- CMCDokumen7 halamanCMCManel MontesinosBelum ada peringkat

- Slides For Multi Level Inverter in Psim PDFDokumen41 halamanSlides For Multi Level Inverter in Psim PDFmuhammad saeedBelum ada peringkat

- Winsci Instruction Manual Operational Specification of Scanreco G2B-G3-G4Dokumen27 halamanWinsci Instruction Manual Operational Specification of Scanreco G2B-G3-G4Paz Yoss100% (1)

- Design and Manufacturing of QuadcopterDokumen47 halamanDesign and Manufacturing of QuadcopterDebashish Behera100% (3)

- Acer Al2017 PDFDokumen40 halamanAcer Al2017 PDFboroda2410Belum ada peringkat

- Mini ProjectDokumen25 halamanMini Projectcharan524Belum ada peringkat

- DKL Installation Manual (English)Dokumen58 halamanDKL Installation Manual (English)류성하Belum ada peringkat

- Three Phase PWM RectDokumen13 halamanThree Phase PWM RectMridul MishraBelum ada peringkat

- Geared & Gearless Elevater DifferenceDokumen4 halamanGeared & Gearless Elevater DifferencePERVEZ AHMAD KHANBelum ada peringkat

- Design and Development of Variable Frequency Ultrasonic Pest RepellerDokumen14 halamanDesign and Development of Variable Frequency Ultrasonic Pest RepellerS shek DhavudBelum ada peringkat

- Design and Development of A Three Phase Induction Motor Drive Using Ni-MyrioDokumen5 halamanDesign and Development of A Three Phase Induction Motor Drive Using Ni-MyriovinaykumaarBelum ada peringkat

- MD380 Series Advanced Vector Vontrol Inverter User ManualDokumen241 halamanMD380 Series Advanced Vector Vontrol Inverter User ManualKs Bharathiyar0% (3)

- Use of PWM Techniques For Power Quality Improvemen PDFDokumen5 halamanUse of PWM Techniques For Power Quality Improvemen PDFnakkasrinuBelum ada peringkat

- Igbt Cm200dy (New)Dokumen4 halamanIgbt Cm200dy (New)GamarJanuzajBelum ada peringkat

- (X) Comparison of 3 PWM Strategies SPWM SVPWM One Cycle CTRLDokumen4 halaman(X) Comparison of 3 PWM Strategies SPWM SVPWM One Cycle CTRLsrikanthboddunaBelum ada peringkat

- Service Manual: DP-3300/DP-3200Dokumen81 halamanService Manual: DP-3300/DP-3200Mohammed SairawanBelum ada peringkat

- Procyon ManualDokumen36 halamanProcyon ManualferrisiamBelum ada peringkat

- Overview and Characteristics of Fan: Technical MaterialDokumen10 halamanOverview and Characteristics of Fan: Technical Materialm3y54mBelum ada peringkat

- Dr. D. Sreenivasarao: Overview and Work Done at Nit WarangalDokumen2 halamanDr. D. Sreenivasarao: Overview and Work Done at Nit WarangalSreenivasaraoDharmavarapuBelum ada peringkat

- Application of Modular Multilevel Converter in Medium Voltage High Power Permanent Magnet Synchronous Generator Wind Energy Conversion SystemsDokumen10 halamanApplication of Modular Multilevel Converter in Medium Voltage High Power Permanent Magnet Synchronous Generator Wind Energy Conversion SystemsAbu Bakr M. SaeedBelum ada peringkat

- User'S Manual: MODEL 402 Pulse Width Modulation Driver / ControllerDokumen22 halamanUser'S Manual: MODEL 402 Pulse Width Modulation Driver / ControllerLogan JohnsonBelum ada peringkat

- EL7-EC Series AC Servo Drive User Manual V1.00Dokumen304 halamanEL7-EC Series AC Servo Drive User Manual V1.00Antek DomańskiBelum ada peringkat

- Fds 6680Dokumen5 halamanFds 6680ExtratenorBelum ada peringkat

- Project Proposal ... DC MotorDokumen6 halamanProject Proposal ... DC MotorIhsan KhanBelum ada peringkat

- ZLTL-1 Truck ZTC250-ZTC800 Operating ManualDokumen75 halamanZLTL-1 Truck ZTC250-ZTC800 Operating ManualSubkhi FauzanBelum ada peringkat

- Stepping Motor: ApplicationsDokumen14 halamanStepping Motor: ApplicationsLeo SalasarBelum ada peringkat

- 8044 Service Manual PDFDokumen154 halaman8044 Service Manual PDFDoDuyBac80% (5)