JXFM325 127e 04S

Diunggah oleh

giahaoJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

JXFM325 127e 04S

Diunggah oleh

giahaoHak Cipta:

Format Tersedia

FCV INTERNAL USE ONLY

MUST NOT BE COPIED Work instruction: PERIODIC INSPECTION WORK INSTRUCTION OF DESMEAR MACHINE

JXFM

PWB Development Section

PERIODIC INSPECTION WORK INSTRUCTION OF DESMEAR MACHINE 1. Purpose This instruction used to periodically inspect the DESMEAR MACHINE 2. Related documents: -Machine management specification STD. No.JXFV425/502E -Rules for equipment maintenance performed by productive maintenance staff JXFV325/001E 3. Contents: Perform to inspect major and important parts, which impact to product quality and machine efficiency. Inspection contents contain in Periodic check sheet attachment: 3.1 Check method 3.1.1 Five-sense checking includes: Touching, Hearing, Visual, and Smelling 3.1.2 Reading inspection: Reading the value on the indicators 3.1.3 Measuring inspection: Using the special tools for measurement 3.2 Inspection criteria: (Detailed in attachment) 3.3 Inspection frequency: (Detailed in attachment) 3.4 Judgement : Good : Average X : Bad 3.5 Treatment: A: Lubricate B: Tighten C: Adjust D: Weld, connect 3.6 Remark: Used for other treatment

Creation section

P.T.HOAN P.T.HOAN N.A.CHI CHECK K.SHOJI K.SHOJI K.ARAI APPR Add 4 items at page 2 Modify check sheet form Modify Page 1,Attachment DESCRIPTION

E: Exchange F:Will be exchanged(Emergency) G:Will be exchanged(within period) H:Other treatment

BEE

04 03 02 REV

05/11/2003 21/6/2003 15/12/1998 DATE

L.Q.HUNG L.Q.HUNG C.D.KHANG DESIGN

STD. No

JXFM 325/127E

STD DIV FCV Inc. SHEET / 7

DATE

22/07/1998

SECTION BE

DESIGN C.D.KHANG

CHECK N.A.CHI

APPR K.ARAI

FCV

FCV STANDARD SHEET

PWB Development Section

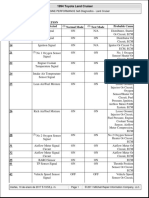

PERIODIC CHECK SHEET

No

Check item

Check part

Machine: CONVEYOR DESMEAR MACHINE Check method

No.

Man Hour Freq. (Month) Jan Feb Apr May (Judgment) Value / Treatment Jul Aug Oct Nov Mar Jun Sep Dec Remark

Criteria

Magnetic contactor 1 Control panel Relay Breaker ELB 2 Desmear and Neutralizer tanks Hot water rinse No.1 Hot water rinse No.2 Dip rinse Recovery Desmear No.1 Desmear pump No.1 Desmear pump No.2 Desmear pump No.3 Electrodes Desmear No.2 Desmear pump No.1 Desmear pump No.2 Desmear pump No.3 Electrodes Water rinse Neutralizer Neutralizer pump No.1 Neutralizer pump No.2 Neutralizer pump No.3

Watching Watching Press the test button Touching, hearing Touching, hearing Touching, hearing Touching, hearing

No loosing terminal, good contactor No loosing terminal, good contactor Breaker works normally Normal Normal Normal Normal

1 1 1 1 1 1 1

Touching, hearing Touching, hearing Touching, hearing Visual

Normal Normal Normal Not be corroded and damaged

1 1 1 1

Touching, hearing Touching, hearing Touching, hearing Visual Touching, hearing

Normal Normal Normal Not be corroded and damaged Normal

1 1 1 1 1

Touching, hearing Touching, hearing Touching, hearing

Normal Normal Normal

1 1 1 JXFM 325/127E _ Page2/7

PWB Development Section Recovery Dip rinse Pressure rinse Cooling system Heating system Water rinse Air shower Blower No.1 Blower No.2 Drying chamber Blower No.1 Blower No.2 3 Conveyor Touching, hearing Touching, hearing Normal Normal Touching, hearing Touching, hearing Normal Normal 1 1 1 1 1 Touching, hearing Touching, hearing Touching, hearing Visual and manual Visual and manual Touching, hearing Normal Normal Normal No leakage and connector must be tight. No leakage and connector must be tight. Normal 1 1 1 1 1 1

Conveyor motor desmear No.1 Conveyor motor Chain Sprocket Gear Gear shaft Touching, hearing Watching, frease up Watching, frease up Watching, frease up Watching Normal No wear, no damage No wear, no damage No wear, no damage No wear, check working normal 1 1 1 1 1

Conveyor motor desmear No.2 Conveyor motor Chain Sprocket Gear Gear shaft Touching, hearing Watching, frease up Watching, frease up Watching, frease up Watching Normal No wear, no damage No wear, no damage No wear, no damage No wear, check working normal 1 1 1 1 1

Conveyor motor neutralizer

JXFM 325/127E _ Page3/7

PWB Development Section Conveyor motor Chain Gear Gear shaft Hot water rinse tank Conveyor motor Chain Sprocket Gear Gear shaft Drying chamber Conveyor motor Chain Gear Gear shaft 4 Make up tank Desmear supply pump Agitator pump Sub desmear supply pump Neutralizer supply pump Solenoid valve Level sensor Bubbling motor Tank Pipe 8 Control panel Touching, hearing Watching, frease up Watching, frease up Watching Touching, hearing Touching, hearing Touching, hearing Touching, hearing Watching, touching, hearing Watching Touching, hearing Watching Watching Normal No wear, no damage No wear, no damage No wear, check working normal Normal Normal Normal Normal No abnormal sound, no liquid leak Check working normally Normal No leak, no damage No leak, no damage 20.2m/min 1 1 1 1 1 1 1 1 1 1 1 1 1 3 JXFM 325/127E _ Page4/7 Touching, hearing Watching, frease up Watching, frease up Watching, frease up Watching Normal No wear, no damage No wear, no damage No wear, no damage No wear, check working normal 1 1 1 1 1 Touching, hearing Watching, frease up Watching, frease up Watching Normal No wear, no damage No wear, no damage No wear, check working normal 1 1 1 1

Solenoid valve, level sensor Bubbling Other

6 7

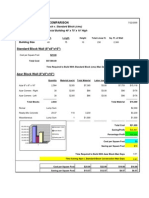

Conveyor revolution Measure with rotation meter meter Temperature controller

PWB Development Section

Desmear Desmear tank No.1 Desmear tank No.2 Recovery tank Dip rinse tank Hot water rinse tank No.1 Hot water rinse tank No.2 Desmear tub No.1 Desmear tub No.2 Mixing tank Neutralizer Neutralizer tank Recovery tank Dip rinse tank Pressure rinse tank Drying chamber 9 Desmear and Neutralizer pumps Hot water rinse No.1 Hot water rinse No.2 Dip rinse Recovery Desmear No.1 Desmear pump No.1 Desmear pump No.2 Desmear pump No.3 Desmear No.2 JXFM 325/127E _ Page5/7 Insulation measurement Insulation measurement Insulation measurement Over 1M Over 1M Over 1M 3 3 3 Measure with themometer Measure with themometer Measure with themometer Measure with themometer Measure with themometer Insulation measurement Insulation measurement Insulation measurement Insulation measurement 4520C 5020C 5020C 5020C 6020C Over 1M Over 1M Over 1M Over 1M 3 3 3 3 3 3 3 3 3 Measure with themometer Measure with themometer Measure with themometer Measure with themometer Measure with themometer Measure with themometer Measure with themometer Measure with themometer Measure with themometer 8520C 8520C 5020C 5020C 5020C 5020C 8620C 8620C 3320C 3 3 3 3 3 3 3 3 3

PWB Development Section Desmear pump No.1 Desmear pump No.2 Desmear pump No.3 Water rinse Neutralizer Neutralizer pump No.1 Neutralizer pump No.2 Neutralizer pump No.3 Recovery Dip rinse Pressure rinse Water rinse Air shower Blower No.1 Blower No.2 Drying chamber Blower No.1 Blower No.2 10 Conveyor Insulation measurement Insulation measurement Over 1M Over 1M Over 1M Over 1M 3 3 3 3 Insulation measurement Insulation measurement Over 1M Over 1M 3 3 Insulation measurement Insulation measurement Insulation measurement Insulation measurement Insulation measurement Insulation measurement Insulation measurement Over 1M Over 1M Over 1M Over 1M Over 1M Over 1M Over 1M 3 3 3 3 3 3 3 Insulation measurement Insulation measurement Insulation measurement Insulation measurement Over 1M Over 1M Over 1M Over 1M 3 3 3 3

Conveyor motor Insulation measurement desmear No.1 Conveyor motor Insulation measurement desmear No.2 Conveyor motor neutralizer Conveyor motor Sprocket Hot water rinse tank Conveyor motor Drying chamber Insulation measurement Insulation measurement Watching, grease up

Over 1M No wear, no damage

3 3

Over 1M

3 JXFM 325/127E _ Page6/7

PWB Development Section

Conveyor motor Sprocket 11 Heater Heater No.1 Heater No.2 12 Make up tank Desmear supply pump Agitator pump Sub desmear supply pump Neutralizer supply pump

Insulation measurement Watching, grease up Insulation measurement Insulation measurement Insulation measurement Insulation measurement Insulation measurement Insulation measurement

Over 1M No wear, no damage Over 10M Over 10M Over 1M Over 1M Over 1M Over 1M

3 3 3 3 3 3 3 3 Month Mgr ignature Date: Revision History Revision 03 04 Change content Modify periodic form Add 4 items at page 2 Checker Egr Svr

[Treatment] : A: Lubricate B: Tighten C: Adjust D: Weld, connect E: Exchanged F: Stop (Wait spare part) G: Will be changed (Emergency) H: Will be changed (within period) K: Other treatment [Judgment] : O: Good : Average X: Bad

JXFM 325/127E _ Page7/7

Anda mungkin juga menyukai

- Food Services Manager CV Resume Template SampleDokumen1 halamanFood Services Manager CV Resume Template SamplegiahaoBelum ada peringkat

- FBSDIKITENDokumen1 halamanFBSDIKITENgiahaoBelum ada peringkat

- Eq 7Dokumen12 halamanEq 7giahaoBelum ada peringkat

- ACS800-07 AC Drives CatalogDokumen4 halamanACS800-07 AC Drives CataloggiahaoBelum ada peringkat

- IML Forged Steel Class 3000 FittingsDokumen1 halamanIML Forged Steel Class 3000 FittingsgiahaoBelum ada peringkat

- NC Drilling Machine SpecificationDokumen4 halamanNC Drilling Machine SpecificationgiahaoBelum ada peringkat

- General Schedule of NorfolkDokumen1 halamanGeneral Schedule of NorfolkgiahaoBelum ada peringkat

- Tan A Trading - Service Construction and Environment Co.,LtdDokumen1 halamanTan A Trading - Service Construction and Environment Co.,LtdgiahaoBelum ada peringkat

- EDI System Report FinalDokumen9 halamanEDI System Report FinalgiahaoBelum ada peringkat

- O&M Manuals - Chilled Water Pumps-PACO PumpDokumen20 halamanO&M Manuals - Chilled Water Pumps-PACO PumpgiahaoBelum ada peringkat

- Testing With Real Load at Ba Ria Vung Tau (Crusher Machine)Dokumen4 halamanTesting With Real Load at Ba Ria Vung Tau (Crusher Machine)giahaoBelum ada peringkat

- Contronic RBL530 Oil Burner ControllerDokumen1 halamanContronic RBL530 Oil Burner ControllergiahaoBelum ada peringkat

- O&M Manuals - Chilled Water Pumps-PACO PumpDokumen20 halamanO&M Manuals - Chilled Water Pumps-PACO PumpgiahaoBelum ada peringkat

- Preventive Maintenance Report for 4 Trane CDHG ChillersDokumen9 halamanPreventive Maintenance Report for 4 Trane CDHG ChillersgiahaoBelum ada peringkat

- Fan CataloguesDokumen1 halamanFan CataloguesgiahaoBelum ada peringkat

- Equipment Specification Project DetailsDokumen1 halamanEquipment Specification Project DetailsgiahaoBelum ada peringkat

- JXFM325 140e 03SDokumen2 halamanJXFM325 140e 03SgiahaoBelum ada peringkat

- Operating Instructions For VT WithdrawalDokumen2 halamanOperating Instructions For VT WithdrawalgiahaoBelum ada peringkat

- Micrometer Work Instruction: FCV Internal Use OnlyDokumen3 halamanMicrometer Work Instruction: FCV Internal Use OnlygiahaoBelum ada peringkat

- NC Drilling Machine SpecificationDokumen4 halamanNC Drilling Machine SpecificationgiahaoBelum ada peringkat

- JXFM325 119e 05 1Dokumen1 halamanJXFM325 119e 05 1giahaoBelum ada peringkat

- JXFM325 132e 05SDokumen4 halamanJXFM325 132e 05SgiahaoBelum ada peringkat

- Micrometer Work Instruction: FCV Internal Use OnlyDokumen3 halamanMicrometer Work Instruction: FCV Internal Use OnlygiahaoBelum ada peringkat

- JXFM325 127e 04SDokumen7 halamanJXFM325 127e 04SgiahaoBelum ada peringkat

- Hypersperse MDC220Dokumen1 halamanHypersperse MDC220giahaoBelum ada peringkat

- JXFM325 152e 02SDokumen6 halamanJXFM325 152e 02SgiahaoBelum ada peringkat

- Warranty Management Tracking Sheet - SPGC Projects Ww35 5'13Dokumen12 halamanWarranty Management Tracking Sheet - SPGC Projects Ww35 5'13giahaoBelum ada peringkat

- Auto SDI ManualDokumen38 halamanAuto SDI ManualscribdkhatnBelum ada peringkat

- Mechanical Monthly Report - Oct 2013 Rev1Dokumen7 halamanMechanical Monthly Report - Oct 2013 Rev1giahaoBelum ada peringkat

- Electrical Engineering Training ProgramDokumen4 halamanElectrical Engineering Training ProgramgiahaoBelum ada peringkat

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (587)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (399)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (73)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (265)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (119)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- Experiment 3: Temperature Measurement MethodDokumen12 halamanExperiment 3: Temperature Measurement Methodmohamad munzirBelum ada peringkat

- 06-Fc428mar Water-in-Fuel Indicator Sensor Circuit - Voltage Above Normal or Shorted To High SourceDokumen3 halaman06-Fc428mar Water-in-Fuel Indicator Sensor Circuit - Voltage Above Normal or Shorted To High SourceSuryadiBelum ada peringkat

- Technical Publications: Direction 2190775 100Dokumen21 halamanTechnical Publications: Direction 2190775 100zakaria alhosinyBelum ada peringkat

- Michelson Interferometer Na Lamp-1Dokumen11 halamanMichelson Interferometer Na Lamp-1SOHINI KAYALBelum ada peringkat

- VisiLogic Software Manual-LadderDokumen158 halamanVisiLogic Software Manual-LadderEduardo Vasquez CastroBelum ada peringkat

- 3RInternational Tetzner Model Based Pipeline LDS 07-2003 PDFDokumen6 halaman3RInternational Tetzner Model Based Pipeline LDS 07-2003 PDFRene ParedesBelum ada peringkat

- Smarter and Safer: Cordless Endodontic HandpieceDokumen2 halamanSmarter and Safer: Cordless Endodontic Handpiecesonu1296Belum ada peringkat

- PDVSA Engineering Design Manual Volume 9–I Process AnalyzersDokumen25 halamanPDVSA Engineering Design Manual Volume 9–I Process AnalyzersAlberto Enrique De Santa Anna CampderáBelum ada peringkat

- Pressure Vessel Rivets Welded Joints MDSP PrimeDokumen16 halamanPressure Vessel Rivets Welded Joints MDSP PrimeIvanBelum ada peringkat

- ESAB Welding HandbookDokumen31 halamanESAB Welding Handbookhooky1100% (4)

- 2 Interference in Spur GearsDokumen2 halaman2 Interference in Spur Gearschris100% (1)

- Engine & Transmission ToolsDokumen45 halamanEngine & Transmission Toolsabduallah muhammad100% (1)

- Tabla 1 Engine ControlDokumen2 halamanTabla 1 Engine Controljulio montenegroBelum ada peringkat

- WPD Flotationdrying PDFDokumen19 halamanWPD Flotationdrying PDFVvbjBelum ada peringkat

- Grounding Vs BondingDokumen2 halamanGrounding Vs BondingVictor HutahaeanBelum ada peringkat

- Siremobil Compact PDFDokumen108 halamanSiremobil Compact PDFhector anguiano100% (2)

- GRI 20RS-12-B Data SheetDokumen6 halamanGRI 20RS-12-B Data SheetJMAC SupplyBelum ada peringkat

- 13 - Principles of Flight - QuestionsDokumen80 halaman13 - Principles of Flight - QuestionsEdgar Muñoz Fernández50% (4)

- 2014-6-2 PCED South Hill Coalition Proposed Elements MatrixDokumen2 halaman2014-6-2 PCED South Hill Coalition Proposed Elements MatrixSpokane City CouncilBelum ada peringkat

- Dimensions of Physical Quantities DensityDokumen100 halamanDimensions of Physical Quantities DensityGerman Rincon UrregoBelum ada peringkat

- AZAR Block CostcomparisonDokumen8 halamanAZAR Block CostcomparisontckittuBelum ada peringkat

- Sad Thesis Guidelines FinalsDokumen13 halamanSad Thesis Guidelines FinalsJes RamosBelum ada peringkat

- Hino 500S Catalog LR PDFDokumen8 halamanHino 500S Catalog LR PDFZulBelum ada peringkat

- Mobiltech (Textile Used in Transportation, Automotive & Aerospace)Dokumen12 halamanMobiltech (Textile Used in Transportation, Automotive & Aerospace)cario galleryBelum ada peringkat

- Specifications: 3516C - SS Marine PropulsionDokumen5 halamanSpecifications: 3516C - SS Marine PropulsionAidel MustafaBelum ada peringkat

- 3 Phase Induction Motors Objective Questions With AnswersDokumen3 halaman3 Phase Induction Motors Objective Questions With AnswersMohan Raj0% (2)

- Online Institute Reporting Slip of The Application Number - 200310422837 PDFDokumen1 halamanOnline Institute Reporting Slip of The Application Number - 200310422837 PDFRohith RohanBelum ada peringkat

- Ashrae - 2009 I-P - F09 - AddDokumen2 halamanAshrae - 2009 I-P - F09 - AddSergio SemmBelum ada peringkat

- Ford Essex V6 EngineDokumen8 halamanFord Essex V6 EngineJoakamaster 16Belum ada peringkat