Cm3068 Alarm Criteria

Diunggah oleh

Larry Vilca DelgadoDeskripsi Asli:

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Cm3068 Alarm Criteria

Diunggah oleh

Larry Vilca DelgadoHak Cipta:

Format Tersedia

SKF Reliability Systems

Recommended Initial Alarm Criteria for Bearing Condition Assessment Using Enveloped Acceleration Measurements

By Jim Wei, Application Engineer SKF Reliability Systems

Introduction

This application note presents a set of guidelines for initially establishing Alert and Danger alarm thresholds for enveloped acceleration measurements for early detection of rolling element bearing damage. The criteria recommended herein should be used to determine initial alarm thresholds only. As with all commonly published severity charts and tables, this method provides target thresholds for new, refurbished, and recently maintained equipment. Once a good operating baseline is established, and sufficient data and experience have been acquired for high confidence statistical alarm calculation on a point-by-point basis, the prudent analyst will abandon these guideline thresholds in favor of an automatically calculated trendbased or statistically-based change technique.

use of enveloped acceleration measurements to detect problems in rolling element bearings. The technique has been used as a quality assurance measurement in SKF bearing factories since the early 1970s. To support SKFs objective of providing the worlds most reliable bearings, acceleration enveloping is the primary measurement for identifying the earliest stages of bearing degradation in SKF research and development laboratories during life-cycle, stress, fatigue, and induced fault run-to-failure tests at the SKF Engineering Research Centre in the Netherlands, and the SKF North American Technical Center near Detroit, Michigan in the USA. In the late 1980s, enveloped acceleration technology was incorporated into SKFs vibration data acquisition instruments designed to support industrial reliability improvement through predictive maintenance techniques. Since enveloped

An accurate enveloped acceleration measurement alarm provides early indication that a bearing is approaching the end of its usable lifetime. Upon such an alarm, the reliability person should more closely monitor the bearing using FFT signature analysis with bearing fault frequency markers to verify the bearing defect and determine proactive maintenance measures, or to plan the most efficient bearing replacement during a scheduled machine outage.

Specific details on the enveloped acceleration technique may be found in the SKF Reliability Systems Application Note, publication CM3013, Questions and Answers About Enveloping.

Background

accelerations introduction into SKFs condition monitoring instrumentation, extensive experience has been gained by monitoring hundreds of thousands of bearings in both the laboratory and industrial service environments.

Application Note

CM3068

SKF, supplier of 20% of the worlds bearings, has extensive experience in the

Recommendation

The formulae for setting enveloped

Recommended Initial Alarm Criteria for Bearing Condition Assessment Using Enveloped Acceleration Measurements

www.skfreliability.com

Table 1. Simplified Formula Results for Setting Initial Enveloped Acceleration Alarm Thresholds.

Example N = 3.6 Kcpm D = 3 inches (76.2mm) Danger (gE) Alert (1/3 of Danger) (gE)

Danger Level Equation SKF Product fmax Metric N (Kcpm) D (mm) Filter #3

[Microlog, Local Monitoring Unit (LMU) and Wireless Sensor System]

English N (Kcpm) D (inch)

40 x N

N x 3

NxD

1.67 x N x

NxD

19.8

6.6

Microlog CMXA 50 Portable Data Collector/FFT Analyzer

Filter #3

[Microlog, Local Monitoring Unit (LMU) and Wireless Sensor System]

20 x N

N x 4

NxD

1.25 x N x

NxD

15.0

5.0

Filter #3

[Microlog, Local Monitoring Unit (LMU) and Wireless Sensor System]

1,000 Hz

N x 3

1.75 x N x

8.0

2.7

Filter #3

MARLIN Condition Detector (MCD Pro IS)

[Microlog, Local Monitoring Unit (LMU) and Wireless Sensor System]

500 Hz

N x 4

1.25 x N x

7.8

2.6

Filter #4

[Mechanical Condition Transmitter (MCT)]

4 kHz

3 xNx 4

3.75 x N x

23.5

7.8

Filter #3

[Mechanical Condition Transmitter (MCT)] MARLIN Condition Detector (MCD)

1 kHz

N x 3

1.70 x N x

10.4

3.5

1.5 kHz

N x 2

2.50 x N x

15.7

5.2

Mechanical Condition Transmitter (MCT)

Local Monitoring Unit (LMU)

Wireless Sensor System

Recommended Initial Alarm Criteria for Bearing Condition Assessment Using Enveloped Acceleration Measurements

www.skfreliability.com

acceleration alarm thresholds for bearing monitoring were established using statistical analysis of existing databases. The database study concluded that critical factors in enveloped acceleration alarm threshold establishment are the bearing diameter and the rotating speed of the shaft, with analysis bandwidth and fmax as user specified input parameters. Once these critical factors were determined, the formulae were developed and applied to existing data for validation. Table 1 presents the results using simplified formula, suitable for a simple handheld calculator, for the most commonly used SKF instrument configurations.

These two formulas are derived from both high and low speed machinery. To represent higher speed machinery, data was taken from pumps and motors running 3600 RPM. Lower speed machinery was represented with paper machine rolls running at 400 RPM. The confidence level for these results is 90%.

Applying the Criteria in Detail

The mathematical equations describing alarm criteria for enveloped acceleration measurements are plotted in Figure 1. Bearing bore diameters and rotating speeds used in Figure 1 represent the majority of bearings used in various industries for rotating machinery. Figure 1s plot was created for an fmax of 1000 Hz (60,000 CPM). If a different fmax value is required for a measurement, an fmax scaling is required. The scaling factor for fmax compensation is shown in Figure 2. To utilize Figures 1 and 2, the following parameters must be known: Bearing bore diameter in mm. If the bearing bore diameter is unknown, multiply the last two digits of the bearing number by 5 to obtain the bearing bore diameter in mm. Shaft speed in RPM fmax The following example describes proper use of Figures 1 and 2. Assumptions are: Bearing Bore Diameter: 100mm Shaft Speed: 1800 RPM fmax: 500 Hz (30,000 CPM) Use the charts in Figures 1 and 2 to determine this enveloped acceleration measurements alert and danger alarm settings: 1. 2. In Figure 1, locate 100mm on the shaft diameter axis. Follow the vertical line representing 100mm to the point where it intersects the 1800 RPM running speed line (the dark circle on the chart). This is your reference point. From your reference point, follow the horizontal lines left to the danger setting (gE) axis to determine your initial danger alarm setting (7.5 gE). From your reference point, follow the horizontal lines right to the alert setting (gE) axis to determine your initial alert alarm setting (2.5 gE). In Figure 2, find 500 Hz on the Fmax axis. Follow the vertical line representing 500 Hz to the point where it intersects the scaling curve.

The Mathematical Model for Initial Enveloped Acceleration Alarm Guidelines

Based on SKFs extensive bearing condition monitoring and evaluation experience, a generic empirical formula using major parameters affecting enveloped acceleration measurements is determined as follows: fmax a ) 1 x a2 x na3 x da4 (gE) where: L= ( 1000 L = Alarm setting for enveloped acceleration measurement. fmax = Maximum frequency in Hz for spectrum band amplitude computation. n = Running speed in RPM. d = Bore diameter of the bearing (load indicator). a1, a2, a3, a4 = Empirical coefficients to be determined statistically using existing databases. The four coefficients in the generic formula were obtained following the steps below: 1) Evaluate available databases using statistical method to obtain alarm levels that are statistically significant to each database. Consult application engineers and experts to ensure that all the field experience from the past are included. 2) Use a curve fitting method to calculate the coefficients in the generic formula to fit alarm levels obtained in the previous step. Without including detailed mathematical deductions, the empirical formulae for danger and warning levels are given below: Danger level:

3.

4.

fmax 0.43 ) x 3.26 x 10-4 x n x d0.55 LD = ( 1000

Alert level: fmax 0.43 ) x 1.09 x 10-4 x n x d0.55 LA = ( 1000

(gE) (Equation 1)

5.

(gE) (Equation 2)

6.

"Recommended Initial Alarm Criteria for Bearing Condition Assessment Using Enveloped Acceleration Measurements"

by Jim Wei, Application Engineer SKF Reliability Systems Figure 1. Initial Enveloped Acceleration Alarm Chart (Fmax = 1000 Hz, 60,000 CPM).

SKF Reliability Systems 4141 Ruffin Road San Diego, California 92123 USA Telephone (+1) 858-496-3400 FAX (+1) 858-496-3531

Web: www.skfreliability.com

Although care has been taken to assure the accuracy of the data compiled in this publication, SKF does not assume any liability for errors or omissions. SKF reserves the right to alter any part of this publication without prior notice. SKF is a registered trademark of SKF USA Inc. All other trademarks are the property of their respective owners.

Figure 2. Scaling Factor for Fmax Compensation for Enveloped Acceleration Measurements.

7. 8.

Read the Scaling Factor value (0.75). Multiply the alarm settings obtained in steps 3 and 4 by the scaling factor. Danger level = 7.5 gE x 0.75 = 5.6 gE ! 6.0 gE Alert level = 2.5 gE x 0.75 = 1.9 gE ! 2.0 gE

Conclusion

This application note presents a method for initial enveloped acceleration alarm criteria for use with new, refurbished, and recently maintained machinery. This method is based on extensive review of empirical data and is 90% effective in identifying bearings at the earliest possible stages of degradation. Once sufficient experience is gained, on a measurement point-by-point basis, this method should be replaced in the users database with trend-based or statistically-based alarm settings.

CM3068 (1-03) Copyright 2003 by SKF Reliability Systems ALL RIGHTS RESERVED

Anda mungkin juga menyukai

- Aviation Electronics Technician 1Dokumen332 halamanAviation Electronics Technician 1hariharasankar100% (3)

- Signature Analysis TechniquesDokumen49 halamanSignature Analysis TechniquesVirgilio100% (1)

- Coupling Failures in VFD Motor Fan: Torsional VibrationDokumen15 halamanCoupling Failures in VFD Motor Fan: Torsional VibrationCairo Oil Refining Co.100% (1)

- Mayo ClinicDokumen48 halamanMayo ClinicAbdul RazzaqBelum ada peringkat

- Vibration in Pumps PDFDokumen5 halamanVibration in Pumps PDFNTRBelum ada peringkat

- Guide to Analyzing Variable Frequency Drive Centrifugal PumpsDokumen26 halamanGuide to Analyzing Variable Frequency Drive Centrifugal PumpsKamal ArreazaBelum ada peringkat

- Edoc-Vibration Study and AnalysisDokumen9 halamanEdoc-Vibration Study and AnalysisEl Comedor BenedictBelum ada peringkat

- Troubleshooting Turbomachinery Using Startup and Coastdown Vibration DataDokumen14 halamanTroubleshooting Turbomachinery Using Startup and Coastdown Vibration DataAhtsham AhmadBelum ada peringkat

- !!!!!!!!!!bearing StorageDokumen10 halaman!!!!!!!!!!bearing StorageJuan Carlos DavidBelum ada peringkat

- Raspberry PiDokumen19 halamanRaspberry PiAnonymous E4Rbo2s100% (1)

- Solving Motor Vibration Problems On Vertical PumpsDokumen5 halamanSolving Motor Vibration Problems On Vertical Pumpsjameel babooramBelum ada peringkat

- Resolving Oil Whirl Issues in a Gas Compressor Case StudyDokumen42 halamanResolving Oil Whirl Issues in a Gas Compressor Case StudyChristian Santillan100% (1)

- Recommended Approach To Control Vibration From Cylinder Gas ForcesDokumen14 halamanRecommended Approach To Control Vibration From Cylinder Gas ForcesKelly Eberle100% (1)

- Paul A. Longley, Michael F. Goodchild, David J. Maguire, David W. Rhind-Geographic Information Systems and Science-Wiley (2005)Dokumen605 halamanPaul A. Longley, Michael F. Goodchild, David J. Maguire, David W. Rhind-Geographic Information Systems and Science-Wiley (2005)KamilaBelum ada peringkat

- Pumps and SystemsDokumen5 halamanPumps and SystemsDhi AdhiBelum ada peringkat

- Analysis and Diagnosis of The Different Defects of The Bearings and Gearings by Vibration AnalysisDokumen6 halamanAnalysis and Diagnosis of The Different Defects of The Bearings and Gearings by Vibration AnalysisJournal of Computer Science and EngineeringBelum ada peringkat

- Monitoring Gearboxes with PeakVueDokumen60 halamanMonitoring Gearboxes with PeakVueeko bagus sunaryo100% (2)

- 12 1989 Shaft StressDokumen4 halaman12 1989 Shaft StressRonald GeorgeBelum ada peringkat

- Vibration Analyst Category IV Equations: Forces Mass UnbalanceDokumen8 halamanVibration Analyst Category IV Equations: Forces Mass UnbalanceEswin Paico de la CruzBelum ada peringkat

- Timebase Plots ExplainedDokumen18 halamanTimebase Plots ExplainedManuel L LombarderoBelum ada peringkat

- Transient Vibration Analysis Dec07 HandoutDokumen24 halamanTransient Vibration Analysis Dec07 HandoutsandragoncBelum ada peringkat

- Easy-Laser - Shaft Alignment WorksheetDokumen2 halamanEasy-Laser - Shaft Alignment WorksheetJR Medel F100% (2)

- Orbit V31N1 2011 Q1Dokumen60 halamanOrbit V31N1 2011 Q1KrishnaBelum ada peringkat

- Dynamic Absorber DesignDokumen14 halamanDynamic Absorber DesignLarry Deem0% (1)

- Why Industrial Bearings Fail: Analysis, Maintenance, and PreventionDari EverandWhy Industrial Bearings Fail: Analysis, Maintenance, and PreventionBelum ada peringkat

- Engineers Guide To Shaft Alignment 1661215823Dokumen192 halamanEngineers Guide To Shaft Alignment 1661215823Michael SanchezBelum ada peringkat

- Crosshead SlapDokumen2 halamanCrosshead SlapJose Luis RattiaBelum ada peringkat

- Envelope Acceleration LDokumen10 halamanEnvelope Acceleration Lsumeet_soporiBelum ada peringkat

- Principles of Welding: Processes, Physics, Chemistry, and MetallurgyDari EverandPrinciples of Welding: Processes, Physics, Chemistry, and MetallurgyPenilaian: 4 dari 5 bintang4/5 (1)

- BHJDynamics Damper InfoDokumen10 halamanBHJDynamics Damper Infosuhas110Belum ada peringkat

- Extracto ISO 10816Dokumen10 halamanExtracto ISO 10816clroyo9475Belum ada peringkat

- Windrock CalculationsDokumen8 halamanWindrock CalculationsManuel Otero AlzaBelum ada peringkat

- StepsDokumen55 halamanStepschoton1230% (1)

- Vibra K Cmva 2006 Spike Energy Paper 430kb PDFDokumen22 halamanVibra K Cmva 2006 Spike Energy Paper 430kb PDFmarvin17Belum ada peringkat

- Iso 13373 9 2017Dokumen12 halamanIso 13373 9 2017ThejaswiniBelum ada peringkat

- 2.2 Difference Between RMS, Peak and Peak-To-Peak Vibration Amplitude?Dokumen10 halaman2.2 Difference Between RMS, Peak and Peak-To-Peak Vibration Amplitude?binsar354Belum ada peringkat

- Structural Health MonitoringDari EverandStructural Health MonitoringDaniel BalageasBelum ada peringkat

- Speed and Vibration ReviewDokumen30 halamanSpeed and Vibration ReviewAndrian Fathurohman PermanaBelum ada peringkat

- Effective Use of Statistical Models To Establish and Update Vibration AlarmDokumen11 halamanEffective Use of Statistical Models To Establish and Update Vibration AlarmMohammadreza GalebanBelum ada peringkat

- Balanceo Rodamiento VidaDokumen6 halamanBalanceo Rodamiento VidaManel MontesinosBelum ada peringkat

- Helical Gear Lubrication RequirementDokumen7 halamanHelical Gear Lubrication RequirementvenkateswaranBelum ada peringkat

- Balance VibrationDokumen4 halamanBalance VibrationZaidiBelum ada peringkat

- Vibration Analysis Dictionary: AccelerationDokumen36 halamanVibration Analysis Dictionary: Accelerationkamal arabBelum ada peringkat

- Online TextbookDokumen6 halamanOnline TextbookYanuar KrisnahadiBelum ada peringkat

- Vibration Measurement and Analysis of Rotational Machines: at Makstil Hotplate MillDokumen4 halamanVibration Measurement and Analysis of Rotational Machines: at Makstil Hotplate MillMarija PetkovskaBelum ada peringkat

- 5000 KW Gearbox High Pinion Bearing Temperatures 1644227029Dokumen7 halaman5000 KW Gearbox High Pinion Bearing Temperatures 1644227029MC ABelum ada peringkat

- Limited End Float Couplings: CautionDokumen2 halamanLimited End Float Couplings: CautionsanthoshBelum ada peringkat

- Vertical Sleeve BearingsDokumen6 halamanVertical Sleeve BearingsRakesh Nair A100% (1)

- Successful Solution: To The Challenge ofDokumen2 halamanSuccessful Solution: To The Challenge ofKenny RuizBelum ada peringkat

- TOMAS UsersManualDokumen94 halamanTOMAS UsersManualrodruren01Belum ada peringkat

- DWDM Unit-5Dokumen52 halamanDWDM Unit-5Arun kumar SomaBelum ada peringkat

- Monitoring and Analysis of Machine VibrationDokumen6 halamanMonitoring and Analysis of Machine VibrationAvinashBelum ada peringkat

- CEP VFD ManualDokumen234 halamanCEP VFD ManualUsama ZubairBelum ada peringkat

- CSI AccessoriesDokumen2 halamanCSI AccessoriesDia Putranto Harmay100% (1)

- FFT Windowing TutorialDokumen10 halamanFFT Windowing TutorialPradeep LoboBelum ada peringkat

- Kim2017 PDFDokumen4 halamanKim2017 PDFkishoreBelum ada peringkat

- Sleeve Bearing Problems: Oil Whip and Whirl ExplainedDokumen2 halamanSleeve Bearing Problems: Oil Whip and Whirl ExplainedmtttusharBelum ada peringkat

- Vibxpert Manual English PDFDokumen86 halamanVibxpert Manual English PDFRizki A-fBelum ada peringkat

- ODS Analysis Identifies Structural Resonance Causing High Fan VibrationDokumen9 halamanODS Analysis Identifies Structural Resonance Causing High Fan VibrationDan-jones TudziBelum ada peringkat

- Power Station Engine Generator Vibration Analysis ReportDokumen5 halamanPower Station Engine Generator Vibration Analysis ReportDerrick AramBelum ada peringkat

- Vibration SwitchesDokumen12 halamanVibration SwitchesAnonymous 1dVLJSVhtrBelum ada peringkat

- Analysis of Fan Excessive Vibration Using Operating Deflection Shape AnalysisDokumen11 halamanAnalysis of Fan Excessive Vibration Using Operating Deflection Shape Analysisbudi_kamilBelum ada peringkat

- Vibration Analysis of Gear Box.5-MilosprokoDokumen3 halamanVibration Analysis of Gear Box.5-MilosprokoRavikiran Hegde100% (2)

- 237258Dokumen14 halaman237258Alberto Remolar100% (1)

- Witout ScrewDokumen15 halamanWitout ScrewkjapashaBelum ada peringkat

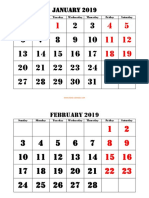

- Printable Monthly 2019 Calendar Large FontDokumen12 halamanPrintable Monthly 2019 Calendar Large FontkjapashaBelum ada peringkat

- Sexual Reproduction in Flowering PlantsDokumen23 halamanSexual Reproduction in Flowering PlantsGhanshyam R. ParmarBelum ada peringkat

- Havells India's Innovative Fan Manufacturing ProcessDokumen122 halamanHavells India's Innovative Fan Manufacturing ProcessSuraj RamanBelum ada peringkat

- KDK FansDokumen10 halamanKDK FanskjapashaBelum ada peringkat

- Sexual Reproduction in Flowering PlantsDokumen23 halamanSexual Reproduction in Flowering PlantsGhanshyam R. ParmarBelum ada peringkat

- Kalingastone Marble Installation ManualDokumen8 halamanKalingastone Marble Installation ManualkjapashaBelum ada peringkat

- Balancing ExplanationDokumen7 halamanBalancing Explanationanalog_kid_2001Belum ada peringkat

- Simple Mortgage DeedDokumen3 halamanSimple Mortgage DeedkjapashaBelum ada peringkat

- Is.303 Plywood.1989Dokumen22 halamanIs.303 Plywood.1989kjapashaBelum ada peringkat

- WA0032 RBI NotificationDokumen3 halamanWA0032 RBI NotificationPGurusBelum ada peringkat

- Simple Mortgage DeedDokumen3 halamanSimple Mortgage DeedkjapashaBelum ada peringkat

- 3rd Semester Paper On Natural GasDokumen4 halaman3rd Semester Paper On Natural GaskjapashaBelum ada peringkat

- The Right Cement: Factors to Consider When Selecting CementDokumen1 halamanThe Right Cement: Factors to Consider When Selecting CementkjapashaBelum ada peringkat

- Flow RecirculationDokumen13 halamanFlow RecirculationkjapashaBelum ada peringkat

- WA0032 RBI NotificationDokumen3 halamanWA0032 RBI NotificationPGurusBelum ada peringkat

- Machine Ranking MatrixDokumen3 halamanMachine Ranking MatrixkjapashaBelum ada peringkat

- Change The Positions of The Frogs On Right and Left. Usually It Can Be Done in 3 Minutes If Your IQ Is Not Under 50Dokumen4 halamanChange The Positions of The Frogs On Right and Left. Usually It Can Be Done in 3 Minutes If Your IQ Is Not Under 50kjapashaBelum ada peringkat

- Toilet Position IndianDokumen4 halamanToilet Position IndiankjapashaBelum ada peringkat

- Suction Piping 1Dokumen6 halamanSuction Piping 1kjapashaBelum ada peringkat

- Chennai Off 2q11Dokumen2 halamanChennai Off 2q11kjapashaBelum ada peringkat

- Change The Positions of The Frogs On Right and Left. Usually It Can Be Done in 3 Minutes If Your IQ Is Not Under 50Dokumen4 halamanChange The Positions of The Frogs On Right and Left. Usually It Can Be Done in 3 Minutes If Your IQ Is Not Under 50kjapashaBelum ada peringkat

- Flow RecirculationDokumen13 halamanFlow RecirculationkjapashaBelum ada peringkat

- Desirable and Undesirable Changes Rev 0Dokumen9 halamanDesirable and Undesirable Changes Rev 0kjapasha0% (1)

- Circulation Systems For Single and Multiple Seal Arrangements - Part 1Dokumen11 halamanCirculation Systems For Single and Multiple Seal Arrangements - Part 1contactdarinBelum ada peringkat

- Change The Positions of The Frogs On Right and Left. Usually It Can Be Done in 3 Minutes If Your IQ Is Not Under 50Dokumen4 halamanChange The Positions of The Frogs On Right and Left. Usually It Can Be Done in 3 Minutes If Your IQ Is Not Under 50kjapashaBelum ada peringkat

- SMRPCO Candidate Guide For Certification Re Certification Feb 14 2012Dokumen39 halamanSMRPCO Candidate Guide For Certification Re Certification Feb 14 2012kjapashaBelum ada peringkat

- Change The Positions of The Frogs On Right and Left. Usually It Can Be Done in 3 Minutes If Your IQ Is Not Under 50Dokumen4 halamanChange The Positions of The Frogs On Right and Left. Usually It Can Be Done in 3 Minutes If Your IQ Is Not Under 50kjapashaBelum ada peringkat

- The Five KalimaDokumen1 halamanThe Five KalimakjapashaBelum ada peringkat

- 850 Fast Secure Redundant CommunicationsDokumen2 halaman850 Fast Secure Redundant CommunicationsamruthkiranbabujiBelum ada peringkat

- Marine Elevators (200902)Dokumen6 halamanMarine Elevators (200902)Arky HarkyanBelum ada peringkat

- Dell EMC Unity Power Down Up ProcedureDokumen5 halamanDell EMC Unity Power Down Up ProcedureShahulBelum ada peringkat

- Test Logic Insertion For Optimization of Testing Parameters On Lower Technology NodeDokumen6 halamanTest Logic Insertion For Optimization of Testing Parameters On Lower Technology NodeshaguftaBelum ada peringkat

- Ckt-Odv065r14b17k-B DS 0-0-1Dokumen2 halamanCkt-Odv065r14b17k-B DS 0-0-1АлександрBelum ada peringkat

- 6av6 640 0ca11 0ax0 Touchpanel TP177 Micro Siemens ManualDokumen32 halaman6av6 640 0ca11 0ax0 Touchpanel TP177 Micro Siemens Manualyassine ELMHBelum ada peringkat

- Assignment 3 3Dokumen4 halamanAssignment 3 3api-236083981Belum ada peringkat

- Product List On Installments Jul 2021Dokumen9 halamanProduct List On Installments Jul 2021Arif AliBelum ada peringkat

- New GD&TDokumen3 halamanNew GD&TvasantBelum ada peringkat

- Manual For (XXX Flow) : CarlcareDokumen11 halamanManual For (XXX Flow) : CarlcareSURYA FCBBelum ada peringkat

- Arduino Interfacing With LCD Without Potentiometer - InstructablesDokumen6 halamanArduino Interfacing With LCD Without Potentiometer - Instructablesakinlabi aderibigbeBelum ada peringkat

- Engine Driven Welders PDFDokumen13 halamanEngine Driven Welders PDFLazzarus Az GunawanBelum ada peringkat

- CV Project Manager Shivam SaxenaDokumen6 halamanCV Project Manager Shivam SaxenaNedlloyd IndiaBelum ada peringkat

- Signed LetterDokumen1 halamanSigned LetterDevBelum ada peringkat

- PanKnob ManualDokumen8 halamanPanKnob ManualJohnBelum ada peringkat

- Lesson 2 RoboticsDokumen3 halamanLesson 2 RoboticsEzekiel DungoBelum ada peringkat

- Audit-Free Cloud Storage via Deniable Attribute-based EncryptionDokumen15 halamanAudit-Free Cloud Storage via Deniable Attribute-based EncryptionKishore Kumar RaviChandranBelum ada peringkat

- Midshire Business Systems - Ricoh MP CW2200SP - A0 Wide Format Colour BrochureDokumen8 halamanMidshire Business Systems - Ricoh MP CW2200SP - A0 Wide Format Colour BrochureadietoppingBelum ada peringkat

- Huawei HCNA-VC Certification TrainingDokumen3 halamanHuawei HCNA-VC Certification TrainingArvind JainBelum ada peringkat

- Udyam Registration Certificate - The Lord's Family SpaDokumen2 halamanUdyam Registration Certificate - The Lord's Family SpaNeekhil PareekBelum ada peringkat

- Embedded Systems Model Question PaperDokumen6 halamanEmbedded Systems Model Question PaperSubramanyaAIyerBelum ada peringkat

- J160 6th Gear ReplacementDokumen6 halamanJ160 6th Gear ReplacementdensasBelum ada peringkat

- Electro Magnetic Braking System Review 1Dokumen18 halamanElectro Magnetic Braking System Review 1sandeep Thangellapalli100% (1)

- Bahu Membahu - Job Vacancy & Talent ListDokumen18 halamanBahu Membahu - Job Vacancy & Talent ListLestari SiregarBelum ada peringkat

- Aashto 1972 CarolDokumen30 halamanAashto 1972 CarolIjeal KuBelum ada peringkat

- JAW Diagnostics Heat-up Test CheckDokumen1 halamanJAW Diagnostics Heat-up Test CheckDirk JonesBelum ada peringkat